- Home >

- Air Compressor >

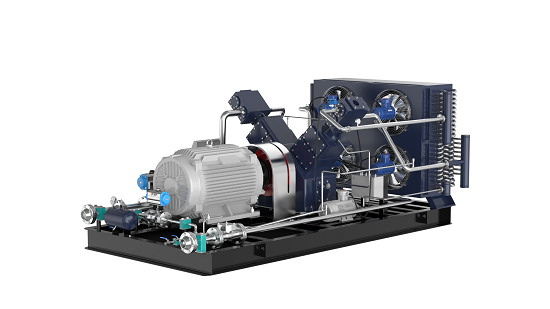

- Two-stage Permanent Magnet Variable Frequency Screw Compressor

Two-stage Permanent Magnet Variable Frequency Screw Compressor

- Discharge Pressure:

- 6~13

- [bar]

- 87~189

- [psig]

- Free Air Delivery:

- 2.7~106

- [m³/min]

- 76~3743

- [cfm]

- Working Power:

- 15~450

- [kW]

- 20~600

- [hp]

Description

The two-stage compressed permanent magnet variable frequency screw compressor has its primary and secondary compression rotors integrated within a single housing and each is directly driven by helical gears. The compression process is as follows: Natural air first passes through an air filter and enters the first stage of compression. In the compression chamber, it will be mixed with a small amount of lubricating oil. Meanwhile, the mixed gas is compressed to the interstage pressure. The compressed gas then enters the cooling channel, where it comes into contact with a large amount of oil mist, thus significantly reducing the temperature. The cooled compressed gas enters the second-stage rotor for secondary compression. Finally, the compressor discharges gas through the discharge valve, completing the entire compression process.

Advantages of two-stage compressed permanent magnet variable frequency screw compressor

