33 years Gas Compressor Experience

Our expertise in hydrogen compression technology has made us the leading provider in China, with over 30 years of experience.

We are proud to have over 2,000 units running successfully in various hydrogen applications, delivering an outstanding combined installed horsepower of over 2 million.

Types and applications of hydrogen compressors

Hydrogen compressors are generally divided into diaphragm-type and reciprocating (piston-type) compressors.

Hydrogen compressors are widely used in industries such as industrial gases, food and pharmaceuticals, petrochemicals, aerospace and nuclear power, military equipment, and scientific research.

What is Hydrogen Compressor ?

The hydrogen compressor is a compressor that discharges the hydrogen collected in the water electrolyzer to the overboard. Common application areas include ship engineering, ship machinery and other fields

Hydrogen compressor packages are used to compress the gas to enormous pressures, usually in excess of 15,000 psi, so that it can be stored in usable quantities There are several different types of compressors used to compress hydrogen; the more common of these are piston or metal diaphragm compressors. Collectively, they are known as reciprocating compressors. They are the most commonly used commercial hydrogen compressors.

Compressors are required for the transport and storage of hydrogen. Our hydrogen compressors are available in various versions to support the entire hydrogen energy chain:

- hydrogen cracking (methanol, natural gas, gas)

- hydrogen production by water electrolysis

- hydrogen filling,

- benzene hydrogenation

- tar hydrogenation

- catalytic cracking

- other hydrogen boosting processes

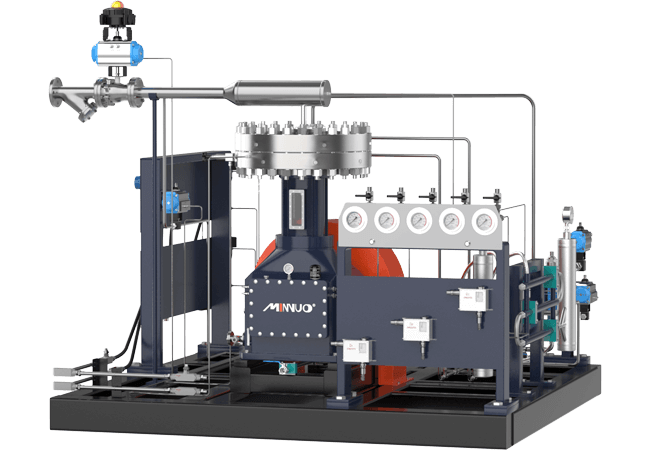

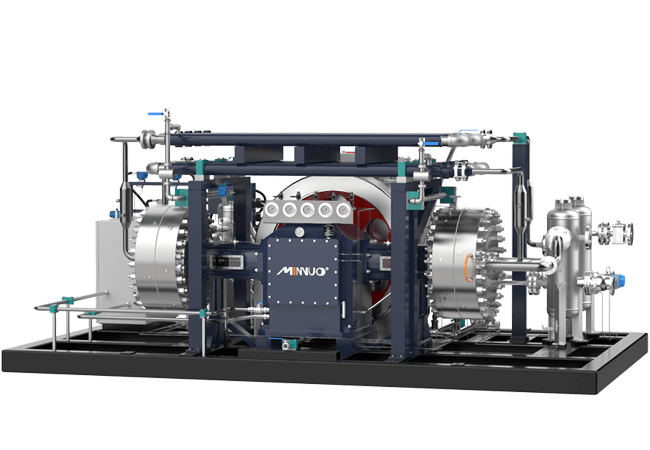

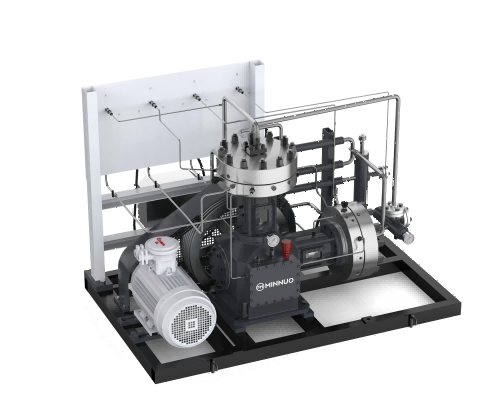

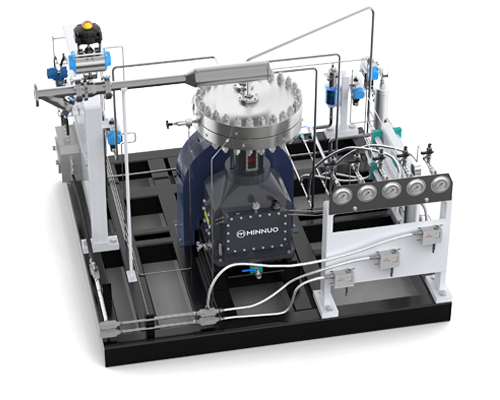

Types of Hydrgen Compressor

The core pressurization equipment for hydrogen refueling stations is the diaphragm compressor. The diaphragm fully isolates the cylinder from the oil chamber, and the diaphragm chamber has excellent sealing properties, ensuring the purity of the hydrogen. The working principle involves the diaphragm performing a reciprocating motion during the oil pressure drop, thereby achieving hydrogen compression.

