Air compressors are indispensable tools in various industries, providing the power needed for a multitude of applications, from inflating tires to powering pneumatic tools. Understanding how long an air compressor lasts is crucial for potential buyers and current users alike. The average lifespan of an air compressor typically ranges between 10 to 15 years, but this can vary significantly based on several factors.

An air compressor generally lasts between 10 to 15 years, depending on factors such as maintenance, usage frequency, and environmental conditions. Regular upkeep can extend its lifespan, while neglect may lead to early failures. Always check for signs of wear and perform routine maintenance to ensure optimal performance.

In this article, we’ll explore the key elements that affect the longevity of air compressors, how to maintain them effectively, and when it’s time to consider a replacement.

What Affects the Lifespan of an Air Compressor?

Quality of the Compressor

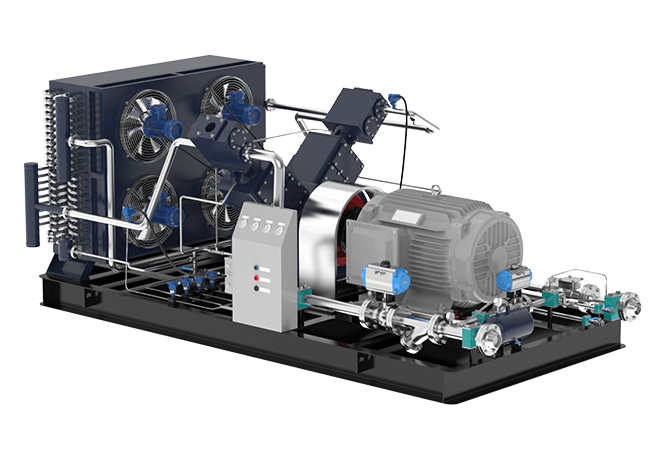

The brand and model of an air compressor play a crucial role in its longevity. High-quality compressors from reputable manufacturers often incorporate better materials and technologies, leading to enhanced durability. For instance, a rotary screw compressor can last up to 20 years with proper maintenance, while cheaper, lower-quality models may fail within just a few years.

Usage Frequency and Conditions

How often and in what conditions you use your compressor significantly impacts its lifespan. Compressors used daily in industrial settings typically have shorter lifespans compared to those used occasionally for home projects. Additionally, exposure to harsh conditions—like extreme temperatures or high humidity—can accelerate wear and tear.

Maintenance Practices

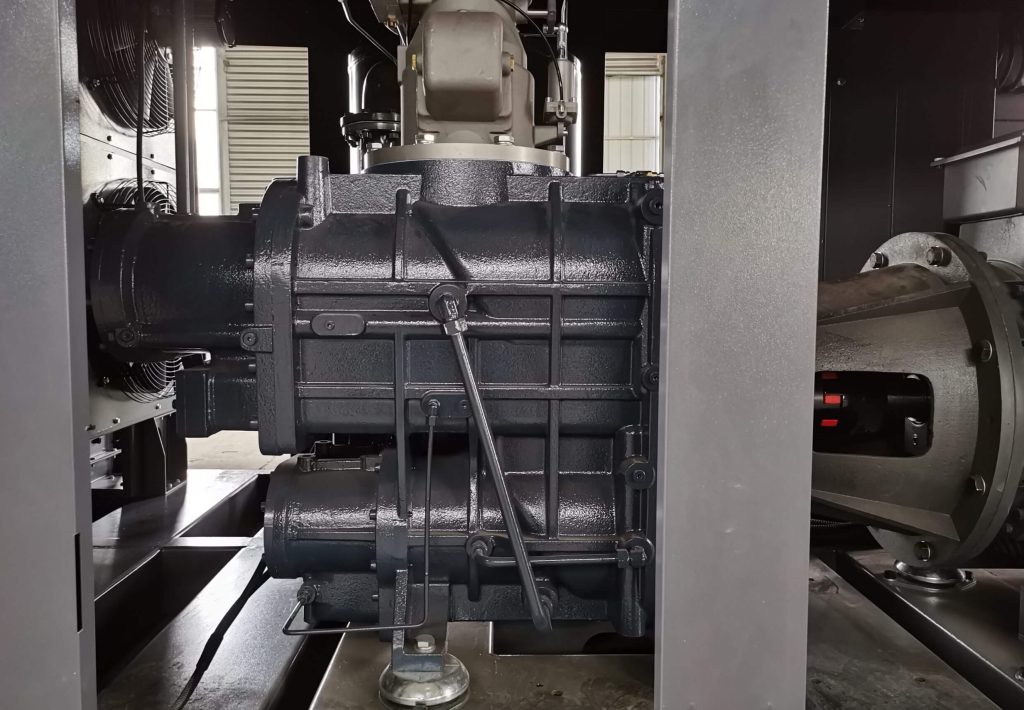

Regular maintenance is the lifeblood of any air compressor. Following the manufacturer’s maintenance schedule can prevent premature failures. Studies indicate that compressors with routine checks, such as oil changes and filter replacements, can last up to 50% longer than those that are neglected. For instance, an oil-lubricated compressor may require more frequent oil checks compared to oil-free models, which can simplify maintenance but may still require attention to other components.

Environmental Factors

Environmental conditions, such as temperature and humidity, can also affect an air compressor’s longevity. For instance, compressors in humid environments may require more frequent drainage of condensation, as excess moisture can lead to internal rust and damage. Dust and dirt accumulation can also affect cooling efficiency and operational integrity, necessitating regular cleaning.

