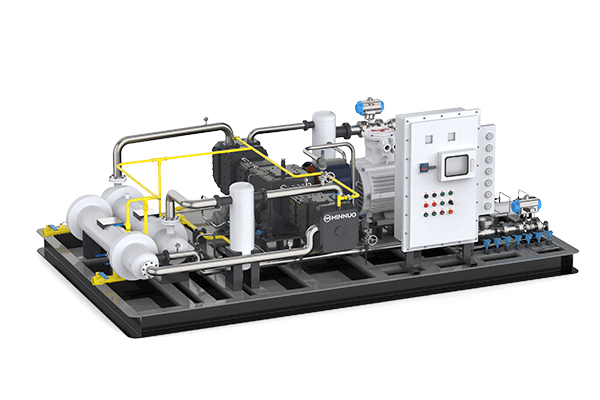

Air compressors are the “power workhorses” for factory production, mechanical processing, construction, and more. However, many users overlook maintenance, leading to frequent equipment failures, soaring energy consumption, and even premature retirement. Industry data shows that regularly maintained air compressors can extend their service life by over 30% and reduce annual maintenance costs by 40%. To help you maintain your equipment efficiently, below are actionable maintenance tips—covering daily checks to core upkeep—tailored to the full lifecycle of your air compressor.

I. Daily Inspection: 5 Minutes a Day to Avoid 80% of Minor Failures

Daily checks require no complex tools. Focus on four key indicators: oil, pressure, temperature, and leaks. We recommend adding these to your daily equipment checklist:

- ✔️ Oil Level Check: Inspect the oil level gauge to ensure the oil level stays between the “MIN” and “MAX” marks (critical for screw air compressors). Too little oil causes insufficient lubrication and bearing wear; too much oil may overload the oil-air separator and trigger abnormal oil consumption.

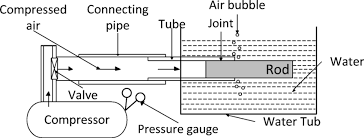

- ✔️ Pressure & Flow Monitoring: Observe the pressure gauge and flowmeter to confirm the discharge pressure and pressure difference (the pressure difference across the oil-air separator should be ≤ 0.15 MPa) match your operational needs. If pressure drops suddenly or fluctuates, check for pipeline leaks or valve malfunctions.

- ✔️ Temperature Monitoring: Ensure the compressor body temperature (≤ 95°C) and discharge temperature (≤ 105°C for screw compressors, ≤ 120°C for reciprocating compressors) stay within normal ranges. Excessive temperature may indicate a blocked cooling system or ineffective lubricating oil—stop the machine immediately for inspection.

- ✔️ Leak Detection: Apply soapy water to pipe joints, valves, and flanges. If bubbles form, tighten connections or replace seals promptly. Even small leaks can waste 5%–10% of compressed air daily, leading to significant long-term energy loss.

II. Regular Core Maintenance: Follow Schedules to Extend Equipment Lifespan

Maintenance cycles vary slightly for different compressor types (screw, reciprocating, centrifugal). Below are general core tasks and recommended intervals—adjust based on your equipment manual:

1. Lubricating Oil: Replace Every 2,000–4,000 Operating Hours (or by Oil Quality)

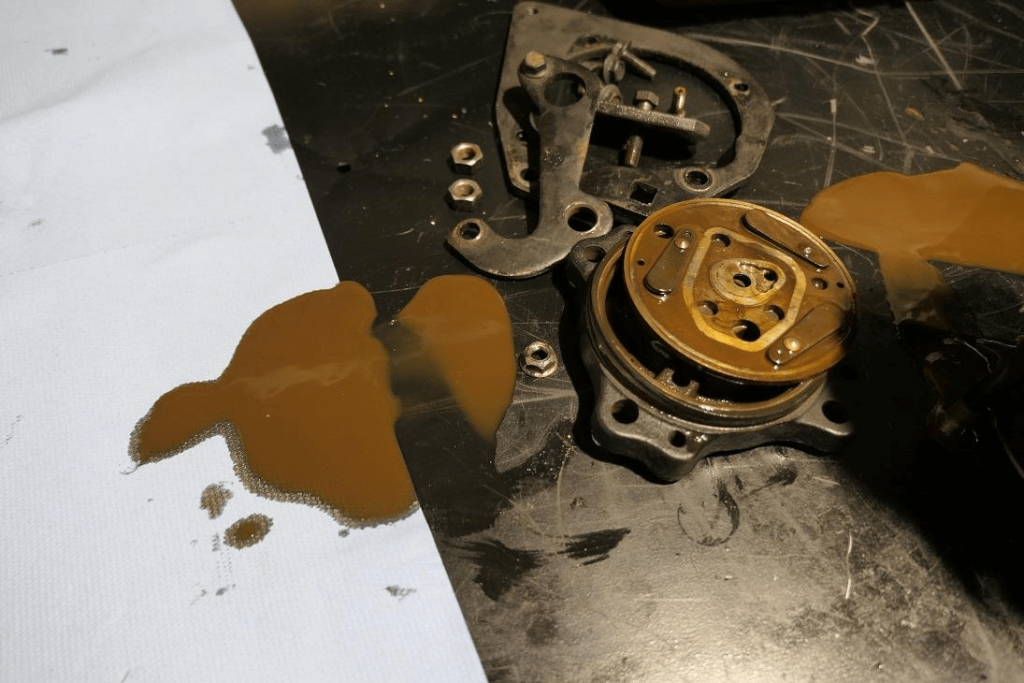

- Replacement Standard: Replace the oil if it turns dark brown, contains impurities, or its viscosity drops significantly—even if the cycle hasn’t ended.

