When choosing between piston compressors and diaphragm compressors, there is often a debate about which is better. While manufacturers of oil-free piston compressors claim that their product is superior, manufacturers of diaphragm compressors argue that their technique is the better solution. However, the truth is that there is no definite answer.

The right choice depends on a range of factors, including:

- The gas to be compressed;

- The working pressure required;

- The volumetric capacity required;

- Cleanliness requirements for the compressed gas (admissibility of oil/oil vapors).

In this article, we’ll take a closer look at these factors to help you decide which compressor is best for your needs.

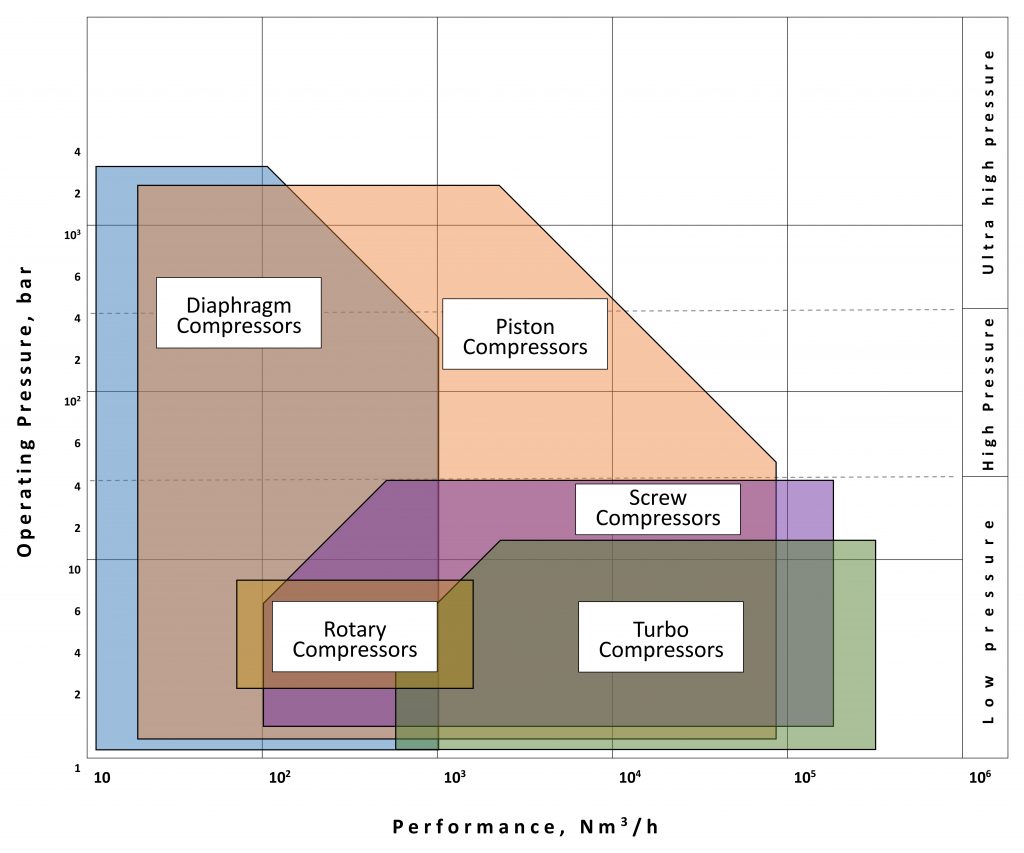

The conditional applicability of compressors

Figure 1 illustrates the conditional applicability of compressors based on their type concerning working pressure and capacity.

Figure 1 illustrates that piston and diaphragm compressors cover a significant capacity and working pressure range. However, piston compressors are preferred for high working pressure exceeding 15 bar and high capacities over 1000 Nm3/h, while diaphragm compressors are the only option for operating pressure above 2000 bars. The overlapping area of the diagrams in Fig. 1 shows where both types can be used, and more specific selection factors come into play in this area.

The main similarity between diaphragm and piston compressors is that both compressors have an oil-filled crankcase where the crank-rod mechanism (CKM) is installed. Additionally, the number of rods and pistons in both compressors equals the number of compression stages of the compressor. However, aside from these standard features, the two compressors differ in design and operation.

We will summarize their other differences in the following table.

Other differences between two types of compressors

| Characteristics | Piston compressors | Diaphragm compressors |

| Compressed gas | Piston compressors are suitable for compressing a limited range of gases due to the materials used in their construction. The specific list of compressible gases depends on the materials of the pistons, piston rings, cylinders, and other components. | They can compress almost any gas without restrictions. Because the compressed gas only comes into contact with high-quality, corrosion-resistant steel parts. |

| Drive type | Piston compressors can be driven either by belt or direct drive using a coupling with elastic elements. | Diaphragm compressors are typically belt-driven, with direct drive being rare. |

| Rotational speed | It can vary, but at higher speeds, the vibration of the compressor increases, making it necessary to install vibration isolation mounts when placing it on a foundation. | Their rotational speed is typically lower, generally at most 500 rpm. The low rotational speed results in low vibration during operation, eliminating the need for vibration isolation when installing the compressor on a foundation. |

