Introduction

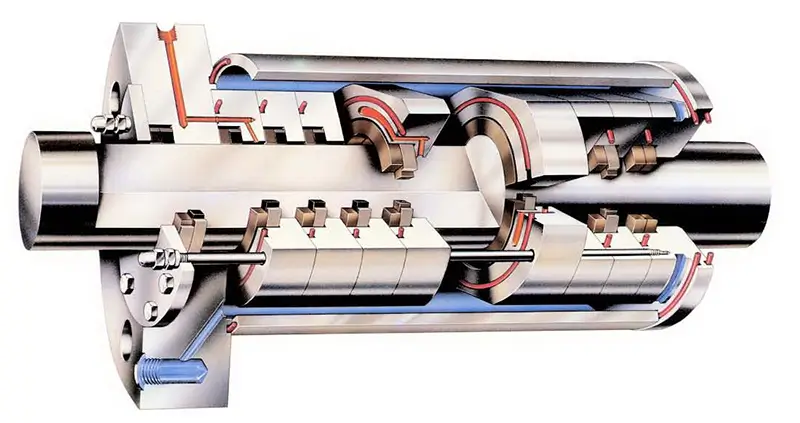

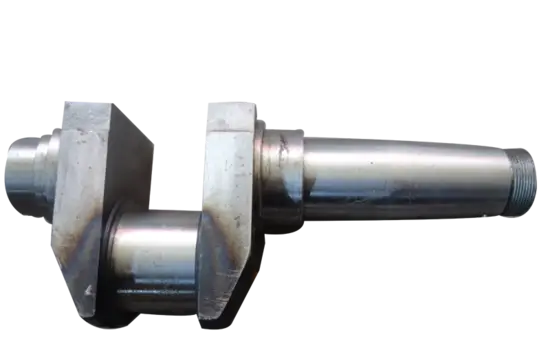

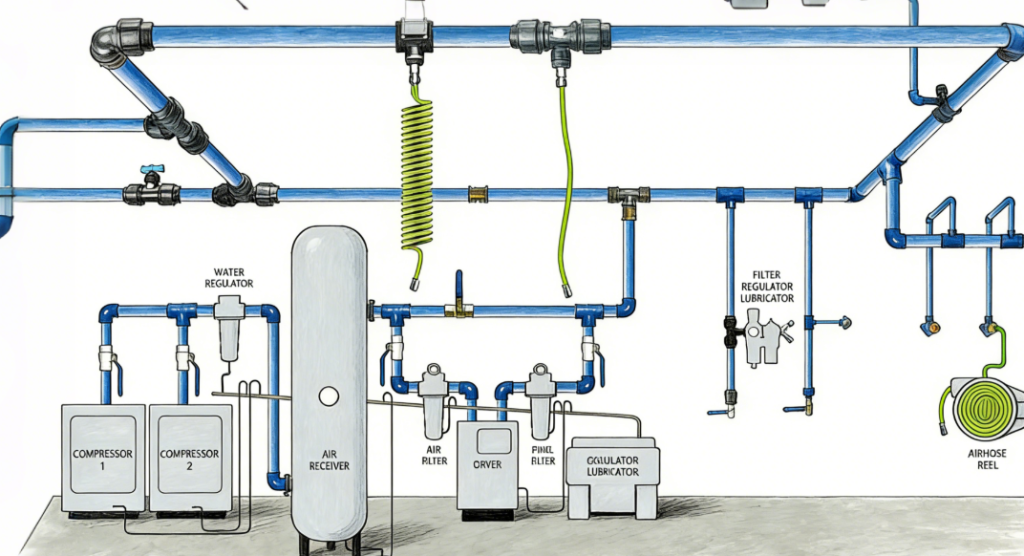

The piston gas compressor is a compressor that pressurizes and delivers gas through the reciprocating motion of the piston. It mainly comprises a working chamber, a transmission part, a fuselage, and auxiliary parts. The working chamber directly compresses the gas and includes a cylinder, cylinder liner, valve, packing, piston, and piston rod. The piston is driven by the piston rod to reciprocate in the cylinder. The volumes of the working chambers on both sides of the piston change sequentially. Due to the increased pressure, the gas on the side with reduced volume is discharged through the air valve. Due to the decreased air pressure, the gas on the side with increased volume is absorbed through the air valve. Transmission components realize reciprocating motion, including crankshaft connecting rod, eccentric slider, swash plate, etc. It consists of a crosshead, connecting rod, and crankshaft.