- Oil Selection: Use dedicated air compressor oil for screw compressors (avoid ordinary motor oil, which causes carbon buildup and clogs the oil-air separator). For low-temperature environments (≤ 5°C), choose antifreeze lubricating oil to prevent solidification.

- Replacement Steps: After stopping the machine, wait for the oil temperature to drop to 40–50°C. Drain the old oil, clean the oil sump, and add new oil—never mix old and new oil, as this impairs lubrication.

2. Filter Elements: Replace Three Key Filters Regularly to Avoid “Clogging & Energy Waste”

| Filter Type | Recommended Replacement Cycle | Risks of Clogging | Replacement Notes |

| Air Inlet Filter | Every 1,000–2,000 hours | Insufficient air intake, 15%+ higher energy consumption, accelerated airend wear | Prevent dust from entering the air intake during replacement |

| Oil Filter | Every 2,000–4,000 hours | Contaminated oil, leading to bearing/rotor wear | Bleed air from the oil circuit after replacement |

| Oil-Air Separator Filter | Every 4,000–6,000 hours | Excessive oil content in compressed air, damaging downstream equipment | Check the pressure difference after replacement (ensure ≤ 0.02 MPa) |

3. Cooling System: Clean Every 3 Months to Prevent “Overheating Shutdowns”

- Air-Cooled Compressors: Clean dust from cooling fans and heat sinks (use compressed air to blow off dust—avoid direct water 冲洗 on the motor) to ensure smooth ventilation.

- Water-Cooled Compressors: Regularly check cooling water quality (use softened water to prevent scale). Clean the cooler pipes every 6 months to avoid scale buildup, which reduces heat dissipation efficiency.

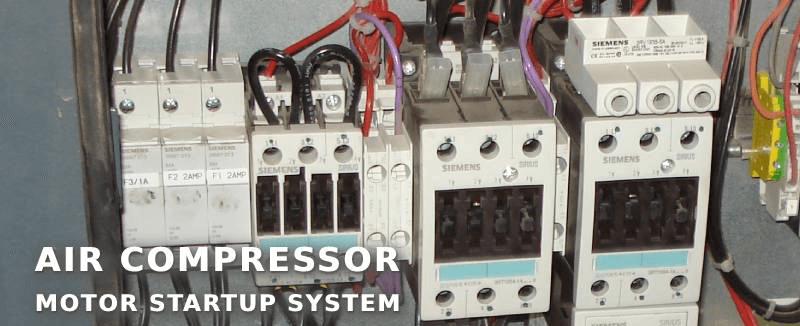

4. Motor & Electrical System: Inspect Every 6 Months to Prevent Risks

- Tighten motor terminal connections and check insulation resistance (≥ 1 MΩ) to avoid motor burnout from loose wiring.

- Clean dust from electrical cabinets and inspect contactor/relay contacts for oxidation. Replace parts with signs of burning immediately.

III. Environmental Maintenance: Create a “Good Environment” for Your Compressor to Reduce Hidden Wear

The operating environment directly affects the compressor’s lifespan. Pay attention to these 3 points:

- ✔️ Good Ventilation: Reserve ≥ 1.5 meters of space around the equipment to avoid temperature buildup in enclosed areas (especially in summer—every 10°C increase in ambient temperature raises compressor energy consumption by ~5%).

- ✔️ Dust Prevention: Keep the compressor away from dusty, wood-chip, or oil-mist-heavy areas (e.g., woodworking shops, welding stations). If unavoidable, install a secondary dust cover at the air intake to reduce air filter clogging.

- ✔️ Moisture & Corrosion Prevention: In humid environments (e.g., basements, outdoor areas during rainy seasons), elevate the compressor base to prevent water damage. For coastal areas, choose compressors with anti-corrosion coatings to avoid salt-induced rust.

IV. Fault Warning: Never Ignore These Signs—Address Them Promptly to Avoid Major Repairs

Stop the machine immediately and troubleshoot if you notice these abnormalities (to prevent minor issues from escalating):

- ⚠️ Unusual Noises: Metallic scraping noises or high-pitched squealing during operation may indicate bearing wear, rotor jamming, or abnormal gear meshing.

- ⚠️ Severe Oil/Gas Leaks: Persistent leaks at pipe joints or heavy oil leakage from the oil-air separator require seal replacement or damaged part repair.

- ⚠️ Sudden Pressure/Temperature Changes: A sudden drop in discharge pressure (excluding load changes) or temperature exceeding 110°C may signal valve failures or cooling system malfunctions.

V. Professional Maintenance: Avoid “DIY” Mistakes—Hire Qualified Teams for Complex Tasks

For overhauls of core components (e.g., airend rotors, bearings, frequency converters), do not attempt DIY repairs. Contact certified service providers:

- Major Airend Overhaul (Every 20,000–30,000 Hours): Qualified technicians should disassemble and inspect rotor clearances (typically ≤ 0.1 mm for screw compressors) and adjust or replace bearings to ensure precision.

- Frequency Converter Maintenance: Have professionals test output voltage and current to avoid motor failures from incorrect parameter settings.

Conclusion: Maintenance Is Not a “Cost”—It’s an “Investment”

A high-quality air compressor can last 8–10 years, but only with scientific maintenance. By spending 5 minutes daily on inspections, performing regular core maintenance, and optimizing the operating environment, you can reduce downtime, cut repair costs, and keep your compressor running efficiently—providing stable power for your production.

If you’re unsure how to create a maintenance plan or need professional support, contact our technical team MINNUO. We offer customized maintenance plans and 24/7 emergency repair support worldwide—making it easier for your air compressor to “serve reliably”!

Email

Email sales:+86 15366749631

sales:+86 15366749631