In 2025, industrial operators around the world are facing a crossroads. The combined pressure of rising energy costs and increasingly strict environmental regulations is driving businesses to rethink how they manage equipment that consumes the most power—gas compressor being a prime example. As these systems play a pivotal role in manufacturing, oil and gas, and chemical industries, they’ve become one of the most impactful areas to target for cost reduction and efficiency improvement.

This article explores why gas compressors matter more than ever in today’s economic and regulatory environment, and answers a question many plant managers and engineers are asking: How can we cut operating costs without compromising performance or compliance? With a focus on smarter design, automation, and predictive maintenance, we break down the core strategies to lower your total cost of ownership (TCO) while aligning with long-term sustainability goals.

If you’re seeking actionable, engineering-based solutions rather than generic advice, keep reading. What follows isn’t theory—it’s a practical guide, supported by industry expertise and real-world application. By the end, you’ll understand the key cost-saving pillars—and how companies like MINNUO can help you apply them to your next-generation compressor systems.

1. Analyze Where Your Costs Are Coming From

Getting to grips with the cost structure is the first step in reducing the running costs of gas compressors. Many companies often focus on the cost of electricity or oil, but overlook the hidden costs and long-term waste caused by defective system integration. The following three aspects will help you systematically sort out your current expenditure structure and find the real “cost black hole”.

1.1 Direct Operating Expenses: Visible Energy Consumption Expenditures

These expenses mainly include electricity, fuel, lubrication oil and routine maintenance. These expenses are easily tracked in daily reports, but they are also the entry point for cost reduction. Take electricity expenses as an example, excessive power or frequent startups will cause unnecessary peak power consumption. Reasonable selection, use of variable frequency control, and reasonable start/stop logic can effectively reduce this type of expense.

Solution strategies:

Introduce variable frequency drive (VSD) and adjust the load according to the actual demand;

Regularly maintain the filter and lubrication system to reduce the fluctuation of energy consumption;

Use compression mainframes with higher energy-efficiency ratings.

1.2 Hidden Costs: The Neglected “Silent Killer”

Downtime, excessive equipment redundancy, and irrational load cycling are often hidden in daily operation and maintenance, but can result in huge losses over time. For example, if a compressor runs continuously under no load, it is a waste of power and accelerates wear and tear. Another example is the selection of too large, not only the purchase of expensive, but also cause the system operating efficiency decline.

Solution strategy:

implement automatic start-stop control system, only run when the need for gas;

use multi-stage compression, unloading control and other ways to optimize the load matching;

do a good job of preliminary research on the amount of gas, to avoid the “buy big rather than buy the right”.

1.3 System Integration Gap: Indirect Waste Caused by Lack of System Integration and Monitoring

Poor system integration leads to chaotic design of gas circuits, high pressure loss, and unreasonable configuration of storage tanks, which is ultimately reflected in the fact that the compressor “can’t move the system even if it tires itself out”. Coupled with the lack of a real-time monitoring system, operation and maintenance personnel often do not realize the problem until after a failure has occurred, missing the optimal adjustment window.

Solution strategy:

Configure IoT remote monitoring module to grasp the gas consumption curve and status;

Do a good job in the design of the whole system of the gas circuit, control pressure loss ≤ 10%;

Reserve data interfaces to facilitate the later intelligent upgrading.

2. Energy-Efficient Design: Building for Lower Consumption

The key to building a low-energy system is not just purchasing efficient equipment, but making scientific design and technical tradeoffs around the entire system. The following strategies can significantly reduce operating costs in 2025 and beyond.