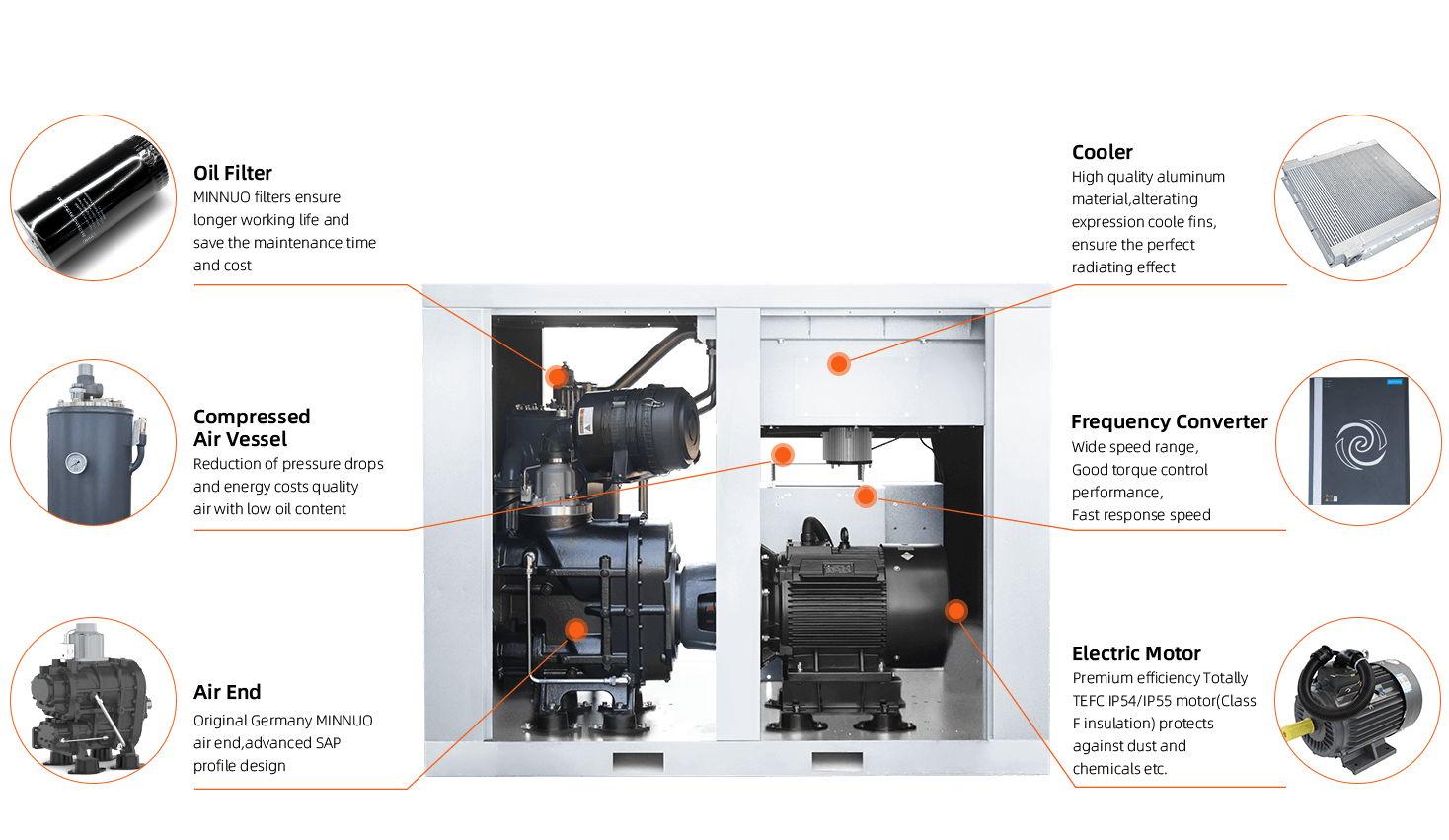

High Energy Efficiency

Two-stage independent compression system with equal pressure ratio and low-speed design achieves 30% energy savings. Gas discharge power increases by 5%-10% compared to standard models.Outstanding Performance

Equipped with BSC or Hanbell AB heads for efficient and stable operation. High-precision CMM measurement ensures accurate and reliable core components.Optimized Design

TInnovative 5:6 asymmetric rotor profile improves compression efficiency. Low-speed operation reduces wear and noise, extending the machine’s lifespan.Intelligent Control

Microcomputer control system with bilingual interface for easy operation. Supports MODBUS RTU protocol and multiple protection features for safe operation.Premium Components

High-performance permanent magnet motor with strong demagnetization resistance and constant torque. >High-quality bearings ensure durability, wear resistance, and extended reliability.-

Energy-Saving Intake and Silent Design

Intake valve made of high-temperature, corrosion-resistant material adjusts air volume precisely to reduce energy consumption. Silent centrifugal fan minimizes noise to 65dB(A) while maintaining durability and stability.

