Hydrogen production by water electrolysis is a clean and sustainable way to produce hydrogen. In recent years, it has attracted much attention due to its huge potential in renewable energy. With the increasing global demand for clean energy, hydrogen production by water electrolysis has gradually become an important part of energy transformation. This article will give you an in-depth understanding of the development status and technical routes of hydrogen production by water electrolysis, and analyze its advantages, challenges and future prospects.

Hydrogen production by water electrolysis is a process of decomposing water into hydrogen and oxygen by electrolyzing it. Although it is currently facing technical and economic challenges, with the advancement of technology and policy support, hydrogen production by water electrolysis will surely occupy an important position in the future energy structure. We believe that through continuous technical optimization and cost reduction, hydrogen production by water electrolysis will promote global energy transformation and inject strong impetus into achieving carbon neutrality goals.

Principle of hydrogen production by water electrolysis

The principle of hydrogen production by water electrolysis is actually not complicated: it uses direct current to decompose water (H₂O) into hydrogen (H₂) and oxygen (O₂), just like “tearing” water to release two elements. This process requires electrical energy, and the chemical reaction formula is very simple:

2H₂O → 2H₂ + O₂

In the electrolyzer, water molecules decompose into oxygen and release electrons at the anode, while hydrogen is produced and electrons are accepted at the cathode. All this seems simple, but it is full of challenges in actual operation. The biggest highlight of water electrolysis for hydrogen production is its high-purity hydrogen output, especially when the electricity comes from renewable energy (such as wind or solar energy), the whole process is basically zero carbon emission, realizing true green hydrogen production.

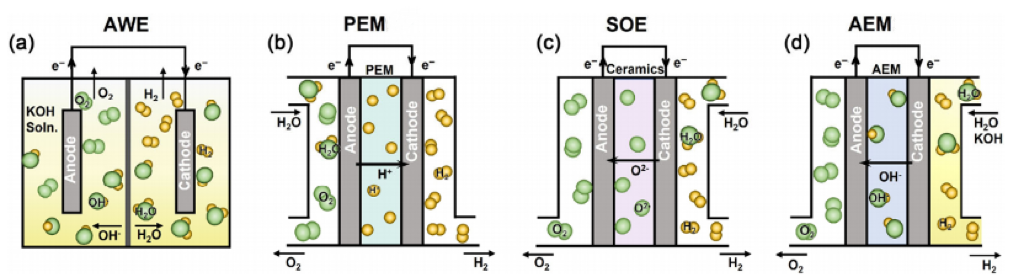

Technical route of water electrolysis for hydrogen production

At present, there are four main technical routes for hydrogen production by water electrolysis: alkaline electrolysis (AWE), proton exchange membrane electrolysis (PEM), solid oxide electrolysis (SOE) and anion exchange membrane electrolysis (AEM). Each technology has unique advantages and application scenarios. Let us learn about them one by one.

Alkaline water electrolysis (AWE)

Alkaline water electrolysis is the oldest and most mature method of water electrolysis for hydrogen production. It uses alkaline electrolyte (usually potassium hydroxide solution) as electrolyte to produce hydrogen and oxygen through electrochemical reactions of electrodes. The advantage of AWE is that the equipment structure is simple and the cost is relatively low, but its energy consumption is high, the operating temperature is between 60-80℃, and the efficiency is not the highest.

Electrodes in alkaline electrolyzers are usually made of nickel or nickel alloys, which have good corrosion resistance and stability, so AWE is widely used in industrial hydrogen production. However, its system is large and has low current density, which is not enough to cope with fluctuating power and rapid load changes.

Proton exchange membrane electrolysis (PEM)

Proton exchange membrane electrolysis uses a solid polymer proton exchange membrane (PEM) as an electrolyte, which has significant advantages in electrolysis efficiency. PEM electrolysis systems are compact, efficient, can operate at higher current densities, and have very fast response speeds, making them very suitable for combining with unstable renewable energy sources such as wind and solar energy.

However, PEM technology also has its “Achilles heel”, that is, the use of expensive precious metal catalysts (such as platinum and iridium), which greatly increases production costs. In recent years, researchers have made a lot of progress in reducing the amount of catalysts and finding alternative materials, hoping to make PEM hydrogen production more affordable.