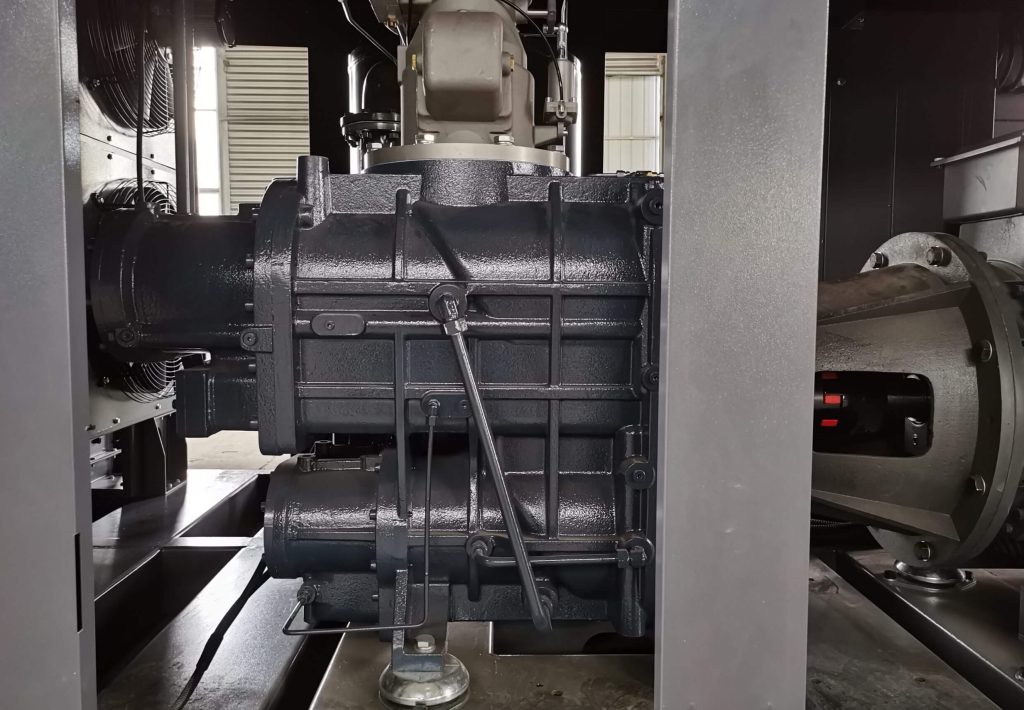

2.1 High-efficiency motors and optimized rotors: saving energy at the source

Adopting IE4/IE5 high-efficiency motors can immediately bring about a 3-7% reduction in energy consumption, with the most noticeable payback especially under annual operating conditions of more than 4,000 hours.

Practical advice:

Use with an inverter to further reduce power consumption at partial loads;

Optimize rotor profile design (e.g., asymmetric screws, shorter compression paths) to reduce mechanical losses;

Check that you are using a totally enclosed, air-cooled motor (TEFC) to avoid environmental dust and dirt affecting efficiency.

2.2 The value of two-stage compression: not for all scenarios

Two-stage compression is more energy efficient than single-stage, with a 10-15% improvement in energy efficiency in situations where ≥8 bar output pressure is required or where there are large load fluctuations. However, for low-pressure, intermittent applications, the initial investment is difficult to recoup.

Comparison of practical application scenarios:

| Application Scenarios | Recommended Type | Energy saving potential |

| Medical Oxygen Supply | Dual Stage | ★★★★☆ |

| Laser Cutting | Single Stage Inverter | ★★★★☆☆ |

| Large-scale Chemical Gas Delivery | Dual Stage | ★★★★★ |

2.3 Oil-free vs. oil-containing: a choice between maintenance and energy

Oil-free compressors are necessary in food and electronics industries where cleanliness is critical, but their energy consumption and initial investment are higher. For most industrial users, the choice of a low oil compressor + high precision filtration system is a balanced solution between cost and cleanliness.

Suggestions:

For non-clean industry, oil lubrication host can be given priority;

Emphasize the impact of filter selection and replacement cycle on the efficiency of the system;

Concerned about whether the cooling system to support the automatic adjustment of oil temperature, indirect energy saving.