The diaphragm compressors designed and manufactured by MINNUO are divided into four main types: V, Z, D, and L, with 26 series and nearly 900 products in total.

Features

- Maximum single-unit displacement: 3000 Nm³/h

- Maximum pressure: 100 MPa

- Maximum piston force: 250 kN

- Maximum drive power: 450 kW

- Long lifespan for diaphragms and wear parts

- Single-unit output up to 1000 kg/d

- Low procurement cost, small footprint, low energy consumption

- High operational safety, no risk of gas leakage due to short-lived wear components

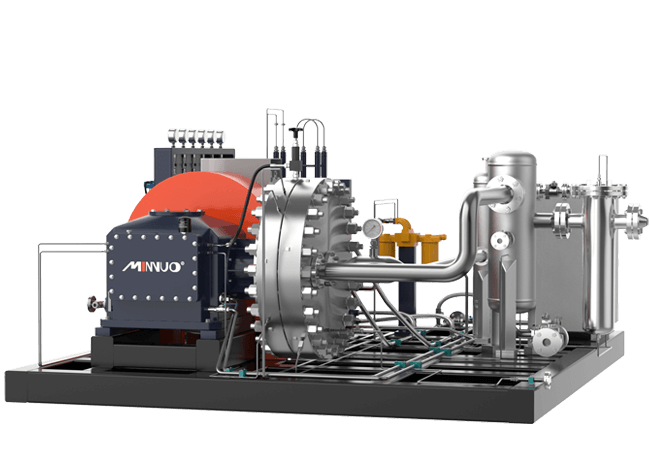

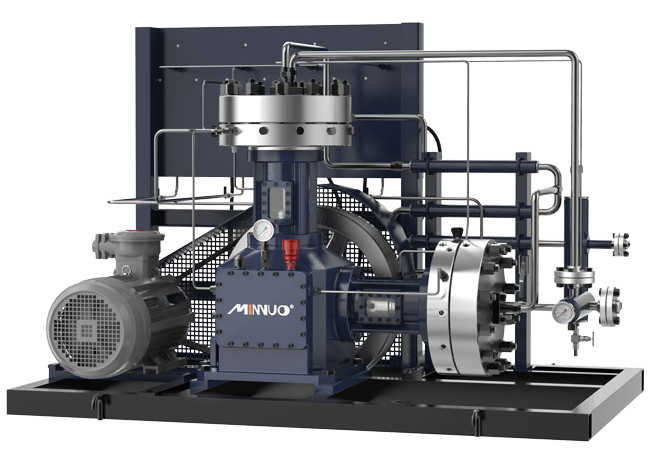

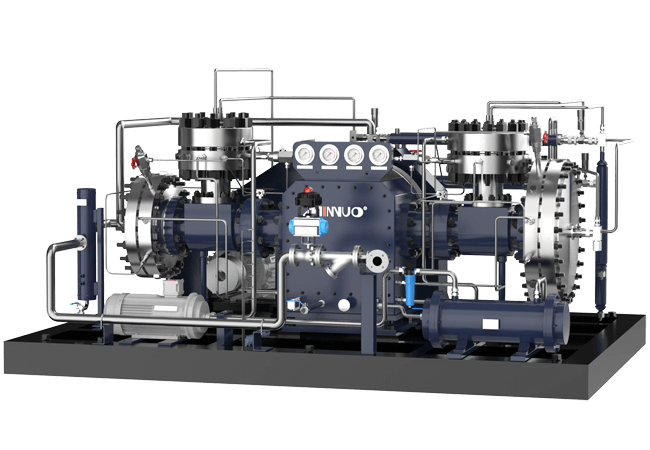

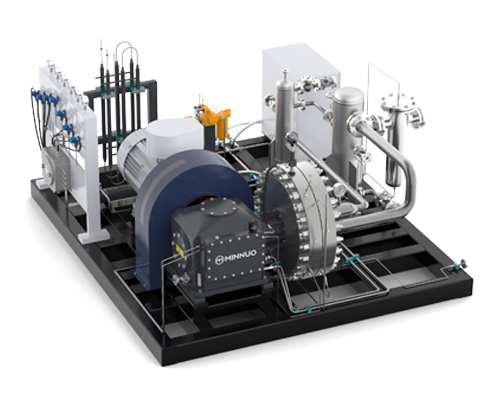

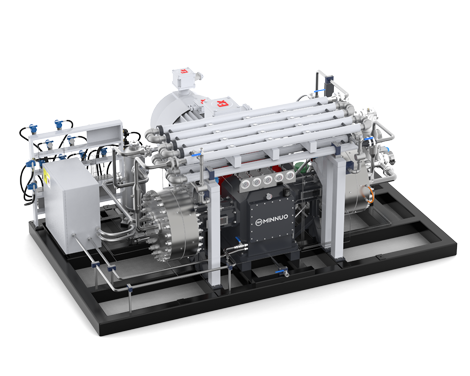

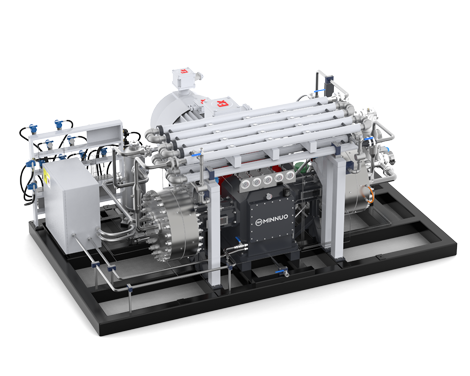

Reciprocating Compressor

The piston-type compressor is driven by a crankshaft and connecting rods, which move the piston up and down to change the cylinder volume, thereby achieving the intake and compression processes. The piston rings serve as seals, and the piston rings inside the cylinder are lubricated by oil.

The piston-type hydrogen compressor manufactured by MINNUO is the most advanced domestically produced reciprocating compressor, incorporating technology from Germany’s MANNES Company. It currently offers four main categories—P, L, D, and M—with 19 series and nearly 700 products.

Features

- Maximum single-unit displacement: 4000 Nm³/min

- Maximum pressure: 20 MPa

- Maximum piston force: 800 kN

- Maximum drive power: 4500 kW

- Control: PLC automatic control

- Drive method: Electric motor

- Cooling method: Air cooling, water cooling, mixed cooling

- Installation type: Container skid-mounted, fixed, soundproof cabin-mounted

Hydrogen Diaphragm Compressor Technology Parameters

Working Principle

The diaphragm hydrogen compressor is an efficient and safe method for compressing hydrogen gas. The basic principle of a diaphragm hydrogen compressor is that it has a flexible membrane between two chambers, with one chamber filled with hydrogen gas and the other pressurized with a non-reactive gas, such as nitrogen.

