Walk through your factory. Do you hear it? That faint, hissing sound from a pipe joint? The gentle sigh from a disconnected hose? It might seem insignificant, but that sound is the sound of your profits escaping—literally.

Compressed air is one of the most expensive utilities in a plant. Generating a single cubic foot of compressed air requires a surprising amount of electricity. When that expensively produced air leaks into the atmosphere before it can do any work, you are flushing pure energy and cash straight down the drain. Industry studies show that an average of 20-30% of generated compressed air is lost to leaks, and in neglected systems, this can soar to 50%.

The good news? This is a problem with a clear, actionable solution. This guide provides a proven 5-step plan to take back control, slash your energy bills, and stop the silent profit killer.

The True Cost of a “Small” Leak (Visualized)

Before we dive in, let’s make the abstract tangible. The table below visualizes the shocking annual electricity waste (calculated at $0.12/kWh) caused by leaks of different sizes at typical industrial pressure (100 PSI / 7 bar):

| Leak Size (Orifice Diameter) | Equivalent to… | Approx. Annual Cost of Wasted Energy |

| 1/32 inch (0.8 mm) | A pin hole | $250 – $500 |

| 1/16 inch (1.6 mm) | A small nail | $1,000 – $1,500 |

| 1/8 inch (3 mm) | A thick wire | $2,500 – $3,500 |

| 1/4 inch (6 mm) | A pencil diameter | $8,000 – $10,000+ |

Now, consider the number of potential leak points in your facility. The numbers add up fast, making leak management one of the highest-return activities your maintenance team can undertake.

Industry-Specific Leak Challenges

- Automotive Parts Manufacturing: Frequently used quick-connects, pneumatic clamps, and robot grippers are major leak sources, with vibration accelerating wear.

- Food & Beverage Processing: Strict hygiene requirements lead to frequent disassembly and cleaning of lines and valves, increasing the risk of seal failure.

- Plastics & Injection Molding: Thermal cycling and humid environments accelerate seal aging, while mold cooling air line leaks are often overlooked.

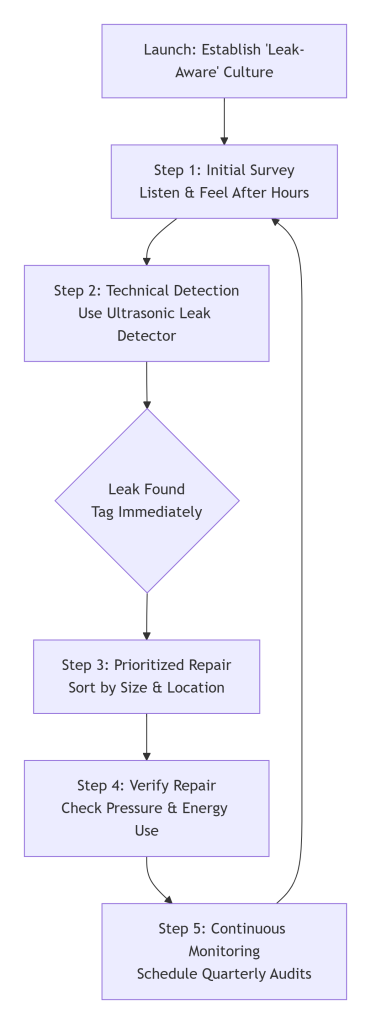

Your 5-Step Leak Detection & Repair Plan (Visualized)

To help you quickly grasp and execute, here is the complete leak management process summarized in a flowchart:

Step 1: Awareness & Preparation

You can’t fix what you don’t know exists. The first step is to recognize that leaks are a continuous battle, not a one-time fix.

- Action: Educate your team. A single leak can cost more in a year than a worker’s annual salary. Create a culture where reporting a leak is seen as valuable, not as a criticism.

Step 2: The Initial Survey (Listen & Feel)

A comprehensive leak detection program starts with a simple after-hours survey.

- Action: When your production floor is quiet, walk the entire compressed air system.

- Listen: Listen closely for the tell-tale hissing or whistling sounds. Quiet sections of your plant are ideal for this.

- Feel: Carefully run your hand along connections, hoses, and fittings. A leak will often feel cold due to the rapid expansion of air.

Step 3: Advanced Detection with Ultrasonic Technology

Many leaks are inaudible to the human ear or are drowned out by ambient noise. This is where technology becomes your best friend.

- How to Choose an Ultrasonic Leak Detector? Focus on sensitivity, directionality, signal filtering, and display type. Industrial-grade models with headphones and LED/decibel displays are preferred. Ensure the tool is recommended for compliance with energy management standards like ISO 50001.

Action: Use an ultrasonic leak detector to comprehensively scan all fittings, valves, hoses, and receivers. Tag every leak you find with a bright, numbered tag. This creates a visual “punch list” for repair and allows you to track the scale of the problem.

Step 4: Prioritize & Repair

Not all leaks are created equal. Focus your efforts where they will have the greatest financial return.

- Action: Use your leak tags and the cost table above to create a prioritized repair list. Larger leaks and those on high-pressure lines should be fixed first. Common culprits include:

- Couplings, hoses, and fittings

- Pressure regulators

- Shut-off and drain valves

- Pipe joints and threaded connections

- Worn tool actuators

Step 5: Implement a Continuous Monitoring Program

Leaks will inevitably reoccur. A one-time repair blitz is not enough.

- Action: Schedule quarterly or bi-annual leak surveys using your ultrasonic detector. Integrate this task into your preventive maintenance work orders. This turns leak management from a reactive cost into a proactive, budgeted profit-saving activity.

Case in Point: A Packaging Plant’s $15,000 Wake-Up Call

- Challenge: A mid-sized packaging plant was experiencing frequent pressure drops, forcing their 100 HP compressor to run almost constantly. Energy bills were soaring.

- Action: They conducted their first formal leak audit using an ultrasonic detector.

- Result: The team found and tagged 87 individual leaks. After a focused repair campaign, the compressor’s load factor dropped significantly. The project cost $2,500 in labor and parts but resulted in annual energy savings of over $15,000, paying for itself in just two months.

Frequently Asked Questions

Q1: How often should we look for leaks?

A1: For most facilities, a formal survey with an ultrasonic detector should be conducted at least every quarter. High-humidity environments or systems with significant vibration may require more frequent checks.

Q2: Is it worth fixing very small leaks?

A2: Absolutely. While a single small leak may not seem significant, the cumulative effect of dozens of small leaks can be enormous. A “zero-tolerance” policy for leaks is the most cost-effective approach.

Q3: We fixed the leaks, but our compressor still seems to run a lot. Why?

A3: Fixing leaks reduces “artificial demand,” but your compressor may still be sized incorrectly or controlled inefficiently. Reducing leaks is the essential first step before optimizing compressor control (e.g., adjusting pressure bands, implementing VSDs).

Conclusion: Turn Off the Tap on Wasted Money

Compressed air leaks are not a maintenance nuisance; they are a severe financial drain. By implementing a disciplined, ongoing leak management program, you transform a hidden cost into a direct contributor to your company’s profitability. The path to savings is clear: detect, tag, repair, and repeat.

Ready to Stop Flushing Money Down the Drain?

A proactive leak management strategy is one of the smartest investments you can make in your operational efficiency. While a DIY approach is a great start, achieving and maintaining a truly leak-free system often benefits from expert insight and the right tools.

Contact MINNUO’s compressed air specialists today. Our experts can provide guidance on selecting the right detection tools, establishing a compliant monitoring program, and implementing a lasting solution to secure your operational profits.

Email

Email sales:+86 15366749631

sales:+86 15366749631