LPG Compressor

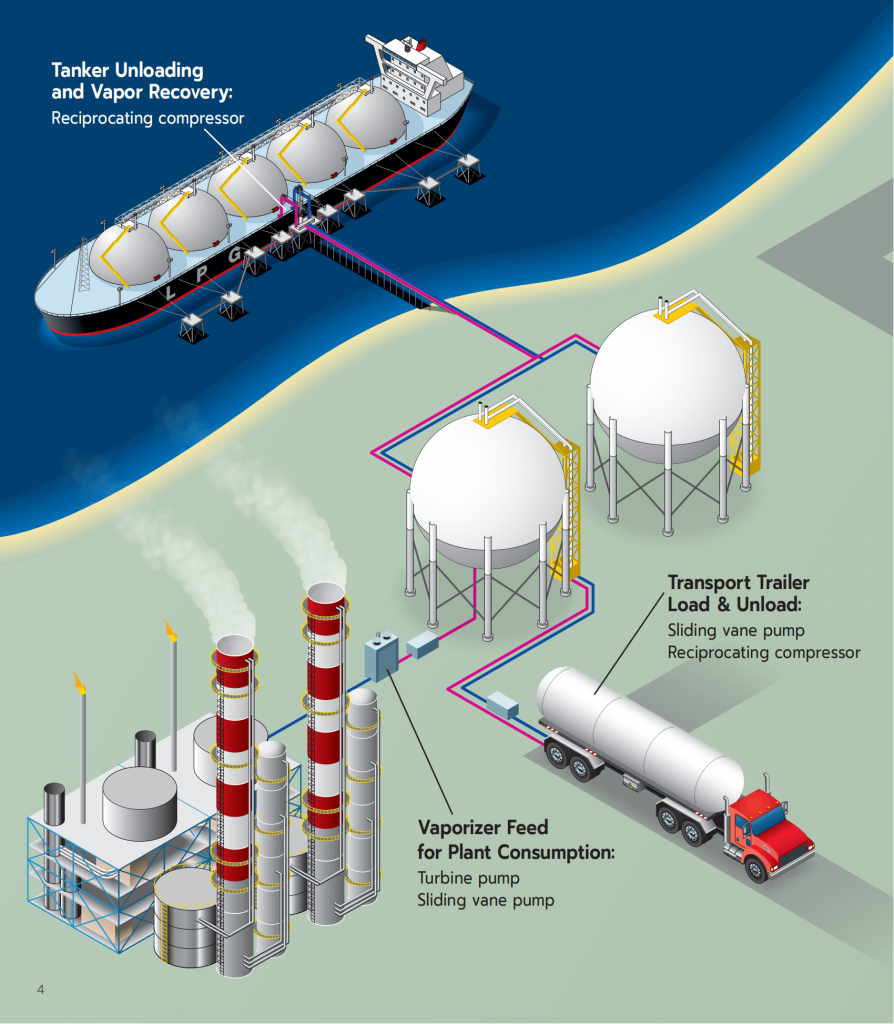

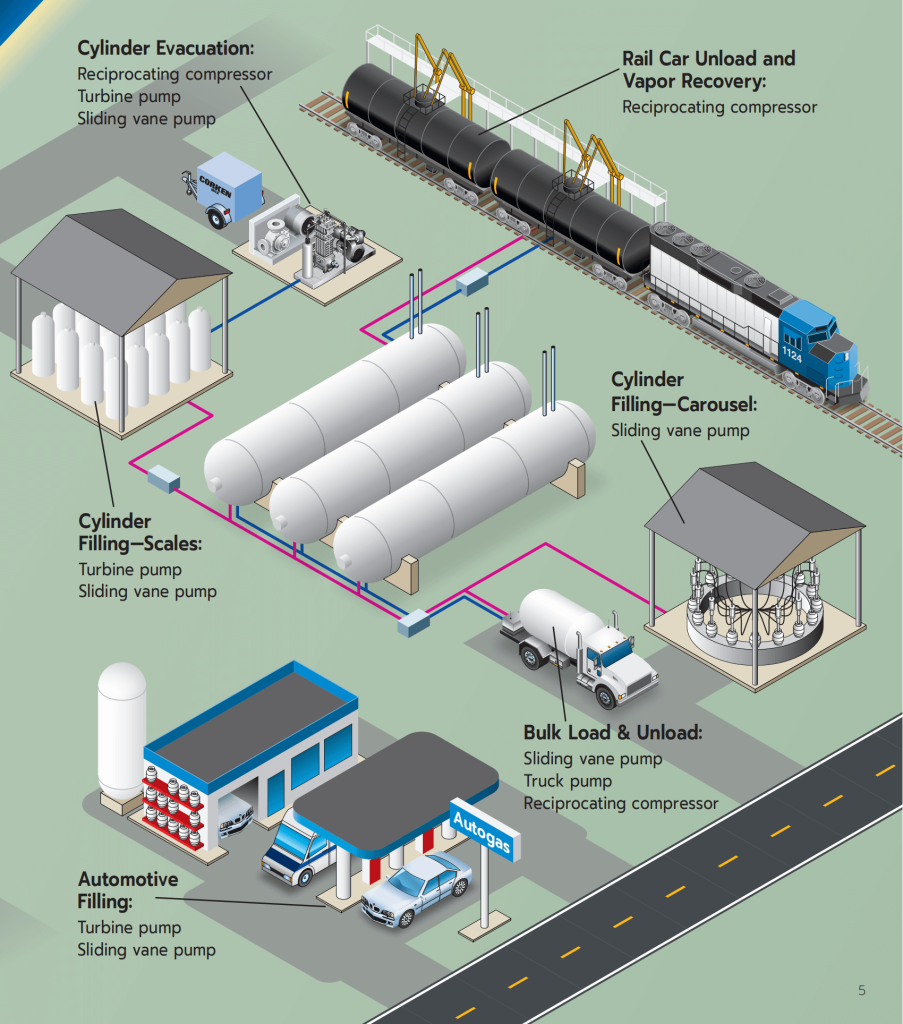

Minnuo provides first class gas compression solutions for factories, mines, docks, marine industry, LPG storage and transportation stations, LPG filling and bottling plants, LPG car filling stations.

The LPG compressor is specially designed for bulk transport needs. They are also suitable for propane transport, butane transport, ammonia transport, cylinder filling, unloading of railway vehicles and vapour recovery.

- Flow rate: 0.45m3/min-80m3/min

- Inlet pressure:1.0MPa

- Discharge pressure:1.6MPa

- Power:7.5kw-1000kw

Type of LPG Compressor

The liquefied gas compressor adopts oil-free lubrication technology, the packing parts should be oil-free lubrication because it ensures the purity of the medium when it works. The crankshaft, connecting rod and crosshead parts are splash lubricated in order to ensure the reliability of the movement and the cleanliness of the gas. The vertical double-cylinder structure makes the whole machine smaller in size and more compact and reasonable in structure, and the working efficiency of the LPG compressor is increased by about 5%.

Get The Latest Distributor Quotion

First Order 15% Discount Freight Fee

No spam, notifications only about new products, updates. new instant price.

Application

1, Loading and unloading of LPG tankers and tankers.

2, Bottling and backfilling at LPG stations or of similar nature

3, Pressurisation of LPG mixing stations.

4, LPG residual gas and residual night recovery.

Working Principle

Using the performance of the LPG compressor to pump and pressurise the output gas, the gas-phase LPG in the storage tank (or tanker) to be filled is passed into the inlet of the compressor, compressed and pressurised and then transported to the tanker (or storage tank) ready for unloading, thus reducing the pressure in the filling tank (or tanker) and increasing the pressure in the unloading tanker (or storage tank), so that the pressure difference required for loading and unloading is formed between the two (0.2 to 0.2 to 0.3 MPa), the liquid LPG will flow into the filling tank (or tanker) under the effect of the pressure difference, in order to achieve the purpose of loading and unloading LPG.

