A noisy air compressor is more than a workplace nuisance; it’s a health hazard that can lead to hearing damage, increased stress, and reduced productivity. High noise levels also often indicate vibration and inefficiency, signaling wasted energy and potential mechanical issues.

Significant noise reduction is achievable through a combination of strategic upgrades and best practices. This guide breaks down the primary sources of compressor noise and provides actionable, tiered solutions—from low-cost fixes to professional installations—to help you reclaim a quieter, safer, and more efficient workshop.

Understanding the 3 Main Noise Sources

To fix the noise, you must first identify its origin.

- Intake/Exhaust Noise (Airborne): The loud “sucking” and “blowing” sound as air moves through the intake filter and out of the cooling fan or exhaust. This is often the dominant high-frequency noise.

- Mechanical & Vibration Noise (Structure-Borne): The “rumble” and “clatter” from the motor, pump, and moving parts. Vibration transfers noise directly into the floor and building structure.

- Radiation from the Casing: The metal cabinet of the compressor acts like a speaker, amplifying internal mechanical and pulsation noises.

Tiered Solutions: From Simple Fixes to Professional Upgrades

Tier 1: Low-Cost, Immediate Actions (The Foundation)

These steps address fundamental issues and should be done first.

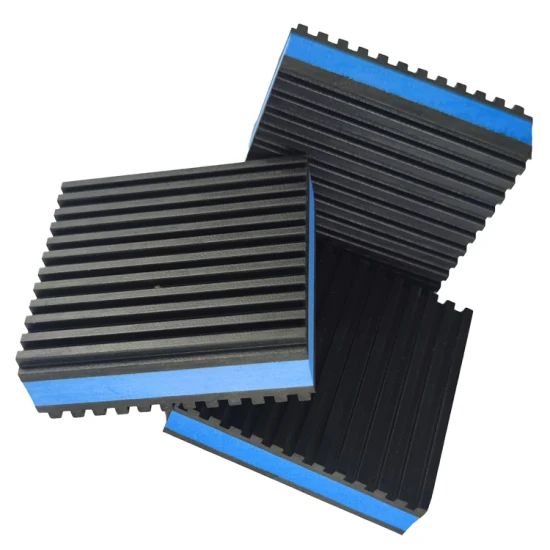

- Secure and Isolate: Ensure all panels and access doors are tightly fastened. Loose parts create rattles. Place the compressor on heavy-duty anti-vibration pads (neoprene or cork) to decouple it from the floor. Never bolt it directly to the concrete.

- Improve Air Intake: The standard intake filter is a major noise source. Install an intake silencer or a remote intake kit. This involves running a hose or pipe from the compressor intake to a quieter location (outside or a separate room) and/or using a specially designed muffler filter.

- Check for Wear: Unusual knocking or grinding noises indicate mechanical problems (worn bearings, loose rods) that must be repaired by a technician. Quieting a failing compressor masks a bigger issue.

Tier 2: Effective Mid-Range Upgrades (Targeted Reduction)

If Tier 1 isn’t enough, these upgrades offer significant improvement.

- Acoustic Enclosure: The most effective single upgrade for stationary compressors. A well-designed compressor acoustic enclosure is a box lined with sound-absorbing foam (mineral wool or acoustic melamine) with baffled vents for airflow.

- Key Principle: Enclosures must allow for adequate cooling air flow. Never operate a compressor in a sealed box.

- DIY Option: Build a frame with MDF/plywood and line it with 2-inch acoustic foam. Ensure large, louvered vents on opposite sides.

- Upgrade the Exhaust: If your compressor has a separate cooling air exhaust, fit it with a ducted exhaust silencer or flexible ducting to direct hot, noisy air outside the workspace.

- Piping Isolation: Use flexible braided hose connectors on the air outlet and any water lines. This prevents vibration from the compressor from being transmitted into the rigid piping system, which acts like a large noise radiator.

Tier 3: Professional & System-Level Solutions (Maximum Quiet)

For environments with strict noise limits or compressors in sensitive areas.

- Dedicated Compressor Room: The gold standard. Build a separate room with mass-loaded vinyl (MLV) walls, acoustic door seals, and proper forced ventilation. This contains noise at the source.

- Vibration Isolation Foundation: For large industrial compressors, install a floating concrete inertia block on spring isolators. This prevents low-frequency vibration from traveling through the building.

- Replace with a Quiet(er) Compressor: If your current unit is old and inherently loud (e.g., a piston compressor), upgrading to a modern oil-injected screw compressor or a scroll compressor can result in a dramatic noise reduction (e.g., from 90 dB(A) to 70 dB(A)).

Noise Reduction by Compressor Type: What to Expect

| Compressor Type | Typical Noise Level | Primary Noise Source | Best Reduction Strategy |

| Small Piston | 75-90+ dB(A) | Intake & Mechanical Vibration | Intake Silencer + Enclosure + Vibration Pads |

| Large Piston | 85-95+ dB(A) | Mechanical Vibration & Exhaust | Dedicated Room or Heavy-Duty Enclosure |

| Screw Compressor | 70-75 dB(A) | Intake & Cooling Fan | Intake Silencer + Acoustic Enclosure |

| Scroll Compressor | 60-68 dB(A) | Very low overall | Often requires only minor isolation; ideal for noise-sensitive areas. |

FAQ: Quieting an Air Compressor

Q1: How loud is too loud for an air compressor?

A1: Prolonged exposure to noise above 85 dB(A) can cause hearing damage. If you have to raise your voice to have a conversation near the compressor, it’s likely above this level and requires hearing protection and noise control measures. OSHA and other regulators have strict limits for workplace noise exposure.

Q2: Can I just build a box around my compressor?

A2: Yes, but with critical caveats. The enclosure must:

- Be made of dense material (MDF, plywood).

- Be lined with non-flammable, heat-resistant acoustic foam.

- Have significantly larger ventilation openings than you think to prevent overheating. Calculate the required airflow based on the compressor’s kW rating.

- Allow for easy access for maintenance.

Q3: Will a longer air hose from the compressor to my tool make it quieter?

A3: No, not for the compressor itself. The hose only reduces noise at the tool by moving you farther away. The compressor unit will still be just as loud at its location. To reduce source noise, you must treat the compressor.

Q4: My compressor is outside. How can I reduce noise for my neighbors?

A4: Use a weatherproof acoustic enclosure designed for outdoor use. Ensure it has corrosion-resistant materials, roof ventilation, and a proper drain. Also, consider positioning the unit away from property lines and using existing walls or fences as noise barriers.

Conclusion: Quiet is a Feature of Good Design

Reducing air compressor noise is a systematic process: isolate vibration, silence air flow, and contain radiated sound. Start with the simple, foundational fixes—they are often the most cost-effective. For persistent noise, targeted investments in intake silencers and enclosures yield excellent returns in comfort and compliance.

Remember, excessive noise is frequently a symptom of inefficiency or wear. A quieter compressor is often a sign of a healthier, better-maintained, and more energy-efficient system.

Need help diagnosing the source of your compressor noise or designing an effective silencing solution? Contact the MINNUO engineering team. We can recommend the right combination of silencers, enclosures, and isolation products tailored to your specific compressor model and workspace layout.

Email

Email sales:+86 15366749631

sales:+86 15366749631