While diaphragm compressors and piston compressors are both reciprocating compressors, they differ in their compression method and the applications for which they are best suited. Both types of compressors are used for gas compression. They take in gas at low pressure and increase it to a desired level. However, the core components of the “reciprocating motion” differ, resulting in different designs and operating conditions.

What are Reciprocating Compressors?

Reciprocating compressor is a volumetric compressor. They work by increasing the pressure of a gas by reducing its volume. They do this by using a reciprocating motion to draw gas into a cylinder or chamber and compressing it using a piston or diaphragm.

The reciprocating motion of the piston or diaphragm creates a pressure differential, which causes gas to flow into the cylinder or chamber. As the piston or diaphragm moves back and forth, the volume of the gas decreases, increasing the pressure of the gas. This compressed gas is discharged from the compressor and sent to the downstream process.

Compared to other types of compressors, such as rotary or centrifugal, they can operate over a wide range of flow rates and pressures. Still, they can be noisy and generate significant vibrations during operation. Reciprocating compressors are well-suited for applications where gas purity is critical, and high compression ratios are required, making them a widely used type of compressor in various industrial applications.

How do Diaphragm Compressors Work?

Diaphragm compressors use a flexible diaphragm to compress the gas in the chamber.” A “diaphragm” is a flexible membrane or thin wall that separates the gas being condensed from the drive mechanism. It is usually made of a flexible material, such as rubber, plastic, or metal, and is installed in a chamber sealed by inlet and outlet valves. The diaphragm divides the room into two parts, a cylinder on the side of the inlet and outlet valves and a cylinder on the side connected to the drive mechanism. When a piston connected to a motor reciprocates in the cylinder, hydraulic fluid is pushed to drive the diaphragm. The diaphragm vibrates back and forth in the chamber, changing the volume of the cylinder, and the gas is compressed and discharged through the outlet valve.

As the diaphragm moves back and forth within the compressor chamber, it draws gas into the room and compresses it. The diaphragm acts as a barrier between the gas being compressed and the drive mechanism, preventing contamination of the gas by the lubricants and other materials used in the compressor.

Diaphragm compressors are often used in applications where gas purity is critical, such as in producing semiconductors, pharmaceuticals, and other high-tech industries. They are also used in applications where the compressed gas is corrosive or toxic, as the diaphragm acts as a barrier to prevent contamination of the drive mechanism.

Furthermore, diaphragm compressors tend to operate more quietly than piston compressors due to their isolation of the gas being compressed from the drive mechanism.

However, diaphragm compressors also have some limitations. They can have a lower flow rate and compression ratio than other types of compressors, such as piston compressors. They can also be more expensive than different types of compressors, as the diaphragm is a wearing component that needs to be replaced periodically.

How do Piston Gas Compressors Work?

Piston compressors use a reciprocating piston to compress gas within a cylinder. The piston is driven by an electric motor, which provides a reciprocating motion to the piston. The cylinder is sealed with inlet and outlet valves, which control the gas flow into and out of the cylinder.

As the piston moves down, it creates a vacuum in the cylinder, which draws gas into the cylinder through the inlet valve. When the piston moves up, it compresses the gas and the pressure within the cylinder increases. As the pressure increases, the outlet valve opens, and the compressed gas is pushed out of the cylinder.

The advantages of piston compressors include their ability to handle high pressures and flow rates, their versatility with a wide range of gases, and their durability and affordability. However, they can be noisy and generate significant vibrations during operation, and they can be less efficient than other types of compressors.

Piston compressors can significantly impact the purity of gases due to the heat generated during compression and potential contamination from oil or other contaminants. Piston compressors may be designed with oil-free cylinders and filters to address these issues. It is also essential to maintain and service the compressor regularly. The impact on gas purity can also vary depending on the specific application and compressed gas. Some gases, such as oxygen or hydrogen, are more sensitive to contaminants than others, so it is essential to select the appropriate compressor for the application and take steps to ensure that the gas remains pure throughout the compression process.

To Conclude

The difference between the two types of compressors

· Working principle

Diaphragm compressors use a flexible diaphragm to compress the gas, while piston compressors use a reciprocating piston to compress the gas.

· Contamination

Diaphragm compressors can be designed to provide oil-free and contamination-free compression, while piston compressors can potentially contaminate the compressed gas with lubricants or other contaminants.

· Applications

Piston compressors are versatile and are often used in high-pressure and high-flow applications such as air compressors or refrigeration systems. On the other hand, Diaphragm compressors have cylinders that require no lubrication and are well sealed, making them suitable for a broader range of gases and often used in compression applications where high purity is required. They are also ideal for compressing corrosive or explosive gases and compressed gases that need to be oil-free or contamination-free. These include, but are not limited to, hydrogen, helium, nitrogen, oxygen, argon, carbon dioxide, methane, and other hydrocarbons. The choice of diaphragm material will depend on the compressed gas and the required gas purity.

· Maintenance

Diaphragm compressors typically require less maintenance than piston compressors because they do not have a piston that requires lubrication, and the diaphragm is not in contact with the gas being compressed. However, diaphragms will wear over time and may need to be replaced periodically.

· Cost

Diaphragm compressors are typically more expensive than piston compressors due to the complexity of the design and the use of high-quality materials. However, lower maintenance requirements and higher gas purity may offset the higher initial cost.

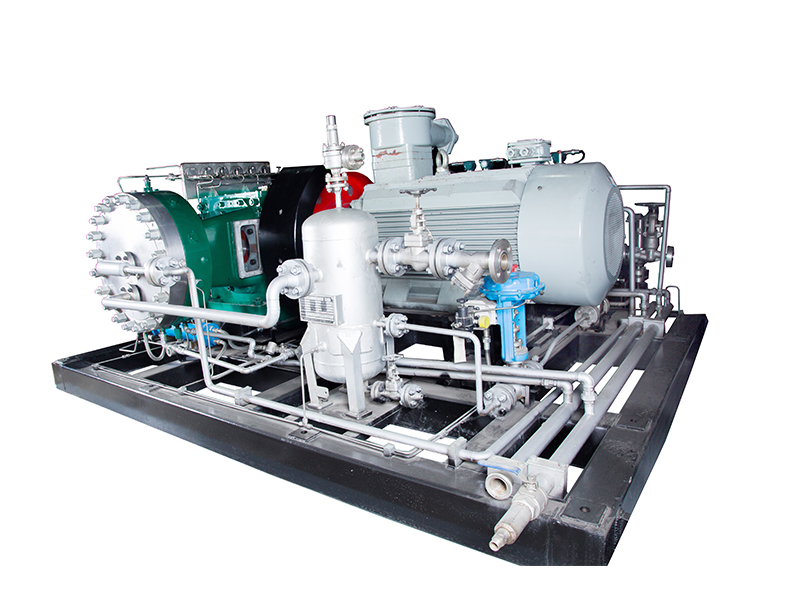

Choose Suitable Compressors for Your Industry

Several factors must be considered when selecting a gas compressor for industrial use. These factors include the gas type, pressure, flow rate requirements, level of gas purity, maintenance requirements, and cost. Our company offers a range of diaphragm and piston compressors to meet various application requirements.

Our diaphragm compressors are suitable for compressing various gases, including corrosive, explosive, and contamination-sensitive gases, providing oil-free compression. Our piston compressors are more cost-effective for high-pressure and high-flow rate applications.

Overall, choosing a suitable compressor depends on the specific application requirements. We provide high-quality compressors and excellent customer service, technical support, and on-time delivery to help companies improve their production efficiency, reduce costs, and maintain high gas quality levels.

Email

Email sales:+86 15366749631

sales:+86 15366749631