Air Compressor Manufacturersave 30-40% energy

30 years+ Air Compressor Manufacturer, 5.5kw-400kW, long service life, High stability, low noise

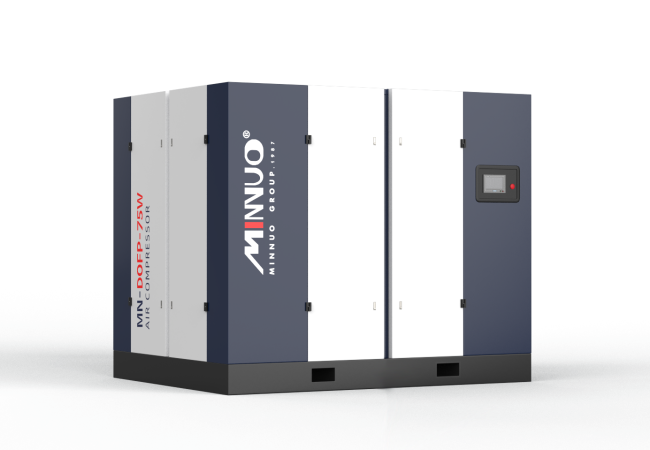

General Hot Selling Air Compressor

35 years manufacturer, free design of air compressor solutions, one-stop service for production + transport + installation, 3 years quality guarantee

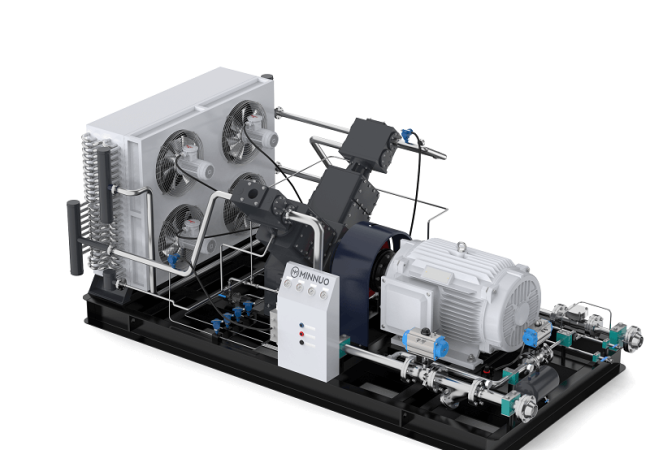

Air Compressor

Treatment Equipment

Air Dryer

Insulation resistance PRI-SEC: ≥500MΩ, waterproof grade IP67

Storage Tank

Air Filter

Why you need Our air compressor ?

At MINNUO, we understand that every industry has unique requirements when it comes to compressed air solutions. That’s why our diverse range of air compressors is designed to meet the specific needs of your business, whether you’re in manufacturing, construction, energy, or healthcare. With advanced technology, energy efficiency, and reliable performance, our air compressors provide the perfect solution to keep your operations running smoothly and efficiently. Let us help you find the ideal compressor for your application, ensuring maximum productivity and cost savings.

MINNUO air compressors can serve the following applications:

Industrial Manufacturing: Commonly used to power pneumatic tools, automation equipment, conveyors, and robotic arms. It provides essential power for various industrial processes like painting, pneumatic nailing, and assembly.

Construction Industry: In construction, compressed air powers drilling machines, pneumatic hammers, and sandblasting equipment. It is also used for paint spraying and cleaning job sites.

Energy Sector: Air compressors are used for gas transport, compression, and storage in the energy industry. For example, in natural gas transmission systems, compressors increase pressure to transport gas more efficiently.

Medical Field: Air compressors supply clean, stable compressed air to meet the demands of medical devices, such as ventilators and anesthesia machines.

Food and Beverage Processing: In the food industry, compressed air is utilized for automated packaging, liquid transfer, and bottle filling, ensuring hygiene and efficiency.

Chemical and Pharmaceutical Industry: Compressed air is used for gas separation, material transfer, and maintaining a stable production environment.

For your project’s varying air demands during peak and off-peak periods, we provide corresponding air compressor solutions. MINNUO air compressors are equipped with features like “multi-unit chaining,” “variable frequency speed control,” and “remote monitoring,” which significantly save energy (reducing electricity costs by 25-40%) and decrease backup machine capacity and investment (by 15-30%), while stabilizing air pressure (±0.1 bar). We carefully consider the appropriate air quality and grade when selecting internal components such as dryers and precision filters. Our air compressors are globally available, offering online installation guidance and continuous maintenance support. We also accept OEM orders and provide a 2-year after-sales guarantee.

WHY CHOOSE US ?

Partners You can Rely On

Why More Than 300+ Clients Trust Us?

- Source factory - 20,000 units per year, factory price, you will save time and money because of our air compressor energy saving 30-50% efficiency

- Quality assurance- fully automatic machining center production, from production to shipment after 5 quality inspection. 100% satisfaction feedback

- Strong technical team - We offer a wide range of cost-effective industrial solutions for every project. Cost savings for you.

