In a craft brewery, compressed air is the silent workhorse behind quality, consistency, and efficiency. From aerating wort to driving canning lines, it touches the product directly or indirectly at multiple stages. Using the wrong type of air compressor can introduce oil contamination, off-flavors, and spoilage microorganisms, risking your entire batch.

Choosing a brewery air compressor isn’t just about CFM; it’s about air quality, reliability, and matching the technology to specific, sensitive processes. This guide walks you through each point of use in your brewery, detailing the exact air requirements to help you specify a system that protects your beer and supports your growth.

The Non-Negotiable Rule: Oil-Free Air

In food and beverage production, ISO 8573-1 Class 0 certification for oil content is the gold standard. For breweries, it’s essential.

- Why: Even “food-grade” lubricated compressors produce microscopic oil aerosols. These can be carried downstream, contaminating tanks, kegs, and cans, causing persistent off-flavors and aromas.

- The Solution: Invest in a true oil-free air compressor (e.g., oil-free scroll or oil-free screw). Alternatively, a high-quality oil-lubricated compressor with absolute (coalescing & activated carbon) filtration can achieve the necessary purity, but adds maintenance complexity and risk.

Point-of-Use Breakdown: Air Requirements in the Brewery

1. Wort Aeration / Oxygenation

- Process: Injecting oxygen into cooled wort before pitching yeast for healthy fermentation.

- Air Quality Needed: Sterile, oil-free oxygen. This is so critical that most breweries use dedicated oxygen generators or bottled oxygen, not general plant air. The gas must be 0.01 micron filtered and sterile.

- Compressor Role: If using an on-site PSA oxygen generator, it will require a clean, dry compressed air feed.

2. Pneumatic Valves & Actuators (Brew House, Tanks)

- Process: Automating grain gates, mash rakes, tank valves, and CIP systems.

- Air Quality Needed: Dry, oil-free plant air (ISO 8573-1 Class 2.4.1 or better). Moisture causes valves to stick and corrode.

- Flow Demand: Low to moderate CFM, but continuous availability is critical for automation.

3. Carbonation (In-Line or in Tank)

- Process: Injecting CO₂ into beer. While the gas is CO₂, the control systems and pneumatic pumps are often driven by compressed air.

- Air Quality Needed: Ultra-dry, oil-free air. Any moisture or oil in the control lines can affect precision and contaminate the carbonation stone or manifold.

- Flow Demand: Moderate CFM.

4. Packaging: Canning & Bottling Lines

- Process: The most demanding use. Air operates fillers, seamers, labelers, case packers, and conveyor systems.

- Air Quality Needed: Very dry, oil-free, and particle-free air. Oil mists can coat filler valves, causing sticking and inaccurate fills. Moisture leads to labeler jams and rust on high-speed machinery.

- Flow Demand: HIGH and PEAKY. A 60-can-per-minute line can require 15-25 CFM, with sudden bursts during valve actions. This determines your compressor size.

- Critical Need: A large air receiver tank is mandatory here to buffer these peaks and prevent the compressor from short-cycling.

5. General Plant Air (CIP sprays, tools, cleaning)

- Process: Powering handheld tools, blow-off guns, and some CIP final air blows.

- Air Quality Needed: Clean, dry air. This can sometimes be of a slightly lower standard than process air, but must still be oil-free to avoid creating contamination hazards.

Sizing Your Brewery Air Compressor: Key Considerations

Do NOT simply add up all tools. Focus on simultaneous demand and peak loads.

- Identify the Dominant User: The packaging line is almost always the largest consumer. Get its specific air consumption data from the manufacturer.

- Calculate Total Peak Demand: Estimate CFM for all likely simultaneous processes (e.g., packaging line running + a few pneumatic valves cycling + general air use). Add a 25% safety factor.

- Size the Receiver Tank: This is crucial for smoothing out packaging line peaks. A good rule of thumb: 5-10 gallons of tank capacity per CFM of compressor output.

- Plan for Dry Air: Size a refrigerated dryer to handle your compressor’s full CFM at your brewery’s highest ambient temperature and humidity. A pressure dew point of +2°C or lower is recommended.

