Helium compressor for industry

Helium compressors are designed to transfer helium gas at high pressure for storage and other industrial processes. Since Helium is a rare and expensive gas, it is crucial to recover and reuse it to ensure the cost-effectiveness of Helium compressor systems. MINNUO helium compressors employ reciprocating piston technology to capture fresh, mixed or recovered Helium gas at both atmospheric and higher inlet pressures. The number of stages in these compressors varies based on the flow and pressure requirements to achieve efficient gas compression and transfer.

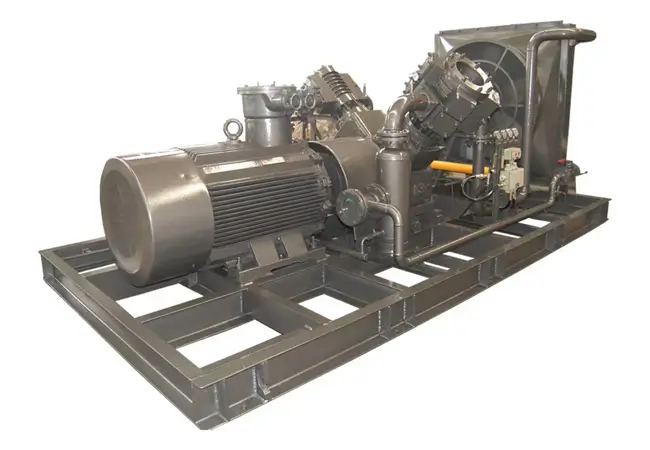

Helium Compressor

The helium compressor is a device used to compress helium gas into a liquid form that can be stored and used for a variety of purposes. The process of compression increases the pressure of the helium so that it can remain in a liquid form, making it easier to transport and store. Helium compressors can range in size from small, portable models to larger commercial devices that are used for industrial purposes.The use of helium compressors is particularly important in the aerospace and manufacturing industries, where cryogenic gases such as helium are a key component of the production process.

Lubrication method: divided into oil lubrication, oil-free lubrication.

Displacement : 10Nm3/h-20000Nm3/h

Exhaust pressure: from 0.1Mpa-30Mpa

Among them, the intake pressure, exhaust pressure and exhaust volume are all allowed to fluctuate up and down; the number of compression stages can be 1 to 5 stages.

