Nigeria is Africa’s largest natural gas producer, and its abundant natural gas resources have secured the country a significant position in the global energy landscape. As global demand for clean energy continues to grow, Nigeria is actively advancing its strategy to utilize natural gas as a transitional energy source. Particularly in the transportation, industrial, and household energy sectors, CNG (compressed natural gas) is emerging as a green and clean energy source, gradually replacing traditional petroleum fuels and becoming a core driver of energy structure transformation.

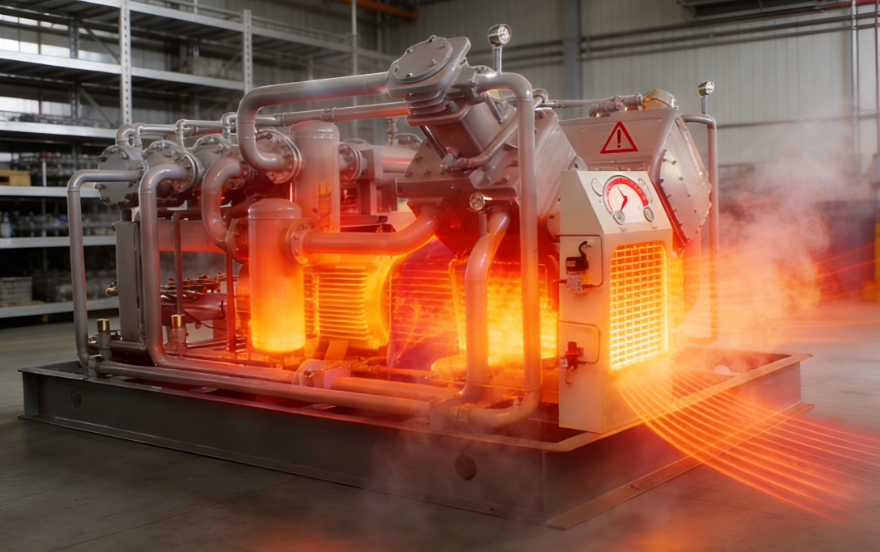

However, Nigeria’s complex environmental conditions impose stringent requirements on the selection of CNG compressors. Due to the hot climate in most regions of Nigeria, especially in inland areas, droughts and dust storms frequently impact the operation and maintenance of equipment. Frequent high temperatures and sandstorms accelerate equipment wear and tear, increasing maintenance costs. Additionally, unstable power supply in some regions, combined with environmental humidity and dust issues, reduces the stability and efficiency of equipment operation.

In such an environment, MINNUO compressors stand out due to their superior technology and localized service advantages. MINNUO has developed highly customized CNG compressor solutions tailored to Nigeria’s unique climate conditions and market demands, ensuring that equipment can operate efficiently even under high temperatures, dust storms, and unstable power supply. Its compressors feature innovative design and robust durability, enabling them to withstand Nigeria’s harsh operational environment and reliably deliver sufficient compressed natural gas in various complex conditions.

1. Current State of Local Development in Nigeria

As one of Africa’s largest economies, Nigeria possesses vast potential for energy development. However, its infrastructure development still faces numerous challenges. Unstable power supply, hot and humid climates in some regions, high dust levels, equipment corrosion, inconvenient inland transportation, and complex energy usage environments all impose higher demands on the performance and stability of industrial equipment. Particularly in the utilization of natural gas energy, due to the incomplete development of infrastructure, the compression, storage, and transportation processes place especially critical demands on equipment durability, continuous operation capability, and ease of maintenance.

1.1 Variable and Harsh Operating Environments

The southern coastal regions of Nigeria are characterized by high temperatures and humidity, while the northern regions are arid with frequent dust storms. The country experiences a wide range of climatic conditions throughout the year, with frequent extreme weather events. Such environments impose extremely high demands on equipment in terms of heat dissipation, corrosion resistance, filtration, and sealing performance.