As the pressure in the nitrogen chamber increases, the flexible membrane stretches and compresses the hydrogen gas in the other chamber, resulting in higher pressure. This higher pressure then allows for the hydrogen gas to be stored or used for a variety of applications.

Benefits

Diaphragm compressor is a special structure of the volume compressor cylinder without lubrication, sealing performance is good, the compression medium does not contact any lubricant, compression process does not produce any pollution, so the compression purity can reach 99.999%. Especially suitable for high-value rare gas and highly corrosive, toxic and harmful, flammable and explosive, radioactive gas compression, transport, and bottling.

Diaphragm compressor cylinder heat dissipation, simple and efficient structure, two-stage compression can achieve high pressure, but also close to isothermal compression, therefore, it is widely used in the fields of industrial gas, food and medicine, petrochemical industry, aviation nuclear power, military equipment, scientific research and experiment, etc. .

Select Your Model

G1 Small diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 80kg

- Maintenance maximum space: the circle shall be not less than 1 m

| Product Model | Volumetric Flow | Intake Pressure | Exhaust Pressure | Water Consumption | Crankshaft Speed | Motor Power | Dimension | Unit Weight |

|---|---|---|---|---|---|---|---|---|

| (Nm³/h) | (MPa(G)) | (MPa(G)) | (L/H) | (r/min) | (KW) | (L×W×H)(MM) | (KG) | |

| GD0-3/200 | 3 | ATM | 20 | / | 750 | 2.2 | 600×500×400 | 200 |

| GL1-5/200 | 5 | ATM | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13 | 10 | ATM | 1.3 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13-200 | 10 | 1.3 | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-5/1-160 | 5 | 0.1 | 16 | 300 | 450 | 3 | 1350×600×950 | 550 |

| GL1-10/4-160 | 10 | 0.4 | 16 | 400 | 600 | 4 | 1350×600×950 | 520 |

| GL1-8/2.5-160 | 8 | 0.25 | 16 | 400 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 15 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/6-200 | 5 | 0.6 | 20 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 16 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/13-400 | 5 | 1.3 | 40 | 300 | 400 | 3 | 1350×600×950 | 500 |