- Huge stock quantity - spot supply, same day delivery at the earliest, 8-10 days for custom-made products. You will get the latest models faster than other dealers

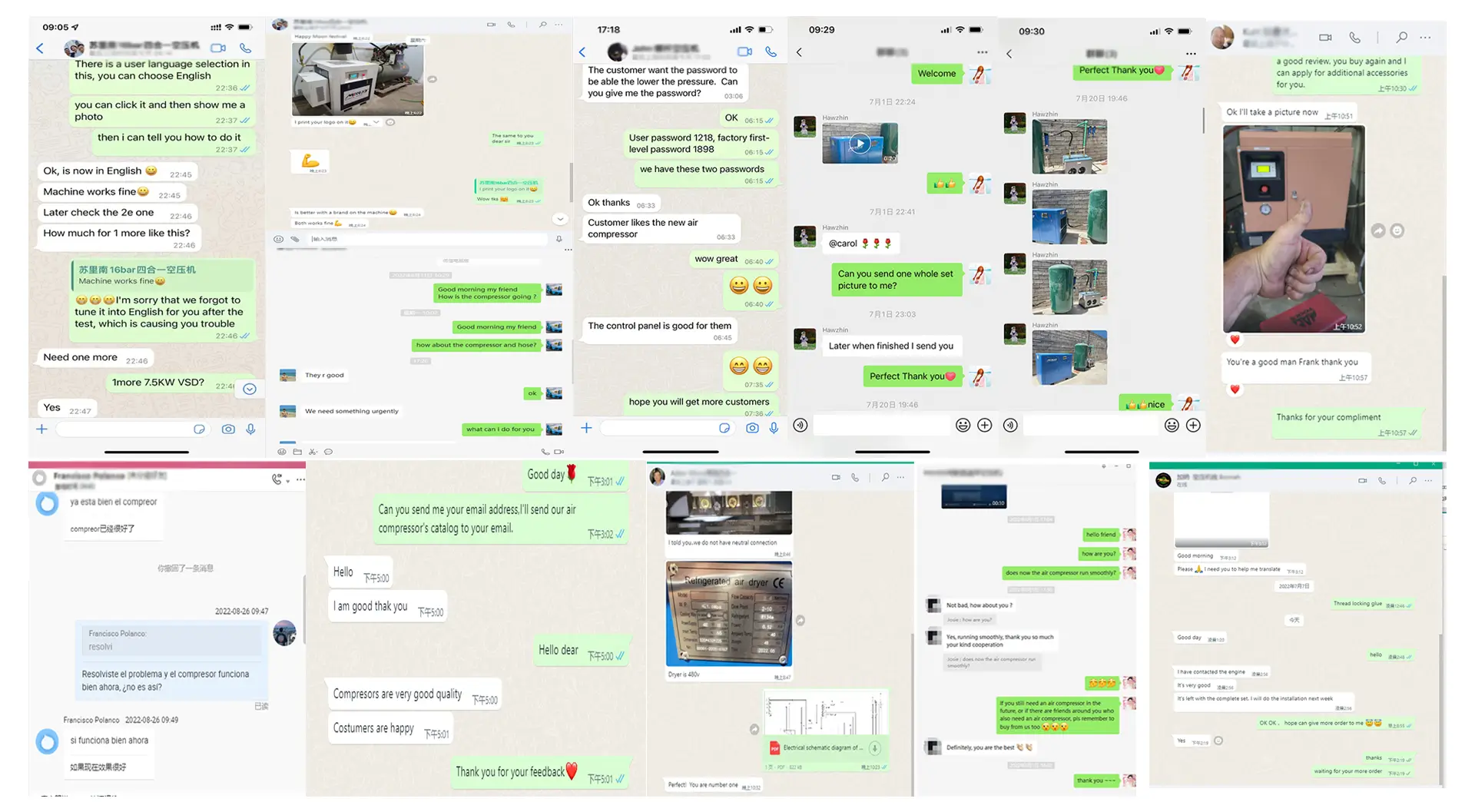

Real Feedback From Our Customers

Frequently Asked Questions

MINNUO air compressors use various oil-free compression technologies, such as oil-free screw, oil-free scroll, and oil-free piston compressors, ensuring the output air is free from oil contamination. This makes them ideal for industries with strict requirements, like food, medical, and electronics. We also provide precision filters and dryers to ensure the compressed air meets the highest cleanliness standards, fully complying with your production environment needs.

MINNUO air compressors are equipped with “multi-unit chaining” and “variable frequency control” technology, which automatically adjusts compressor operation based on your air consumption. This intelligent adjustment not only keeps the air pressure stable within ±0.1 bar but also effectively saves energy, preventing waste and reducing your operational costs.

MINNUO air compressors use high-quality core components and advanced designs to ensure exceptional durability. We pay attention to material selection and craftsmanship, guaranteeing that the equipment can run stably over extended periods under high-intensity working conditions. In addition, we offer a remote monitoring system to track the compressor’s status in real-time, helping to identify and resolve potential issues promptly, thus extending the equipment’s lifespan.

Yes, MINNUO is committed to providing high-quality service to customers worldwide. We support global air compressor supply, offering online installation guidance, comprehensive maintenance, and a 2-year after-sales guarantee. No matter where you are, our technical team will ensure you receive timely service and support.

MINNUO air compressors adopt advanced variable frequency technology and efficient designs, effectively reducing electricity costs with energy savings averaging between 25%-40%. By precisely controlling the output of compressed air and avoiding unnecessary energy waste, we help significantly lower your operational costs while improving overall equipment efficiency.

Estimated Cost

The cost of a screw air compressor will depend on several factors, such as the size of the compressor, the brand of accessories and features.

On average, a 37kw screw air compressor price from $1,500 to $5000. Installation and maintenance costs should also be considered. Contact us and we’ll arrange for a professional engineer to estimate the cost of your project at a competitive price!

Fill Form Get Our Compelete price list

Your email address will not be published. Required fields are marked *

Email

Email sales:+86 15366749631

sales:+86 15366749631