| Model | MN-60A-DT | MN-75A-DT | MN-100A-DT | MN-125A-DT | MN-150A-DT | MN-180A-DT | MN-220A-DT | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume Flow | NM³/Min | 7.3 | 7.2 | 6.2 | 9.4 | 9.3 | 7.1 | 6.1 | 12.4 | 12.2 | 9.1 | 15.4 | 15.0 | 12.1 | 20.1 | 19.9 | 14.8 | 12.0 | 23.0 | 22.5 | 19.7 | 14.6 | 28.5 | 28.0 | 22.5 | 21.5 |

| Pressure | MPa | 0.7 | 0.8 | 1.0 | 0.7 | 0.8 | 1.0 | 1.3 | 0.7 | 0.8 | 1.3 | 0.7 | 0.8 | 1.0 | 0.7 | 0.8 | 1.0 | 1.3 | 0.7 | 0.8 | 1.0 | 1.3 | 0.7 | 0.8 | 1.0 | 1.3 |

| Power | (KW) | 45 | 55 | 75 | 90 | 110 | 132 | 160 | ||||||||||||||||||

| Pipe Diameter | G1-1/2 | G2-1/2 | G2-1/2 | G2-1/2 | DN65 | DN65 | DN100 | |||||||||||||||||||

| Weight | (KG) | 700 | 1100 | 1200 | 1500 | 1800 | 1900 | 3000 | ||||||||||||||||||

| Dimension | L(mm) | 500 | 1700 | 7700 | 2100 | 2250 | 2250 | 2900 | ||||||||||||||||||

| W(mm) | 1000 | 1210 | 1210 | 1400 | 1510 | 1510 | 1800 | |||||||||||||||||||

| H(mm) | 1350 | 1550 | 1550 | 1650 | 1850 | 1850 | 2100 | |||||||||||||||||||

- Home >

- Air Compressor >

- Fixed Speed Air Compressor

Fixed Speed Air Compressor

- Working Pressure:

- 7-13

- [bar]

- 102-189

- [psig]

- Free Air Delivery:

- 25-2190

- [cfm]

- 0.7-62

- [m³/min]

- Working Power:

- 7.5-355

- [kW]

- 10-473

- [hp]

Fixed Speed Compressor Manufacturer

We were established in 1987, a leading air compressor manufacturer,Factory directly price with top quality Fix speed air compressors are widely used in wood furniture, general parts manufacturing, hardware, and building materials, electronics and precision machinery manufacturing, textile and knitting industry, everyday goods manufacturing, paper printing and packaging, metallurgical casting/metal processing, food, industrial machinery, spray painting, etc.

