What Makes Diaphragm Compressors Indispensable?

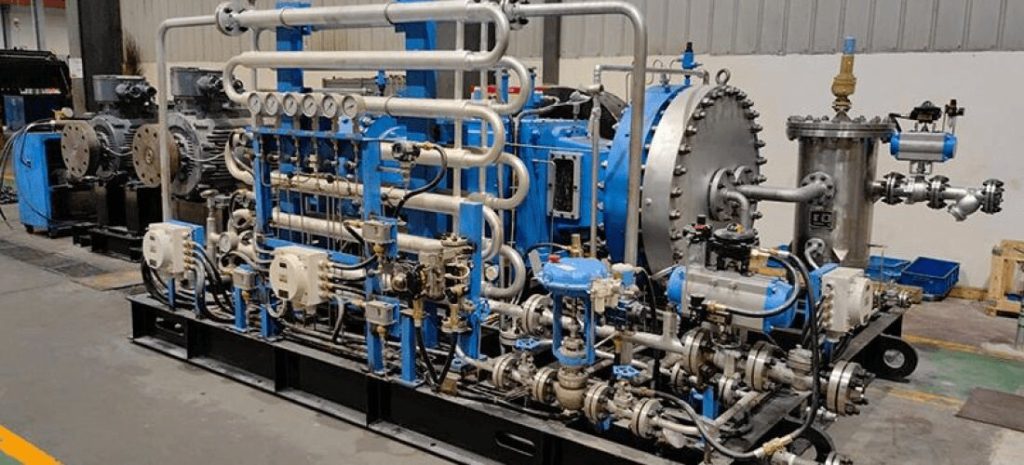

Diaphragm compressors stand out in industrial settings for their hermetic sealing design—a flexible diaphragm isolates the compression chamber from drive components, ensuring zero contact between the medium and lubricants or contaminants. This unique feature makes them the go-to choice for handling high-purity, toxic, flammable, or corrosive gases, where safety, purity, and reliability are non-negotiable.

Key Industrial Applications

Diaphragm compressors excel across critical sectors, solving unique gas-handling challenges:

1. Energy & Chemicals

- Hydrogen Compression: For green hydrogen production (electrolysis), fuel cell refueling stations, and hydrogen storage, where ultra-purity (99.999%+) and leak-tightness prevent explosion risks.

- Specialty Gases: Compression of chlorine, ammonia, or fluorinated gases, where corrosion resistance and zero emissions are mandatory.

2. Electronics & Semiconductors

- High-Purity Gas Delivery: Precise compression of ultra-clean gases (e.g., nitrogen, argon, silane) for wafer fabrication, ensuring no particle contamination that could ruin microchips.

3. Medical & Pharmaceutical

- Sterile Gas Handling: Compression of medical oxygen, nitrous oxide, or anesthesia gases, where the diaphragm’s inert materials (e.g., PTFE, Hastelloy) avoid chemical reactions and maintain sterility.

4. Food & Beverage

- Food-Grade Gas Processing: Compression of CO₂ for carbonation, nitrogen for packaging (to extend shelf life), with materials certified for food contact (FDA, EU 10/2011 compliance).

5. Environmental & Waste Treatment

- Toxic Gas Management: Safe compression of volatile organic compounds (VOCs) or hazardous emissions for capture and destruction, preventing environmental leaks.

Critical Selection Considerations

Choosing the right diaphragm compressor requires aligning technical specs with your operational needs:

1. Gas Properties

- Corrosiveness: Select diaphragm materials (e.g., Hastelloy for acids, PTFE for strong chemicals) and cylinder liners (ceramic, nickel alloys) to resist degradation.

- Purity Requirements: For semiconductors or pharmaceuticals, opt for oil-free designs with polished compression chambers to avoid particle shedding.

- Flammability/Explosivity: Ensure ATEX or IECEx certification for explosive environments, with integrated pressure relief valves and flame arrestors.

2. Pressure & Flow Needs

- Max Discharge Pressure: Diaphragm compressors handle up to 10,000 bar (ideal for high-pressure storage), but match your system’s required pressure (e.g., 350 bar for H₂ refueling).

- Flow Rate: Calculate gas demand (Nm³/h) to avoid undersizing (inefficiency) or oversizing (unnecessary energy costs).

3. Material Compatibility

- Diaphragm: Elastomers (EPDM) for low-pressure, non-corrosive gases; metal (titanium, stainless steel) for high-pressure, aggressive media.

- Valves & Seals: Use inert materials (e.g., PEEK, graphite) to prevent gas adsorption or reaction.

4. Reliability & Maintenance

- Diaphragm Lifespan: Check expected cycle life (e.g., 1-5 million cycles) to plan replacements and minimize downtime.

- Service Access: Prioritize designs with easy-to-reach components (valves, diaphragms) for quick maintenance—critical for 24/7 operations.

5. Compliance & Certifications

- International standards: ASME BPVC (pressure vessels), ISO 13485 (medical), CE PED (EU pressure equipment) to ensure global market acceptance.

Why Choose a Diaphragm Compressor?

In industries where gas purity and safety are mission-critical, diaphragm compressors deliver unmatched performance: no cross-contamination, minimal maintenance, and adaptability to the most challenging media.

Need help selecting a model for your application? MINNUO technical team specializes in customizing diaphragm compressors for hydrogen, specialty gases, and high-purity systems. Contact us today for a tailored solution.

Optimize your gas handling with precision—trust diaphragm compressors for reliability that scales with your industrial needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631