High Pressure Air Compressor

Minnuo, as one of the professional high pressure air compressor manufacturers and suppliers in China, has 30 years + experience in manufacturing and selling energy-saving, efficient and stable high pressure air compressors!

- Pressure range: 10-70Mpa

- Flow range: 0.1-50m³/min

- Widely used in: petrochemical, testing, marine, injection molding, ships

High Pressure Air Compressor

High-pressure air compressor is to compress the air in free state to the compressed air with gauge pressure of 10MPa/35MPa. After flowing through the oil-water separator and activated carbon molecular sieve filter in the unit, it removes the water, oil and impurities in the high-pressure air, so that the discharged gas is clean and odorless, and the quality of the gas conforms to the standard of DIN EN 12021 for breathing air, and it is a trustworthy and safe and reliable system to supply the air and high-pressure air source. It is a reliable, safe and reliable breathing air and high pressure gas supply system.

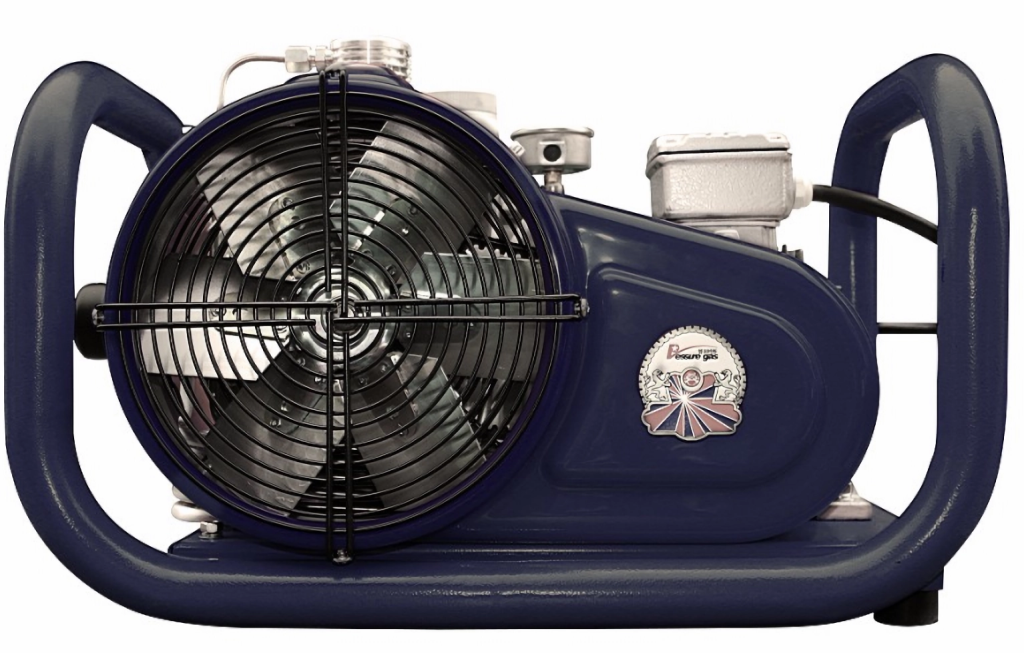

Portable High Pressure Air Compressor

Working pressure: 15-35MPaExhaust flow rate: 0.1m³/min

Features

- Compact overall layout structure, small and lightweight body, easy to extract.

- Microparticle intake anechoic filter to ensure the quality of intake air.

- Stainless steel cooler and air-cooled intercooler to maximize the heat dispersed from the machine body.

- Cooling fan and header flywheel integrated design, reasonable structure.

- Interstage and end-stage safety valves to ensure the overall safety of the machine.

- Three and four-stage oil-water separator, filtering and purifying the compressed gas.

- Pressure maintaining check valve to improve the purity of air and the service life of filter element.

- Equipped with oil level mirror, which is convenient to monitor the oil level of crankcase from time to time.

Optional items

- Automatic condensate drain.

- Automatic shutdown pressure controller.

Features

- Retractable portable handle, easy to move and pack for transportation.

- Stainless steel cooler and air-cooled intercooler to maximize the heat dissipation of the machine body.

- Each stage is equipped with a safety valve to ensure the overall safety of the machine.

- The second and third stage cylinders are equipped with oil-water separators to separate the oil and water in the compressed gas.

- Two oil drain ports are arranged on the left side and rear end to facilitate the replacement of lubricating oil.

- The oil level eyepiece display can monitor the crankcase oil level level from time to time.

Optional items

- Low pressure oil pump and lube oil filter

- Automatic condensate drain

- Automatic shutdown pressure controller

- Low oil level protection

Mobile High Pressure Air Compressor

Working pressure:15-35MPaExhaust flow rate: 0.22~0.27m³/min

Enclosed High Pressure Air Compressor

Working pressure:15-50MPaExhaust flow rate: 0.35-3.5m³/min

Features

- Box-type frame structure design, effectively reduce noise.