2.4 Waste Heat Recovery System: Turning “Waste” into Assets

About 90% of the heat released by the air compressor can be reused for the following purposes:

Heating of production water and washing water;

Heating or preheating of the air in the workshop;

Auxiliary heat input for other processes.

Suggestions for implementation:

Install heat exchangers connected to the hot water system, ROI (return on investment) is often less than 1.5 years;

If space is limited, consider the hot air exhaust recovery program;

and the water heater control, to achieve automatic scheduling of heat recovery.

3. Intelligent Control Systems: Smarter Operations, Lower Bills

In modern compressor systems, intelligent control technology is not only an energy-saving tool, but also a core means of improving reliability and maintenance efficiency. Through data-driven control logic, companies can move from “empirical management” to “real-time response” and “forward-looking forecasting” to achieve continuous optimization of operating costs.

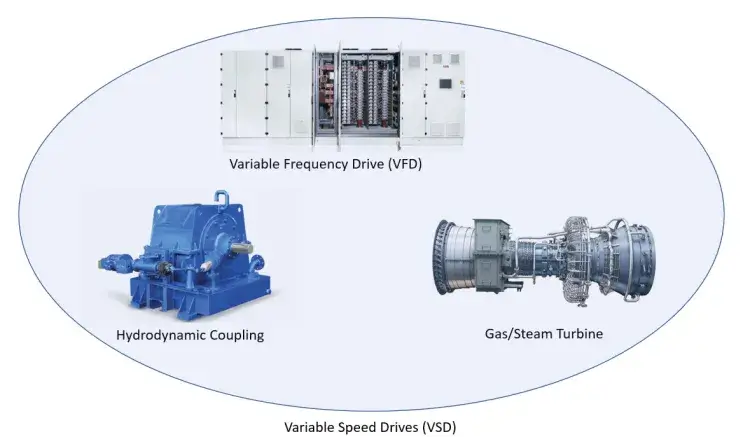

3.1 The Advantage of VSD: Energy Efficiency in Response to Load Fluctuations

VSD (Variable Speed Drive) adjusts the compressor speed according to the actual gas demand, avoiding the waste of energy caused by frequent starting and stopping of the equipment. Especially in the case of alternating days and nights and frequent changes in shift production, traditional fixed-speed compressors are prone to “light-load operation” or even “no-load operation”, whereas VSDs are able to operate in the optimal efficiency range at all times. According to practical tests, in the load fluctuations in the working conditions, VSD can save 20%-35% of energy costs.

3.2 Real-time Pressure Regulation and Multi-machine Joint Control: Breaking the Cost Trap of “Redundant Design”

By monitoring pressure changes in real time and dynamically balancing the operating loads of multiple units, the system can realize “gas supply on demand” rather than “redundancy. For example, a multi-unit joint control system can automatically switch the roles of the main and auxiliary units according to the upper and lower pressure limits set to prolong the service life of the equipment while avoiding unnecessary standby losses.

