CNG(compressed natural gas) is becoming the fuel of choice for the automotive transportation industry. CNG has a strong potential for growth as it is more efficient, less expensive, and safer than fuel. As natural gas vehicles are gaining importance, CNG refueling stations are being established. At CNG filling stations, the natural gas from the pipeline is compressed to provide high-quality and safe compressed natural gas to vehicles. This article will show you how CNG fueling stations work.

What is a CNG refueling station?

A CNG refueling station is a place that provides fuel to natural gas vehicles and large CNG sub-station vehicles. The station includes energy in the form of compressed natural gas (CNG).

Types of CNF refueling stations

Unlike gasoline or diesel stations, compressed natural gas stations are not one-size-fits-all. Making the right choice for the type of station and the amount of gas storage in the station will affect the cost of fuel and the mileage of the vehicle.

Classification by filling time

The filling times are classified as fast-fill, normal (slow) fill, and a mixture of both. The main structural differences between these two systems are the available storage capacity and the size of the compressor. These factors determine the amount of fuel to be dispensed and the CNG delivery time. Most compressed natural gas stations include one of these two system types, but “combination filling” stations include both types.

Classification by gas supply situation

CNG conventional stations, CNG parent stations, and CNG sub-stations, according to the availability of pipeline natural gas at or near the station site.

Conventional stations are built in places where natural gas pipelines can pass, and take gas directly from natural gas pipelines. Natural gas goes through processes such as desulfurization and dehydration, enters the compressor for compression, and then enters the gas vending machine to refuel vehicles.

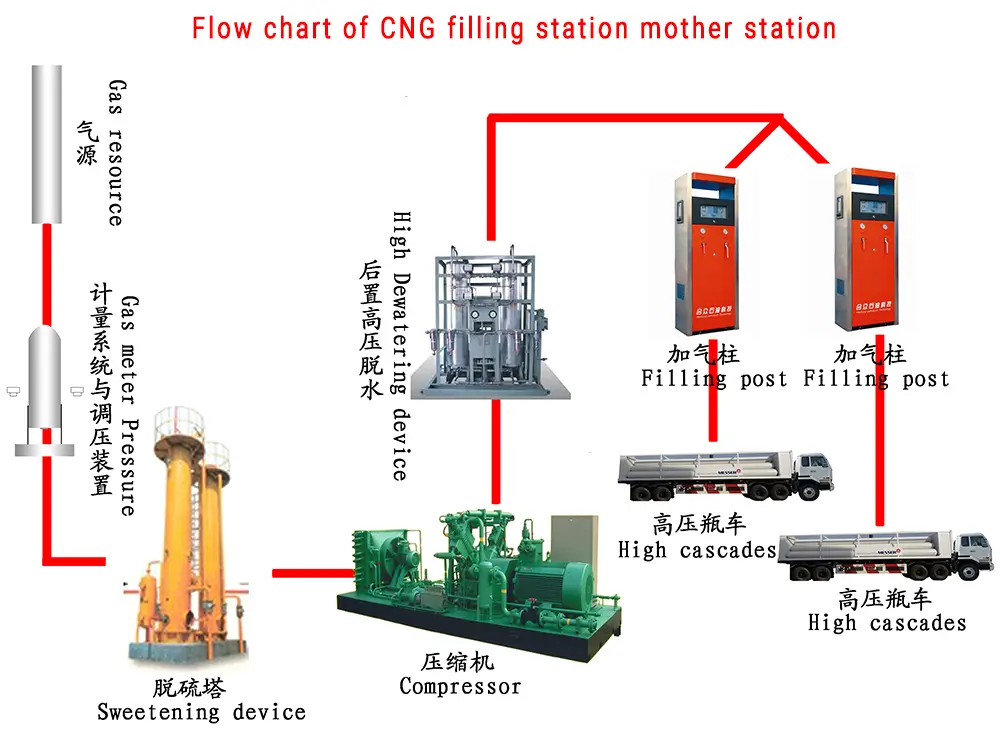

The mother station is mainly built in the place near the natural gas pipeline gate station, taking gas directly from the natural gas pipeline, through the process of desulfurization, dehydration, etc., into the compressor compression, and then transported to the sub-station through the trailer with storage cylinders to refuel vehicles, it also has the function of a conventional station.

Sub-station is built in place around the refueling station without natural gas pipeline, through the sub-station operation vehicle from the mother station to refuel natural gas vehicles, generally also need It is usually equipped with small compressors and storage cylinders.

To improve the gas collection rate of the operating vehicle, the compressor is used to pressurize the low-pressure gas in the operating vehicle and then transfer it to the storage cylinder set or directly refuel the natural gas vehicle.

Refueling process and equipment of CNG refueling station

The natural gas of the refueling station is drawn from the high-pressure or medium natural gas pipeline network. Then it enters the dryer after filtering and metering, and then enters the compressor for pressurization after being dried.

After that, it is buffered by the buffer tank, and then fills the natural gas for the storage well set through the priority/sequence control panel, or directly delivered to the refueling machine for refueling CNG-fueled vehicles. Or we can use the natural gas in the storage well set to refuel CNG-fueled vehicles through the refueling machine.

Thus, the main equipment of the CNG refueling station is.

Filter, flow meter, regulator.Dryer.

Buffer tank, compressor, recovery tank.

Sequence control panel, gas storage well, gas storage cylinder set (large and small).

Gas filling machine.

How do these types of equipment work?

Dryer

Adsorption drying is a physical process in which the adsorbent separates the water from the natural gas when the natural gas containing water passes through the adsorbent bed, thus drying the natural gas. After the adsorbent reaches saturation, the adsorbent bed is regenerated by means of high-temperature regeneration of the gas to drive the moisture out of it, thus realizing the regeneration of the adsorbent.

Compressor

The CNG compressor is the heart of the whole refueling station, which is the equipment to compress and pressurize the raw natural gas to make the pressure rise not more than 25MPA. Its performance directly affects the reliability and economy of the whole refueling station operation.

The sequence control panel

Compressed natural gas is sequentially distributed to each individual storage cylinder group (well) in the order of high, medium, and low, until the storage cylinder group (well) is full, to achieve the purpose of the compressor in the order of high, medium, and low filling.

The gas storage

Gas storage well storage is a way to store high-pressure natural gas using the mature drilling and storage technology of the petroleum system, using underground wells.

Gas filling machine

A filling machine is a filling device that fills the high-pressure natural gas from the storage unit into the vehicle’s gas cylinder. The filling machine handles controlling the sequence and flow rate of the gas selling process and ensures the safety of the gas selling process.

How to make CNG refueling station work safely?

- 1. Smoke and fire are strictly prohibited inside the station.

- 2. Vehicles entering the station must slow down and drive at a speed limit of 5KM/per hour.

- 3. Passengers must be dropped off outside the station, and no one should be carried to refuel.

- 4. When refueling, the vehicle must be turned off, all electrical devices on board must be turned off, and reliable braking measures must be taken.

- 5. It is forbidden to use communication tools in the production operation area or gas refueling area.

- 6. Prohibit drivers and non-workers from filling gas, and prohibit filling gas cylinders with safety hazards.

- 7. Inbound personnel must not wear chemical fiber clothing and shoes with iron nails near or into the explosion hazard area.

- 8. Gas filling operators should go through professional training by the company and local departments and get a CNG filling qualification certificate before they are allowed to work.

With the exploitation of natural gas resources and the increasingly serious pollution caused by traditional energy sources to the environment, natural gas vehicles will become more and more common.

Therefore, CNG filling stations will become one of our indispensable infrastructures. Understanding how CNG filling stations work will help you in your travel life.