| GL1-15/10-150 | 15 | 1 | 15 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-10/7-320 | 10 | 0.7 | 32 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-5/4-350 | 5 | 0.4 | 35 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GZ1-5/13 | 5 | ATM | 1.3 | 200 | 450 | 1.5 | 1100×600×950 | 450 |

| GZ1-5/13-200 | 5 | 1.3 | 20 | 200 | 450 | 1.5 | 1100×600×950 | 420 |

| GZ1-5/30-400 | 5 | 3 | 40 | 300 | 400 | 3 | 1100×600×950 | 400 |

| GZ1-70/30-35 | 70 | 3 | 3.5 | 200 | 400 | 4 | 1100×600×950 | 420 |

G2 Medium-sized diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 100kg

- Maintenance maximum space: the circle shall be not less than 1 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm3/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GL2-20/200 | 20 | ATM | 20 | 700 | 400 | 7.5 | 1700×850×1150 | 1100 |

| GL2-40/13 | 40 | ATM | 1.3 | 700 | 400 | 7.5 | 1700×850×1150 | 1200 |

| GL2-40/13-200 | 40 | 1.3 | 20 | 700 | 400 | 7.5 | 1700×850×1150 | 1000 |

| GL2-25/1-160 | 25 | 0.1 | 16 | 1000 | 400 | 11 | 1700×850×1150 | 1100 |

| GL2-40/4-160 | 40 | 0.4 | 16 | 1000 | 400 | 11 | 1700×850×1150 | 1050 |

| GL2-50/7-160 | 50 | 0.7 | 16 | 1200 | 400 | 11 | 1700×850×1150 | 1000 |

| GL2-40/7-320 | 40 | 0.7 | 32 | 1200 | 420 | 11 | 1700×850×1150 | 900 |

| GL2-60/12-160 | 60 | 1.2 | 16 | 1000 | 360 | 11 | 1700×850×1150 | 900 |

| GL2-40/13-400 | 40 | 1.3 | 40 | 1000 | 400 | 11 | 1700×850×1150 | 900 |

| GL2-30/4-350 | 30 | 0.4 | 35 | 1000 | 420 | 11 | 1700×850×1150 | 900 |

| GD2-60/30-400 | 60 | 3 | 40 | 1200 | 400 | 11 | 1700×850×1150 | 850 |

| GL2-15/350 | 15 | 0 | 35 | 1500 | 400 | 18.5 | 1700×1200×1150 | 1500 |

| GZ2-10/10-150 | 10 | 1 | 15 | 400 | 420 | 4 | 1400×850×1150 | 800 |

| GZ2-15/13 | 15 | ATM | 1.3 | 400 | 400 | 4 | 1400×850×1150 | 800 |

| GZ2-15/13-200 | 15 | 1.3 | 20 | 400 | 400 | 4 | 1400×850×1150 | 750 |

G3 Medium-sized diaphragm compressor

- Structure: Z, L,V, P, D-type

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 800kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GL3-60/200 | 60 | ATM | 20 | 1600 | 400 | 30 | 2800×1600×2000 | 5500 |

| GL2-40/13 | 120 | ATM | 1.3 | 1600 | 400 | 30 | 2800×1600×2000 | 5000 |

| GL3-110/20-200 | 110 | 2 | 20 | 1600 | 400 | 30 | 2800×1600×2000 | 4000 |

| GL3-75/20 | 75 | ATM | 2 | 4000 | 450 | 45 | 2800×1600×2000 | 5500 |

| GL3-50/5-160 | 50 | 0.5 | 16 | 2000 | 400 | 30 | 2800×1600×2000 | 4200 |

| GL3-150/10-160 | 150 | 1 | 16 | 3500 | 360 | 37 | 2800×1600×2000 | 4200 |

| GL3-80/7-320 | 80 | 0.7 | 32 | 2500 | 400 | 30 | 2800×1600×2000 | 4000 |

| GL3-180/12-160 | 180 | 1.2 | 16 | 3500 | 360 | 37 | 2800×1600×2000 | 4200 |

| GL3-120/13-400 | 120 | 1.3 | 40 | 3000 | 400 | 37 | 2800×1600×2000 | 4000 |

| GL3-80/4-350 | 80 | 0.4 | 35 | 3000 | 400 | 30 | 2800×1600×2000 | 4200 |

| GL3-800/300-700 | 800 | 30 | 70 | 5000 | 400 | 55 | 3600×2400×2000 | 6000 |

| GL3-200/20-200 | 200 | 2 | 20 | 3000 | 360 | 37 | 2800×1600×2000 | 4200 |

| GZ3-50/10-150 | 50 | 1 | 15 | 1000 | 400 | 11 | 2400×1400×2000 | 3500 |

| GZ3-60/13 | 60 | ATM | 1.3 | 1000 | 400 | 15 | 2400×1400×2000 | 3600 |

| GZ3-60/13-200 | 60 | 1.3 | 20 | 1000 | 400 | 15 | 2400×1400×2000 | 3500 |

G4 Medium-sized diaphragm compressor (compact structure)