Solid Oxide Electrolysis (SOE)

Solid oxide electrolysis is a high-temperature electrolysis technology, usually carried out at high temperatures of 700-1000℃. SOE electrolysis is operated through a solid oxide electrolyte. Its biggest feature is high energy efficiency, especially when combined with industrial waste heat, which can significantly reduce electricity consumption.

SOE has the potential for high efficiency, but high-temperature operation places strict requirements on materials: they must be resistant to high temperatures, corrosion, and have good long-term stability. This is why SOE, although promising, is still in the development and verification stage and still has a long way to go before large-scale commercial applications.

Anion Exchange Membrane Electrolysis (AEM)

Anion exchange membrane electrolysis (AEM) is an emerging water electrolysis hydrogen production technology that combines the advantages of alkaline water electrolysis and proton exchange membrane electrolysis. AEM uses anion exchange membrane as an electrolyte, and the electrolyte conducts anions (such as hydroxide ions) instead of protons. This method does not require the use of expensive precious metal catalysts, so it has a cost advantage over PEM.

An important feature of AEM electrolysis is that it can achieve efficient hydrogen production at a relatively low cost, which is particularly suitable for distributed hydrogen production applications in combination with renewable energy. However, AEM technology is still in the research and development stage, and the main challenges it faces include the long-term stability and durability of membrane materials. How to improve electrolysis efficiency and extend equipment life is the key to future development.

Current status of water electrolysis hydrogen production

With the increasing emphasis on renewable energy, water electrolysis hydrogen production technology is also constantly improving. In particular, PEM and AWE have entered the commercialization stage and are widely used in hydrogen production and energy storage. More and more companies and research institutions are investing in the research and development of water electrolysis hydrogen production technology, hoping to accelerate the popularization of hydrogen energy by improving efficiency and reducing costs.

Governments of various countries are also promoting the development of water electrolysis hydrogen production through policies. For example, the European Union proposed in its “Hydrogen Strategy” that by 2030, large-scale deployment of water electrolysis hydrogen production equipment will be carried out to promote green energy transformation. China is also formulating a hydrogen energy development plan, incorporating it into the national energy strategy, and building multiple green hydrogen production bases.

Advantages of water electrolysis hydrogen production

Clean and environmentally friendly

The biggest advantage of water electrolysis hydrogen production is environmental protection. When electricity comes from renewable energy, the entire process is almost zero carbon emissions, which is true “green hydrogen energy” and has great appeal in achieving the goal of zero carbon emissions.

High-purity hydrogen

Compared with other hydrogen production methods, the hydrogen produced by water electrolysis is extremely pure, which is particularly suitable for applications with strict requirements on hydrogen purity, such as fuel cells and the electronics industry.

Strong flexibility

The water electrolysis hydrogen production system can flexibly adjust the production volume according to the fluctuation of power supply, which gives it a natural advantage in combination with intermittent renewable energy, and can effectively absorb excess electricity and help the power grid to operate stably.

Modular design

Especially PEM electrolysis equipment, its modular characteristics make it easy to expand, whether it is centralized or distributed hydrogen production, PEM can easily do it.

Technical Challenges of Hydrogen Production by Water Electrolysis

Although hydrogen production by water electrolysis is full of potential, its large-scale application still faces many challenges.

High cost problem

Currently, one of the biggest obstacles to hydrogen production by water electrolysis is the high cost, especially the precious metal catalysts used in PEM. How to reduce the use of these materials or find effective alternatives is a focus of current research and development.

Renewability of power sources

Whether hydrogen production by water electrolysis is truly green depends on the source of electricity used. If fossil fuels are used for power generation, the carbon emissions of the entire hydrogen production process cannot be ignored. Therefore, closely combining water electrolysis with renewable energy power generation is the key to achieving truly green hydrogen energy.

Durability and stability

Water electrolysis systems need to remain stable in long-term operation, especially PEM and SOE technologies. Under high temperature and high pressure environments, the life and performance of membrane materials and other components are key factors affecting economics.

Equipment integration and scale-up

Effective integration of water electrolysis equipment with power grids, renewable energy power generation equipment, and hydrogen storage facilities to ensure that the entire system can operate efficiently and reliably still requires a lot of optimization and testing.

