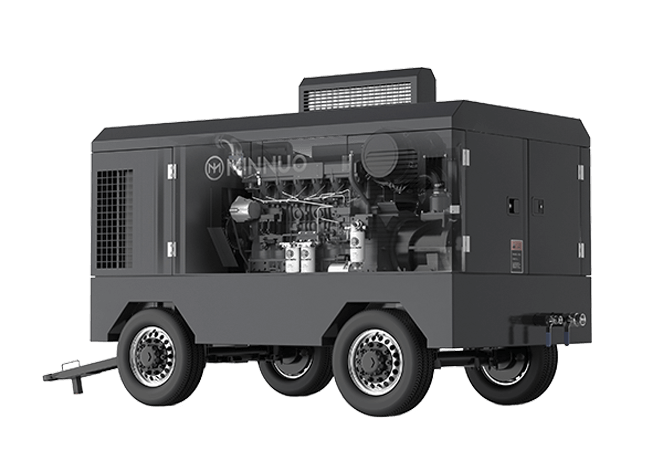

Diesel mobile air compressors are revolutionizing industries that require efficient, portable, and reliable compressed air solutions, particularly in sectors such as construction, mining, industrial applications, and agriculture. As a global leader in air compression technology, MINNUO provides advanced diesel mobile air compressors that ensure customers receive high-quality compressed air at any location and under any conditions. This article will delve into the working principles, technical specifications, industry-specific applications, and why on-site air production is the future of industrial air compression.

A diesel mobile air compressor is a portable air compression device powered by a diesel engine, widely used in construction sites, mining, oil and gas extraction, industrial equipment maintenance, and other sectors. Its working principle includes air intake and pre-treatment, compression, and storage. Through on-site air production, diesel mobile air compressors can provide reliable air supply at any site, significantly improving construction efficiency and reducing operational costs.

1. Working Principles of Diesel Mobile Air Compressors

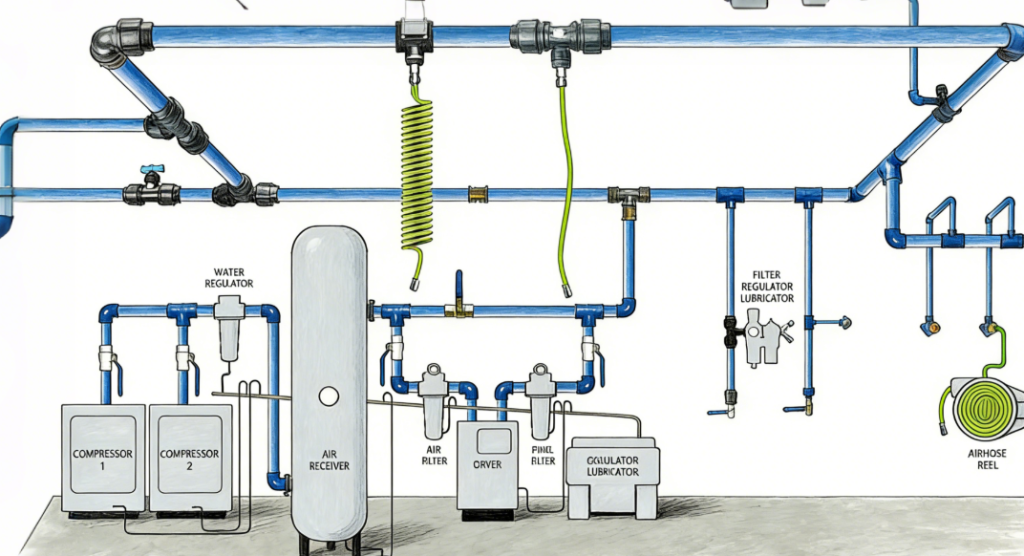

The working process of a diesel mobile air compressor mainly involves the following steps:

- Air Intake and Pre-treatment:The diesel mobile air compressor draws in air from the environment through high-efficiency air filters. The air is then filtered in multiple stages to remove dust, impurities, and moisture, ensuring that only clean air enters the compression system. After the air is filtered, it moves to the compression stage, ensuring long-term stable operation of the compressor.

- Air Compression:Once the air enters the main compression unit, it undergoes multi-stage compression, gradually increasing in pressure. This process significantly raises both the pressure and temperature of the air to the required working pressure. MINNUO’s diesel mobile air compressors use advanced screw compression technology, which offers higher energy efficiency and stability, ensuring a continuous and reliable air supply under various environmental conditions.

- Storage and Output:Compressed air is stored in a storage tank, ensuring that the air supply system can provide a sufficient amount of air in an instant. With a precise regulation system, the diesel mobile air compressor can output high-quality compressed air according to actual needs, meeting the requirements of different equipment.

2. Types of Diesel Mobile Air Compressors

| Type | Pressure Range | Flow Rate | Best Application Areas |

| Fixed Type | 7–15 bar | 10–30 m³/h | Small and medium construction, mining |

| High Pressure | 15–40 bar | 30–60 m³/h | Oil and gas extraction, deep sea construction |

| Ultra High Pressure | 40–100 bar | 60–120 m³/h | Special industrial tasks, deep well work |

3. Industry-Specific Applications

- Construction Industry:In the construction industry, diesel mobile air compressors provide a convenient air supply solution. They can supply sufficient compressed air for drilling, demolition, grinding, and other tasks, ensuring construction progress and efficiency. Due to their high durability, these compressors can operate reliably even in harsh environments, meeting the high-demand needs of construction sites.

