Beer brewing is a complex industrial process where oil-free compressors enhance beer quality by providing contamination-free power and ensuring stable conditions during canning, bottling, and barreling. As consumers increasingly demand higher-quality beer, leveraging advanced oil-free compressor technology has become a critical focus for the brewing industry, addressing both quality preservation and operational efficiency.

Oil-free compressors play a pivotal role in the beer brewing process, particularly in providing stable air sources, controlling pressure and temperature. In the packaging stages of beer, such as canning, bottling, and barreling, they help maintain the freshness and taste quality of beer by ensuring the stability of process conditions. Moreover, advanced industrial compressor technology can optimize the supply of air and carbon dioxide, improving the efficiency of the beer brewing and storage processes, thereby effectively enhancing the overall quality of beer.

1.The Importance of Air in the Beer Brewing Process

Throughout the beer production process, air is involved in multiple core stages of physical and chemical reactions.

1.1 Initial Brewing Stage

In the initial brewing stage, industrial compressors use the principle of isentropic compression to intake ambient air and pressurize it to 0.5 – 0.8MPa (depending on different brewing process requirements), providing a suitable pressure environment for the subsequent beer brewing process. This ensures that liquid materials can be smoothly transported in the pipeline system and maintains the required dissolved oxygen levels during brewing to meet the metabolic needs of yeast during the aerobic respiration phase, promoting yeast proliferation and fermentation activity.

1.2 Air Filtration Stage

Air filters use high-precision filtration media, such as glass fiber filter paper or polytetrafluoroethylene (PTFE) membranes, with a filtration precision of up to 0.01μm, effectively removing dust particles, microorganisms, and oil mist from the air, ensuring the purity of the air entering the brewing system.

1.3 Air Drying Stage

Dryers use adsorption or freezing drying technology to lower the dew point temperature of the air to below -40℃, maintaining the dryness of the air and avoiding interference with the pH value during the beer brewing process, ensuring the stability of saccharification, fermentation, and other processes.

1.4 Cooling Stage

The cooler system rapidly cools the boiled wort before fermentation. Through the principle of heat exchange, the wort is cooled from high temperature to the suitable fermentation temperature range (generally 7 – 15℃) in a short time, preventing the growth of bacteria and excessive oxidation of flavor substances.

1.5 Bottling Stage

In the final bottling stage, compressed air is used to fill the top space of the bottles, preventing the beer from coming into contact with oxygen during storage and transportation, ensuring the freshness and flavor stability of the beer.

Any contamination of air in any of these stages can trigger a series of chain reactions, severely affecting beer quality. For example, during the cooling process, if the air in the cooling system contains bacteria or chemical pollutants, it may contaminate the wort during the cooling stage, interfering with the normal fermentation process of yeast, leading to abnormal fermentation and the production of undesirable flavor substances, such as an imbalance in higher alcohols and esters, thereby altering the taste and aroma quality of the beer.

2.Problems with Traditional Oil-Lubricated Compressors

2.1 Impact on Beer Flavor

Traditional oil-lubricated compressors, widely used in breweries, inevitably mix lubricating oil into the compressed air due to the friction and lubrication needs of mechanical components during operation. When oil-containing air enters the beer brewing system, oil particles can affect the formation of flavor substances and yeast metabolism through various pathways.

Research shows that unsaturated fatty acids in the oil may undergo oxidation reactions during the brewing process, generating off-flavor substances such as aldehydes and ketones, which can mask the original aroma characteristics of the beer, making the aroma thin and impure. At the same time, oil-containing air can erode yeast cells in the beer, altering the permeability of yeast cell membranes and affecting the uptake of nutrients and secretion of metabolites by yeast.

For example, yeast normally produces an appropriate amount of ester substances during fermentation, imparting pleasant aromas such as fruity and floral notes to the beer. However, in an oil-containing air environment, yeast metabolism is disrupted, reducing the synthesis of ester substances, leading to insufficient beer aroma and a bland taste, greatly diminishing the consumer drinking experience. A well-known brewery, before replacing its compressor, used gas chromatography-mass spectrometry (GC-MS) to analyze the components of some batches of beer with poor taste and found that the beer contained various off-flavor substances caused by oil contamination, and the ester content was significantly lower than normal levels, confirming the negative impact of traditional oil-lubricated compressors on beer flavor.

2.2 Hazards to Beer Quality

Oil particles in the air not only affect beer flavor but may also carry various microorganisms, heavy metal ions, and other chemical pollutants. Even with high-performance air filters, it is difficult to completely eliminate the potential threats these pollutants pose to beer quality.

