Compressors are essential power sources in nearly every modern industry, including industrial production, food processing, medical equipment, and building HVAC. By compressing gases (such as air, nitrogen, and refrigerants), increasing their pressure or density, they provide a stable power source for various processes. Whether it’s driving pneumatic tools in automotive manufacturing, vacuum packaging for food preservation, or oxygen supply systems in hospitals, efficient compressor operation is essential.

However, faced with the wide variety of compressors on the market (from small household to large industrial-grade), many buyers, technicians, and even industry practitioners are easily overwhelmed by the dilemma of “choice difficulties”: What are the differences between different types of compressors? What scenarios are suitable for their working principles? How can I choose the most cost-effective equipment based on my needs? As a professional manufacturer with 38 years of experience in the compressor field, Jiangsu Minnuo Group Co., Ltd., we rely on our mature R&D system, intelligent production base, and full-chain service network to provide customers in more than 50 countries and regions around the world with a variety of compressor solutions, including screw, piston, and scroll types. This article will combine our production experience with industry insights to comprehensively disassemble the core knowledge of compressors from five dimensions: type classification, working principle, industry application, purchasing guide, and maintenance techniques. It can be called the ultimate manual “from entry to mastery”.

Compressor core types: classification, characteristics and applicable scenarios

Compressors can be categorized in various ways. Based on their operating principle, they can be divided into two main groups: positive displacement compressors and dynamic compressors . Each of these groups includes several sub-types. Different compressor types vary significantly in pressure range, flow output, energy efficiency, and applicable media. Choosing a compressor requires careful consideration of specific operating requirements.

1. Positive displacement compressor: compression is achieved by reducing the volume of gas

The core principle of positive displacement compressors is “physical compression”—they use mechanical structures (such as pistons, rotors, and scrolls) to change the volume within a cylinder or chamber, forcibly compressing the gas and increasing the pressure. This type of compressor is suitable for low- to medium-pressure (some can reach high pressure) and small to medium flow rates, and has the widest range of applications.

Reciprocating piston compressor : The piston reciprocates in the cylinder, completing the cycle through three stages: suction, compression, and exhaust.

Pressure range: 0.3-35MPa (high pressure possible) ; flow range: 0.1-100m³/min ,

Advantages: simple structure, low cost, flexible pressure adjustment, and adaptability to a variety of gases (air, oxygen, nitrogen, etc.)

Disadvantages : large vibration, high noise (usually 75-90dB), many wearing parts (piston rings, valves), and frequent maintenance

Typical application scenarios: small factory pneumatic tools, auto repair shop air pumping equipment, laboratory high-pressure gas preparation

Screw compressor : A pair of intermeshing male and female rotors rotate at high speed, and the volume between the teeth gradually decreases to achieve compression

Pressure range: 0.7-1.6MPa (conventional); up to 4.0MPa (two-stage compression) ; flow range: 1.0-1000m³/min Advantages: compact structure, stable operation (low vibration), long continuous operation life (main engine design life 20,000-40,000 hours), high energy efficiency

Disadvantages: high manufacturing cost, low cost performance for small models, not suitable for ultra-high voltage scenarios

Typical application scenarios: industrial production lines (such as electronic component assembly), central air conditioning in large buildings, and air supply for food processing workshops

Scroll compressor : The orbiting scroll rotates eccentrically around the stationary scroll, forming a shrinking closed chamber to compress the gas.

Pressure range: 0.3-2.0MPa ; Flow range: 0.1-50m³/min

Advantages: no reciprocating motion, extremely low noise (usually 55-70dB), small size, high energy efficiency ratio (COP), few wearing parts Disadvantages: difficult to maintain (scroll disc requires high precision), not suitable for gases containing impurities (easy to get stuck)

Typical application scenarios: household air conditioners, commercial cold chain equipment, medical equipment (such as dental chairs), food preservation (oil-free)