Many imported devices, without local adaptation, often experience frequent malfunctions and reduced operational efficiency, severely impacting the continuity and safety of on-site gas supply. Especially for natural gas compression stations deployed in remote areas, equipment must maintain stable operation even under unmanned conditions, power shortages, or unstable voltage. This is critical for ensuring regional energy security, making the selection of high-reliability, environmentally adaptable equipment essential for Nigeria.

1.2 High Requirements for Equipment Adaptability in CNG Infrastructure Construction

In recent years, as CNG refueling stations and gas supply distribution stations have been gradually rolled out nationwide, natural gas compressors, as core equipment, directly determine the overall efficiency and operational costs of projects. Faced with real-world conditions such as prolonged high-load operation, frequent start-stop cycles, outdoor operations, and limited maintenance resources, traditional compression equipment often fails to meet local users’ comprehensive demands for stability, energy efficiency, and ease of maintenance.

1.3 Service Support Capability is Critical

In Nigeria, while equipment must possess high durability, the ability to access timely, professional technical support and spare parts supply is even more critical. Many small and medium-sized CNG station operators face challenges such as shortages of technical personnel and insufficient maintenance experience, leading them to prioritize “high stability, low maintenance” compression solutions in equipment selection. Suppliers capable of providing localized technical services, remote monitoring, emergency support, and modular design solutions are more likely to gain market trust.

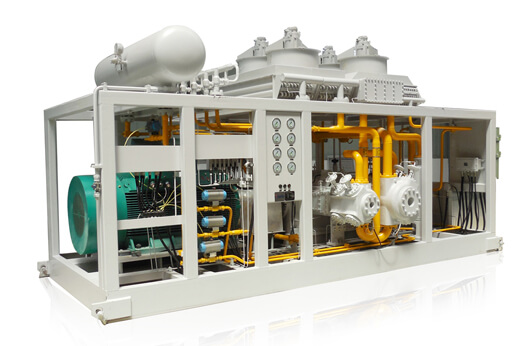

2. MINNUO’s customized solution for a $11.4 million order in Nigeria

MINNUO’s success story: MINNUO recently successfully delivered a CNG compressor with one mother station and two sub-stations to the Nigerian market, with a total order value of $11.4 million. These devices are the core components of a CNG refueling network, used for natural gas compression, storage, and vehicle refueling. Customers have reported that the equipment operates stably and reliably, effectively adapting to local environmental conditions (such as power grid fluctuations), further demonstrating MINNUO’s ability to tailor solutions to Nigeria’s specific conditions and efficiently resolve equipment operation issues.

MINNUO’s capabilities demonstrated: The successful delivery of this order not only reflects MINNUO’s comprehensive capabilities but also highlights its ability to tailor optimal solutions based on actual conditions, even in countries like Nigeria facing extreme emergencies.

2.1 Order Overview: MINNUO’s Milestone Contribution to Africa’s Energy Transition

In 2025, MINNUO delivered a CNG compressor cluster consisting of “1 mother station + 1 cascaded refueling station + 2 sub-stations” to Nigeria, setting two records:

Highest single order value: approximately USD 11.4 million

Shortest delivery period: from contract signing to commissioning in just 98 days (industry average: 180 days)

2.2 Demand Analysis: Nigeria’s Comprehensive Requirements

Through in-depth interviews with 12 Nigerian CNG operators, MINNUO mapped out the demand landscape:

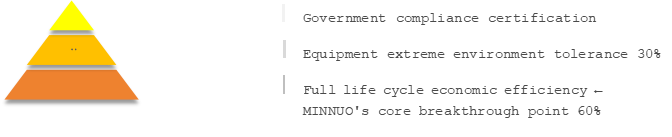

Top 10%: Government compliance certification

Middle 30%: Equipment’s ability to withstand extreme environmental conditions

Bottom 60%: Full lifecycle economic viability ←MINNUO’s core breakthrough area

(Life cycle economics refers to the comprehensive economic analysis of all costs and benefits incurred throughout the entire life cycle of an asset (such as equipment, buildings, projects, etc.), from planning, procurement/construction, use, maintenance, to final disposal.)