- Structure: D-type (two, three, four cylinders)

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled

- Maintenance maximum weight per piece: 1000kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | T | |

| GD4-90/200 | 90 | ATM | 20 | 3200 | 430 | 45 | 4000×2850×2000 | 10.8 |

| GD4-100/160 | 100 | ATM | 16 | 3700 | 430 | 45 | 4000×2850×2000 | 10.8 |

| GD4-240/16-300 | 240 | 1.6 | 30 | 4700 | 360 | 55 | 3800×2600×1800 | 8.5 |

| GD4-240/6-150 | 240 | 0.6 | 15 | 5000 | 400 | 55 | 3800×2600×1800 | 9 |

| GD4-300/15-210 | 300 | 1.5 | 21 | 5300 | 400 | 75 | 3800×2600×1800 | 9.5 |

| GD4-800/12-40 | 800 | 1.2 | 4 | 5400 | 400 | 75 | 3800×2600×1800 | 9.2 |

| GD4-200/15-350 | 200 | 1.5 | 3.5 | 4600 | 360 | 55 | 3800×2600×1800 | 9 |

| GD4-300/5-52 | 300 | 0.5 | 5.2 | 4800 | 430 | 55 | 3800×2600×1800 | 9 |

| GD4-870/11-31 | 870 | 1.1 | 3.1 | 5000 | 420 | 55 | 3800×2850×2000 | 9.5 |

| GD4-240/5-140 | 240 | 0.5 | 14 | 5000 | 400 | 55 | 3800×2600×1800 | 9 |

| GD4-225/9-200 | 225 | 0.9 | 20 | 5000 | 420 | 55 | 3800×2600×1800 | 9.5 |

| GD4-300/5-52 | 300 | 0.5 | 5.2 | 5000 | 430 | 55 | 3800×2600×1800 | 9.5 |

| GD4-280/0.18-5 | 280 | 0.018 | 0.5 | 4000 | 420 | 45 | 4200×2600×2100 | 15 |

| GD4-240/0,24-6.17 | 240 | 0.024 | 0.617 | 4000 | 420 | 45 | 4200×2600×2100 | 14 |

| GD4-300/10-250 | 300 | 1 | 25 | 5500 | 420 | 75 | 3800×2600×1800 | 9.5 |

G5 Super-large diaphragm compressor

- Structure: D-type (two, three, four cylinders)