| Stage pressure ratio (ratio of suction pressure to discharge pressure of each compressor stage) | As a general rule, the stage pressure ratio of piston compressors is limited to no more than 1:8. If the ratio is higher, it can lead to excessive heating of the compression stage. | The stage pressure ratio of diaphragm compressors is typically more than 1:15. This high compression ratio enables the compressor to achieve high outlet pressures with fewer stages than piston compressors. |

| Cooling | Piston compressors can be either air-cooled or water-cooled. Air-cooled compressors generate considerable noise from the running fan and require the removal of hot air from the room. The cylinders of air-cooled compressors are typically finned, which makes the design more complex and expensive. In contrast, water-cooled compressors use water as the cooling medium and are generally quieter than air-cooled compressors. | Diaphragm compressors are usually water-cooled; in some cases, combined cooling can be used. It uses an additional pump to circulate the coolant in a closed circuit and cools the liquid in a radiator blown up by a fan. However, this cooling system has the disadvantages of conventional air cooling. Additionally, the combined cooling system can be expensive due to the use of an additional pump and radiator. |

| Contact of compressed gas with oil | The contact between compressible gas and oil is present in oil-lubricated piston compressors. It limits their use for compressing clean gases because there is a risk of contamination from the oil. However, in oil-free compressors, there is no contact between the gas and oil due to the piston rings or shaft packing that prevent oil from entering the compression chamber. However, there is a risk of oil vapors or ingress if the rings separating the compression chamber from the oil circuit become worn. In such cases, there is no emergency protection against oil ingress, which can lead to contamination of the compressed gas. | Diaphragm compressors have no contact of the compressible gas with oil due to the three-layer diaphragm. This design ensures that the oil is completely separated from the gas, and even a rupture of one of the diaphragms results in an immediate emergency stop of the compressor. Therefore, diaphragm compressors are suitable for compressing a wide range of gases without any limitations due to contact with oil. |

| Lubrication of rubbing parts | The rubbing parts of piston compressors are usually lubricated by either splash lubrication or forced lubrication. In crosshead compressors, special devices called lubricators are required to lubricate the pistons and cylinders. It is essential to monitor the operation of these devices and adjust them properly, as the failure of the lubricator can lead to catastrophic consequences such as seizures. In oil-free compressors, the cylinders and pistons do not require lubrication. However, they need unique materials and a more complex cooling system to ensure proper operation. | Parts of the crankcase are lubricated by splashing or forced lubrication. The compression of the gas is achieved by the movement of the diaphragm, which separates the hydraulic fluid and the gas being compressed. The hydraulic fluid is a medium to transfer pressure from the drive mechanism to the diaphragm. This design eliminates the need for lubrication of the gas compression parts, as there is no direct contact between the gas and any rubbing parts. |

| Feasibility to adjust the discharge pressure for each stage immediately | Not available. | Diaphragm compressors allow for adjusting the final compression pressure of each stage using hydraulic bypass valves. It enables changing the compression characteristic of the compressor easily and quickly on site. |

| Tightness | The compression chambers (cylinders) of piston compressors are sealed with fixed (gaskets, etc.) and movable (glands, etc.) seals to ensure tightness. However, the moving seals are susceptible to mechanical wear, so regular monitoring of their condition is necessary. | In diaphragm compressors, the tightness of the compression chambers is maintained solely by fixed seals. Piston compressors have no movable seals and, therefore, no mechanical wear. |

| Easy maintenance | Maintenance of piston compressors can be complex and time-consuming, depending on the design and number of compression stages. Single-acting and double-acting compressors may require different maintenance procedures, and additional equipment, such as lubricators, can also affect the maintenance process. Specialized equipment and tools may be necessary, and only qualified personnel should perform maintenance to ensure proper operation and prevent damage to the compressor. | Maintenance of diaphragm compressors is relatively simple and does not require specialized equipment or highly skilled technicians. The design of the compressor is simple and easy to access, making it straightforward to replace parts such as diaphragms and seals. |

This additional information is also essential for your choice.

- Diaphragm compressors are ideal for compressing clean/ultra-pure/toxic gases where the slightest oil vapor and compression cavity contact is unacceptable.

- Diaphragm compressors can handle any inlet pressure, while piston compressors have limitations.

- The gas to be compressed must be dry and moisture-free in diaphragm compressors to prevent increased wear and premature failure.

- Diaphragm compressors are larger and more expensive than reciprocating compressors with similar characteristics.

- Diaphragm compressors are recommended to compress expensive, rare, and pure gases to avoid impurities and oil vapors that can lead to huge losses.

To conclude

At Jiangsu Minnuo, we offer piston and diaphragm compressors and professional services to help you select the suitable compressor for your needs. Our experienced technicians can provide installation, maintenance, and repair services to ensure your compressor operates efficiently and reliably. Contact us today to learn more about our products and services.

Email

Email sales:+86 15366749631

sales:+86 15366749631