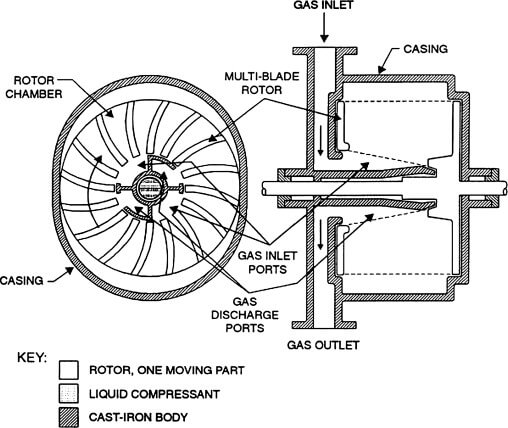

Vane compressor : The vanes on the rotor cling to the inner wall of the cylinder under the action of centrifugal force, forming a chamber with variable volume

Pressure range: 0.7-1.2MPa ; Flow range: 0.5-30m³/min

Advantages: simple structure, easy maintenance, strong ability to adapt to changing working conditions

Disadvantages: The sliding blade wears quickly (lifespan is about 2000-5000 hours), and the energy efficiency drops significantly in long-term operation.

Typical application scenarios: small pneumatic equipment (such as paint spray guns), mobile air compressors, short-term temporary gas use scenarios

2. Dynamic compressor: converts gas velocity into pressure

Dynamic compressors (also known as speed compressors) rely on high-speed rotating impellers or blades to transfer mechanical energy to the gas, giving the gas kinetic energy. This energy is then converted into pressure energy through a diffuser. This type of compressor is suitable for high-flow, medium- and low-pressure applications and is particularly widely used in large-scale industrial projects.

Centrifugal compressor : Multi-stage impellers rotate at high speed (usually 10,000-30,000 rpm), repeatedly accelerating the gas and increasing the pressure through the diffuser

Pressure range: 0.3-4.0MPa ; Flow range: 50-10000m³/min

Advantages: large flow, no wearing parts (simple structure), stable operation (almost no vibration), suitable for continuous large-scale gas use Disadvantages: poor adaptability to variable working conditions (easy to “surge” when flow rate is lower than the design value), large starting current, and high initial investment

Typical application scenarios: large chemical plants (such as synthetic ammonia production), thermal power plants (boiler blast), natural gas pipelines

Axial flow compressor : The blades push the gas to flow axially, and the pressure is gradually increased through multiple stages of blades.

Pressure range: 0.15-0.8MPa ; flow range: 100-20000m³/min

Advantages: large flow, small pressure loss, small footprint

Disadvantages: weak pressure raising capability (only applicable to low pressure) and extremely high manufacturing precision requirements

Typical application scenarios: large-scale wind tunnel experiments, metallurgical industry (blast furnace blast), aircraft engine compressors

How a compressor works: Understanding how gas is pressurized in one article

Regardless of the type, the core task of a compressor is to convert low-pressure gas into high-pressure gas, but the implementation methods vary greatly among different types. The following explains the working principles of mainstream compressors through a simple explanation and core steps:

1. Working Principle of Positive Displacement Compressor (Taking the Most Widely Used Screw Compressor as an Example)

Screw compressors (especially two-stage screws) are the “workhorse” of the industrial field. Their working principle can be summarized as “rotor engagement → volume reduction → gas pressurization”:

1. Inhalation stage: The yin and yang rotors rotate in opposite directions driven by the motor. When the rotor slots are connected to the suction port, gas (such as air) enters the slots under the action of pressure difference, completing the suction;

2. Compression stage: As the rotor continues to rotate, the tooth slots are gradually closed and the volume continues to shrink (because the rotor teeth are spiral, the tooth slot space is squeezed when meshing). The gas is forcibly compressed, and the pressure and temperature gradually increase;

3. Exhaust stage: When the tooth groove rotates to connect with the exhaust port, the gas compressed to the set pressure is discharged from the exhaust port and enters the subsequent cooling and filtration system (such as dryer, precision filter), and finally outputs clean high-pressure gas.