- Lubrication: splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled

- Maintenance maximum weight per piece: 1500kg

- Maintenance maximum space: the circle shall be not less than 1.5 m

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | T | |

| GD5-150/200 | 150 | ATM | 20 | 7000 | 430 | 90 | 4400×2850×2200 | 13 |

| GD5-525/6-200 | 525 | 0.6 | 20 | 12000 | 400 | 132 | 3800×2700×2000 | 10.8 |

| GD5-250/0.3-12 | 250 | 0.03 | 1.2 | 4700 | 375 | 55 | 4200×2900×1800 | 14 |

| GD5-2900/45-120 | 2900 | 4.5 | 12 | 13200 | 429 | 160 | 4000×2900×2450 | 16 |

| GD5-9000/78-83 | 9000 | 7.8 | 8.3 | 3700 | 450 | 45 | 3800×2600×2500 | 15 |

| GD5-1300/45-220 | 1300 | 4.5 | 22 | 13500 | 429 | 160 | 4000×2900×2450 | 16 |

| GD5-8000/235-250 | 8000 | 23.5 | 25 | 3800 | 429 | 45 | 3800×2600×2500 | 15 |

| GD5-500/0.8-10 | 500 | 0.08 | 1 | 6800 | 429 | 75 | 4400×2850×2200 | 16 |

| GD5-500/10-200 | 500 | 1 | 20 | 12000 | 400 | 132 | 3700×2750×2000 | 10 |

| GD5-550/17-200 | 550 | 1.7 | 20 | 9500 | 400 | 110 | 3700×2750×2000 | 10 |

| GD5-1080/5-31.5 | 1080 | 0.5 | 3.15 | 12000 | 429 | 132 | 4400×2850×2200 | 14 |

| GD5-500/0.7-23 | 500 | 0.07 | 2.3 | 9500 | 429 | 110 | 4400×2850×2200 | 14 |

| GD5-600/15-350 | 600 | 1.5 | 35 | 12800 | 429 | 160 | 4000×2850×2100 | 12 |

| GD5-4500/185-190 | 4500 | 18.5 | 19 | 5000 | 420 | 45 | 3800×2600×2500 | 15 |

| GD5-1000/15-180 | 1000 | 1.5 | 18 | 15000 | 420 | 160 | 4000×2850×2100 | 12 |

G1 Small diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication:splash

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece:80kg

- Maintenance maximum space:the circle shall be not less than 1 m

| Product Model | Volumetric Flow | Intake Pressure | Exhaust Pressure | Water Consumption | Crankshaft Speed | Motor Power | Dimension | Unit Weight |

|---|---|---|---|---|---|---|---|---|

| (Nm³/h) | (MPa(G)) | (MPa(G)) | (L/H) | (r/min) | (KW) | (L×W×H)(MM) | (KG) | |

| GD0-3/200 | 3 | ATM | 20 | / | 750 | 2.2 | 600×500×400 | 200 |

| GL1-5/200 | 5 | ATM | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13 | 10 | ATM | 1.3 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-10/13-200 | 10 | 1.3 | 20 | 300 | 600 | 3 | 1350×600×950 | 550 |

| GL1-5/1-160 | 5 | 0.1 | 16 | 300 | 450 | 3 | 1350×600×950 | 550 |

| GL1-10/4-160 | 10 | 0.4 | 16 | 400 | 600 | 4 | 1350×600×950 | 520 |

| GL1-8/2.5-160 | 8 | 0.25 | 16 | 400 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 15 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/6-200 | 5 | 0.6 | 20 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GL1-10/6-160 | 10 | 0.6 | 16 | 400 | 400 | 4 | 1350×600×950 | 520 |

| GL1-5/13-400 | 5 | 1.3 | 40 | 300 | 400 | 3 | 1350×600×950 | 500 |

| GL1-15/10-150 | 15 | 1 | 15 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-10/7-320 | 10 | 0.7 | 32 | 400 | 450 | 4 | 1350×600×950 | 520 |

| GL1-5/4-350 | 5 | 0.4 | 35 | 300 | 400 | 3 | 1350×600×950 | 520 |

| GZ1-5/13 | 5 | ATM | 1.3 | 200 | 450 | 1.5 | 1100×600×950 | 450 |

| GZ1-5/13-200 | 5 | 1.3 | 20 | 200 | 450 | 1.5 | 1100×600×950 | 420 |

| GZ1-5/30-400 | 5 | 3 | 40 | 300 | 400 | 3 | 1100×600×950 | 400 |

| GZ1-70/30-35 | 70 | 3 | 3.5 | 200 | 400 | 4 | 1100×600×950 | 420 |

G2 Medium-sized diaphragm compressor

- Structure: Z, L, P, D-type

- Lubrication:Forced lubrication

- Oil type:compulsory oil supplement

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece:100kg

- Maintenance maximum space:No less than 1 meter around

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm3/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GL2-20/200 | 20 | ATM | 20 | 700 | 400 | 7.5 | 1700×850×1150 | 1100 |