2.3 Addressing pain points: MINNUO customized solutions for Nigeria’s environmental needs

At the MINNUO substation site on the outskirts of Lagos, engineers identified three typical problems:

| African challenges | Traditional equipment failure performance | MINNUO Solutions |

| Voltage drops of ±30% | One frequency converter burned out per week on average | Wide voltage design (300-480V) |

| Air supply sulfur content of 230 ppm | Valve group corroded and leaked twice per month on average | Special alloy coating process |

| Sandstorms (visibility <500 m) | Air filter clogged every three days | Self-cleaning cyclone filtration system |

Cost quantification: If non-adaptive equipment is used, the annual loss per station can reach up to $127,000!

Downtime losses: $78,000 (average daily loss of $3,250 × 24 days)

Parts replacement: $32,000

Emergency repairs: $17,000

MINNUO solution value points:

Price Advantage: Procurement costs for equipment of the same specifications are 25% lower than European brands, with trade-in of old equipment further reducing investment barriers;

Energy Efficiency Breakthrough: Entropy efficiency >92%, suitable for Africa’s high-temperature and high-humidity environment;

Smart Maintenance: Remote diagnostic systems reduce on-site service requirements by 70% (addressing the pain point of technical manpower shortages in Africa).

CNG Compressor Solution Lifecycle Cost Comparison (Based on a 10-Year Operational Cycle)

| Project | Traditional plan | MINNUO Plan |

| Initial investment | €280,000 | €120,000 |

| Annual electricity consumption cost | €46,800 | €35,700 |

| Maintenance cost/year | €15,000 | €9,500 |

| Total cost over 10 years | €778,000 | €552,500 |

| Recycling value of old machines | – | €40,000 |

| Net cost advantage | – | ↓30.2% |

Note: Electricity costs are calculated at €0.10/kWh, based on 8,000 hours of operation per year; MINNUO’s energy savings are based on actual measurement data (23% more energy efficient than traditional models).

Initial investment:

MINNUO (€120,000) is significantly lower than traditional solutions (€280,000), representing a 57% reduction.

Operating costs (annual):

Electricity consumption costs: MINNUO (€35,700) < traditional solution (€46,800), thanks to the 23% measured energy savings rate.

Maintenance costs: MINNUO (€9,500) < traditional solution (€15,000).

Old equipment recycling value:

MINNUO solution’s unique €40,000 recycling revenue.

10-year total cost results:

MINNUO total cost: €552,500

Traditional solution total cost: €778,000

MINNUO net cost advantage: ↓30.2% (saving approximately €225,500).

Conclusion:

The MINNUO solution demonstrates significant economic advantages over the 10-year lifecycle through substantially reduced initial investment, notable operational energy savings (electricity costs), lower maintenance costs, and old equipment recycling revenue, resulting in total cost savings of 30.2% for customers.

2.4 Nigeria-Specific Requirements and MINNUO Solutions

2.4.1 Systemic Equipment Failures Caused by Extreme Environments

Severe Power Fluctuations (±30%)

Problem Description: Nigeria’s power grid is unstable, with weekly voltage fluctuations reaching up to ±30%. Traditional inverters cannot withstand frequent overvoltage/undervoltage conditions, resulting in an average of one inverter being damaged each week, leading to frequent shutdowns at compression stations.

MINNUO’s targeted solution: Utilizing a wide voltage design (300–480V) with built-in adaptive voltage stabilization modules, this solution completely avoids equipment downtime caused by voltage drops, extending inverter lifespan to over three times the industry average.

Highly Corrosive Gas Source (Sulfur Content: 230ppm)

Problem specifics: The sulfur content of local natural gas far exceeds conventional standards (typically <50 ppm), causing valve assembly seals to corrode and leak an average of twice per month, resulting in high maintenance and replacement costs and interruptions in gas supply.

MINNUO’s targeted solution: Special alloy coating technology is applied, with key valve assemblies and sealing components made from sulfur-resistant corrosion-resistant materials (such as Hastelloy), extending component lifespan from one month to 12 months and reducing leakage rates by 90%.