| Model | Power (KW) |

Pressure (MPa) |

Volume flow (m³/ min) |

Pipe Diameter |

Weight (kg) |

Dimension (mm) |

|---|---|---|---|---|---|---|

| MN-20A-TSPM | 15 | 0.6 | 3.5 | G1 | 500 | 1300×900×1220 |

| 0.7 | 2.9 | |||||

| 0.8 | 2.7 | |||||

| 1.0 | — | |||||

| 1.3 | — | |||||

| MN-25A-TSPM | 18.5 | 0.6 | 4.2 | G1 | 550 | 1300×900×1220 |

| 0.7 | 3.8 | |||||

| 0.8 | 3.4 | |||||

| 1.0 | 2.8 | |||||

| 1.3 | — | |||||

| MN-30A-TSPM | 22 | 0.6 | 4.6 | G1 | 500 | 1300×980×1220 |

| 0.7 | 4.3 | |||||

| 0.8 | 4.1 | |||||

| 1.0 | 3.5 | |||||

| 1.3 | 2.7 | |||||

| MN-40A-TSPM | 30 | 0.6 | 6.8 | G1 1/2 | 800 | 1400×1100×1450 |

| 0.7 | 6.4 | |||||

| 0.8 | 5.9 | |||||

| 1.0 | — | |||||

| 1.3 | 3.9 | |||||

| MN-50A-TSPM | 37 | 0.6 | 8.5 | G1 1/2 | 850 | 1400×1100×1450 |

| 0.7 | 7.5 | |||||

| 0.8 | 7.2 | |||||

| 1.0 | 6.3 | |||||

| 1.3 | 5.4 | |||||

| MN-60A(W)-TSPM | 45 | 0.6 | 10.7 | G2 1/2(A) DN50(W) |

1500 | 2100×1440×1650 |

| 0.7 | 10.0 | |||||

| 0.8 | 9.5 | |||||

| 1.0 | 8.0 | |||||

| 1.3 | 6.8 | |||||

| MN-75A(W)-TSPM | 55 | 0.6 | 14.0 | G2 1/2(A) DN50(W) |

1700 | 2100×1440×1650 |

| 0.7 | 13.0 | |||||

| 0.8 | 12.5 | |||||

| 1.0 | 9.5 | |||||

| 1.3 | 8.0 | |||||

| MN-100A(W)-TSPM | 75 | 0.6 | 18.0 | G2 1/2(A) DN50(W) |

1800 | 2100×1440×1650 |

| 0.7 | 15.5 | |||||

| 0.8 | 15.2 | |||||

| 1.0 | 13.0 | |||||

| 1.3 | 11.5 | |||||

| MN-125A(W)-TSPM | 90 | 0.6 | 22.0 | DN65(A) DN8O(W) |

2400(A) 2700(W) |

2450×1700×1760(A) 2550×1680×1850(W) |

| 0.7 | 20.5 | |||||

| 0.8 | 19.5 | |||||

| 1.0 | 16.5 | |||||

| 1.3 | 14.0 | |||||

| MN-150A(W)-TSPM | 110 | 0.6 | 27.2 | DN80 | 2800 | 2600×1900×1890(A) 2550×1680×1850(W) |

| 0.7 | 24.0 | |||||

| 0.8 | 23.0 | |||||

| 1.0 | 20.0 | |||||

| 1.3 | 16.5 | |||||

| MN-180A(W)-TSPM | 132 | 0.6 | 32.0 | DN80 | 3000(A) 2800(W) |

2600×1900×1890(A) 2550×1680×1850(W) |

| 0.7 | 29.0 | |||||

| 0.8 | 27.0 | |||||

| 1.0 | 23.7 | |||||

| 1.3 | 19.0 | |||||

| MN-220A(W)-TSPM | 160 | 0.6 | 38.5 | DN100 | 4300(A) 3450(W) |

3250×2100×2200(A) 3000×2000×2000(W) |

| 0.7 | 35.3 | |||||

| 0.8 | 33.5 | |||||

| 1.0 | 30.6 | |||||

| 1.3 | 26.0 | |||||

| MN-250A(W)-TSPM | 185 | 0.6 | 43.8 | DN100 | 4500(A) 4000(W) |

3250×2100×2200(A) 3000×2000×2000(W) |

| 0.7 | 41.0 | |||||

| 0.8 | 38.0 | |||||

| 1.0 | 34.5 | |||||

