In the compressor industry, PSI (Pounds per Square Inch), PSIA (Pounds per Square Inch Absolute), and PSIG (Pounds per Square Inch Gauge) are common pressure units used widely in gas compression, refrigeration, and heating systems. Understanding the differences and applications of these units is crucial for evaluating compressor performance, ensuring system safety, and maintaining stability. This article explores the definitions, calculation methods, and roles of PSI, PSIA, and PSIG in compressor operations.

PSI, PSIA, and PSIG are essential pressure units. PSI measures the pressure magnitude of a system, PSIA indicates the pressure relative to absolute vacuum and is suitable for high-precision applications, while PSIG measures pressure relative to atmospheric pressure, commonly used in industrial equipment. PSIA includes atmospheric pressure, whereas PSIG only accounts for relative pressure. (PSIA = PSIG + 1 ATM, PSIG = PSIA – 1 ATM).

Definitions and Significance of PSI, PSIA, and PSIG

Basic Definition of PSI

PSI (Pounds per Square Inch) is a unit of pressure in the imperial system, representing the pressure exerted on one square inch of area. 1 PSI equals 6.895 kPa. PSI is widely used in Western countries, and in daily life, it is commonly used to measure the air pressure in car tires, typically ranging from 30-35 PSI.

Absolute Pressure (PSIA)

PSIA (Pounds per Square Inch Absolute) is a unit of pressure relative to absolute vacuum, with absolute vacuum as the zero point. PSIA accurately reflects the true pressure state of a system, eliminating the influence of atmospheric pressure fluctuations. PSIA is particularly important in aerospace and high-precision applications. For example, spacecraft pressure monitoring uses PSIA to maintain a stable life-support environment.

Gauge Pressure (PSIG)

PSIG (Pounds per Square Inch Gauge) measures the pressure difference between the system and the local atmospheric pressure. In industrial applications, PSIG reflects the pressure in pipes or equipment relative to atmospheric pressure. For instance, a pressure gauge on a chemical pipeline typically indicates the pressure above atmospheric pressure in PSIG.

The Role of PSI, PSIA, and PSIG in Compressor Operations

Pressure Behavior During the Intake Process

In the intake process of a compressor, PSIA accurately reflects the actual pressure of the gas entering the compressor. Since PSIA is not affected by external atmospheric pressure variations, it provides real pressure data, ensuring the compressor operates under stable conditions. For example, in aircraft engines, PSIA measures the intake pressure under varying altitudes and weather conditions to ensure stable engine operation.

Pressure Influence During the Compression Process

During the compression process, both PSI and PSIA provide valuable information. PSIA monitors the absolute pressure of the compressed gas to ensure the compressor operates within the optimal pressure range. PSIG is used to assess the pressure differential between the compressed gas and atmospheric pressure, assisting operators in adjusting equipment settings and preventing overpressure that could damage the system.

Pressure Analysis During the Exhaust Process

During the exhaust phase of the compressor, both PSIA and PSIG play vital roles. PSIA is used to measure the absolute exhaust pressure, ensuring the compressor discharges gas within the designated pressure range. PSIG helps monitor the pressure difference between the gas and atmospheric pressure, ensuring the system operates within a safe range and preventing malfunctions caused by excessive or insufficient exhaust.

Calculation Methods for PSI, PSIA, and PSIG

Relationship Between PSI, PSIA, and PSIG

Although PSI, PSIA, and PSIG are all units used to describe pressure, they have distinct differences. The most important distinction is whether atmospheric pressure is considered. The relationship between PSIA and PSIG can be expressed by the following formulas:

- PSIA = PSIG + 1 ATM

- PSIG = PSIA – 1 ATM

Where 1 ATM represents atmospheric pressure, approximately 14.7 PSI. Therefore, PSIA is always 14.7 PSI higher than PSIG because PSIA includes atmospheric pressure, while PSIG only reflects the relative pressure of the system.

Example Application

Assume that at sea level, the pressure measured in a compressed air system is 30 PSIA. This means the system’s pressure is 30 PSI plus atmospheric pressure (14.7 PSI). If measured in PSIG, the system’s pressure would be:

- 30 PSIA – 14.7 PSI = 15.3 PSIG

Thus, the gauge pressure of this compressor in this environment is 15.3 PSIG.

Common Pressure Unit Conversions

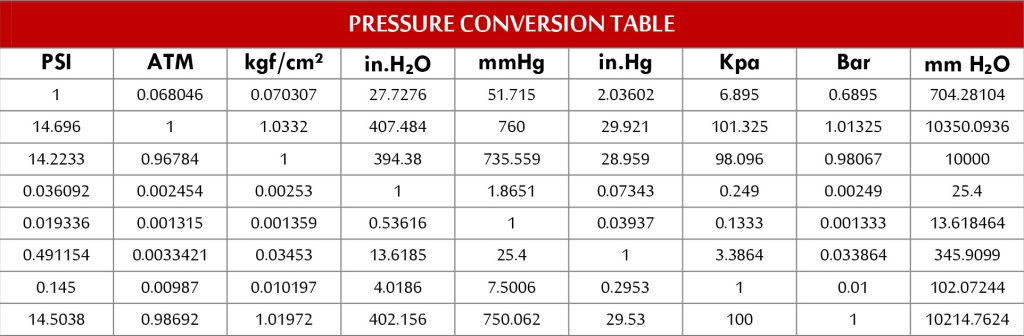

Here is a commonly used pressure conversion table, and the instructions for using it are as follows:

- Locate the column for the unit you wish to convert and move down the column until you find the number “1.”

- In the same row, move horizontally to find the conversion factor for the desired ratio.

- Multiply the conversion factor (the number in the box) by the quantity you want to convert to obtain the pressure.

Conclusion

PSI, PSIA, and PSIG are used to describe different pressure states, and understanding the differences between them is crucial for compressor optimization and safety. Through precise pressure measurements, engineers and technicians can ensure that compressor systems operate efficiently and safely.

For more professional information, feel free to consult MINNUO!

Email

Email sales:+86 15366749631

sales:+86 15366749631