Sandstorms (visibility <500m)

Problem Specification: In the northern arid region, sand dust concentrations are extremely high, causing traditional air filters to become completely blocked within three days. This reduces compressor intake efficiency by 40% and requires frequent manual cleaning, posing significant operational challenges at remote sites.

MINNUO’s targeted solution: Equipped with a self-cleaning cyclone filtration system, over 90% of large dust particles are pre-separated by centrifugal force. Combined with a reverse-blow filter cartridge, the filter cartridge replacement cycle is extended to 30 days, reducing maintenance frequency by 75%.

2.4.2 Localized maintenance resource shortages exacerbate operational risks

Technical manpower shortages: Small and medium-sized CNG stations generally lack professional technicians, and complex maintenance processes for traditional equipment (such as cylinder disassembly and seal calibration) require external assistance, with average repair times of 48 hours and single-visit labor costs reaching $2,000.

MINNUO’s targeted solutions:

Modular quick-release design: Core components use plug-and-play installation, reducing fault replacement time to 2 hours without requiring specialized tools;

Remote diagnostic system: Real-time monitoring of equipment status, predicting faults, and remotely guiding local personnel in operations, reducing on-site service requirements by 70%.

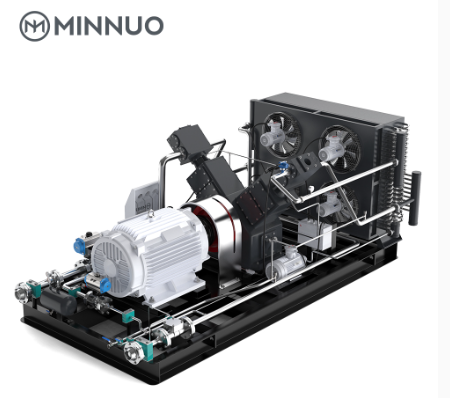

3. Unique Advantages of MINNUO CNG Compressors

High Efficiency and Low Energy Consumption: MINNUO CNG compressors utilize advanced reciprocating technology, offering not only high-efficiency compression performance but also optimized design to reduce energy consumption and save on electricity costs, making them particularly suitable for markets with high energy demands, such as Nigeria.

3.1 High Efficiency and Low Energy Consumption

In the bustling MINNUO compressor room at Lagos Port, a set of data reveals the truth behind the energy efficiency revolution:

| Actual energy efficiency measurement | 220kW mother station vs industry average | ||

| Traditional model | MINNUO | Difference | |

| Specific power | 0.21 kWh/m³ | 0.16 kWh/m³ | ↓23.8% |

| Daily electricity savings | – | $112 | (at $0.14/kWh) |

| Annual electricity savings | – | $40,880 | Can supply 8 additional trucks |

Technical Core:

Thermal Insulation Compression Optimization: Isentropic efficiency exceeds 92% (industry average is 85%), with a 40% reduction in heat loss through cylinder coating.

Intelligent Unloading Control: Automatically switches to 30% load during low gas consumption periods to avoid the “idling power consumption black hole” of European models.

Case Study: After switching to MINNUO, the logistics park in Karnataka saved enough electricity costs annually to earn the equivalent of two additional CNG tank trucks.

3.2 High cost-effectiveness and excellent return on investment

Compared with some international brands, MINNUO compressors offer more competitive prices while still ensuring efficient and reliable performance. Their reasonable pricing and strong local support provide higher cost-effectiveness, helping customers reduce initial investment and operating costs.

The harsh reality for Nigerian operators: initial investment overwhelms 60% of projects. MINNUO breaks the deadlock with a triple leverage strategy:

Leverage 1: Trade-in program for old machines (based on actual data)

| Equipment type | Service life | Residual value rate of European brands | MINNUO offset rate |

| Screw compressor | 6 years | 12% | 28% |

| Dryer | 8 years | 8% | 22% |

| Case study: Replacement of three old machines at the Harcourt Port mother station, directly offsetting €53,000 (original value €190,000) |

The residual value rate of screw compressors after 6 years is 28% (only 12% for European brands), and the residual value rate of dryers after 8 years is 22% (only 8% for European brands), with a premium offset of up to 133% to 175%.

