An Oil-Free Air Compressor is a specialized air compression device that eliminates the use of lubrication oil during the air compression process. This document provides a comprehensive overview of its definition, working principles, application areas, selection criteria, common misconceptions, and answers to frequently asked questions.

An oil-free air compressor is a device that compresses air without using lubricating oil. It employs special designs, such as self-lubricating materials or water-lubricated technologies, to ensure the air remains pure and avoid oil contamination. These compressors are widely used in industries such as healthcare, food, electronics, and pharmaceuticals, where air quality standards are stringent. The main advantages include zero oil contamination, low maintenance costs, environmental friendliness, energy efficiency, and high safety. The compressor operates through an optimized mechanical structure, delivering clean compressed air through cooling, separation, and storage stages.

1. Definition and Core Features

An oil-free air compressor is designed to compress air without lubricating oil. It utilizes innovative technologies such as self-lubricating materials, water-lubrication systems, or advanced coating processes to ensure compressed air purity and prevent oil mist contamination. This makes it indispensable in industries with strict air quality standards, including healthcare, food production, electronics, and pharmaceuticals.

Core Advantages:

- Zero Oil Contamination: Meets the ISO 8573-1 Class 0 standard for oil-free air, ideal for sensitive applications.

- Low Maintenance: Eliminates the need for regular oil changes, reducing maintenance frequency and costs.

- Environmental & Energy Efficiency: Minimizes oil waste and aligns with sustainability goals.

- High Safety: Reduces risks of flammable oil vapors, suitable for hazardous environments like chemicals and mining.

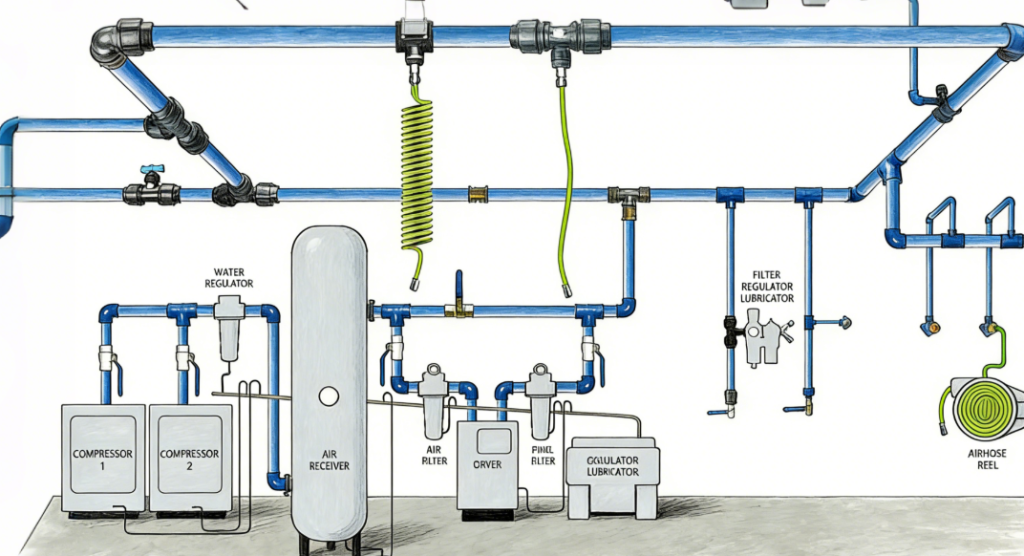

2. Working Principle

Oil-free compressors achieve contamination-free compression through a structured process:

- Intake Filtration: Air is filtered to remove dust and particles.

- Compression Methods:

- Reciprocating Piston: Motor-driven crankshaft mechanisms compress air via cylinder volume changes (common in small units).

- Screw Type: Non-contacting rotating screws use centrifugal force to compress air and separate moisture (suited for high-flow needs).

- Cooling & Separation: Hot compressed air is cooled via radiators, with separators removing moisture and impurities.

- Storage & Output: Clean air is stored in tanks, regulated, and delivered to end-users.

3. Application Areas

| Industry | Key Applications |

| Medical & Pharmaceuticals | Ventilators, anesthesia machines, sterile air for drug manufacturing. |

| Food & Beverage | Filling, packaging, and coding equipment to prevent oil contamination in food. |

| Electronics Manufacturing | Chip production, circuit board testing, and precision equipment maintenance. |

| Automotive Industry | Painting, tire inflation, and coating processes requiring dry, oil-free air. |

| Laboratories | Reliable gas sources for analytical instruments (e.g., gas chromatographs). |

4. Common Misconceptions vs. Facts

| Misconception | Fact |

| “Fully oil-free in all components.” | While the compression chamber is oil-free, other parts (e.g., gearboxes) may use oil, isolated by seals. |

| “No need for post-treatment.” | Compressed air still requires filtration (e.g., activated carbon) and drying to meet ISO standards. |

| “Higher operational costs.” | Higher upfront costs are offset by long-term savings in filters and energy efficiency. |

5. How to Choose the Right Oil-Free Air Compressor?

- Flow & Pressure Requirements: Match air consumption (e.g., 1 m³/min) and pressure (e.g., 8–10 bar).

- Industry Certifications: FDA/CE for medical use, NSF for food industry compliance.

- Energy Efficiency: Prioritize models with low “specific power” (kW/m³/min) for better efficiency.

- After-Sales Support: Choose brands with global service networks (e.g., MINNUO).

6. FAQ: Top 10 User Questions

Q1: What differentiates oil-free and oil-lubricated compressors?

A1: Oil-free compressors avoid oil in the compression chamber, ensuring clean air; oil-lubricated models require filtration to prevent contamination.

Q2: Does it need regular maintenance?

A2: Yes (filter replacements and seal checks), but no oil handling reduces complexity.

Q3: Suitable for high-humidity environments?

A3: Yes, but pair with a high-efficiency dryer to prevent pipeline corrosion.

Q4: Are they environmentally compliant?

A4: Yes—oil-free design reduces waste, and some models use energy-saving permanent magnet motors.

Q5: How to verify air quality?

A5: Test against ISO 8573-1 Class 0 standards via third-party certification.

Q6: Noise levels?

A6: Soundproof models with low-speed designs operate below 60 dB, suitable for labs.

Q7: Do you offer custom solutions?

A7: Yes—MINNUO provides tailored pressure, flow, and material options (e.g., stainless steel).

Q8: What is the lifespan?

A8: High-quality models last 10+ years with proper maintenance.

Q9: How to troubleshoot fault codes?

A9: Real-time monitoring via intelligent panels/apps, with 24/7 technical support from MINNUO.

Q10: How to optimize energy efficiency?

A10: Regular radiator cleaning, variable frequency drives (VFD), and load-based operation adjustments.

7. Conclusion

MINNUO, a global leader in oil-free air compression, offers ISO/FDA-compliant solutions across 20+ industries. Our customizable products and technical expertise drive efficient, safe, and sustainable operations.

Contact us today for free consultations and industry whitepapers!

Email

Email sales:+86 15366749631

sales:+86 15366749631