In the grand landscape of modern industry, there exist some inconspicuous yet crucial foundational equipment. These components operate silently at the core of factories, akin to the heart of a precise circulatory system, delivering indispensable “lifeblood” – namely, high-purity, ultra-pure, and even specially hazardous industrial gases – to critical processes. This domain demands near-absolute standards of reliability, safety, and purity, where traditional fluid transfer equipment often falls short. In this context, a device based on the ingenious principle of physical isolation – the diaphragm compressor – has emerged as the unsung champion ensuring the smooth operation of numerous cutting-edge industries.

This article delves into the core technical principles of diaphragm compressors, their irreplaceable role in various industrial scenarios, and highlights the profound expertise, technological breakthroughs, and exemplary practices of a leading enterprise in this specialized field.

I. Uncompromising Purity: The Design Philosophy and Technical Core of Diaphragm Compressors

To comprehend the significance of diaphragm compressors, one must first confront three core challenges in high-end industrial gas applications: purity, safety, and stability.

1.1 Limitations and Ceilings of Traditional Compression Technologies

Prior to the widespread adoption of diaphragm compressors, piston-type and screw-type positive displacement compressors dominated the market. Their working principles inherently prevent complete physical separation between the lubrication system and compression chamber. Even with oil-free lubrication designs, micron-level wear particles can still be generated at the piston ring-cylinder interface, and long-term reliability remains challenging. For gases requiring purity levels of 99.999% (5N) or higher, any trace of hydrocarbons, particulates, or moisture introduction can be catastrophic. In semiconductor manufacturing, this directly impacts chip yield rates; in the pharmaceutical sector, it could lead to contamination and rejection of entire batches.

Moreover, for special gases such as hydrogen, oxygen (especially under high pressure where contact with oil may cause explosions), chlorine, and hydrogen chloride – which are flammable, explosive, strongly oxidizing, or highly corrosive – the dynamic sealing structures of traditional compressors remain potential leakage points, posing serious safety and environmental hazards.

1.2 The Wisdom of Physical Isolation: Core Working Principles of Diaphragm Compressors

The design philosophy of diaphragm compressors elegantly addresses all these challenges through an exceptionally simple yet efficient approach. The core concept is to achieve absolute physical isolation between the compressed gas and hydraulic drive system via a flexible yet robust metal diaphragm.

This system can be simplified into three core chambers and one critical component:

- Gas Chamber: The space directly contacting and compressing the process gas, with specially treated inner walls that are extremely smooth and exhibit minimal surface activity.

- Oil Chamber: Filled with hydraulic oil, powered by a piston pump.

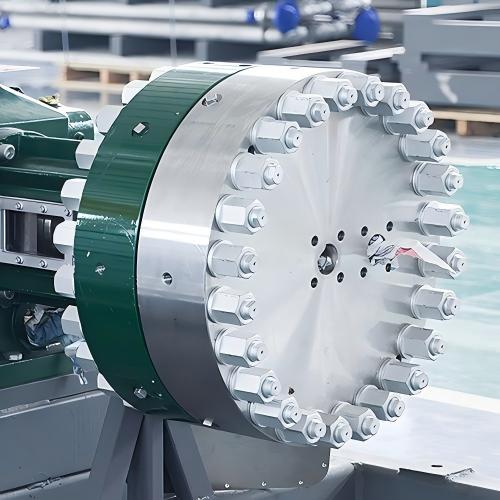

- Diaphragm: Sandwiched between the gas and oil chambers, typically composed of multiple layers of special alloy (such as stainless steel, Hastelloy, or titanium) thin sheets. It serves as a dynamic, wear-free barrier, completely separating gas and oil.

- Oil Supply Pump and Control System: Precisely maintains hydraulic system pressure and flow, ensuring smooth and controlled diaphragm movement.

The working process resembles an efficient and precise “metal lung” breathing: when the piston pushes hydraulic oil, the oil pressure acts on the diaphragm, causing it to bulge toward the gas chamber and compress the gas; during piston retraction, hydraulic system pressure changes, and the diaphragm returns to its original position through its own elasticity or auxiliary systems, increasing gas chamber volume and drawing in new gas. This cycle repeats, achieving continuous, contamination-free gas compression.

1.3 In-depth Analysis of Technical Advantages

This unique working principle endows diaphragm compressors with a series of unparalleled advantages:

- Ultimate Purity Assurance: The compressed gas only contacts highly polished, inert-treated gas chamber walls and the diaphragm, fundamentally eliminating contamination from lubricating oil and wear particles. This is the only way to achieve ultra-high purity gas transfer.

- Intrinsic Safety Enhancement: Static metal seals replace dynamic piston ring seals, resulting in extremely low leakage rates. For handling hazardous media, diaphragm compressors are among the safest options. Their multi-layer safety diaphragm design ensures that even if a single layer fails under extreme conditions, the system can prevent gas-oil intermixing through alarms or interlock shutdowns, avoiding accidents.