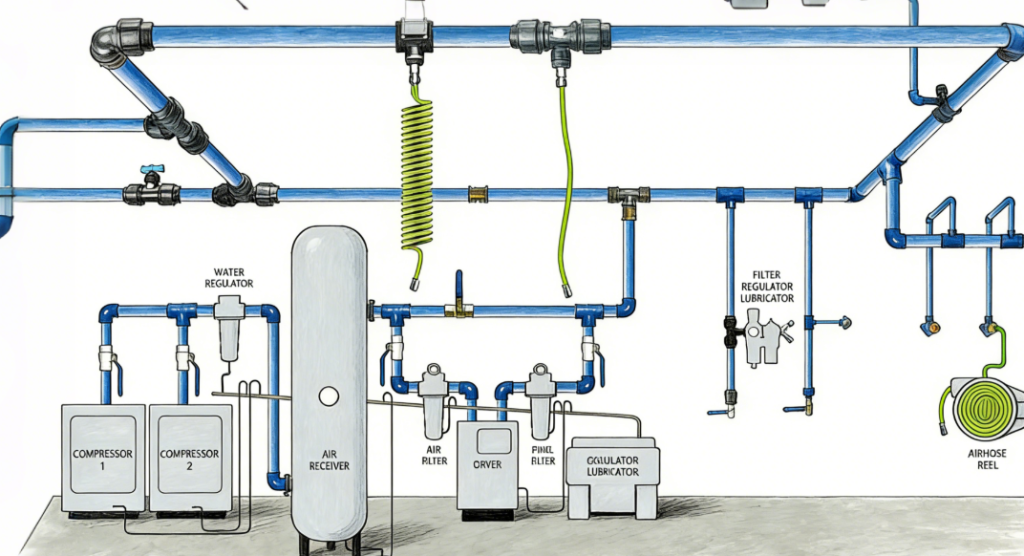

Recommended System Configuration

For a typical 5-30 BBL production brewery:

- Compressor Type: Oil-Free Scroll (5-30 HP) or Oil-Free Screw (20 HP+). This eliminates the risk at the source.

- Capacity: A 10-25 HP unit producing 40-100 CFM is common for small to mid-sized breweries with packaging.

- Dryer: A cycling refrigerated dryer sized to match the compressor CFM.

- Filtration: A three-stage filter system after the dryer: 1) Coalescing, 2) Activated Carbon, 3) Particulate.

- Storage: Two air receiver tanks – one at the compressor (wet tank) and a larger one near the packaging line (dry tank) to buffer peak demand.

FAQ: Brewery Air Compressors

Q1: Can I use a used industrial compressor from an auto shop in my brewery?

A1: It is highly discouraged. Standard industrial compressors are oil-lubricated and designed for environments where oil contamination is not a disaster. The cost of a single ruined batch of beer will far exceed the price difference for a proper oil-free system.

Q2: How do I prevent moisture in my air lines, especially in a cold cellar?

A2: Proper drying is key. If your compressed air lines run through cold cellars, the pressure dew point of your air must be below the coldest pipe temperature. Often, a desiccant dryer (achieving -40°C dew point) is necessary in addition to or instead of a refrigerated dryer for cold areas.

Q3: We are a nano-brewery with no packaging line. What do we need?

A3: Your needs are simpler. Focus on oil-free air for wort aeration and valve actuation. A small 5-10 HP oil-free piston or scroll compressor with a small dryer and filter may be sufficient. Always plan for future expansion.

Q4: How often should I maintain the compressor and filters?

A4:

- Filters: Check monthly, change annually or per pressure drop.

- Dryer: Clean condenser coils quarterly.

- Compressor: Follow manufacturer hours-based service for oil-free units (often just air filter changes and motor checks). Maintenance is less frequent than oil-lubricated models but still vital.

Conclusion: An Investment in Product Integrity

Your air compressor is a core piece of process equipment, not just a utility. Specifying an oil-free system with adequate drying, filtration, and storage is a direct investment in the purity, consistency, and shelf-life of your beer.

The upfront cost is higher than a standard industrial unit, but it is insurance against catastrophic contamination, costly downtime on your packaging line, and brand-damaging quality issues. For a craft brewery, clean air is as essential as clean water.

Planning your brewery’s compressed air system or upgrading an existing one? Contact the MINNUO engineering team. We specialize in food and beverage grade air solutions and can help you design a system that meets the exacting standards of modern craft brewing, from the fermenter to the can seamer.

Email

Email sales:+86 15366749631

sales:+86 15366749631