- Pressure gauges at all levels are installed on the panel, dynamically displaying the pressure at each level.

- The system is equipped with automatic condensate drainage and collection system, which realizes automatic drainage and collection of sewage and no-load start-up operation.

- The compressor automatically stops when the set pressure is reached.

- Equipped with low oil pressure pump and lubricating oil filter.

- The compressor system is equipped with low oil level protection.

- Oil/water separator after each cylinder stage and safety valves at all stages.

- The form of interface can be reserved according to the customer’s needs.

Optional items

- PLC and text display

- Integral silent type structure

- Air compressor heating system

Hot High Pressure Air Compressor for Sale

30 years + experience in manufacturing high pressure air compressors, providing perfect air compressor customization service and after-sales guide!

Product Parameter

| Model | Pressures | Flow rate | Level | RPM | Motor | Power | Size | Weight | |

|---|---|---|---|---|---|---|---|---|---|

| MPa | m³/ min | m³/h | KW | HP | L*W*H( mm) | Kg | |||

| PGA15-0.1 | 15 | 0.1 | 6 | 4 | 2100 | 3 | 4 | 580*410*410 | 43 |

| PGA25-0.1 | 25 | ||||||||

| PGA35-0.1 | 35 | ||||||||

| PGA15-0.22 | 15 | 0.22 | 13.2 | 3 | 1350 | 4 | 5.5 | 1070*510*650 | 146 |

| PGA25-0.22 | 25 | ||||||||

| PGA35-0.22 | 35 | ||||||||

| PGA15-0.27 | 15 | 0.27 | 16.2 | 3 | 1550 | 5.5 | 7.5 | 1160*600*610 | 156 |

| PGA25-0.27 | 25 | ||||||||

| PGA35-0.27 | 35 | ||||||||

| PGA15-0.35 | 15 | 0.35 | 21 | 4 | 1550 | 7.5 | 10 | 720*1100*1500 | 280 |

| PGA25-0.35 | 25 | ||||||||

| PGA35-0.35 | 35 | ||||||||

| PGA42-0.35 | 42 | ||||||||

| PGA15-0.68 | 15 | 0.68 | 40.8 | 4 | 1350 | 15 | 20 | 820*1100*1600 | 300 |

| PGA25-0.68 | 25 | ||||||||

| PGA35-0.68 | 35 | ||||||||

| PGA42-0.68 | 42 | ||||||||

| PGA15-0.85 | 15 | 0.85 | 51 | 4 | 1180 | 18.5 | 25 | 1554*805*960 | 510 |

| PGA25-0.85 | 25 | ||||||||

| PGA35-0.85 | 35 | ||||||||

| PGA42-0.85 | 42 | ||||||||

| PGA15-1.0 | 15 | 1.0 | 60 | 4 | 1320 | 22 | 30 | 1980*800*700 | 570 |

| PGA25-1.0 | 25 | ||||||||

| PGA35-1.0 | 35 | ||||||||

| PGA42-1.0 | 42 | ||||||||

| PGA15-1.5 | 15 | 1.5 | 90 | 4 | 1400 | 37 | 50 | 2030*850*730 | 780 |

| PGA25-1.5 | 25 | ||||||||

| PGA35-1.5 | 35 | ||||||||

| PGA42-1.5 | 42 | ||||||||

| PGA15-2.0 | 15 | 2.0 | 120 | 4 | 1180 | 45 | 61 | 2500*900*800 | 1750 |

| PGA25-2.0 | 25 | ||||||||

| PGA35-2.0 | 35 | ||||||||

| PGA42-2.0 | 42 | ||||||||

| PGA15-3.5 | 15 | 3.5 | 210 | 4 | 1180 | 75 | 102 | 3000*1000*1500 | 1950 |

| PGA25-3.5 | 25 | ||||||||

| PGA35-3.5 | 35 | ||||||||

| PGA42-3.5 | 42 | ||||||||

High Pressure Air Compressor Structure and Workflow

High-pressure air compressor unit mainly consists of the main compressor, driving machine (motor), interstage cooler, compressed air separation, purification and other processing devices, as well as pressure display, control and safety devices.

Specific workflow:

- Initial Compression: Air enters the first-stage cylinder through the intake filter, where it undergoes preliminary compression.

- Cooling and Separation: The compressed air flows into the interstage cooler and separator, where it is cooled and oil is separated.

- Second Compression Stage: The cooled air then moves into the second-stage cylinder for further compression.

- Additional Cooling and Separation: After this, the air passes through the second and third interstage cooler and separator, allowing for more cooling and oil removal.

- Final Compression: The air enters the third-stage cylinder for final compression, achieving the desired high pressure.

- Purification: The high-pressure air is then processed through a separator and filter to eliminate oil, condensate, and oil vapor.