| 1.3 | 29.0 | |||||

| MN-270A(W)-TSPM | 200 | 0.6 | 48.8 | DN125(A) DN100(W) |

6000(A) 5600(W) |

3800×2300×2200(A) 3600×2200×2200(W) |

| 0.7 | 45.0 | |||||

| 0.8 | 42.0 | |||||

| 1.0 | 38.0 | |||||

| 1.3 | 31.5 | |||||

| MN-300A(W)-TSPM | 220 | 0.6 | 53.0 | DN125(A) DN100(W) |

6500(A) 6000(W) |

3800×2300×2200(A) 3600×2200×2200(W) |

| 0.7 | 50.0 | |||||

| 0.8 | 46.0 | |||||

| 1.0 | 41.0 | |||||

| 1.3 | 35.0 | |||||

| MN-350A(W)-TSPM | 250 | 0.6 | 58.0 | DN125(A) DN100(W) |

7000(A) 6500(W) |

3800×2300×2200(A) 3600×2250×2300(w) |

| 0.7 | 55.5 | |||||

| 0.8 | 53.0 | |||||

| 1.0 | 45.8 | |||||

| 1.3 | 40.5 | |||||

| MN-380A(W)-TSPM | 280 | 0.6 | 63.5 | DN125 | 7500(A) 7000(W) |

3800×2300×2200(A) 3600×2250×2300(W) |

| 0.7 | 62.0 | |||||

| 0.8 | 60.0 | |||||

| 1.0 | 52.0 | |||||

| 1.3 | 43.0 | |||||

| MN-420A(W)-TSPM | 315 | 0.6 | 81.0 | DN125 | 8500(A) 7500(W) |

4300×2300×2430(A) 4000×2300×2320(W) |

| 0.7 | 74.0 | |||||

| 0.8 | 67.0 | |||||

| 1.0 | 59.0 | |||||

| 1.3 | 52.0 | |||||

| MN-480A(W)-TSPM | 355 | 0.6 | 85.0 | DN125 | 9500(A) 8000(W) |

4700×2250×2420(A) 4000×2300×2320(W) |

| 0.7 | 81.0 | |||||

| 0.8 | 78.0 | |||||

| 1.0 | 64.0 | |||||

| 1.2 | 60.0 | |||||

| 1.3 | 56.0 | |||||

| MN-540A(W)-TSPM | 400 | 0.6 | 92.5 | DN125(A) DN150(W) |

10000(A) 9000(W) |

4700×2250×2420(A) 4200×2350×2350(W) |

| 0.7 | 89.0 | |||||

| 0.8 | 84.5 | |||||

| 1.0 | 77.0 | |||||

| 1.3 | 64.0 | |||||

| MN-600W-TSPM | 450 | 0.6 | 106.0 | DN150 |

10000(W) |

4200×2350×2350(W) |

| 0.7 | 101.0 | |||||

| 0.8 | 96.0 | |||||

| 1.0 | 85.0 | |||||

| 1.3 | 79.0 |

Why Choose Us?

- Energy-saving and consumption reduction:Frequency conversion speed regulation, automatic adjustment of operation, saving energy consumption.

- Adaptability to harsh environments: Moisture and dust-proof, suitable for high temperature, high pressure, and other harsh working conditions.

- Reduction of wear: Wear-resistant materials, prolonging service life. Extending maintenance intervals and reducing maintenance costs.

- Excellent adaptability: High starting torque, quick start. Multiple operating modes to adapt to different working conditions.

- Comprehensive service assurance: 24-hour online service, available to answer questions anytime. Quick response, timely recovery of operation.