Types Of Helium Compressor

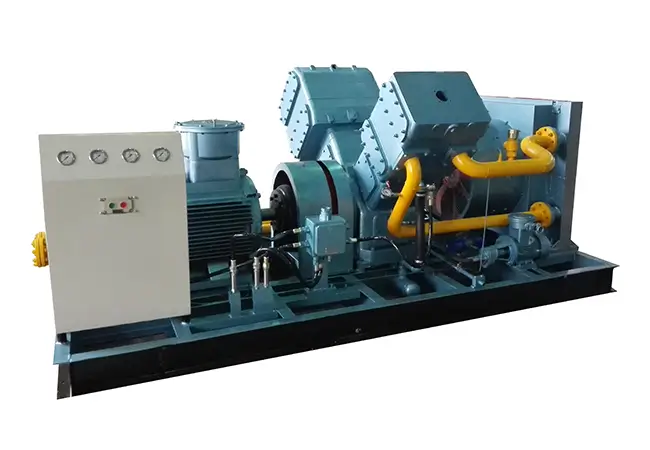

D Type

DW-8-160

Price: $54335~$62080

Compressor model: DW-8/160

Compressed media: helium

Structure type: Type DW

Nominal volume flow:480Nm3/min

Inlet pressure:atmospheric pressure

Outlet pressure:16Mpa

Cooling method: Air cooling

Equipped power: 132KW

Dimensions (L×W×H) :4500*3300*1850mm

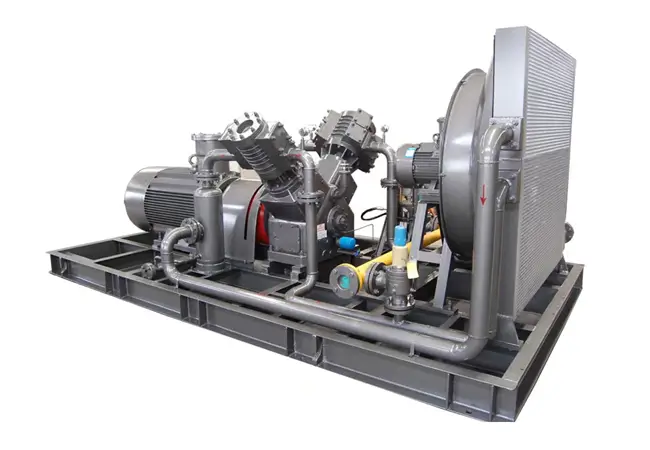

DW-10-150

Price: $64335~$72080

Compressor model: DW-10/150

Compressed media: helium

Structure type: Type DW

Nominal volume flow:600Nm3/min

Inlet pressure:atmospheric pressure

Outlet pressure:15Mpa

Cooling method: Air cooling

Equipped power: 132KW

Dimensions (L×W×H) :4500*3300*1800mm

D Type

Z/V Type

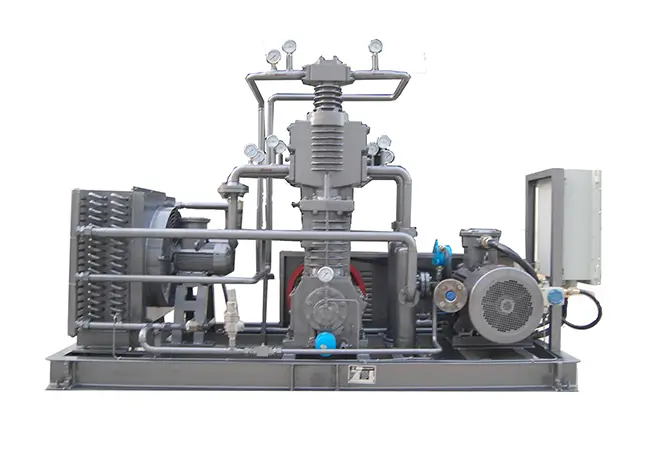

ZW-2-160

Price: $33740~$38546

Compressor model: ZW-2/160

Compressed media: helium

Structure type: Type ZW

Nominal volume flow:120Nm3/min

Inlet pressure:atmospheric pressure

Outlet pressure:16Mpa

Cooling method: Air cooling

Equipped power: 37KW

Dimensions (L×W×H) :2100*1180*1960mm

ZW-3-200

Price: $38000~$41000

Compressor model: ZW-3/200

Compressed media: helium

Structure type: Type ZW

Nominal volume flow:180Nm3/min

Inlet pressure:atmospheric pressure

Outlet pressure:20Mpa

Cooling method: Air cooling

Equipped power: 37KW

Dimensions (L×W×H) :2180*1250*2360mm

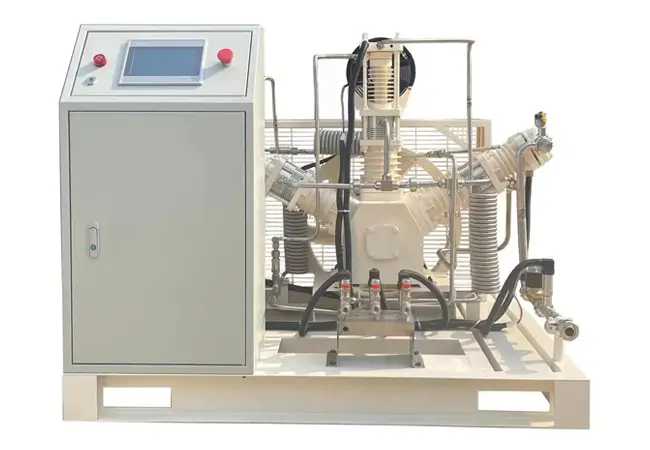

VW-0.83-150

Price: $14300~$16300

Compressor model: VW-0.83/150

Compressed media: helium

Structure type: Type VW

Nominal volume flow:80Nm3/min

Inlet pressure:atmospheric pressure

Outlet pressure:15Mpa

Cooling method: Air cooling

Equipped power: 22KW

Dimensions (L×W×H) :1680*800*1300mm

VW-1.33-150

Price: $15952~$18217

Compressor model: VW-1.33/150

Compressed media: helium

Structure type: Type VW

Nominal volume flow:80Nm3/min

Inlet pressure:atmospheric pressure

Outlet pressure:15Mpa

Cooling method: Air cooling

Equipped power: 30KW

Dimensions (L×W×H) :1680*800*1300mm

The difference between the water cooling and air cooling system of the compressor.

1. Compressors are distinguished by cooling and heat dissipation methods: water cooling and air cooling.

The water cooling and air cooling of the compressor are two different cooling and heat dissipation methods. The air cooling heat dissipation system uses forced air convection to dissipate heat, while the water cooling with relatively good heat dissipation effect uses cooling water to dissipate heat and cool down.

2. Different levels of complexity.

Air-cooled and water-cooled compressors are completely different in cooling and heat dissipation methods, and the complexity of the two cooling and heat dissipation systems is completely different. The water-cooled heat dissipation system is relatively complicated, and the air-cooled heat dissipation system is only a fan system, which is relatively simple.

3. The cost of the two cooling systems is different.

Compared with air cooling, water cooling is more expensive purely from the cooling system, because the water cooling system is complex. Regardless of the cost of the cooling system itself, water cooling is still more expensive. This is because water cooling uses cooling water to dissipate heat and requires continuous injection of cooling water to maintain normal operation, while air cooling relies on the atmosphere, which is almost free of cost. of.