Check Cataglogue

01. Top Quality Materials

Choose top quality materails to proof high qulity

02. Branded explosion-proof motors

Adopting Mitsubishi, ABB, Yaskawa, siemen and other brands of motor, strong power, energy saving and environmental protection

03.Enhanced air valve

Special materials and specially treated valves for improved wear resistance and higher work efficiency

04. High precision bearings

Brand bearings, high precision, low noise, smooth running

05. Carbon fibre piston rings

The use of special material piston rings and packing rings with the company's patented technology, so that the compressor sealing structure, sealing effect is stable

06. Cylinder mesh truss grinding

The use of mesh truss grinding technology, with a corrosion-resistant coating, guarantees uniform self-lubrication, resulting in reduced friction

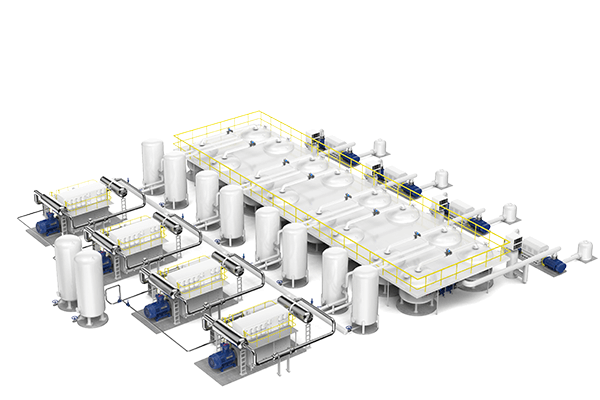

Case Project

Minnuo offers the petroleum, chemical, gas, food, power and other industries according to the customer’s usage requirements (flow/temperature/pressure, usage environment, main applications and special customer requirements). Independent solutions, from design to product, tailored to the customer.

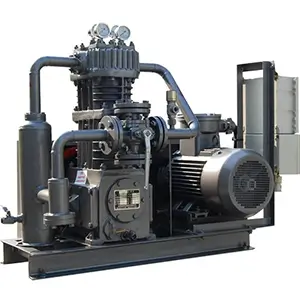

The LPG compressors we have designed are small in size, light in weight, smooth in operation, low in noise, simple in structure, easy in operation and reliable in installation. Among them, ZW series and CZW series compressors are the more advanced units at present, with various technical indicators reaching advanced level. It integrates the compressor, motor, gas pipeline system, energy gas-liquid separator and four-way valve, which makes the installation and operation more convenient.

Get Your LPG Compressor Solution

Minnuo helps keep your business running at peak productivity with efficient and reliable products and world-class engineered solutions. Our goal is to help you reduce operating costs, downtime and wear and tear on your equipment.

You May Like

Get LPG Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631