Note: Two-stage screw compressors add an “intermediate cooling” link based on the above – after the gas is compressed in the first stage, it is first cooled by the cooler before entering the second stage of compression. This can reduce energy consumption (saving 15%-20% energy compared to a single stage) and reduce the exhaust temperature (avoiding the impact of high temperature on equipment and processes).

2. Working principle of dynamic compressor (taking centrifugal type as an example)

Centrifugal compressors rely on “speed conversion” , and the core steps are divided into “acceleration → expansion → supercharging”:

1. Acceleration stage: The motor drives the impeller to rotate at high speed (speed can reach over 20,000 rpm). The blades on the impeller generate centrifugal force on the gas, pushing the gas out of the impeller at an extremely high speed (up to hundreds of meters per second);

2. Diffusion stage: High-speed gas enters the diffuser (a channel with a gradually expanding cross-sectional area). As the space becomes larger, the gas flow rate decreases. According to the “Bernoulli principle”, kinetic energy is converted into pressure energy, and the gas pressure initially increases;

3. Multi-stage boosting: The boosting capacity of a single-stage impeller is limited (usually only 0.1-0.3MPa), so centrifugal compressors often use “multi-stage series” – the gas that has been expanded by the first stage enters the next stage impeller for further acceleration and expansion, and after repeated multiple times, it reaches the target pressure and is finally output from the exhaust port.

Compressor Industry Application: From Industry to People’s Livelihood, Covering All Scenario Needs

Compressors are used in almost all industries, and the core requirements of different industries vary significantly, which directly determines the choice of compressor type. The following are the specific requirements and adaptation solutions for several core application areas:

1. Manufacturing: Pursuing “stability, efficiency, and low cost”

Core requirements: Provide a continuous air source for pneumatic tools (such as wrenches, spray guns, and manipulators) and assembly line conveying systems, requiring stable pressure (0.7-1.0 MPa), sufficient flow, and low energy consumption for long-term operation;

Suitable for medium and large screw compressors (single or two-stage). If the factory’s gas consumption fluctuates greatly, it can be equipped with a frequency conversion system (which automatically adjusts the speed according to gas consumption, saving 20%-30%).

Case: An automotive parts factory uses a two-stage variable frequency screw compressor, which can not only meet the high-pressure gas demand of the welding workshop, but also adapt to the intermittent gas use of the assembly line through frequency conversion, saving more than 100,000 yuan in electricity costs annually.

2. Food and pharmaceutical industry: Emphasis on “sterile, oil-free, and compliant”

Core requirements: Compressed gas directly or indirectly contacts food/pharmaceuticals (e.g., bread proofing, freeze-drying of medicines), must be free of oil and impurity contamination, and must comply with FDA, EU GMP, and 3A hygiene standards;

Applicable types: Oil-free scroll compressors (small scenarios, such as laboratories) and oil-free screw compressors (large workshops). Parts in contact with gas must be made of 316L stainless steel and support CIP (cleaning in place) and SIP (sterilization in place).

Key requirement: Compressed air must meet ISO 8573-1:2010 Class 1 standard (oil content ≤ 0.001 mg/m³, solid particles ≤ 0.1 μm) to avoid affecting product quality.

3. Petrochemical industry: Focus on “high pressure, explosion-proof, and corrosion-resistant”

Core requirements: Providing high-pressure gas for chemical reactors, pipeline transportation, and oil and gas extraction (such as nitrogen for pipeline purging and hydrogen for synthesis reactions), and the presence of flammable and explosive gases (such as methane and ethane) on site requires explosion-proof design;

Applicable types: high-pressure reciprocating piston compressors (pressure can reach 35MPa, suitable for small flow and high-pressure scenarios), multi-stage centrifugal compressors (large flow and medium-pressure scenarios, such as natural gas transmission);

Safety standards: The equipment must comply with ATEX explosion-proof certification (EU) or UL certification (USA), and components such as motors and controllers must adopt explosion-proof structures to avoid dangers caused by sparks.