Reciprocating compressors will inevitably have some failures during operation. When a problem occurs, measures must be taken to eliminate it and ensure the compressor can return to normal working conditions. This article analyzes common faults of piston gas compressors and discusses how to deal with them.

Insufficient displacement

Air intake filter failure

- For piston gas compressors, fouling and clogging will reduce displacement.

- The suction pipe is too long, and the pipe diameter is too small, increasing the suction resistance and affecting the gas volume.

The cleaning frequency and effect of the intake filter affect the final exhaust capacity. So, the filter should be cleaned regularly.

Poor use environment

Generally speaking, reciprocating compressors are suitable for various regions and industries. It has specific environmental requirements, including temperature, humidity, and air pressure. Suppose the equipment that should be used in plain areas is used in a plateau environment. In that case, it will often lead to insufficient suction pressure and a corresponding reduction in exhaust volume.

Therefore, it is necessary to pay attention to the operating environment of the reciprocating compressor. Adjust the temperature, humidity, air pressure, and other indicators to a suitable environment before running the compressor.

Cylinder, piston, and piston ring wear

With the use of piston gas compressor, the cylinder, piston, and piston ring will be worn to a certain extent, increasing the relevant gap and the leakage, and affecting the displacement. For different degrees of wear, the solution is also different:

- When it is normal wear and tear, it is necessary to replace the wearing parts in time, such as piston rings.

- If the degree of wear exceeds the normal working range of the machine, it will lead to insufficient exhaust volume. Therefore, these accessories must be replaced in time. And during the replacement process, prevention and testing are carried out according to the requirements to ensure the normal operation of the overall device.

- If the installation is incorrect and the gap is unsuitable, it should be corrected according to the drawing. If there is no drawing, the gap can be adjusted according to experience. For the gap along the circumference between the piston and the cylinder, the gap value is 0.06/100~0.09/100 of the cylinder diameter if it is a cast iron piston. For the aluminum alloy piston, the gap is 0.12/100~0.18/100 of the gas diameter; The steel piston can take the smaller value of the aluminum alloy piston.

Loose stuffing box

- The stuffing box itself is not manufactured to meet the requirements

- During installation, the center of the piston rod and the stuffing box is not well aligned, resulting in wear, strain, etc., resulting in air leakage

Solution: Generally, lubricating oil is added to the stuffing box, which can play the role of lubrication, sealing, and cooling.

Low intake pressure

- The pressure gauge is faulty. Solution: Replace the pressure gauge.

- The pressure switch is faulty. Solution: Repair and replace the pressure switch if necessary.

Damaged valve plate

- Valve plate fatigue damage

- Valve wear

- The quality of the valve itself

Solution: Overhaul or replace the valve slice.

Damaged spring

- The spring valve plate is fatigued, weak and deformed during frequent opening and closing.

- The friction between the spring and the wall of the hole increases the degree of wear and tear, causing the spring to break.

- The gas medium is corrosive to a certain extent, resulting in faster damage to the spring.

Solution: Overhaul or replace the valve spring

Abnormal exhaust temperature

The abnormal exhaust temperature is generally higher than the design value, which is generally caused by the abnormal intake temperature, pressure ratio, and compression index. The fundamental factors that affect the high exhaust temperature are:

Piston ring wear or cylinder wall wear

The piston ring is used to seal the gap between the mirror surface of the cylinder and the piston. If the piston ring leaks or fails during the compression process, the high-temperature gas on the high-pressure side leaks to the low-pressure side, increasing the temperature of the suction side in the cylinder. When the piston moves in the opposite direction, the gas on the original suction side is compressed again, and the high-temperature gas on the high-pressure side leaks again to the low-pressure side. During several working cycles of the piston, the exhaust gas temperature will increase cumulatively.

Solution: Overhaul or replace the piston ring.

Increased valve wear and leakage

If the gas valve leaks, it will not only affect the exhaust temperature rise but also cause the interstage pressure to change. The exhaust temperature will increase as long as the pressure ratio is higher than normal.

Solution: grind the valve seat and valve plate or replace the damaged parts

Other excessive temperature

- The suction temperature can be lowered when the suction temperature is too high.

- Forced ventilation can be performed when the ambient temperature is too high.

Bad water cooling effect

The lack of or insufficient water in water-cooled machines will increase the exhaust temperature. When the cooling water flow is not smooth, the frictional heat will affect the suction and exhaust temperature in the cylinder, resulting in an abnormal increase in the exhaust temperature.