Application prospects of hydrogen production by water electrolysis

With the rapid development of the hydrogen economy, hydrogen production by water electrolysis has shown great application potential in various fields.

Industrial hydrogen

In traditional industries such as chemical and metallurgical industries, hydrogen is an indispensable raw material. Today, hydrogen production by water electrolysis can be used as a clean alternative to reduce carbon emissions in these industries, thereby helping to achieve carbon neutrality goals.

Transportation fuel

Hydrogen fuel cell vehicles are seen as an important part of future green transportation. Hydrogen production by water electrolysis can provide clean hydrogen for these vehicles, and fuel cell vehicles have advantages such as long driving range and short hydrogen refueling time, which are a powerful supplement to internal combustion locomotives and electric vehicles.

Energy storage and peak shaving

Renewable energy such as wind and solar energy is volatile, and hydrogen production by water electrolysis can convert excess renewable energy into hydrogen for storage and release it during peak electricity demand periods, thereby helping to achieve energy peak shaving and stabilize grid operation.

Home and community energy supply

In the future, distributed hydrogen production by water electrolysis can even enter homes and communities. By combining solar power generation with water electrolysis, hydrogen can be used for household electricity, heating and fuel, forming a small, independent clean energy system.

Development prospects and strategies for hydrogen production by water electrolysis

In order to truly realize large-scale commercial application of hydrogen production by water electrolysis, the following challenges need to be overcome:

Technological progress and cost reduction

Continuous technological innovation is the key to reducing the cost of hydrogen production by water electrolysis. For example, developing new catalyst materials to reduce dependence on precious metals or improving the energy efficiency of the system are important means to reduce production costs.

Policy support and industrial chain construction

Government policy support plays an important role in promoting the development of hydrogen production by water electrolysis. Through incentives such as subsidies and tax incentives, companies can be encouraged to increase investment and R&D efforts. In addition, the improvement of the hydrogen energy industry chain is also crucial. From equipment manufacturing, hydrogen storage and transportation to terminal applications, all links need to work closely together.

Combination with renewable energy

Closely combining water electrolysis with renewable energy such as wind and solar energy can achieve true green hydrogen production. Through the integrated wind, solar and hydrogen system, the utilization rate of renewable energy can be improved, the pressure on the power grid can be relieved, and the energy system can be optimized.

Large-scale and commercial application

With the advancement of technology and the reduction of costs, water electrolysis hydrogen production needs to enter the stage of large-scale commercial application. Through large-scale production, the cost can be further diluted to achieve the dual benefits of economy and environmental protection. In hydrogen energy demonstration cities and industrial parks, water electrolysis hydrogen production equipment will become an important infrastructure.

Future potential of hydrogen energy and the development of water electrolysis hydrogen production

Hydrogen energy is undoubtedly an important part of the future energy system, and water electrolysis hydrogen production is one of the core technologies for realizing the green hydrogen supply chain. Whether in the production, storage, transportation, or practical application of hydrogen, water electrolysis hydrogen production plays an indispensable role.

Globally, many countries and regions have formulated detailed hydrogen energy development roadmaps. The European Union proposed to deploy 40GW of water electrolysis hydrogen production capacity by 2030, and China is also building multiple large-scale water electrolysis hydrogen production projects to promote the industrial application and large-scale development of hydrogen energy. In the future, with the continuous advancement of new material technology and electrolysis process, the cost of water electrolysis hydrogen production will be further reduced, and the efficiency will continue to improve, laying a solid foundation for the large-scale promotion of hydrogen energy.

Conclusion

In the future, hydrogen production by water electrolysis will not only become an important pillar of the hydrogen energy economy, but also a core link in the global clean energy system. On this road ahead, technological innovation, policy support and industrial collaboration are the keys to achieving breakthroughs. As humans continue to overcome challenges in the field of clean energy, the bright prospects of hydrogen production by water electrolysis are already expected, injecting new impetus into achieving a global zero-carbon future.If you want to know more about hydrogen production, please pay attention to MINNUO official website, we will provide you with the most perfect air solution.

Email

Email sales:+86 15366749631

sales:+86 15366749631