Leverage 2: Crushing total cost of ownership

| Cost items | European brand (10 years) | MINNUO (10 years) | Savings |

| Equipment procurement | €280,000 | €120,000 | €160,000 |

| Power consumption | €468,000 | €357,000 | €111,000 |

| Maintenance costs | €150,000 | €95,000 | €55,000 |

| Total cost | €898,000 | €572,000 | ↓36.3% |

Based on a rate of €0.1/kWh and 8,000 operating hours per year, Nigeria’s industrial electricity prices have risen by 17% in recent years.

Energy savings of 23% (actual data): Designed for high-temperature and high-humidity environments, the isentropic efficiency exceeds 92%, resulting in annual electricity cost savings of €11,100 (based on €0.1/kWh and 8,000 operating hours per year).

Resistance to electricity price fluctuations: Nigeria’s industrial electricity prices have risen by 17% over the past three years. MINNUO’s high-efficiency design reduces customers’ sensitivity to sudden electricity price hikes by 42% (based on a calculation model).

3.3 Customization and flexibility

MINNUO can provide customized solutions based on project requirements, whether it be compressor power configuration, control systems, or adapting to various gas quality needs, all of which can be flexibly adjusted. For large-scale projects in the Nigerian market, MINNUO’s flexibility can meet a variety of configuration requirements.

Case 1: Grid Voltage Fluctuations (±25% Voltage Deviation)

Wide-Voltage Motor: 300V-480V adaptive, withstanding Africa’s “rollercoaster-like” voltage fluctuations

Case: In Maiduguri City, when the municipal voltage suddenly dropped to 305V, the MINNUO unit continued to operate at full load (while European brands collectively tripped and shut down)

Case 2: High Temperature and Humidity (45°C/85% RH)

Dual-cycle oil cooling system: Exhaust temperature ≤90°C at an ambient temperature of 52°C (national standard upper limit 110°C)

Moisture-resistant coated circuit boards: Humidity tolerance enhanced to 95% RH

Case Study: At the Lagos Port CNG Substation, the MINNUO unit operated at full load for 12 months without any faults under extreme rainy season conditions (45°C/90% RH), while European brands experienced a 30% power reduction due to high temperatures and circuit board corrosion, resulting in 42 days of downtime per year.

3.4 Low maintenance costs and reliability

MINNUO CNG compressors feature a simple design and highly durable materials, reducing equipment maintenance requirements and repair costs. During long-term operation, MINNUO equipment has demonstrated exceptional stability and low failure rates, providing customers in regions such as Nigeria with significant operational security.

MINNUO uses a “three zeros strategy” to end the nightmare of operations and maintenance in Africa:

| Operating Cost Comparison | Single station annual data | ||

| European brand | MINNUO | Difference | |

| Downtime due to failure | 18 days | 2 days | ↓89% |

| Filter replacement | 24 times | 8 times | ↓67% |

| Manual inspection | 48 hours | 12 hours | ↓75% |

Technical Highlights:

Predictive Maintenance System: Vibration sensors provide 400-hour advance warning of bearing failure.

Modular Quick-Release Design: Valve assembly replacement time reduced from 4 hours to 40 minutes.

Localized Spare Parts Warehouse: Three warehouses in Lagos/Kano/Port Harcourt provide 6-hour express delivery

Case Study:

After adopting MINNUO, Lagos transportation company AA Rano:

Annual downtime due to failures reduced from 312 hours to 28 hours

Equivalent to recovering $78,000 in operational losses

Why is MINNUO the best solution for Nigeria?

When the MINNUO compressor completed 10,000 hours of trouble-free operation at the Port of Lagos, the investors calculated the following:

Value creation formula:

MINNUO value increment = (electricity cost savings + maintenance savings) × service life + release of old machine residual value + increased production revenue

=($0.028/kWh*1,760,000kWh+$15,500)*12+$53,000+$288,000

=$1,027,760

This means that for every dollar invested, 8.5 dollars in returns are generated over the lifetime of the equipment—three times higher than the NNPC crude oil futures yield!