With increasingly stringent food standards, countries have established strict limits on the content of pollutants in beer. For example, Australia, based on its Food Standards Code (FSANZ), clearly stipulates that beer must not contain pollutants that may pose a food safety hazard, with extremely low limits for oil pollutants. Even trace amounts of oil contamination can increase the turbidity of beer, reduce foam stability, and damage the appearance quality of beer. At the same time, oil contamination may also pose a risk of microbial contamination, as oil particles provide a nutrient source for microorganisms, leading to secondary fermentation and spoilage during beer storage.

A beer company was ordered to rectify its operations after failing to meet product quality standards, with testing revealing that traditional oil-lubricated compressors caused excessive oil contamination in the beer. This incident not only caused the company to lose a significant market share but also required substantial investment in equipment replacement, product recalls, and quality rectification, resulting in huge economic losses and damage to brand reputation.

3.How Oil-Free Compressors Enhance Beer Quality

3.1 Ensuring Air Purity and Compliance with Strict Standards

Advanced oil-free compressed air systems on the market use various cutting-edge technologies to fundamentally eliminate the risk of oil contamination, effectively reducing the possibility of pollutants entering the production system. They fully comply with the food-grade compressed air quality standards set by the International Organization for Standardization (ISO), such as ISO 8573-1:2010, which has strict classification requirements for solid particles, moisture, and oil content in compressed air.