| GL2-40/13 | 40 | ATM | 1.3 | 700 | 400 | 7.5 | 1700×850×1150 | 1200 |

| GL2-40/13-200 | 40 | 1.3 | 20 | 700 | 400 | 7.5 | 1700×850×1150 | 1000 |

| GL2-25/1-160 | 25 | 0.1 | 16 | 1000 | 400 | 11 | 1700×850×1150 | 1100 |

| GL2-40/4-160 | 40 | 0.4 | 16 | 1000 | 400 | 11 | 1700×850×1150 | 1050 |

| GL2-50/7-160 | 50 | 0.7 | 16 | 1200 | 400 | 11 | 1700×850×1150 | 1000 |

| GL2-40/7-320 | 40 | 0.7 | 32 | 1200 | 420 | 11 | 1700×850×1150 | 900 |

| GL2-60/12-160 | 60 | 1.2 | 16 | 1000 | 360 | 11 | 1700×850×1150 | 900 |

| GL2-40/13-400 | 40 | 1.3 | 40 | 1000 | 400 | 11 | 1700×850×1150 | 900 |

| GL2-30/4-350 | 30 | 0.4 | 35 | 1000 | 420 | 11 | 1700×850×1150 | 900 |

| GD2-60/30-400 | 60 | 3 | 40 | 1200 | 400 | 11 | 1700×850×1150 | 850 |

| GL2-15/350 | 15 | 0 | 35 | 1500 | 400 | 18.5 | 1700×1200×1150 | 1500 |

| GZ2-10/10-150 | 10 | 1 | 15 | 400 | 420 | 4 | 1400×850×1150 | 800 |

| GZ2-15/13 | 15 | ATM | 1.3 | 400 | 400 | 4 | 1400×850×1150 | 800 |

| GZ2-15/13-200 | 15 | 1.3 | 20 | 400 | 400 | 4 | 1400×850×1150 | 750 |

G3 Medium-sized diaphragm compressor

- Structure: Z、L、V、P、D Type

- Lubrication:Forced lubrication

- Oil type:Oil replenishment

- Cooling way:water cooled or air cooled

- Maintenance maximum weight per piece: 60-70 KG

- Maintenance maximum space:No less than 1 meter around

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | KG | |

| GL3-60/200 | 60 | ATM | 20 | 1600 | 400 | 30 | 2800×1600×2000 | 5500 |

| GL2-40/13 | 120 | ATM | 1.3 | 1600 | 400 | 30 | 2800×1600×2000 | 5000 |

| GL3-110/20-200 | 110 | 2 | 20 | 1600 | 400 | 30 | 2800×1600×2000 | 4000 |

| GL3-75/20 | 75 | ATM | 2 | 4000 | 450 | 45 | 2800×1600×2000 | 5500 |

| GL3-50/5-160 | 50 | 0.5 | 16 | 2000 | 400 | 30 | 2800×1600×2000 | 4200 |

| GL3-150/10-160 | 150 | 1 | 16 | 3500 | 360 | 37 | 2800×1600×2000 | 4200 |

| GL3-80/7-320 | 80 | 0.7 | 32 | 2500 | 400 | 30 | 2800×1600×2000 | 4000 |

| GL3-180/12-160 | 180 | 1.2 | 16 | 3500 | 360 | 37 | 2800×1600×2000 | 4200 |

| GL3-120/13-400 | 120 | 1.3 | 40 | 3000 | 400 | 37 | 2800×1600×2000 | 4000 |

| GL3-80/4-350 | 80 | 0.4 | 35 | 3000 | 400 | 30 | 2800×1600×2000 | 4200 |

| GL3-800/300-700 | 800 | 30 | 70 | 5000 | 400 | 55 | 3600×2400×2000 | 6000 |

| GL3-200/20-200 | 200 | 2 | 20 | 3000 | 360 | 37 | 2800×1600×2000 | 4200 |

| GZ3-50/10-150 | 50 | 1 | 15 | 1000 | 400 | 11 | 2400×1400×2000 | 3500 |

| GZ3-60/13 | 60 | ATM | 1.3 | 1000 | 400 | 15 | 2400×1400×2000 | 3600 |

| GZ3-60/13-200 | 60 | 1.3 | 20 | 1000 | 400 | 15 | 2400×1400×2000 | 3500 |

G4 Medium-sized diaphragm compressor (compact structure)

- Structure: D Type (Two cylinders, Three cylinders,Four cylinders)