4. Maintenance is different.

The maintenance methods of the cooling and heat dissipation methods of the two compressors are also different. The maintenance of air cooling mainly requires the lubrication of the bearings of the motor and fan, the dust cleaning of the fan, and the guarantee of the surrounding air environment, while the maintenance of water cooling Maintenance is mainly focused on the cooling water tower of the water cooling system and the heat dissipation of the cooling water, and to ensure that the scaling problem in the cooling system can be cleaned and cleaned in time, and the water quality of the cooling water should be guaranteed.

| No. | Model | Displacement Nm3/h | Inlet Pressure MPa | Outlet Presure MPa | Motor Power KW | Dimension mm | Weight kg |

|---|---|---|---|---|---|---|---|

| 1 | VW-0.5/150 | 30 | Atmospheric pressure | 15.0 | 15 | 1680*800*1300 | 1000 |

| 2 | VW-0.83/150 | 50 | Atmospheric pressure | 15.0 | 22 | 1680*800*1300 | 1000 |

| 3 | VW1.33/150 | 80 | Atmospheric pressure | 15.0 | 30 | 1680*800*1300 | 1100 |

| 4 | ZW-2/160 | 120 | Atmospheric pressure | 16.0 | 37 | 2100*1180*1960 | 2800 |

| 5 | ZW-3/200 | 180 | Atmospheric pressure | 20.0 | 75 | 2180*1250*2360 | 3600 |

| 6 | ZW-3.34 /150 | 200 | Atmospheric pressure | 15.0 | 75 | 2180*1250*2360 | 3600 |

| 7 | ZW-41/72-80 | 250 | 7.2 | 8.0 | 90 | 2180*1250*2360 | 3200 |

| 8 | ZW-5/80 | 300 | Atmospheric pressure | 8.0 | 110 | 3150*1350*2360 | 4300 |

| 9 | ZW-3/2-250 | 540 | 0.2 | 25.0 | 110 | 2180*1250*2360 | 3200 |

| 10 | ZW-5/150 | 200 | 0.1 | 8.0 | 132 | 3150*1350*2360 | 4500 |

| 11 | ZW-6/200 | 540 | 0.2 | 10.0 | 132 | 3150*1350*2360 | 4500 |

| 12 | ZW-3.33/1-80 | 200 | 0.1 | 8.0 | 55 | 2180*1250*2360 | 3200 |

| 13 | LW-8/150 | 480 | Atmospheric pressure | 15.0 | 132 | 3000*1950*2450 | 4500 |

| 14 | LW-15/2-10 | 2700 | 0.2 | 1.0 | 110 | 2300*1200*2300 | 3800 |

| 15 | LW-7.5/200 | 450 | Atmospheric pressure | 20.0 | 160 | 3200*1950*2450 | 4200 |

| 16 | LW-15/2-10 | 2700 | 0.2 | 1.0 | 110 | 2300*1200*2300 | 3800 |

| 17 | DW-8/160 | 480 | Atmospheric pressure | 16.0 | 132 | 4500*3300*1850 | 15000 |

| 18 | DW-8/220 | 480 | Atmospheric pressure | 22.0 | 160 | 4500*3300*1850 | 16000 |

| 19 | DW-10/150 | 600 | Atmospheric pressure | 15.0 | 185 | 4500*3300*1800 | 17000 |

| 20 | DW-18/250 | 1080 | Atmospheric pressure | 25.0 | 320 | 4500*3400*1800 | 18000 |

Applications

Apart from general industrial applications, helium compressors are also crucial in various operations and industries such as:

- Helium is utilized as a protective gas to pressurize metals, including magnesium, zirconium, aluminum, and titanium.

- Recovery, pressurized filling, and storage of helium are crucial due to its high cost. Methods such as waste purification and recycling are employed for HEW HED applications.

- Helium has various uses, such as in high vacuum devices and nuclear reactors. It also serves as a pressurized gas for delivering liquid propellants like liquid hydrogen and oxygen on rockets and spacecraft.

Benifits

Safety

MINNUO offers a range of highly secure methods to control gas leakage. When it comes to safe compression, it’s crucial to consider the entire gas mixture, not just individual gases. Some gas mixtures can lead to hazardous interactions that can increase their toxicity, corrosiveness, or flammability. To guarantee secure operations, rely on MINNUO’s specialized guidance.

Flexibility

Our solutions are custom-engineered to meet the unique requirements of each customer. By providing us with specific details of your needs, our experts can design a compressor tailored to your application with suitable materials and compatibility. Our high-quality materials have the capability to meet the necessary requirements for most industrial gases.

Reliability

MINNUO gas compressors are engineered to operate at slower speeds, ensuring consistent and dependable performance. With this design, our compressors can run continuously without compromising quality or efficiency, operating 60 minutes per hour, 24 hours per day, and 365 days per year. This eliminates the risk of unexpected downtime, providing uninterrupted operation.

We Serivice for many customer

Minuo offers independent solutions according to flow/purity/pressure, usage environment, main application, and special customer requirements at a competitive prices. Our compressor booster is made of high-quality materials and has been tested thoroughly to ensure the best quality.

Get Your Free Solution

We design and manufacture helium compressors more quickly and ideally to reach more optimal pressures, whether you need to fill cylinders, or perform leak detection tests, our helium compressors can help to do it faster and more efficiently at any time. So what are you waiting for, let us start by designing a high-quality quote for you.

You May Like

Get Helium Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.