- Storage: Finally, the purified high-pressure air is stored in high-pressure cylinders for later use.

Applications

High pressure air compressors are important pieces of industrial equipment designed for specific applications in a wide and diverse range of applications.

Aerospace

Chemical Industry

Wind power industry

Mining Industry

Glass Industry

WHY CHOOSE US

Partners You can Rely On

Why More Than 300+ Clients Trust Us?

- Source factory - 20,000 units per year, factory price, you will save time and money because of our air compressor energy saving 30-50% efficiency

- Quality assurance- fully automatic machining center production, from production to shipment after 5 quality inspection. 100% satisfaction feedback

- Strong technical team - We offer a wide range of cost-effective industrial solutions for every project. Cost savings for you.

- Huge stock quantity - spot supply, same day delivery at the earliest, 8-10 days for custom-made products. You will get the latest models faster than other dealers

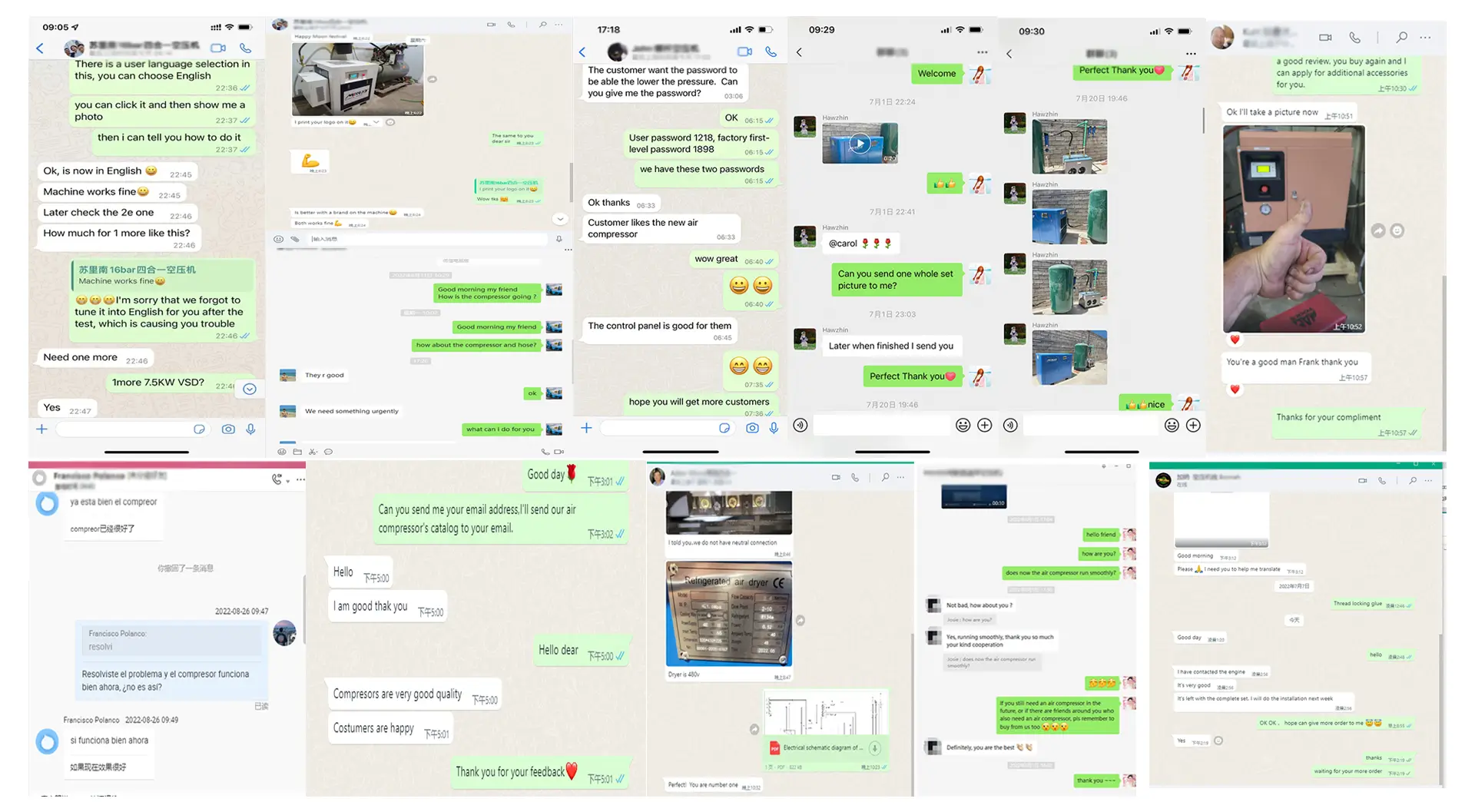

Real Feedback From Whatsapp

Frequently Asked Questions

Send Your Inquiry Now!

Get High Pressure Air Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631