- Exceptional Compression Efficiency and Wide Operational Adaptability: Diaphragm compressors can achieve high compression ratios (typically up to 1:8 or higher) in a single stage, making them particularly suitable for boosting low-pressure gases to medium-high pressures. Through targeted selection of diaphragm materials and chamber materials (such as stainless steel, Monel, nickel-based alloys, etc.), they can handle various gas compression tasks ranging from inert gases to highly corrosive media.

- Smooth Operation and Extended Maintenance Intervals: Moving parts (pistons) do not directly contact high-load friction pairs, with main resistance coming from hydraulic oil, resulting in low noise, minimal vibration, negligible wear, and theoretical service life far exceeding traditional compressors.

II. Leading the Industry: Deep Cultivation and Value Creation in Diaphragm Compressors

Understanding the technical sophistication of diaphragm compressors allows us to better appreciate the profound technical accumulation, manufacturing expertise, and engineering experience required to transform this ingenious principle into reliable equipment capable of stable, efficient, and long-term operation in various harsh industrial environments. A pioneering enterprise in China has stood as a focused and steadfast practitioner and innovator in this field, dedicating years to advancing the technology and application of diaphragm compressors.

2.1 Rooted in Materials Science and Precision Manufacturing

The enterprise recognizes that the soul of diaphragm compressors lies in the materials and manufacturing quality of their core components.

- The Art of Diaphragms: Diaphragms are not ordinary metal sheets. The enterprise collaborates with top domestic materials research institutes to select and customize specialized alloy strips tailored to different gas characteristics (such as hydrogen embrittlement, chloride ion corrosion, hydrogen sulfide stress corrosion, etc.). In diaphragm forming processes, precise hydraulic bulging and heat treatment technologies ensure uniform microstructure, excellent fatigue strength, and high-precision geometric shapes, guaranteeing reliability and longevity through millions or even billions of cycles.

- The Craftsmanship of Gas Chambers: The inner surface quality of gas chambers directly affects gas purity. The enterprise employs high-precision CNC machining for chamber processing, combined with self-developed electrochemical polishing (ECP) or mechanical polishing processes, achieving mirror-like inner surface roughness of Ra≤0.1μm. This ultra-smooth surface significantly reduces particle adhesion and gas flow resistance, enhancing compression efficiency.

- Valve Optimization: Inlet and exhaust valves are critical components affecting compressor efficiency and reliability. The enterprise’s engineering team continuously optimizes valve flow characteristics, opening/closing response speed, and sealing performance, using high-strength, impact-resistant specialized valve materials. Through extensive computational fluid dynamics (CFD) simulations and bench tests, they ensure efficient, low-loss, and low-noise valve operation under various pressure conditions.

2.2 System Integration and Intelligent Control Evolution

An excellent diaphragm compressor is far more than a simple assembly of core components. The enterprise is committed to building highly integrated, intelligent complete compression systems.

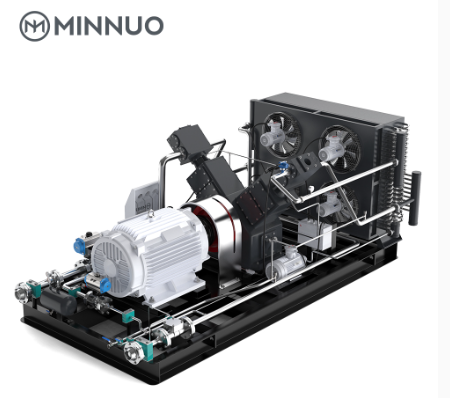

- Thermal Management Design: High-pressure compression generates substantial heat, where excessive temperatures can affect gas properties, equipment lifespan, and even safety. The enterprise’s compressors feature efficient interstage and cylinder head cooling designs, offering optional air, water, or hybrid cooling methods based on customer conditions, precisely controlling discharge temperatures at all stages to ensure optimal thermal operation.

- Comprehensive Condition Monitoring and Safety Interlocks: The enterprise’s standard configurations include various sensors for pressure, temperature, and vibration, enabling real-time equipment status monitoring. The system integrates multiple safety interlock functions such as diaphragm rupture alarms, high oil temperature, and overpressure protection. Through PLC or touchscreen human-machine interfaces, operators can intuitively access all operating parameters and achieve remote start/stop and intelligent early warning.