4. Building and HVAC: Focus on “energy saving, quietness, and miniaturization”

Core requirements: Refrigerant compression in central air-conditioning systems (such as chillers) and air delivery in building ventilation systems, requiring equipment to be small and low noise (to avoid disturbing residents);

Compatible types: scroll compressor (household/commercial air conditioner, noise level 55-65dB), screw compressor (large central air conditioner, noise level 70-80dB, requires a soundproof cover);

The key to energy saving: Choose a variable frequency model, which automatically adjusts the compressor speed according to the indoor temperature, saving 30%-40% energy compared to a fixed frequency model.

5. Medical industry: requires “precision, sterility, and high reliability”

Core requirements: Hospital oxygen supply systems (compressed oxygen), dental chair pneumatic tools, and surgical instrument sterilization equipment (compressed steam) require precise pressure (error ≤ ±0.02MPa), absolute sterility of the gas, and the equipment cannot be shut down (otherwise it will affect diagnosis and treatment);

Applicable types: oil-free piston compressor (small dental clinics), oil-free screw compressor (large hospitals, requiring spare units);

Reliability design: The equipment must have “dual-path cooling” and “automatic fault switching” functions, and the core components (such as motors and main units) must have a warranty period of no less than 5 years to ensure long-term stable operation.

Compressor Buying Guide: 4 Steps to Choose the Best Equipment for You

When purchasing a compressor, blindly pursuing “high configuration” or “low price” will lead to soaring costs in the future. The following four core steps will help you accurately match your needs:

1. Clarify core parameters: pressure, flow, and medium

Exhaust pressure: Determined according to process requirements, a 10%-20% margin should be reserved (to avoid insufficient pressure due to operating condition fluctuations). For example, if a pneumatic tool requires 0.7MPa, a model with a rated pressure of 0.8-1.0MPa should be selected;

Exhaust flow rate: Calculated based on “maximum air consumption + simultaneous usage rate” using the formula: Actual required flow rate = Sum of the maximum air consumption of each device × simultaneous usage rate (usually 0.6-0.8). For example, if three pneumatic tools each require 2 m³/min and the simultaneous usage rate is 0.7, the required flow rate = 3 × 2 × 0.7 = 4.2 m³/min. A model with a rated flow rate of 5 m³/min should be selected.

Medium characteristics: If the compressed gas is flammable and explosive gas such as oxygen and hydrogen, you need to choose an explosion-proof model; if the gas comes into contact with food or medicine, you need to choose an oil-free model; if the gas contains dust or water vapor, you need to equip it with an additional pre-treatment system (such as a filter or dryer).

2. Weighing energy consumption and costs: short-term investment vs. long-term operation

Energy efficiency level: Give priority to Class 1 energy efficiency models (such as those that comply with the EU ECODESIGN directive and China’s GB 19153-2021 standard). Although the initial price is 10%-15% higher, it can save 30%-50% in electricity costs over the long term (calculated based on a 10-year lifespan);

Variable frequency vs. fixed frequency: If gas demand fluctuates greatly (e.g., full load during the day, low load at night), choose a variable frequency model; if gas demand is stable (e.g., 24-hour continuous production), a fixed frequency model is more cost-effective.

Waste heat recovery: For industrial scenarios (such as factories requiring heating and hot water), you can choose models with waste heat recovery function to recycle the heat generated during the compression process (accounting for about 80% of the total energy consumption) and further reduce overall costs.

3. Focus on compliance and adaptation: industry standards + site conditions

Industry certification: The food and pharmaceutical industries require FDA and 3A certification; exports to Europe require CE certification; explosion-proof scenarios require ATEX certification; the medical industry requires ISO 13485 certification;

Installation conditions: Check the workshop voltage (e.g., 380V/50Hz in Europe, 460V/60Hz in the United States), space size (screw-type requires 1.5m of maintenance space), and cooling method (air cooling requires good ventilation, water cooling requires a circulating water system).

Environmental requirements: The EU region must comply with the RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electronic Equipment) directives. Noise-sensitive areas (such as hospitals and residential areas) should select models with a noise level of ≤70dB.