- Mining Industry:Diesel mobile air compressors are widely used in mining, particularly for drilling, dewatering, and rock crushing operations, providing a reliable air source. MINNUO’s diesel air compressors offer the required air volume and stable pressure to ensure the smooth operation of equipment in mines.

- Oil and Gas Industry:The oil and gas extraction industry requires strong and reliable air compression systems to drive drilling equipment and improve operational efficiency and safety. Diesel mobile air compressors, with their excellent output pressure and flow rate, have become indispensable tools in this industry.

- Industrial Equipment Maintenance:In industrial equipment maintenance, diesel mobile air compressors also play a crucial role. They provide continuous compressed air for cleaning, disassembling, and repairing tasks, ensuring that maintenance work is completed smoothly. Their high flow rate makes them particularly suitable for maintenance projects that require large amounts of air.

4. Key Advantages of Diesel Mobile Air Compressors

- Cost-effectiveness:Diesel mobile air compressors change the traditional way of obtaining compressed air by enabling on-site production. This method eliminates the high costs associated with air transportation and storage. With on-demand production, these compressors can significantly reduce energy waste, providing businesses with substantial cost savings.

- High Efficiency:MINNUO’s diesel mobile air compressors utilize advanced screw compression technology that offers high compression efficiency and low fuel consumption. These compressors operate efficiently in various environments, ensuring continuous and reliable performance.

- Flexibility and Convenience:Diesel mobile air compressors are compact, durable, and suitable for various work sites. They are highly flexible and can be quickly moved to any required location, providing on-site support for operations.

- High Durability:Diesel mobile air compressors are designed to withstand harsh work environments such as high temperatures, humidity, and dust. MINNUO compressors are built with durability in mind, ensuring high performance even in challenging conditions.

5. Technical Specifications: Choosing the Right Diesel Mobile Air Compressor

Pressure Requirements

- Low to Medium Pressure: Suitable for general construction, maintenance, and regular industrial applications

- High Pressure: Suitable for deep well work, mining, and oil and gas extraction

- Ultra High Pressure: Suitable for specialized tasks such as deep-sea operations

Flow Rate Requirements

- Small Sites: 10–30 m³/h

- Medium Sites: 30–60 m³/h

- Large Sites: 60 m³/h and above

Fuel Consumption

- Low to Medium Pressure: 5–10 L/h

- High Pressure: 10–20 L/h

- Ultra High Pressure: 20 L/h and above

Space Requirements

MINNUO provides diesel mobile air compressors in various sizes, including compact models and larger units, to meet different space constraints at work sites.

6. Installation and Maintenance

Site Preparation

Before installing a diesel mobile air compressor, the work site should be stable, with good ventilation and cooling conditions. A dedicated power source (industrial model 380–480V) should be available to ensure a stable power supply for the equipment.

Daily Maintenance

- Daily: Check oil levels, air filters, and cooling systems to ensure smooth operation. Clean the air intake to maintain proper air flow.

- Monthly: Check pressure gauges and flow meters to ensure accurate measurements. Inspect the diesel engine to ensure its efficient operation.

- Annually: Replace air filters, oil filters, and other worn parts to maintain optimal performance.

7. Frequently Asked Questions (FAQs)

Q1: How do I choose the right diesel mobile air compressor for my construction site?

A: Depending on the project scale, required pressure, and flow rate, MINNUO offers a variety of models to suit different application scenarios.

Q2: Are MINNUO’s diesel mobile air compressors suitable for harsh environments?

A: Yes, MINNUO’s diesel mobile air compressors are designed to perform well in high temperatures, humidity, and dusty environments, ensuring reliable operation.

Q3: Is maintaining a diesel mobile air compressor difficult?

A: Daily maintenance is relatively simple, mainly focusing on air filters, oil levels, and cooling systems.

Q4: Are diesel mobile air compressors environmentally friendly?

A: MINNUO’s diesel air compressors are designed with low fuel consumption and low emissions, reducing environmental impact.

8. Case Study: Real-world Application of MINNUO Compressors

- Client: A construction company in the Middle East

- Challenge: High compressed air transportation costs (USD 12,000 per month) and unstable supply

- Solution: Installation of a MINNUO high-pressure diesel mobile air compressor (flow rate: 50 m³/h, pressure: 15 bar)

- Results: Saved USD 8,500 per month in operational costs.• Increased work efficiency by 30%, ensuring timely completion of the project.

9. The Future Trends of Diesel Mobile Air Compressors

- Energy Efficiency and Environmental Friendliness:As energy efficiency standards improve, diesel mobile air compressors will further develop in the direction of lower fuel consumption and emissions, minimizing environmental impact.

- Smart Features:MINNUO plans to introduce more smart technologies, including remote monitoring, data analytics, and predictive maintenance, to improve the efficiency and reliability of compressor management.

- Miniaturization:Portable diesel mobile air compressors will continue to be upgraded, with applications expanding to small construction sites and emergency operations, providing reliable air supply for urgent medical rescue and special environmental tasks.

10. MINNUO’s Advantages

- Precision Engineering: ±0.1 bar pressure control ensures stability.

- Global Support Network: 24/7 technical support in 12 languages.

- Custom Solutions: Diesel mobile air compressors tailored to unique industry needs.

11. Conclusion

Diesel mobile air compressors will continue to drive industry advancements. MINNUO is committed to technological innovation, providing more efficient, environmentally friendly, and smart air compression solutions for customers worldwide. By choosing MINNUO, you’re not just selecting a diesel mobile air compressor; you’re partnering with a technology leader, helping your business stay competitive in the global market.

Email

Email sales:+86 15366749631

sales:+86 15366749631