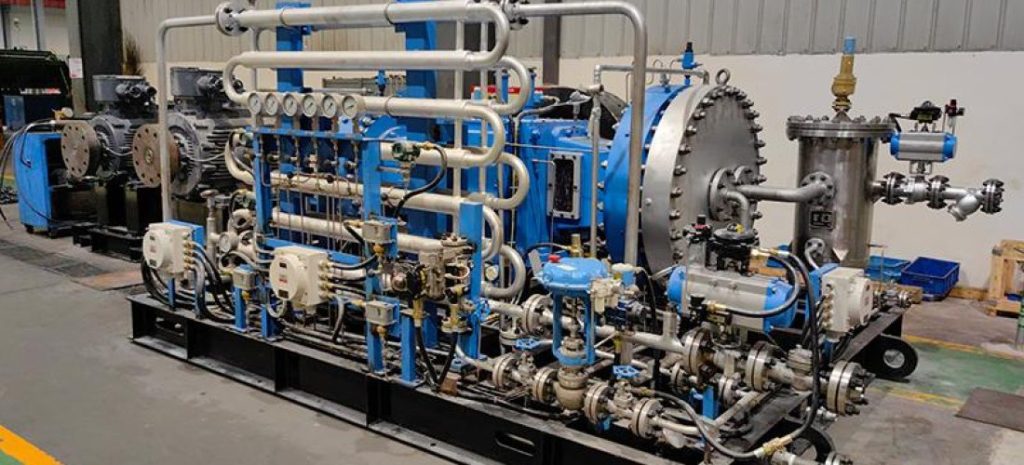

- Modular and Customized Design: Facing diverse customer needs, the enterprise adheres to modular design principles. Based on standard platforms, they can quickly and flexibly implement customized configurations, including special material upgrades, enhanced explosion-proof ratings (such as ExdIICT4), inlet/outlet connection forms, and skid-mounted integration (integrating compressors, cooling systems, buffer tanks, and control systems on a common base), providing “tailor-made” solutions for customers.

2.3 Practical Cases: Concrete Validation of Industrial Capabilities

Theoretical advantages must be validated through practice. The enterprise’s diaphragm compressors have proven their value in multiple critical industrial fields.

- Case 1: Photovoltaic Industry – Large-scale Hydrogen Recovery and Pressurization: A leading polysilicon manufacturer in East China needed to recover and pressurize substantial by-product hydrogen from its silane process for reuse in high-pressure pipelines. This application demanded extremely high equipment reliability, sealing performance (hydrogen is highly prone to leakage), and continuous operation capability. The enterprise provided multiple large, high-pressure diaphragm compressor units with special materials and sealing designs adapted to hydrogen’s permeation characteristics. These units have operated stably for over three years, achieving near-zero emissions and efficient reuse of by-product hydrogen, delivering significant economic and environmental benefits to the customer and becoming their preferred supplier for subsequent expansion projects.

- Case 2: Electronic Specialty Gases – Stable Supply of High-purity Chlorine: An electronic-grade specialty gas company in South China required compression and filling of chlorine gas with purity up to 99.999% into cylinders. Chlorine’s extreme corrosiveness and toxicity posed ultimate challenges to compressor materials and sealing. Leveraging profound expertise in special material applications, the enterprise customized a diaphragm compressor with core components made of Hastelloy C-276. This equipment not only ensured absolute stability of gas purity during compression but also earned high recognition from the customer’s safety department for its intrinsically safe design, safeguarding production personnel’s health and environmental cleanliness.

- Case 3: Scientific Research Frontier – Laboratory Micro High-pressure Compressor: A top domestic university’s chemical engineering laboratory required catalyst evaluation experiments involving compression of small quantities of rare gases to ultra-high pressures above 50MPa. Demonstrating technical flexibility, the enterprise developed a small-scale, low-flow, ultra-high-pressure laboratory-grade diaphragm compressor, meeting special research requirements for pressure accuracy, equipment quietness, and space occupancy, showcasing comprehensive technical capabilities from large-scale industrial to precision research applications.

III. Conclusion: Embracing Reliable Partners for Industrial Advancement

In the context of increasingly fierce global industrial chain competition and the nation’s heightened emphasis on high-end equipment manufacturing, domestically produced high-end equipment with independent intellectual property rights and stable, reliable performance has become crucial for ensuring national industrial security and enhancing corporate core competitiveness.

Among these outstanding domestic enterprises, Jiangsu Minnuo Group Co., Ltd. has emerged as a remarkable representative in the diaphragm compressor field. Its independently developed diaphragm compressors embody the persistent pursuit of “excellence and professional reliability” craftsmanship spirit, crystallizing multidisciplinary knowledge in materials science, mechanical engineering, and automatic control.

Looking ahead, whether in the hydrogen energy industry driven by “carbon neutrality” goals, the continuously innovating integrated circuit manufacturing sector, or the ever-evolving biopharmaceutical and fine chemical fields, the demand for safe and efficient handling of high-purity and specialty gases will undoubtedly grow. Minnuo will continue to deepen its technical accumulation in this field, providing increasingly valuable and trustworthy products and services to domestic and international customers through continuous technological iteration and process optimization.

Choosing a technically advanced and trustworthy enterprise like Minnuo means selecting a long-term partner with core technologies to jointly face future challenges. We look forward to infusing high-end industrial processes with the “silent power” of diaphragm compressors, delivering robust and reliable momentum for sustainable development.

Email

Email sales:+86 15366749631

sales:+86 15366749631