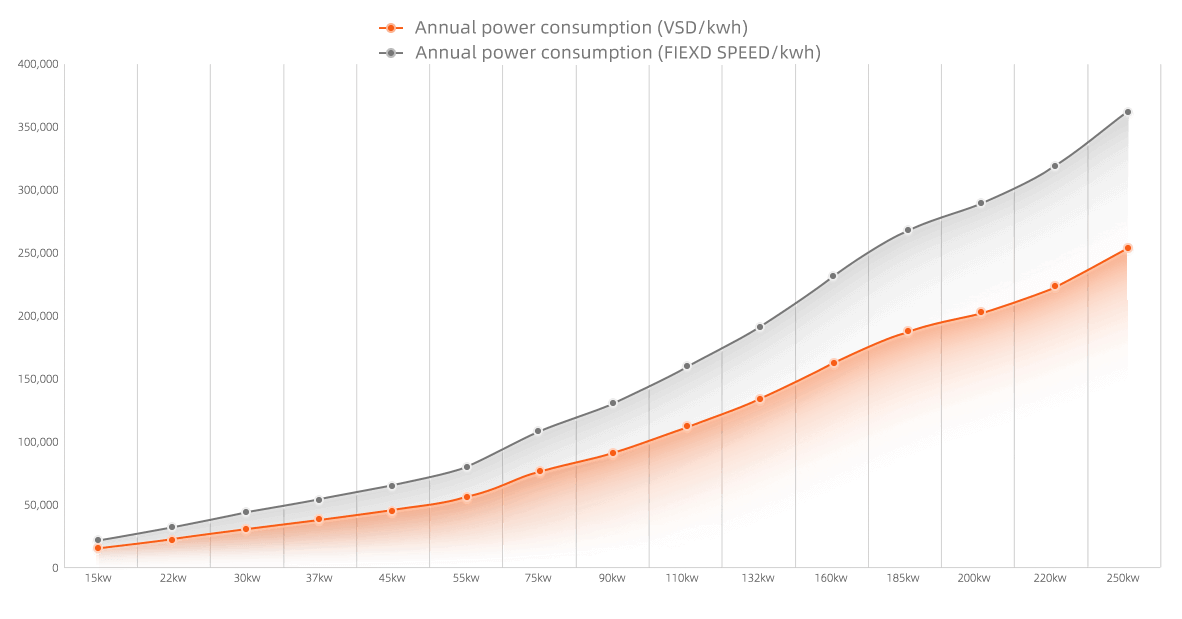

We focus on saving energy - VSD

For example 37kw screw compressor, the average annual operation is 8,000h, and the cost of electricity is $0.1. We save electricity than ordinary screw compressor per year.

218500-165620=52880KW

52880✖0.1=$5288

each year save $5288

Choosing Minnuo’s portable diesel air compressor means selecting exceptional quality, enhanced productivity, and reliable after-sales support. Let’s work together to take your business to the next level!

Frequent Asked Question

A two-stage compression permanent magnet variable frequency air compressor uses two independent compression systems with an equal pressure ratio design to improve efficiency. It combines a permanent magnet synchronous motor and variable frequency speed control technology to achieve energy savings and efficient operation. This technology automatically adjusts the speed under varying load conditions to ensure optimal performance and minimal energy consumption.

A two-stage compression system divides the compression process into two stages, with an intercooler to lower air temperature between stages. Key advantages include:

- Higher Efficiency: Saves up to 30% energy through optimized pressure distribution.

- Lower Operating Temperatures: Intercooling reduces heat, extending component lifespan.

- Durability: Reduced stress on parts ensures long-term reliability.

- Higher Output Pressure: More efficient at handling high-pressure requirements.

- Smooth Operation: Lower noise and vibration enhance user experience.

The two-stage compression permanent magnet variable frequency air compressor is suitable for various industrial environments, especially those with high energy efficiency and stability demands, such as manufacturing, electronics, and pharmaceutical industries. Its superior cooling system and low-noise design make it particularly effective in high-temperature, humid, or noise-sensitive environments.

- Regularly check and replace air filters to ensure clean air supply.

- Perform scheduled maintenance on the lubrication system according to the manual.

- Monitor the cooling system’s operation to prevent overheating.

- Perform self-diagnostics via the intelligent control system regularly to identify potential faults and reduce downtime.

- Segmented Compression Reduces Energy Consumption: Two-stage compression reduces the load on each stage, effectively lowering overall power consumption.

- Variable Frequency Technology Matches Air Demand: By adjusting output based on demand, variable frequency technology avoids the energy waste caused by frequent start-stop cycles in traditional air compressors.

- Intelligent Start-Stop Function: The system supports automatic start and stop based on air demand, especially during nighttime or low-load periods, further reducing operating costs.

When selecting a suitable compressor, consider the following factors:

- Air demand (flow) and working pressure

- Working environment: temperature, humidity, and air source cleanliness

- Electrical standards: voltage, current, and frequency requirements

- Special needs: such as low noise or specific industry certifications

Once this information is provided, we can help you choose the best model to maximize equipment performance and energy efficiency.

Send Your Inquiry Now!

Get The Latest Distributor Quotion

First Order 15% Discount Freight Fee