Air compressors are incredibly versatile machines used in various fields, from DIY home projects to industrial applications. Whether you need to inflate tires, power pneumatic tools, or operate machinery, an air compressor is a must-have tool. However, if you’re new to using one, the process can seem a bit intimidating.

To use an air compressor:

- Place the compressor on a flat surface.

- Connect the air hose to the compressor and your desired tool.

- Power on the compressor and allow it to build pressure.

- Adjust the pressure regulator to the desired PSI.

- Use your air tool, monitoring the pressure gauge for consistency.

- After use, turn off the compressor and release air pressure from the tank by opening the drain valve.

This step-by-step guide ensures safe and efficient air compressor use, helping you complete your tasks easily.

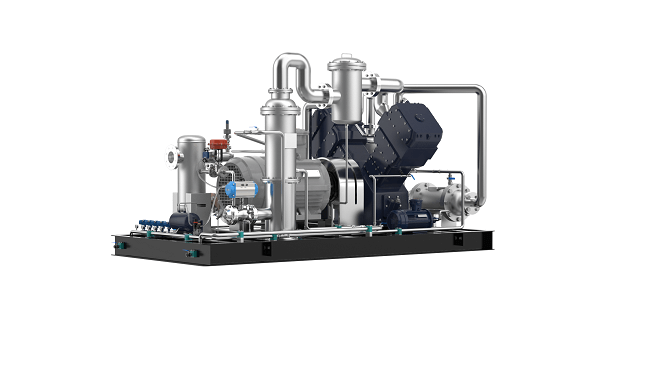

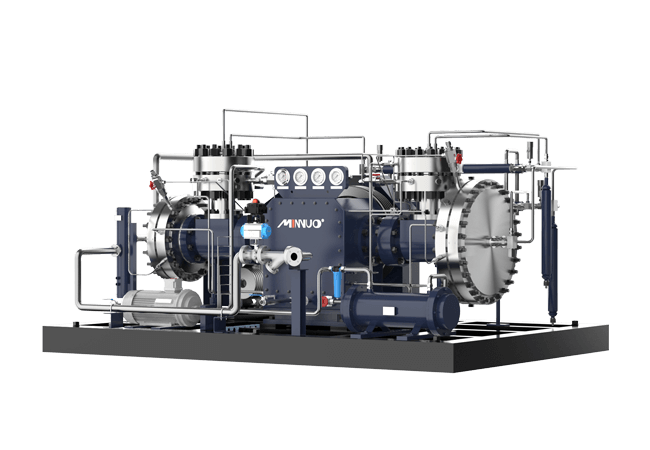

Getting to Know Your Air Compressor

Before we dive into the operational steps, it’s important to understand the key components of an air compressor and the types available. This foundation will make it easier for you to set up, use, and maintain the machine, ensuring that you get the best results from your air compressor. Knowing how different parts work and the differences between compressor types will also help you choose the right machine for your specific needs.

Preparing the Air Compressor for Use

Now that you have a general understanding of how an air compressor works and its different components, it’s time to prepare the machine for actual use. This preparation phase is crucial because skipping it can lead to improper operation, reduced efficiency, or even safety hazards. Let’s begin by addressing a few essential steps before powering up the compressor.

Safety Precautions

Safety should always come first when working with machinery, especially with equipment that operates under high pressure like an air compressor. Here are the key precautions to ensure that you operate the machine safely and avoid accidents.

Inspect the Compressor

Before you start, it’s important to conduct a quick inspection to ensure your air compressor is in good condition. This step might seem minor, but it can prevent issues such as air leaks or mechanical malfunctions that can arise from damaged or worn-out parts.

Setting Up the Compressor

Once the safety checks are complete and the compressor has passed inspection, you can proceed with the setup. Proper setup is critical to ensure optimal performance and the longevity of the machine. Let’s break down how to correctly set up your air compressor, from connecting hoses to attaching your tools.

Operating the Air Compressor

After preparing and setting up your compressor, it’s time to put it to work. Operating an air compressor involves a few essential steps to ensure it functions properly and efficiently for your task. Whether you’re inflating tires, using a nail gun, or running a paint sprayer, following these steps will help you get the most out of your air compressor. Let’s start with turning it on and building pressure.

Starting the Compressor

The first step in operating the air compressor is powering it on and letting it build pressure. This process involves ensuring that the compressor reaches the correct PSI for the task at hand before starting to use your air tools. Here’s how to get started.

Adjusting the Pressure

Once the compressor has built sufficient pressure, you need to adjust the air pressure according to the tool you’re using. Different tools require different PSI levels, so this is a critical step in ensuring your equipment operates efficiently and safely.

Using the Tool

Now that the pressure is set, you can begin using your air tool. Whether it’s a tire inflator, paint sprayer, or pneumatic wrench, the correct operation of the tool depends on maintaining consistent pressure and following the proper usage guidelines.

Shutting Down and Storing the Air Compressor

Once you’ve finished using your air compressor, the job isn’t quite done yet. Proper shutdown procedures are just as important as proper operation. This ensures the longevity of your machine and prepares it for future use. Let’s go over how to safely turn off and store your air compressor after completing your tasks.

Powering Off

The first thing you should do when you finish using the compressor is power it off properly. This step ensures that you avoid any residual pressure issues that could lead to damage or safety risks.

Draining the Compressor Tank

After powering off, it’s critical to release any air and moisture that may have accumulated in the tank. This prevents rust and extends the life of your compressor. It’s a simple but essential step for keeping your machine in top condition.

Storing the Compressor

Finally, it’s time to store the compressor in a way that ensures it stays in good condition between uses. Proper storage not only protects your compressor from environmental damage but also ensures it’s ready for the next job when you need it.

Maintenance for Optimal Performance

To keep your air compressor running smoothly and avoid costly repairs, regular maintenance is a must. Whether you use it occasionally or frequently, routine care ensures that your compressor works efficiently and lasts as long as possible. Let’s walk through the key maintenance steps you should follow.

Routine Maintenance Tasks

Regular maintenance tasks like draining moisture, checking for leaks, and replacing air filters will keep your compressor in peak condition. By incorporating these simple tasks into your routine, you can avoid common compressor problems and extend the machine’s lifespan.

Extending the Compressor’s Life

By following these maintenance steps and regularly inspecting your compressor, you can extend its life by several years. Proper care ensures that the machine operates efficiently and helps you avoid costly repairs or replacements.

Conclusion

By following this comprehensive guide, you can confidently use an air compressor for various tasks, from simple DIY jobs to more complex industrial applications. Remember that proper setup, operation, and maintenance are the keys to keeping your compressor running smoothly for years. Whether you’re a first-time user or a seasoned pro, these steps will help you get the most out of your air compressor.

With routine care and attention to safety, your air compressor will serve as a reliable tool for countless tasks, big or small.

FAQs

Understanding the PSI requirements for different tools ensures safe and efficient operation. For example, nail guns typically require 70-90 PSI, while tire inflation may need only around 30-35 PSI. Always refer to the manufacturer’s guidelines for the tool in use.

Yes, but ensure proper ventilation, especially with gas-powered compressors, as they emit fumes. Also, consider the noise level, as some compressors can be loud. Look for models with noise-dampening features if working indoors.

If your compressor isn’t building pressure, the issue could be due to air leaks, a faulty pressure switch, or a blocked air filter. Regular maintenance and inspections help avoid these problems.

Email

Email sales:+86 15366749631

sales:+86 15366749631