- Lubrication:Forced lubrication

- Oil type:Forced Oil Replenishment

- Cooling way:Water cooling

- Maintenance maximum weight per piece:1000 KG

- Maintenance maximum space:No less than 1.5 meters around

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | T | |

| GD4-90/200 | 90 | ATM | 20 | 3200 | 430 | 45 | 4000×2850×2000 | 10.8 |

| GD4-100/160 | 100 | ATM | 16 | 3700 | 430 | 45 | 4000×2850×2000 | 10.8 |

| GD4-240/16-300 | 240 | 1.6 | 30 | 4700 | 360 | 55 | 3800×2600×1800 | 8.5 |

| GD4-240/6-150 | 240 | 0.6 | 15 | 5000 | 400 | 55 | 3800×2600×1800 | 9 |

| GD4-300/15-210 | 300 | 1.5 | 21 | 5300 | 400 | 75 | 3800×2600×1800 | 9.5 |

| GD4-800/12-40 | 800 | 1.2 | 4 | 5400 | 400 | 75 | 3800×2600×1800 | 9.2 |

| GD4-200/15-350 | 200 | 1.5 | 3.5 | 4600 | 360 | 55 | 3800×2600×1800 | 9 |

| GD4-300/5-52 | 300 | 0.5 | 5.2 | 4800 | 430 | 55 | 3800×2600×1800 | 9 |

| GD4-870/11-31 | 870 | 1.1 | 3.1 | 5000 | 420 | 55 | 3800×2850×2000 | 9.5 |

| GD4-240/5-140 | 240 | 0.5 | 14 | 5000 | 400 | 55 | 3800×2600×1800 | 9 |

| GD4-225/9-200 | 225 | 0.9 | 20 | 5000 | 420 | 55 | 3800×2600×1800 | 9.5 |

| GD4-300/5-52 | 300 | 0.5 | 5.2 | 5000 | 430 | 55 | 3800×2600×1800 | 9.5 |

| GD4-280/0.18-5 | 280 | 0.018 | 0.5 | 4000 | 420 | 45 | 4200×2600×2100 | 15 |

| GD4-240/0,24-6.17 | 240 | 0.024 | 0.617 | 4000 | 420 | 45 | 4200×2600×2100 | 14 |

| GD4-300/10-250 | 300 | 1 | 25 | 5500 | 420 | 75 | 3800×2600×1800 | 9.5 |

G5 Super-large diaphragm compressor

- Structure: D Type (Two cylinders, Three cylinders, Four Cylinders or Six Cylinders )

- Lubrication:Forced Lubrication

- Oil type:Forced oil replenishment

- Cooling way:Water cooling

- Maintenance maximum weight per piece:5000 KG

- Maintenance maximum space:No less than 2.5 meters around

| Product Model | Volumetric flow | Intake pressure | Exhaust pressure | Water consumption | Crankshaft speed | Motor power | Dimension | Unit weight |

|---|---|---|---|---|---|---|---|---|

| Nm³/h | MPa(G) | MPa(G) | L/H | r/min | KW | L×W×H(MM) | T | |

| GD5-150/200 | 150 | ATM | 20 | 7000 | 430 | 90 | 4400×2850×2200 | 13 |

| GD5-525/6-200 | 525 | 0.6 | 20 | 12000 | 400 | 132 | 3800×2700×2000 | 10.8 |

| GD5-250/0.3-12 | 250 | 0.03 | 1.2 | 4700 | 375 | 55 | 4200×2900×1800 | 14 |

| GD5-2900/45-120 | 2900 | 4.5 | 12 | 13200 | 429 | 160 | 4000×2900×2450 | 16 |

| GD5-9000/78-83 | 9000 | 7.8 | 8.3 | 3700 | 450 | 45 | 3800×2600×2500 | 15 |

| GD5-1300/45-220 | 1300 | 4.5 | 22 | 13500 | 429 | 160 | 4000×2900×2450 | 16 |

| GD5-8000/235-250 | 8000 | 23.5 | 25 | 3800 | 429 | 45 | 3800×2600×2500 | 15 |

| GD5-500/0.8-10 | 500 | 0.08 | 1 | 6800 | 429 | 75 | 4400×2850×2200 | 16 |

| GD5-500/10-200 | 500 | 1 | 20 | 12000 | 400 | 132 | 3700×2750×2000 | 10 |

| GD5-550/17-200 | 550 | 1.7 | 20 | 9500 | 400 | 110 | 3700×2750×2000 | 10 |

| GD5-1080/5-31.5 | 1080 | 0.5 | 3.15 | 12000 | 429 | 132 | 4400×2850×2200 | 14 |

| GD5-500/0.7-23 | 500 | 0.07 | 2.3 | 9500 | 429 | 110 | 4400×2850×2200 | 14 |

| GD5-600/15-350 | 600 | 1.5 | 35 | 12800 | 429 | 160 | 4000×2850×2100 | 12 |

| GD5-4500/185-190 | 4500 | 18.5 | 19 | 5000 | 420 | 45 | 3800×2600×2500 | 15 |

| GD5-1000/15-180 | 1000 | 1.5 | 18 | 15000 | 420 | 160 | 4000×2850×2100 | 12 |

Case Project

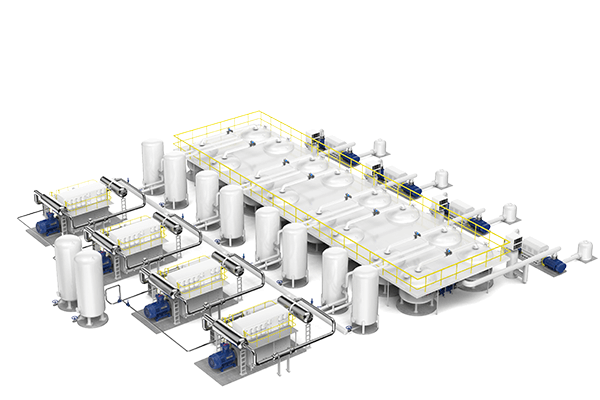

2000Nm³/h hydrogen production and delivery integration project

20MPA Hydrogen Compressor

3000Nm³/h Coal to Hydrogen Project

Hydrogen Filling Diaphragm Compressor Project

You May Like

Get Hydrogen Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales1:+1 213 865 6075

sales1:+1 213 865 6075