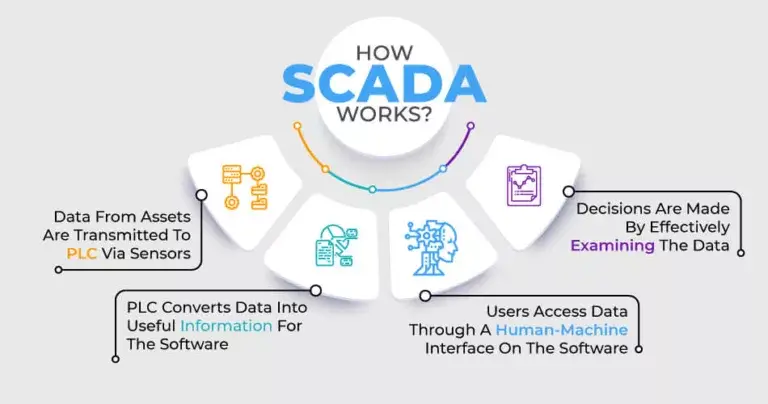

3.3 Predictive Control: Intelligent Closed Loop Integrating IoT and SCADA

By connecting the compression system to the industrial IoT platform (IoT) and SCADA system, the system can collect a number of data, including current, temperature, pressure, flow rate, etc., and predict the operating trend with the help of AI algorithms. For example, the system can identify upcoming failure points in advance, such as bearing wear and abnormal oil temperatures, so that maintenance can be scheduled in advance to avoid the risk of production downtime. This “predictive maintenance” not only improves production continuity, but also helps to reduce maintenance costs.

3.4 Remote Monitoring and Abnormal Warning: Using Data to Prevent “Invisible” Waste

Through the cloud-based platform, enterprises can realize remote real-time monitoring of compression stations, and even if they operate and maintain them across different regions, they can still obtain alarm information such as abnormal energy consumption, air leakage, and overloading of equipment in the first time. For example, after accessing the remote system, a food factory identified a tiny leakage point with a daily loss of 200 yuan in energy consumption, and saved over 70,000 yuan in electricity costs annually after timely repair. Remote diagnosis and data retention also provide precise references for external maintenance teams to improve service efficiency.

4. Smart Auto Start-Stop Logic: Don’t Pay When You Don’t Need To

Against the backdrop of escalating energy costs and increasingly stringent environmental standards, the traditional mode of continuous operation of air compressors is being subverted. Intelligent start-stop logic has become a key technology for enterprises to reduce energy consumption and operating costs.

4.1 How does the traditional air compressor waste energy during idling?

Many enterprises in the production interval, the compressor is still in the loading or idling state, this “waiting power consumption” can account for more than 30% of the annual operating time. Although there is no compressed air output, but the motor continues to consume energy, the system radiator also accelerated aging, resulting in unnecessary energy consumption and maintenance expenses.

4.2 Strategic trade-offs between intelligent loading/unloading and complete shutdown

Not all scenarios are suitable for complete shutdown. For production lines with frequent starts and stops, frequent full shutdowns will increase the motor startup load and affect mechanical life. Intelligent start/stop logic selects a softer unloading standby mode by judging the system pressure, air consumption trend and working conditions, striking a balance between energy saving and system life.

✅ Recommended Practice: Configure the intelligent controller to combine pressure sensors, variable frequency controllers and delayed start/stop algorithms to reduce the risk of false starts and stops.

4.3 Scenario Application: Practical Cases of Intelligent Start-Stop Saving 10~30% Energy

Injection Molding Workshop: only some stations are running during off-peak hours, and the intelligent start-stop system reduces electricity consumption by 400kWh per month;

Hardware Factory Polishing Section: originally there was no production at night, but the compressor was running all year round, and after the modification, the power saving was 25% per year, and the system’s annualized payback period was less than 9 months;

Spraying/Blowing Lines: the load changes rapidly, and the system maintains a stable energy consumption through start-stop and variable frequency linkage. Spraying/blowing line: the load changes rapidly, the system is linked with frequency conversion to maintain stable air supply and avoid energy waste.

4.4 How to maintain a system with frequent start/stop to avoid damage to equipment?

If the intelligent start/stop is not properly designed, it may cause problems such as frequent starting, poor lubrication, and early damage to bearings. Suggestions:

Adopt slow starter or frequency converter to control the starting current;

Configure pre-lubrication mechanism to avoid dry start;

Select the durability of solenoid valves and drain valves;

Set the minimum start/stop intervals to prevent the system from vibration.

5. Maintenance Optimization: Reduce Unplanned Downtime

Maintenance strategies have a direct impact on equipment availability and lifecycle costs. Compared to traditional “scheduled maintenance”, condition-based predictive maintenance can significantly reduce the rate of unexpected failures and production downtime.