Advantages of Fixed Speed Air Compressor

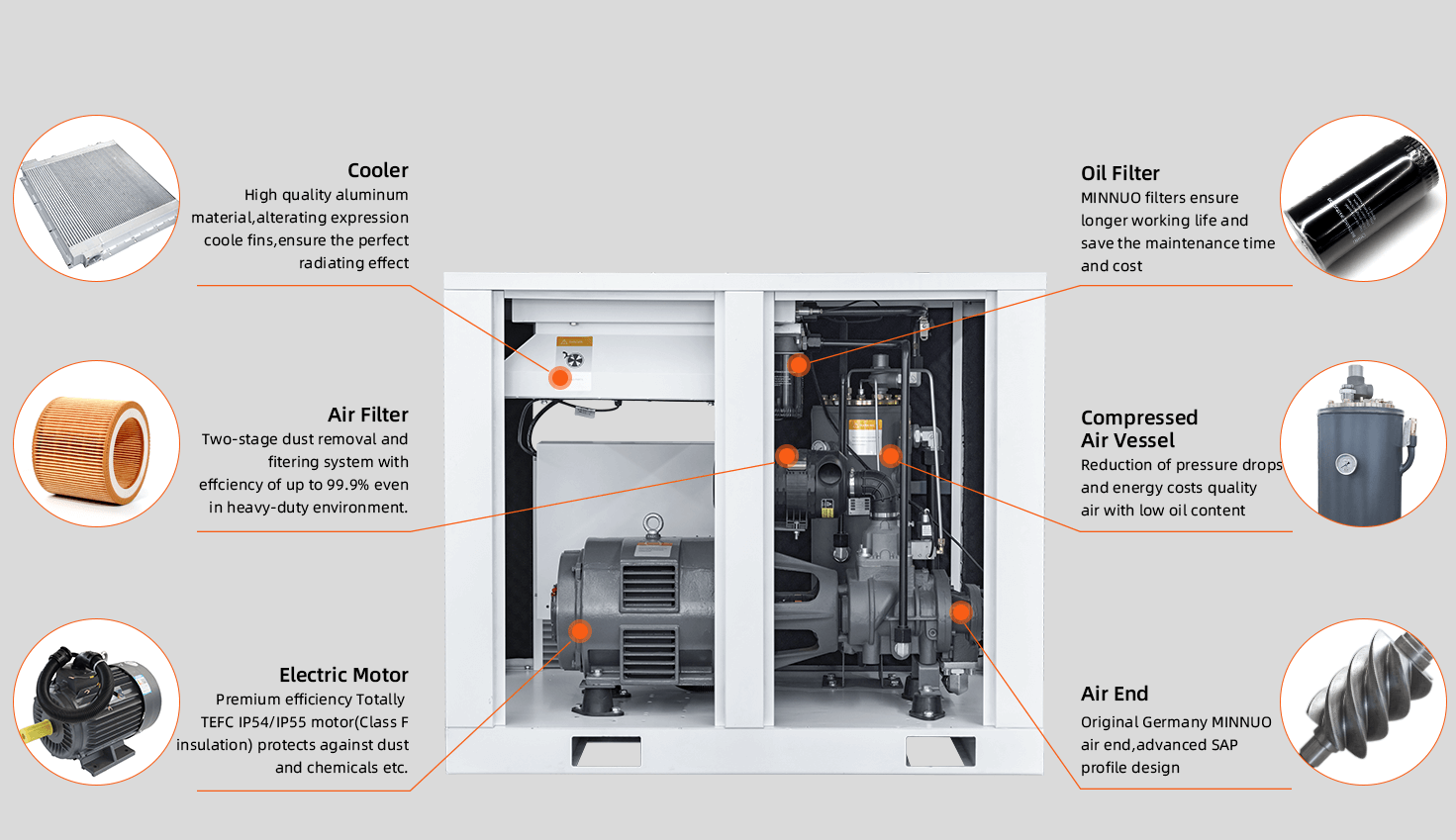

1. Compressor Air End Brand Assurance, Stable Airflow

Equipped with BSC/Hanbell AB series compressor air ends, ensuring stable and efficient airflow, meeting ISO 9001 and ISO 1217 standards, and extending equipment lifespan.

2. Electrical Components from Leading Global Brands

Featuring Siemens or Schneider electrical components and an intelligent variable frequency control system, providing energy efficiency and meeting CE, UL, and IEC safety standards.

3. High Protection Level Motor

The motor meets IP54/IP55 protection ratings and IE3 efficiency standards, offering dust and water resistance, low noise design, enhancing efficiency, and extending equipment life.

4. Internal Noise Reduction Design for Enhanced User Experience

The use of fire-resistant, sound-absorbing materials inside the compressor keeps noise levels below 75 dB(A), meeting UL94-V0 fire-retardant standards, reducing noise, and enhancing safety and comfort.

5. Efficient Cooling System to Extend Service Life

High-efficiency cooling design with a cooling efficiency of ≥90%, preventing overheating damage to equipment and meeting GB/T 19930 cooling equipment standards for long-term stable operation.

6. High-precision coupling, low energy consumption with high energy efficiency

High-precision flexible coupling for direct driven air compressor, 1:1 transmission ratio, lower energy consumption, higher efficiency

| Model | MN-10A-DT | MN-15A-DT | MN-20A-DT | MN-25A-DT | MN-30A-DT | MN-40A-DT | MN-50A-DT | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume Flow | NM³/Min | 1.2 | 1.1 | 0.9 | 0.7 | 1.7 | 1.6 | 1.3 | 1.0 | 2.4 | 2.2 | 2.0 | 1.6 | 2.9 | 2.8 | 2.7 | 2.2 | 3.5 | 3.4 | 3.2 | 2.4 | 4.7 | 4.6 | / | 3.1 | 6.4 | 6.3 | / | 4.7 |

