It is well known that in the field of compressed air, air compressors are indispensable equipment in industrial production. Among the many types of air compressors, scroll and screw air compressors are favored for their stability and efficiency. Both have their own advantages and disadvantages and are suitable for different application scenarios. This article will compare the differences between scroll and screw air compressors in detail to help you choose the most suitable compressed air solution.

Scroll and screw air compressors differ in working principles, performance differences, maintenance and costs, noise and applicable environments. Scroll air compressors are suitable for small applications and have the characteristics of low noise, oil-free and simple maintenance. Screw air compressors are suitable for industrial large flow requirements and have the advantages of strong power and high efficiency and stability. The selection of the two needs to be evaluated based on specific needs, such as gas volume, noise, operating costs and other factors to achieve the best economic benefits and production efficiency.

What are scroll and screw air compressors?

Scroll air compressor

Scroll air compressors compress gas through a pair of scroll disks. One scroll disk is fixed, while the other one orbits around it, forming multiple continuously changing air cavities, which gradually compress the gas and discharge it to the center. The scroll compressor has a relatively simple structure, continuous and pulsation-free air flow, and high efficiency, making it particularly suitable for medium and low pressure applications. Its lightweight design and quiet operation make it an ideal choice for many occasions that require clean compressed air.

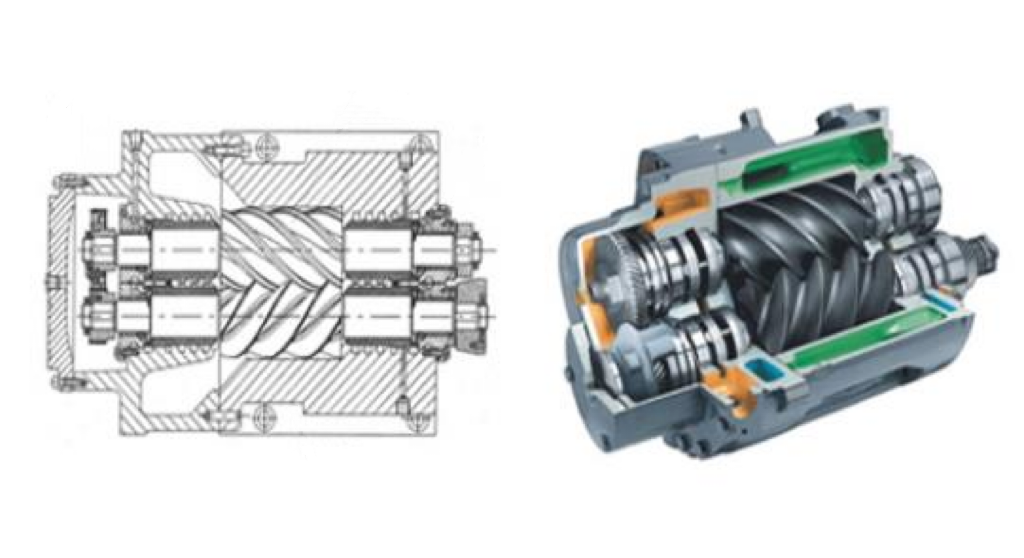

Screw air compressor

The core of the screw air compressor is composed of a pair of spiral rotors. Air enters between the spiral teeth from the suction end, and as the rotor continues to rotate, the gas is gradually compressed and discharged. Due to its unique rotor design, the screw air compressor has extremely high stability and can provide continuous and efficient compressed air for a long time. Its strong power and reliability make it particularly outstanding in industrial occasions that require large flow and high pressure.

Performance differences between scroll and screw air compressors

Exhaust volume and pressure

Screw air compressors have obvious advantages in exhaust volume and pressure, and can usually meet the gas demand of large and medium-sized factories, especially suitable for production processes that require continuous high-pressure gas sources. Scroll air compressors have a smaller exhaust volume and are suitable for applications with low air volume requirements, such as laboratory equipment and medical equipment. They pay more attention to a quiet working environment and a stable air supply.

Efficiency and energy saving

Under partial load conditions, scroll air compressors are generally more efficient than screw air compressors because they reduce the energy waste of over-compression. In addition, scroll compressors start quickly, which can effectively reduce energy consumption and achieve energy saving. Screw air compressors are most efficient when running at full load, and are particularly suitable for industrial environments with stable and continuous air volume and pressure requirements.