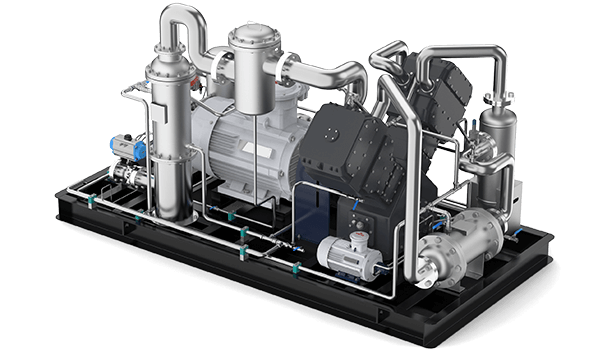

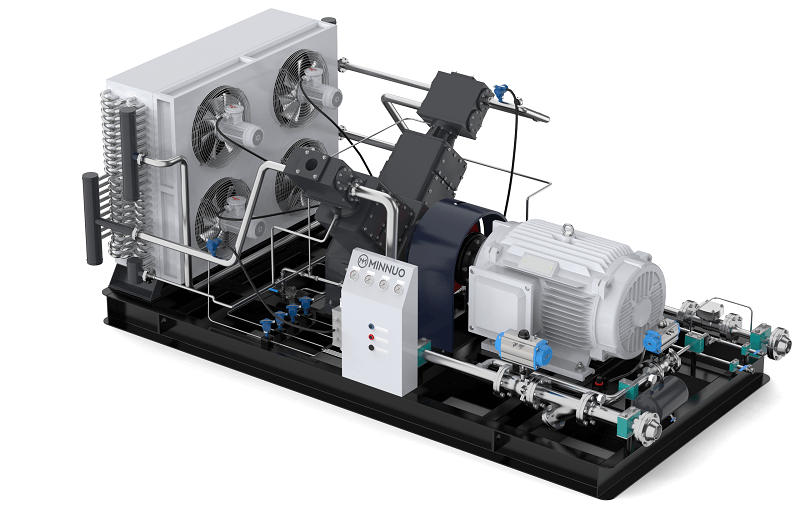

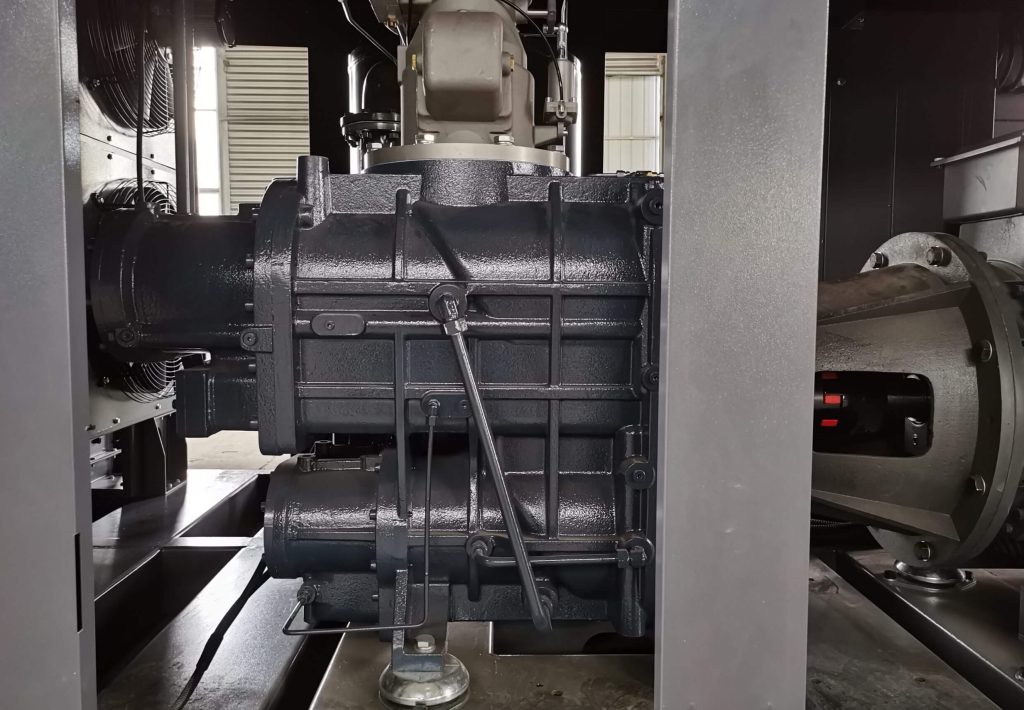

For example, MINNUO’s oil-free compressors use special dry sealing technologies, such as carbon ring seals or labyrinth seals, combined with high-precision piston rings and cylinder surface treatment processes, ensuring complete isolation of lubricating oil from compressed air during compressor operation, introducing zero oil content per million into the compressed air used in the manufacturing process. At the same time, during the air compression process, the built-in multi-stage filtration system purifies the compressed air in real-time, further removing any solid particles and microorganisms, ensuring the purity of the compressed air reaches the highest grade in the ISO 8573-1 standard, providing a clean, pollution-free air environment for high-quality beer brewing, and safeguarding beer quality safety from the source.

3.2 Avoiding Oil Contamination, Enhancing Beer Flavor and Taste

Using oil-free compressors completely avoids the negative impact of oil contamination on beer yeast, allowing yeast to metabolize and ferment normally in a pure air environment. Research shows that in an oil-free air environment, yeast has higher fermentation activity, more effectively utilizing the sugars and nutrients in the wort to produce rich flavor substances, such as esters, higher alcohols, and aldehydes. These substances coordinate with each other to form the unique flavor and taste of beer.

On the basis of the four basic physical components of beer production (grains, hops, yeast, and water), ensuring the freshness and purity of the fifth “invisible” component—air—provides a significant competitive advantage in taste tests. According to professional sensory evaluation experiments and consumer market research data, beer produced using oil-free compressors scores 10% – 15% higher on average in terms of aroma intensity, taste richness, and balance compared to beer produced using traditional compressors, with consumer repurchase rates increasing by 20% – 30%, indicating that beer produced with oil-free compressors better meets consumer demand for high-quality beer taste.

3.3 Long-Term Cost Advantages, Supporting Continuous Quality Improvement

Although oil-free compressors may have a slightly higher initial investment compared to traditional oil-lubricated compressors, they offer significant advantages in terms of long-term operating costs and overall benefits for beer production companies.

On one hand, oil-free compressors avoid product quality issues caused by oil contamination, reducing economic losses due to increased defect rates, product recalls, and brand reputation damage. On the other hand, oil-free compressors do not require frequent replacement of oil filter elements in air filters, also reducing equipment maintenance and cleaning costs caused by oil contamination.

Among our customers, a medium-sized brewery with an annual capacity of 100,000 tons experienced significant improvements after upgrading its equipment. By implementing oil-free compressors that enhance beer quality, the brewery achieved a 15% increase in sales within a year, while the defect rate dropped from 5% to 1%. Additionally, equipment maintenance costs were reduced by 30%. These savings can be reinvested into optimizing brewing processes, developing new products, and strengthening quality control systems. This creates a virtuous cycle that continuously improves beer quality and boosts the company’s market competitiveness.

4.Conclusion

As a key piece of equipment in the beer brewing process, industrial compressors have a crucial impact on beer quality. Oil-free compressors enhance beer quality by ensuring contamination-free air supply and maintaining stable production conditions. Beer brewers should select high-quality MINNUO oil-free air compressors based on their production scale, process characteristics, and quality goals, driving beer quality to even higher levels.

If you would like more detailed configurations and solutions, MINNUO welcomes you!

Email

Email sales:+86 15366749631

sales:+86 15366749631