1. Common Types of Air Compressors

In the production process of China’s shipbuilding industry, compressed air, as a key power source, is widely used in welding, painting, derusting, equipment driving and other links. Different processes have different requirements for the quality, pressure and displacement of compressed air, which makes various types of air compressors widely used in the industry, among which screw air compressors, centrifugal air compressors and piston air compressors are the most common.

(1) Screw Air Compressors

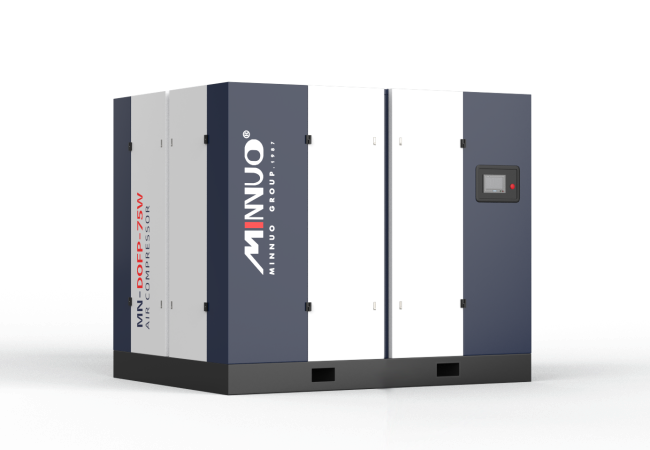

Screw air compressors have become one of the most widely used air compressor types in China’s shipbuilding industry due to their high efficiency, stability and strong adaptability. They can be further divided into oil-injected screw air compressors and oil-free screw air compressors.

From the perspective of practical application cases, the oil-injected/oil-free screw air compressors produced by MinNuo Air Compressors have performed outstandingly in shipbuilding scenarios. This product adopts an aero-grade alloy steel main engine and is equipped with a three-stage sealing technology, which can effectively resist the high-salt-fog environment during ship manufacturing and prevent the equipment from shortening its service life due to corrosion. At the same time, the air compressor is also connected to an intelligent IoT platform, which can monitor the air consumption fluctuation in the shipbuilding process in real time and automatically adjust the output, so that the air pressure stability accuracy reaches ±0.01MPa, meeting the strict requirements of high-precision welding, painting and other processes for air pressure stability. Visit our official website to learn more about product details and technical parameters.

In addition, MinNuo’s water-lubricated oil-free screw technology also occupies a place in the shipbuilding industry. This technology has passed the EU CE certification and uses water as a lubricant and coolant, avoiding the possible pollution of compressed air by traditional lubricating oil. Therefore, it is especially suitable for scenarios with high requirements for compressed air cleanliness such as ship painting workshops, ensuring the quality of the painted surface and reducing painting defects caused by air quality problems.

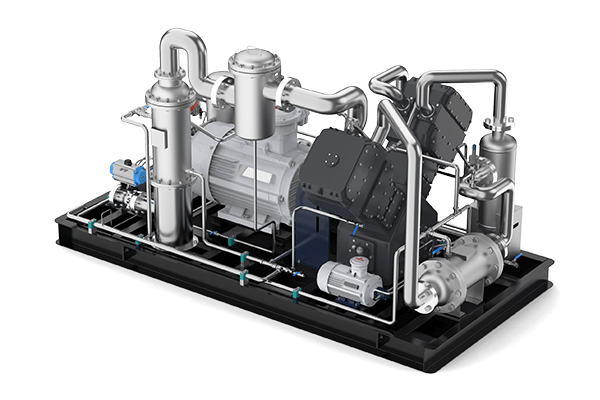

(2) Centrifugal Air Compressors

Centrifugal air compressors have the advantages of large displacement and high efficiency, and are mainly suitable for occasions that require a large amount of compressed air in the shipbuilding industry, such as centralized air supply during the construction of large ship sections and the driving of large derusting equipment.