Air Compressor Lifespan Expectations

While the average air compressor lasts between 10 to 15 years, the type of compressor significantly influences this range. Here’s a breakdown of various types and their expected lifespans:

- Rotary Screw Compressors: Often found in industrial settings, these can last up to 20 years with proper care. Their continuous operation makes them suitable for high-demand environments.

- Reciprocating Compressors: Common in smaller operations, their lifespan usually ranges from 10 to 15 years. These compressors are versatile but may require more maintenance.

- Centrifugal Air Compressors: Designed for large-scale applications, these compressors can last 15 to 20 years. They are efficient for continuous high-volume air supply but can be expensive to repair.

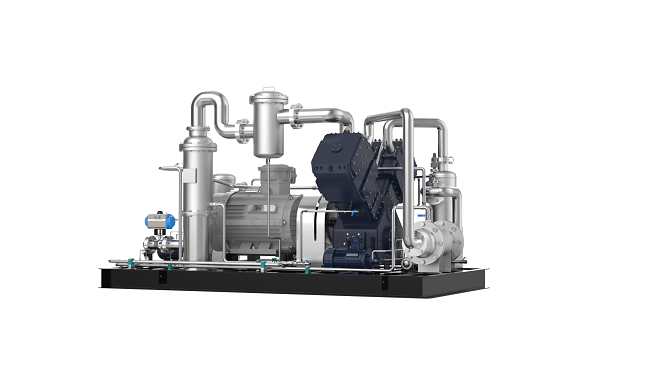

- Oil-Free Rotary Screw Compressors: Ideal for applications requiring clean air, such as in the food and pharmaceutical industries, these compressors typically last 10 to 15 years. They have lower maintenance needs but may not handle heavy loads as well as oil-lubricated models.

- Diaphragm Compressors: Used in specialized applications, these can last between 10 to 20 years, depending on usage. They are ideal for low-pressure, high-purity air applications.

Real-world examples show that with diligent maintenance, many users have successfully operated compressors for over 15 years.

Signs That Your Air Compressor Is Aging

As your air compressor ages, it may exhibit certain signs indicating it’s time for a check-up or replacement:

Decreased Efficiency: If you notice a drop in power or pressure, it could signal wear. This might manifest as longer cycle times or inadequate pressure for tools.

Unusual Noises: Grinding, knocking, or hissing sounds can indicate internal problems that may require immediate attention.

Frequent Breakdowns: If repairs become more common, it may be time to consider a replacement. Keep a log of breakdowns to assess frequency.

Increased Energy Consumption: Higher utility bills can suggest that the compressor is working harder due to inefficiencies. An increase of more than 10% in energy costs could be a warning sign.

Maintenance Tips to Extend Lifespan

To keep your air compressor running smoothly and extend its lifespan, consider the following maintenance tips:

- Regular Oil Changes: Like any machinery, changing the oil regularly is vital. Check the manufacturer’s guidelines for specific intervals.

- Filter Replacements: Ensure air filters are clean to maintain efficiency. Clogged filters can drastically reduce airflow and pressure.

- Drain Condensation: Regularly drain moisture from the tank to prevent rust. Aim to do this after each use, especially in humid climates.

- Periodic Inspections: Schedule regular checks to catch potential issues early. Consider hiring a professional for thorough assessments.

- Keep It Clean: Regularly clean the exterior and components to prevent dust buildup, which can hinder performance.

When to Replace Your Air Compressor

Deciding to replace your air compressor involves evaluating several factors:

- Cost of Repairs vs. New Purchase: If repair costs approach 50% of the purchase price of a new unit, replacement may be the better option. Analyze the total cost of ownership, including energy consumption.

- Technological Advancements: Newer models often offer improved efficiency and features that can justify an upgrade. Look for models with variable speed drives for enhanced energy savings.

- Business Growth: If your demands have outgrown your current compressor, it’s time to consider a larger or more efficient model. This is especially important in industries with fluctuating workloads.

Choosing a New Air Compressor

When selecting a new air compressor, keep these factors in mind:

- Capacity Needs:

Ensure the compressor can meet your specific requirements. Calculate your peak air demand to choose the right size.

- Type of Compressor:

Understand the differences between rotary screw and reciprocating compressors, and select based on your operational needs.

- Brand Reputation:

Research brands known for reliability and customer service. User reviews and industry ratings can be invaluable.

- Warranty Coverage:

A strong warranty can provide peace of mind. Look for manufacturers that offer extended warranties for parts and labor.

Conclusion

Understanding how long an air compressor lasts and the factors that influence its lifespan is vital for anyone considering a purchase or currently using one. With proper maintenance and care, these machines can provide reliable service for years. Investing in quality equipment and regular upkeep not only enhances performance but also ensures you get the most out of your compressor.

FAQs

Popular brands include Ingersoll Rand, Chicago Pneumatic, and Minnuo, known for their reliability and efficiency. Research user reviews and warranty options to guide your choice.

Look for decreased efficiency, unusual noises, or increased energy costs. A significant drop in output pressure is also a strong indicator.

Regular oil changes, filter replacements, and periodic inspections are crucial for optimal performance. Always refer to the manufacturer’s manual for specific maintenance schedules.

Email

Email sales:+86 15366749631

sales:+86 15366749631