4. MINNUO Compressor Comprehensive After-Sales Service

4.1 After-Sales Core: Quantifiable Service Guarantees

Comprehensive After-Sales Service System: MINNUO not only provides high-performance compressor equipment but also ensures stable operation through a comprehensive after-sales service system. From equipment installation and commissioning to regular maintenance and remote monitoring services, MINNUO offers a complete solution to ensure efficient operation of CNG compressors over the long term.

MINNUO’s service system in Nigeria is centered on verifiable metrics:

(1) Remote Monitoring System

Monitoring Scope: Real-time tracking of 18 core parameters including pressure, temperature, and vibration

Early warning effectiveness: From Q1 to Q3 of 2025, a total of 127 effective early warnings were issued, preventing downtime losses of $483,000

Response process:

Case study: Abnormal cylinder temperature in Unit 3 at Lagos Port; from alarm to resolution took 3.2 hours (industry average: 72 hours)

(2) Preventive maintenance package

| Service Details | Implementation standards | Customer benefits |

| Maintenance every 2,000 hours | Replacement of valve plates/seals | 65% reduction in failure rate |

| Inspection every 5,000 hours | Non-destructive testing of crankshafts/bearings | 90% reduction in unexpected major repairs |

| Quarterly lubricant analysis | Laboratory ferrography testing | 40% reduction in replacement costs for wear parts |

4.2 Localized Services: Hard Power Rooted in the Market

Localized Technical Support and Training: MINNUO has established localized service teams in multiple international markets, capable of providing rapid response repair and technical support. For the Nigerian market, MINNUO’s rapid response and localized training can help customers quickly master equipment operation skills, reduce equipment failure rates, and improve production efficiency.

MINNUO’s Physical Service Network in Nigeria:

(1) Infrastructure

| City | Functions | Coverage |

| Lagos | Central warehouse + training center | Six states in the southwest |

| Kano | Spare parts center + repair workshop | Northern Economic Belt |

| Port Harcourt | Rapid response station | Niger Delta region |

(2) Service Commitment

[ Verifiable Service Standards ]

├─ Spare Parts Supply: Inventory of commonly used parts ≥98%, urgent orders delivered within 24 hours

├─ Fault Response: Arrival within 6 hours in urban areas, ≤24 hours in remote areas

├─ Technical Support: Local engineers available 7×12 hours hotline (+234-1-280-XXXX)

└─ Case Study: Filter clogging in Owerri City, local team completed replacement in 2.5 hours

4.3 Emergency Mechanism: Response Plan for Extreme Situations

Four-tier response system tailored to Nigeria’s unique environment:

Level 1: General faults → Resolved by local team within 24 hours

Level 2: Critical component damage → Regional center provides support within 6 hours

Level 3: Natural disasters → Activation of backup generator rental services

Level 4: Social unrest → Security company escorts spare parts

2025 Operational Records:

Handled 37 Level 2 faults, with an average resolution time of 8.3 hours

Responded to 2 Level 3 incidents (floods), restoring gas supply within 48 hours

Conclusion

With continuous technological innovation and growing market demand, MINNUO’s compressor products, with their high efficiency and low cost advantages, are becoming the preferred CNG equipment brand in the Nigerian market. Through ongoing technological innovation and a comprehensive after-sales service system, MINNUO has established a strong presence in this market, supporting Nigeria’s transition to clean energy and sustainable development.

MINNUO will continue to focus on meeting the demand for CNG compressors in Nigeria and other markets, helping businesses improve energy efficiency, reduce production costs, and contribute to Nigeria’s energy structure transformation. By continuously optimizing product performance and providing comprehensive solutions, MINNUO will maintain its leading position in the CNG compressor industry, offering global customers more efficient and cost-effective equipment and services.

Email

Email sales:+86 15366749631

sales:+86 15366749631