When the exhaust gas temperature rises abnormally, the following measures should be taken:

- Remove the piston, check whether the piston ring is damaged or worn, and replace it in time if there is any problem;

- Use a temperature measuring gun to check the temperature of each cylinder’s suction and exhaust valve chamber and check whether the temperature of individual valve chambers is higher than the normal temperature to identify whether the valve is faulty. If the air valve fails, the air valve should be dismantled, repaired, or replaced;

- Observe the water sight mirror on the cylinder cooling water return pipeline, or compare the temperature of the cylinder cooling water inlet and outlet to ensure that the cylinder cooling water is unimpeded.

High exhaust pressure

- The system is mixed with air and other non-condensable gases. Solution: remove the air.

- The condenser cooling water pump and fan are not turned on. Solution: Turn on the water pump and fan.

- The water volume of the condenser is insufficient, and the water temperature is too high. Solution: Increase the cooling water to clean the water pipes, valves, and filters.

- The air volume of the air-cooled condenser is insufficient, and the temperature is high. Solution: Increase the air volume to prevent short-circuit circulation or blockage of airflow

- The tube wall of the condenser is too thick. Solution: clean the condenser.

- Too much refrigerant in the system. Solution: Take out excess refrigerant

- The exhaust valve is not fully opened, and the exhaust pipe is not smooth. Solution: fully open the exhaust valve and clear the exhaust pipe.

- The liquid inlet valve of the fluid reservoir is not opened or not fully opened. Solution: open the inlet valve, open fully

- The oil separation of the device is poor. The system collects too much oil. The flow resistance of the pipeline increases and the heat exchange effect is poor. Solution: Check, adjust the oil separator, and drain the oil from the system.

Abnormal sound

If some part of the compressor fails, there will be an abnormal sound. Generally speaking, operators who have used piston gas compressors for some time can tell whether the sound is weird. There are several reasons for this failure:

- Metal blocks (such as broken pieces as valve plates or springs) falling between the cylinder head and the piston produce impact sounds. Solution: Stop in time to take out the metal block.

- The piston and cylinder mirror surfaces are damaged and stick to each other. Solution: Remove and overhaul.

- The air valve is loose. Solution: Check and tighten the air valve.

- The nut connecting the piston rod and the piston is loose, and the screw plug on the end face of the piston is damaged. Solution: Check the nut and tighten it according to the regulations.

- The piston rod and crosshead are not fastened firmly and collide with the cylinder head. Solution: After adjusting the dead-center gap at both ends, tighten the crosshead nut.

- The gap between the connecting rod’s large and small end-bearing shells is too large. Solution: Repair or replace the large and small head-bearing bushes.

- The nuts of the connecting rod bolts are loose. Solution: Lock the nut.

- The suction and exhaust valves are loose in the valve hole of the cylinder head, and the gas impacts and produces noise. Solution: Tighten the air valve.

- The bearing cover is loose. Solution: Tighten the nut on the bearing cover.

- Too much lubricating oil. Solution: Adjust the oil volume.

- The bearing bush and journal are worn, the ellipse is too large, and the gap between the crosshead and the crosshead guide rail is large. Solution: Grinding or replacement.

Temperature problems

During the reciprocating compressor’s operation, the parts’ friction will inevitably occur, followed by the rise of heat, which will easily lead to the overheating failure of the machine’s overall temperature. This overheating is a vicious circle, which will aggravate the wear problem between the various components and also cause damage to the components. If timely treatment is not carried out, the heat will continue to accumulate, and even the friction surface of the element may be directly burned by the high temperature, causing a fire accident.

For this problem, the main thing is to carry out standardized maintenance on the equipment and apply quality lubricating oil between each component. Ensure each component’s contact area and position, which can effectively reduce the overheating problem caused by harmful friction.

Conclusion

Piston gas compressors are widely used, and the vast number of uses will inevitably lead to the diversification of faults and increased occurrences. Therefore, to give full play to the role of reciprocating compressors, it is necessary to know about their common defects, causes, and solutions and carry out enough study and mastery. Besides, the regular maintenance of the equipment must be carried out by the requirements of the manual. Only in this way can the failure of the compressor be reduced, the qualification rate of the operating efficiency equipment can be significantly improved, and a reliable guarantee can be provided for enhancing productivity and production efficiency.

Email

Email sales:+86 15366749631

sales:+86 15366749631