4. Evaluate after-sales service: Avoid the situation of “affordable to buy, but unable to repair”

Warranty period: The warranty period for core components (host, motor, controller) is at least 3 years, and the warranty period for the whole machine is more than 2 years;

Localized service: Give priority to brands with local service centers, ensuring on-site service within 48 hours after a failure (24-hour emergency service is recommended for industrial scenarios);

Spare parts supply: Confirm local inventory of commonly used spare parts (such as filters, seals, and lubricants) to avoid downtime caused by spare parts shortages (ideal spare parts supply cycle ≤ 7 days).

Compressor maintenance tips: extend life and reduce failure rate

The life and operating efficiency of a compressor depend largely on routine maintenance. The following five key maintenance points can extend the life of the equipment by 5-10 years:

1. Regularly check core components

Pressure and temperature: Check the exhaust pressure (error ≤ ± 0.05MPa) and exhaust temperature (screw type ≤ 100℃, piston type ≤ 120℃) every week. If they exceed the range, stop the machine and conduct an investigation immediately.

Oil level and oil quality: For oil-free models, check the seal status. For oil-based models, check the oil level weekly (check after 10 minutes of downtime, the oil level should be between 1/2 and 2/3 of the oil mark). Replace the lubricating oil every 3-6 months (based on operating hours, usually 2000-4000 hours).

Filter: Clean the air filter (washable filter element) every 1-2 months, and replace the precision filter element every 6-12 months (according to the pressure differential gauge, it needs to be replaced if the pressure differential exceeds 0.1MPa).

2. Maintain the cooling system

Air-cooled models: Clean the cooling fan and radiator monthly (use compressed air to remove dust and avoid blockage), and ensure that the ambient temperature is ≤ 40°C.

Water-cooled models: Check the cooling water quality every 3 months (to avoid scaling), clean the cooler every 6 months (using citric acid solution for circulating flushing), and maintain the cooling water pressure at 0.2-0.3MPa.

3. Keep the equipment clean and dry

Clean the equipment surface every day (especially in the food and pharmaceutical industries, use food-grade detergents) to avoid accumulation of dust and oil;

Regularly check whether there is water accumulation inside the equipment (such as gas tanks and pipes), and open the drain valve every week to drain the condensed water (it is recommended to install an automatic drain in humid areas).

4. Pay attention to abnormal operation signals

Noise and vibration: If abnormal noise (such as metal friction sound) or increased vibration (amplitude exceeds 0.1mm) occurs, stop the machine immediately for inspection (it may be due to bearing wear, rotor imbalance, etc.);

Pressure fluctuation: If the exhaust pressure fluctuates, it may be due to a faulty intake valve or a clogged filter, which requires prompt repair.

Increased energy consumption: If the electricity bill increases by more than 10% under the same operating conditions, it may be due to wear of the main unit or decreased motor efficiency. You need to contact the manufacturer for performance testing.

5. Create a maintenance schedule

Develop a “daily inspection, weekly inspection, monthly inspection, and annual inspection” schedule based on the equipment model and frequency of use, clearly identify responsible individuals, and record maintenance details (such as replacement spare part models, pressure and temperature data) to facilitate problem tracing and provide a basis for equipment upgrades or replacements.

Conclusion: Choosing a compressor is choosing the “foundation of efficient production”

From home air conditioners to large chemical plants, compressors play the crucial role of “powering the heart” of everything. Whether in the manufacturing industry, which strives for extreme energy efficiency, or in the food and pharmaceutical industry, which adheres to strict sterility standards, only compressors precisely matched to their “type, parameters, and compliance requirements” can truly reduce costs and improve efficiency.

We hope this guide can help you overcome selection confusion. If you still have questions about specific scenarios (such as “How to select an oil-free compressor for a food processing plant” or “How to avoid surge in a centrifugal compressor”), feel free to contact Jiangsu Minnuo Group Co., Ltd. for customized solutions. Remember: a good compressor is not just “equipment” but also a “long-term partner.”

Email

Email sales:+86 15366749631

sales:+86 15366749631