| Pressure | Mpa | 0.7 | 0.8 | 1.0 | 1.3 | 0.7 | 0.8 | 1.0 | 1.3 | 0.7 | 0.8 | 1.0 | 1.3 | 0.7 | 0.8 | 1.0 | 1.3 | 0.7 | 0.8 | 1.0 | 1.3 | 0.7 | 0.8 | / | 1.3 | 0.7 | 0.8 | / | 1.3 |

| Power | (KW) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | |||||||||||||||||||||

| Pipe Diameter | / | G1/2 | G3/4 | G3/4 | G1 | G1 | G1 | G1-1/2 | |||||||||||||||||||||

| Weight | (KG) | 190 | 320 | 340 | 400 | 430 | 460 | 650 | |||||||||||||||||||||

| Dimension | L(mm) | 900 | 1150 | 1150 | 1350 | 1350 | 1350 | 1500 | |||||||||||||||||||||

| W(mm) | 650 | 750 | 750 | 850 | 850 | 850 | 1000 | ||||||||||||||||||||||

| H(mm) | 860 | 960 | 960 | 1110 | 1110 | 1110 | 1350 | ||||||||||||||||||||||

| Model | MN-250A-DT | MN-270A-DT | MN-300A-DT | MN-350A-DT | MN-380A-DT | MN-420A-DT | MN-480A-DT | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume flow | NM³/Min | 30.5 | 30.0 | 27.0 | 22.5 | 29.2 | 25.5 | 42.0 | 41.5 | 28.5 | 44.0 | 43.5 | 41.2 | 31.5 | 43.0 | 47.0 | 42.5 | 62.0 | 61.0 | ||||||||||

| Pressure | MPa | 0.7 | 0.8 | 1.0 | 1.3 | 1.0 | 1.3 | 0.7 | 0.8 | 1.3 | 0.7 | 0.8 | 1.0 | 1.3 | 1.0 | 1.3 | 1.3 | 0.7 | 0.8 | ||||||||||

| Power | (KW) | 185 | 200 | 220 | 250 | 280 | 315 | 355 | |||||||||||||||||||||

| Pipe Diameter | DN100 | DN125 | DN725 | DN125 | DN725 | DN125 | DN150 | ||||||||||||||||||||||

| Weight | (KG) | 3500 | 4800 | 5000 | 5900 | 6500 | 7000 | 8000 | |||||||||||||||||||||

| Dimension | L(mm) | 2900 | 3800 | 3800 | 3800 | 3800 | 3800 | 4300 | |||||||||||||||||||||

| W(mm) | 1800 | 2300 | 2300 | 2300 | 2300 | 2300 | 2300 | ||||||||||||||||||||||

| H(mm) | 2100 | 2300 | 2300 | 2200 | 2200 | 2200 | 2430 | ||||||||||||||||||||||

Frequent Asked Question

A fixed-speed air compressor is a device that compresses air by using rotors with helical teeth that mesh together in opposite directions to pressurize the gas. It operates at a constant frequency, meaning the motor speed does not adjust based on air demand. Therefore, for customers with energy-saving needs, a permanent magnet variable frequency air compressor is a more ideal choice. It can adjust the motor speed according to actual demand, achieving higher energy efficiency.

VSD is to add frequency converter on the basis of industrial frequency machine to realize frequency conversion, the frequency can be large or small, using the frequency regulation to control the main engine speed. Achieve the effect of energy saving and power saving without idle load.

- Please provide the required power (KW) and pressure (bar) for the screw air compressor.

- Please provide the voltage (V) and frequency (Hz) specifications.

- Please specify the intended application for the screw air compressor.

- Please provide details of your working environment (humidity conditions, dust levels).

- Please share the local electricity rate (per KWh).

In this way, we can provide you with a comprehensive gas solution.

1 year warranty for whole machine and 2 years warranty for the air end except consumables.

If the requirements for the air pressure used are not high, and the air volume generated by the selected air compressor is close to the required air volume, it is recommended to use the fix speed.

If your power supply costs are high, the compressor runs for many hours a day, and your needs vary widely, then VSD makes sense. In addition,a clean, dry installation area and good power supply are required for VSD.

Our standard delivery time for permanent magnet variable frequency air compressors is typically between 4 to 6 weeks, depending on the specific configuration and customization requirements. However, we strive to accommodate urgent orders, so please feel free to discuss any time-sensitive needs with us, and we will do our best to expedite the process.

Email

Email sales:+86 15366749631

sales:+86 15366749631