Maintenance and cost: Which is more worry-free?

Maintenance difficulty

Scroll air compressors have a simple structure and few moving parts, so they are very easy to maintain. Its daily maintenance mainly focuses on the cleaning of the filter element and cooling system, with a low failure rate, and it can be said to be very worry-free to use.

In contrast, the maintenance of screw air compressors is slightly more complicated. Since the rotor and other parts require precise coordination, lubricating oil replacement and seal inspection are required regularly. Although the maintenance cycle is long, the maintenance cost is relatively high. However, the high efficiency and powerful performance of screw compressors can usually make up for the complexity of maintenance.

Service life and operating costs

Screw compressors are generally designed to have a long life, can withstand high operating pressures, and are suitable for 24-hour continuous operation, especially for occasions that require long-term and efficient operation. However, it should be noted that it requires frequent lubricant replacement, which also increases certain operating costs. Scroll compressors, on the other hand, have a long service life and do not require lubricants during operation, so their operating costs are relatively low, making them a good choice for small applications.

Noise and applicable environment of scroll and screw compressors

Noise level

Scroll compressors usually have very low operating noise because there are no high-speed friction parts, making them suitable for environments with strict noise requirements, such as hospitals, laboratories and offices. In these occasions, a quiet working environment is extremely important, and the low noise characteristics of scroll compressors are undoubtedly one of their biggest highlights.

Screw compressors are relatively noisy. Although modern screw compressors reduce noise through soundproof covers and mufflers, they are still not suitable for noise-sensitive occasions. However, in industrial environments where noise requirements are not high but there is a large demand for compressed air, screw air compressors are still a good choice.

Applicable environment

Scroll air compressors are particularly suitable for industries with high requirements for compressed air cleanliness and environmental noise due to their low noise and oil-free design, such as medical, electronics and other fine manufacturing industries. Screw air compressors are widely used in environments that require large flow and continuous and stable air supply, such as manufacturing and chemical industries. They require strong compressed air support to ensure the stable operation of the production line.

Differences in technology and application scenarios between scroll and screw air compressors

Application scenarios of scroll air compressors

The structure and performance characteristics of scroll air compressors make them very suitable for small and medium-sized occasions, especially in the following applications:

Medical equipment

Due to the low noise and high air cleanliness of scroll compressors, they are widely used in various medical equipment in hospitals and clinics, such as ventilators, anesthesia machines, etc. In these environments, the quality of compressed air and the quiet operation of equipment are crucial.

Food and beverage industry

For food and beverage manufacturers, the cleanliness of compressed air is particularly critical. The oil-free characteristics of the scroll air compressor ensure the purity of the air without the risk of oil contamination, making it an ideal choice for food packaging and beverage filling.

Laboratory

The laboratory has high requirements for the stability and cleanliness of compressed air. The scroll air compressor has become an ideal equipment for laboratory compressed air supply with its low noise and oil-free advantages.

Application scenarios of screw air compressors

Screw air compressors are widely used in various industrial occasions, especially in environments where a large amount of compressed air is required and continuous operation is required. Specific applications include:

Manufacturing

In the automotive, machinery manufacturing and other industries, screw air compressors are one of the most common compressed air supply equipment. It can stably provide high-pressure, large-flow compressed air to ensure the efficient operation of the production line.

Chemical industry

Chemical production has strict requirements on the pressure and flow of compressed air. Screw air compressors have become an indispensable equipment in the chemical industry because they can continuously and efficiently output compressed air.

Construction industry

In construction, compressed air is often needed to drive various pneumatic tools, such as pneumatic picks and pneumatic hammers. Screw compressors have high output characteristics that can meet the needs of these tools and make construction more efficient.

Energy efficiency and environmental protection of scroll and screw compressors

Energy efficiency comparison

In terms of energy efficiency, scroll and screw compressors have their own advantages. Scroll compressors usually perform better under partial load because their design reduces sliding friction and energy loss. Screw compressors are most efficient under full load conditions and are suitable for those occasions where the demand for compressed air is stable and continuous.

Modern screw compressors have added variable frequency control technology, which can adjust the output of the compressor according to actual needs, thereby significantly improving energy efficiency under partial load. For companies that want to save energy costs, choosing a screw compressor equipped with a frequency converter is undoubtedly an efficient solution.