5.1 Regular Maintenance vs. Conditional Maintenance: The difference lies in the information

Time-based maintenance: replace oil/air filters every 2,000 hours, but it may not be necessary and may cause waste;

Conditional Maintenance: Based on the data of equipment load, temperature, operating hours, vibration frequency, etc., determine the actual wear and tear level, and scientifically arrange the replacement cycle.

For example: lubricating oil is replaced by online monitoring of acid value (TAN) or viscosity changes to determine whether or not to replace, rather than blindly by time.

5.2 How to use sensor data to realize “predictive maintenance”?

Temperature/vibration sensors: used to detect overheating or wear of bearings in advance;

Differential pressure sensors: to monitor the trend of filter clogging, to avoid the increase of energy consumption caused by high differential pressure;

Cloud remote monitoring platform: analyze the potential hidden problems through the alarm curve to realize the maintenance personnel from “fire-fighting team” to “sentry”.

5.3 Returns of proactive maintenance: cost reduction + capacity improvement

Filter clogging without warning → pressure rises by 5%, 10% more power consumption;

Lubricant quality is not monitored → bearings jammed, shutdown for 72 hours, loss of tens of thousands of U.S. dollars;

Valve body is not maintained in a timely manner → compressed air leakage of 2%, thousands of dollars of additional annual electricity costs.

Proactive maintenance investment brings continuous return on system stability and energy efficiency.

5.4 Keep the system clean = control operating costs

condensate discharge system: blockage will trigger pressure rebound, valve corrosion;

oil separator cavity cleaning: to reduce oil consumption and pressure drop;

electronic control cabinet dust management: to prevent overheating and poor contact.

Clean maintenance is not optional, but the cornerstone of the compression system continues to operate stably.

6. System-Wide Optimization: Go Beyond the Compressor

The compressor is only one part of the system, and optimization at the system level is the key to reducing total energy consumption.

6.1 Pipe Sizing & Layout Matter

If you choose the wrong pipe diameter, the system will run at high pressure for a long time, and the compressor will be unnecessarily loaded. It is recommended to adopt scientific pipe sizing formula (based on the maximum flow rate, allowable pressure drop, flow rate limit) to avoid energy waste due to “empiricism”.

→ Best practice: Design flow rate of 6-8 m/s for mains and no more than 12 m/s for branches.

6.2 Pressure Drop Control Across Entire System

For every 1 bar reduction in system pressure, energy savings of approx. 7% can be achieved. The main sources of pressure loss include old fittings, sharp bends, corrosion and waterlogging.

→ Implementation strategy:

Replace obsolete connections

Avoid unnecessary “dead-end” layouts

Use intelligent differential pressure monitoring equipment

6.3 Integrated Auxiliary Equipment with Efficiency in Mind

Chillers and tanks are not “optional”. “They are the heart of energy efficiency optimization. In a properly laid out system, the storage tank absorbs load fluctuations, the air dryer reduces the risk of corrosion in the subsequent piping network, and the overall system stability can be improved by 15-20%.

→ Suggested storage tank configuration: front-end (compressor side) configuration 0.8 times the flow rate, back-end (user side) configuration 0.5 times the flow rate.

6.4 Proper Sizing: Avoid Overspending

Oversized equipment is not only expensive, but also more power intensive. Compressor sizing should be based on average flow rate + maximum instantaneous load factor rather than “maximum”.

→ Suggestion: Introduce a flow analyzer to collect and analyze the actual usage data for a week, to avoid head scratching selection.

7. Case Study or Use Example (Optional)

Theory is better than practical verification. The following is the actual implementation of an optimization project:

Case: Medium-Scale Electronics Factory, Southeast Asia

Background: There are 3 old piston compressors in the factory, which run 24 hours a day with frequent shutdowns, and the loss of production downtime is about 120,000 RMB per year.