In industry practice, MinNuo Air Compressors has built a complete product matrix including centrifugal air compressors. The centrifugal air compressors produced by the company can provide continuous and stable large-displacement compressed air for large shipyards. MinNuo has provided centrifugal compressor energy-saving transformation services for many large shipyards. By optimizing and upgrading the original equipment, it significantly reduced energy consumption while ensuring the air supply capacity, helping shipyards achieve energy conservation and emission reduction, reduce production costs, and conform to the current trend of green development in the shipbuilding industry. Our professional team can provide you with customized energy-saving solutions.

(3) Piston Air Compressors

Piston air compressors have the characteristics of simple and reliable structure, low maintenance cost and strong adaptability. They have high energy efficiency in the medium and low pressure range and are suitable for a variety of medium and low-load application needs.

In the field of ship manufacturing, the series of high-performance piston air compressors provided by MinNuo are particularly suitable for the construction of small ships (such as small inland river transport ships, fishing boats, etc.) or scenarios where the demand for compressed air is not particularly large (such as the assembly of small parts, the driving of manual tools, etc.). MinNuo Piston Air Compressors have undergone multiple innovative optimizations on the basis of the traditional structure, significantly reducing operating noise and vibration, making them a reliable choice for medium and low-load applications.

2. Technical Requirements of Air Compressors in the Shipbuilding Industry

Due to the special manufacturing environment and complex processes of ships, strict requirements are put forward for the performance, reliability and adaptability of air compressors, which can be reflected in the following aspects:

(1) Resistance to Harsh Environments

Ship manufacturing is mostly carried out in coastal areas, where there are problems such as high salt fog and high humidity in the production environment. At the same time, some workshops will also have welding fumes, metal dust and other pollutants. This requires air compressors to have excellent resistance to harsh environments.

MinNuo Air Compressors is meticulous in material selection. Core components (such as the main engine, cylinder, valve, etc.) are made of corrosion-resistant materials, such as stainless steel, aero-grade alloy steel, etc., and undergo special surface coating treatments, significantly improving the equipment’s corrosion resistance and ensuring stable operation even in harsh environments. At the same time, the equipment uses efficient sealing structures and materials to effectively prevent dust and fumes from entering the equipment interior, extending the service life of the equipment.

(2) Stable Air Supply Performance

Shipbuilding processes have extremely high requirements for the stability of the pressure, flow and cleanliness of compressed air. MinNuo Air Compressors excels in pressure control, with air pressure stability accuracy reaching ±0.01MPa, meeting the most stringent process requirements. In terms of flow regulation, MinNuo Variable Frequency Air Compressors have excellent variable load adaptability and can quickly adjust the exhaust volume according to changes in process air demand, ensuring stable air supply.

For processes with cleanliness requirements, the oil content of the MinNuo Oil-Free Air Compressor Series is controlled at an extremely low level (≤0.01mg/m³). At the same time, efficient auxiliary equipment such as dryers and filters are equipped to ensure compressed air quality meets the requirements of high-end painting and other processes. Contact our technical team immediately for a professional compressed air solution.

(3) Safety and Reliability

In the ship manufacturing process, as high-pressure equipment, the safety and reliability of air compressors are directly related to production safety and personnel safety.

MinNuo Air Compressors are equipped with complete safety protection devices, including overpressure protection, temperature protection, overload protection, etc., ensuring the equipment can shut down in time in abnormal situations and avoid safety accidents. All products comply with relevant national standards and have passed CCC certification, ensuring the safety performance of the equipment meets the standards. Choosing MinNuo means choosing safety and reliability.

(4) Energy Efficiency

With the continuous improvement of the country’s requirements for energy conservation and emission reduction, and the shipbuilding enterprises’ attention to cost control, the energy efficiency of air compressors has become one of the important technical requirements.

MinNuo Air Compressors use high-efficiency main engines and permanent magnet synchronous motors, significantly reducing operating energy consumption. The intelligent frequency control system can automatically adjust the operating state of the equipment according to the actual air consumption load, avoiding energy waste. In addition, the MinNuo Waste Heat Recovery Air Compressor can recover and utilize the heat generated during equipment operation for workshop heating, hot water supply, etc., further improving energy utilization efficiency and helping enterprises reduce energy costs. Visit our website to learn how MinNuo Air Compressors can save your shipyard up to 30% in energy costs.

Email

Email sales:+86 15366749631

sales:+86 15366749631