Environmental performance

Scroll compressors have a natural advantage in environmental protection due to their oil-free characteristics. In industries that require high clean air, the oil-free design avoids the risk of oil contamination and ensures the safety of products and processes.

Traditional screw compressors require lubricating oil to reduce friction, but with the improvement of environmental awareness, many manufacturers have begun to provide oil-free screw compressors. These devices reduce the impact on the environment while maintaining high efficiency, providing reliable solutions for industries with high requirements for air quality, such as food processing and pharmaceuticals.

Reliability and life of scroll and screw compressors

Reliability

Scroll compressors are usually very reliable due to their simple structure and few moving parts. Especially in small and medium-sized applications, scroll compressors have fewer failure points, and once a failure occurs, repairs are relatively simple and maintenance costs are low.

The structure of screw compressors is relatively complex, especially in terms of the precision of the rotor, and it is necessary to ensure its long-term stable operation. However, thanks to the use of high-strength materials and sophisticated design, screw compressors can also perform well in more demanding industrial environments and have extremely high reliability.

Life

Scroll compressors have a relatively long life due to the lack of complex friction parts. With simple regular maintenance, such as cleaning the air filter and cooling system, scroll compressors can run stably for many years, providing users with continuous and reliable compressed air.

Although screw compressors require more frequent maintenance and care, they are also designed to last a very long time. A well-maintained screw compressor can be used for decades, especially for industrial enterprises that require long-term investment and long-term stable operation.

Cost considerations: Which is more cost-effective, scroll or screw compressor?

Initial investment

The initial investment of a scroll compressor is usually lower than that of a screw compressor, especially for small applications. Its simple structure makes the manufacturing cost lower, suitable for small enterprises and laboratories with limited budgets.

Screw compressors usually have a higher initial investment because they use a more complex design and high-precision manufacturing process. However, considering its high efficiency and stability in large-flow compressed air applications, the long-term economic benefits of screw compressors are also very significant.

Operation and maintenance costs

Scroll air compressors do not require lubricating oil during operation, and daily maintenance is also very simple, which makes their operation and maintenance costs low, especially for those companies with low air source requirements and limited budgets. However, screw air compressors have relatively high operating costs because they need to regularly replace lubricating oil and maintain other precision parts. However, the high efficiency and stability of screw air compressors can usually reduce overall operating costs in long-term use, which is particularly suitable for industrial occasions that require high efficiency and long-term operation.

Market trends and selection suggestions for scroll and screw air compressors

Market trends

With the gradual increase in energy-saving and environmental awareness, the air compressor market is moving towards a more efficient and environmentally friendly direction. Variable frequency screw air compressors and oil-free scroll air compressors are gradually becoming the mainstream choice in the market. In addition, the introduction of intelligent control systems allows companies to monitor the operating status of air compressors in real time through Internet of Things technology, further improving management efficiency and equipment utilization.

For some industries that are sensitive to energy consumption, it is also a trend to choose screw air compressors equipped with energy recovery systems. These devices can recover the heat generated during the compression process and use it for other purposes, such as factory heating or hot water supply, further reducing operating costs.

Selection Recommendations

The choice between scroll and screw air compressors depends mainly on the specific application requirements. If your needs are concentrated in small flow, low noise, clean compressed air occasions, such as laboratories, medical equipment or food processing, then scroll air compressors are undoubtedly the best choice. If your company needs a high flow, continuous and stable compressed air supply, especially in large industrial occasions such as manufacturing and chemical industries, screw air compressors are more suitable for long-term investment and efficient operation.

In addition, for companies that pay special attention to operating costs, it is recommended to choose screw air compressors equipped with inverters, or oil-free scroll air compressors to reduce energy consumption and reduce environmental risks.

Conclusion

When choosing an air compressor, companies should evaluate it according to their specific needs, including air volume, pressure requirements, environmental noise, maintenance capabilities and budget. Of course, if you still find it difficult to make a decision, don’t worry, MINNUO can provide you with personalized customization services, and there are many suitable compressed air solutions for you to choose from to assist you in comprehensive consideration. After choosing MINNUO air compressor, you can not only improve production efficiency, but also effectively reduce operating costs and achieve the best economic benefits.