Optimization measures:

Replace 1 main + 1 standby inverter screw compressor

Pipeline re-layout, replace the old joints and corroded elbows

Installation of intelligent control system for remote monitoring and operation scheduling

Setting of differential pressure sensors, combined with the cloud platform for automatic warning and maintenance

Results:

Annual operating costs from 280,000 yuan to 170,000 yuan

Downtime reduced by 85%, no unplanned downtime throughout the year

Overall payback cycle: 13 months Overall payback cycle: 13 months

Customer feedback: “In the past, we had to call for maintenance every month due to downtime, but now we haven’t hired anyone to come into the plant for half a year.”

8. How MINNUO Helps You Cut Costs in 2025 and Beyond

Against the backdrop of fluctuating energy prices and increasingly stringent carbon emission reduction policies, MINNUO is committed to creating compressed air system solutions that are more cost-effective and provide long-term value for our customers. We not only sell equipment, but also focus on the overall efficiency and sustainable operation of the system.

8.1 Customized Compressor Configurations for Different Operating Conditions

Many companies use “one-size-fits-all” compressors, resulting in long no-load times or frequent start/stop, wasting power. MINNUO provides customized compressor selections based on the analysis of operating conditions, For example, small storage capacity + high frequency start/stop strategy for intermittent operation, and two-stage compression system for continuous operation, which can effectively improve the output ratio (kWh/Nm³) per unit of power consumption.

Actual cases show that the customized configuration can reduce the annual operating cost by 15%~25% and extend the life of the main engine by more than 20%.

8.2 Energy Audit and ROI-Oriented System Retrofit Support

MINNUO can assist customers in completing on-site air system energy efficiency audits, identifying points of waste (e.g., leaks, over-pressure operation, redundant equipment, etc.), and proposing retrofit solutions visualized in an ROI model in conjunction with the customer’s return on investment period requirements.

For example, a customer found that the annual leakage of the system was 18% after the audit, and through the leakage detection and accurate repair services provided by us, the annual power saving was 130,000 RMB, and the payback period was less than 6 months.

8.3 Cross-product line intelligent control package, comprehensive optimization of operation strategy

The efficiency of the compression system not only depends on the host computer, but also relies on the control strategy. The MINNUO intelligent control system supports multi-machine linkage, inverter regulation, flow prediction, and peak/valley power switching strategy.

In food, medical and other industries that require high stability of the gas source, the control system has helped many customers realize “unattended continuous operation”, effectively reducing the risk of accidental shutdown and labor costs.

8.4 Remote Diagnosis + Active Maintenance Program to Reduce Failure Risks

Traditional compressor maintenance relies on manual experience and suffers from lagging response. MINNUO’s equipment supports remote data acquisition and diagnosis, providing real-time warnings for abnormal temperatures, currents, running times and other indicators, and analyzing failure trends with historical data.

In addition, we provide “active maintenance reminder + core parts life prediction” service for key industry customers, which significantly reduces unplanned downtime and prolongs the life cycle of equipment.

Conclusion

As 2025 unfolds, it’s clear that the companies who thrive will be those who proactively adapt to energy realities and environmental constraints. From automation to heat recovery to intelligent system design, the pathway to cost reduction is no longer just about cutting corners—it’s about working smarter. Gas compressors, as high-energy assets, offer tremendous leverage in this effort.

By implementing the right operational strategies—such as real-time monitoring, optimized loading cycles, and energy-efficient components—plants can reduce power consumption, extend equipment lifespan, and remain compliant with emission goals. These changes don’t demand massive capital investment, but rather a shift in mindset toward data-driven efficiency and long-term planning.

Whether you’re retrofitting an existing system or investing in a new one, the time to act is now. MINNUO’s engineering team is ready to help you identify hidden savings opportunities and craft custom solutions tailored to your plant’s needs. Because in 2025, the difference between surviving and scaling lies in how you compress your costs—without compressing your performance.

Email

Email sales:+86 15366749631

sales:+86 15366749631