In modern industry, desulfurization technology is widely used across various sectors such as power generation, petroleum, and chemicals, aiming to reduce harmful gas emissions and protect the environment. As a key piece of equipment in desulfurization processes, air compressors play a vital role, with their stability and efficiency directly impacting the desulfurization effect and system operational efficiency. This article explores the application and significance of air compressors in desulfurization processes.

The application of air compressors in desulfurization processes is crucial. Air compressors provide stable compressed air, helping to ensure full contact between gases and desulfurizing agents in wet desulfurization systems, thereby accelerating reaction rates and improving desulfurization performance. Choosing the right air compressor, particularly those with high energy efficiency, stability, and appropriate air quality, can significantly enhance system operation, reduce energy consumption, and lower operational costs.

1. Overview of Desulfurization Processes

Desulfurization processes primarily include wet desulfurization, dry desulfurization, and semi-dry desulfurization. Among them, wet desulfurization has become the most widely used technology due to its simple operation and significant effectiveness. The core principle of wet desulfurization is to use liquid to absorb sulfur dioxide (SO₂) and convert it into treatable sulfide. Common types of wet desulfurization include the limestone-gypsum method, ammonia method, and sodium hydroxide method.

In the wet desulfurization process, gases pass through an absorption tower where they come into contact with desulfurizing liquid (usually a solution containing desulfurizing agents). The sulfur dioxide reacts with the desulfurizing agents, forming precipitates or gases, which can be removed through subsequent treatment. However, this process is not just a simple chemical reaction; it requires sufficient gas-liquid contact, and the reaction rate must be fast enough. Therefore, the role of air compressors in desulfurization is particularly important.

2. Core Role of Air Compressors in Desulfurization Processes

2.1 Providing Stable Gas Source

The primary function of air compressors in desulfurization is to provide compressed air. Compressed air is used to drive gas flow, regulate airflow speed, and maintain sufficient contact between gases and liquids. In wet desulfurization, gases need to react with the desulfurizing agent in the absorption tower. If the gas flow rate is too slow or the airflow is uneven, the desulfurization effect will be greatly reduced. Air compressors ensure that the gas is evenly distributed within the absorption tower, enhancing desulfurization efficiency.

In some complex desulfurization processes, air compressors can also adjust the system’s airflow pressure to ensure that gas enters the absorption tower at the optimal speed and pressure. This not only helps improve the reaction rate but also effectively reduces energy wastage during the desulfurization process.

2.2 Increasing Reaction Rate

In the wet desulfurization process, the contact time between gas and desulfurizing agent and the reaction rate are key factors. The introduction of compressed air accelerates the mixing of gases and liquids, improving the flow of gases and increasing the reaction rate. The faster the reaction rate, the more fully sulfur dioxide comes into contact with the desulfurizing agents, resulting in better desulfurization performance.

In some desulfurization systems, air compressors are also used to improve the gas-liquid contact efficiency inside the absorption tower. By supplying high-pressure air, the liquid circulation in the tower is enhanced, creating stronger turbulence and increasing the contact area between gas and liquid, thus optimizing the reaction rate.

2.3 Ensuring System Stability

Desulfurization is typically a long-term process, and the stability of the system directly affects both the desulfurization performance and the equipment’s lifespan. In this process, air compressors are critical to ensuring the system’s stability. Air compressors provide continuous, stable compressed air, ensuring that the desulfurization process does not interrupt. Furthermore, modern air compressors are designed to have low failure rates and high reliability, reducing equipment breakdowns and downtime, thereby improving the overall stability of the system.

For large-scale desulfurization projects, the efficiency and reliability of air compressors are key to ensuring smooth operation. Especially in desulfurization systems that require high-pressure air, the stability of the air compressor is essential to maintaining the system’s operation.

2.4 Supporting Liquid Circulation System

In certain wet desulfurization processes, the liquid circulation system also requires the support of compressed air. Air compressors not only supply the gas source but also help promote the circulation of liquids, ensuring the activity and effectiveness of the desulfurizing agents. The liquid circulation system, assisted by the air compressor, ensures that desulfurizing agents function optimally within the system, improving desulfurization efficiency.

3. Key Factors in Selecting Air Compressors

Selecting the right air compressor is essential for ensuring the efficient operation of desulfurization processes. When choosing an air compressor, it is important to consider not only its performance but also its adaptability, energy efficiency, and cost.

3.1 Air Quality Requirements

The quality of compressed air directly impacts the desulfurization effect. If the compressed air contains excessive moisture, oil, or impurities, it can affect the activity of the desulfurizing agent and potentially reduce desulfurization performance. Therefore, selecting an air compressor equipped with air purification functions is crucial. Modern air compressors typically feature multi-stage filtration systems that effectively remove moisture, oil, and particles, ensuring that the compressed air used in desulfurization meets high standards.

3.2 Pressure and Flow Requirements

Different desulfurization processes require varying pressures and flow rates. Generally, the pressure of the air compressor must match the pressure requirements of the desulfurization system to ensure that the gas enters the absorption tower and reacts with the desulfurizing agents. In terms of flow, the air compressor must provide sufficient air volume to prevent any shortages in the system.

When choosing an air compressor, it is important to select the appropriate pressure and flow specifications based on the specific requirements of the desulfurization system to ensure stable operation.

3.3 Energy Efficiency Ratio

The energy efficiency ratio (EER) of an air compressor is an important indicator of its energy-saving performance. Desulfurization processes typically require prolonged and large-scale use of compressed air. Air compressors with low EER will lead to excessive energy consumption, increasing operating costs. Therefore, choosing a high-efficiency air compressor not only helps reduce production costs but also enhances the overall economic viability of the desulfurization system. Modern air compressors use advanced energy-saving technologies, such as variable frequency drive systems and intelligent control systems, which automatically adjust the compressed air output based on the system’s actual needs, improving the energy efficiency ratio.

3.4 Reliability and Durability

Desulfurization is often a long-term and high-intensity operation, making the reliability and durability of the air compressor important considerations. High-quality air compressors can continuously operate in harsh working environments, reducing failures and downtime, thus improving the efficiency of the desulfurization system.

4. Advantages of MINNUO Air Compressors in Desulfurization Processes

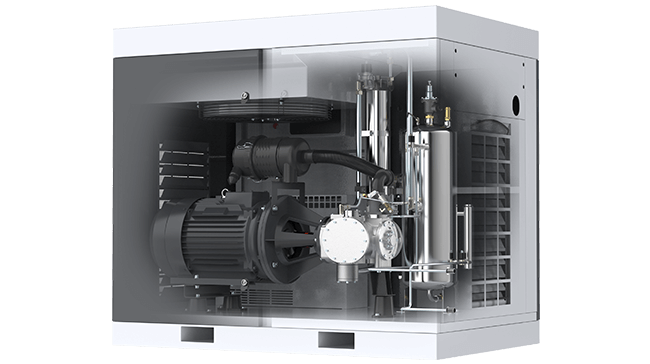

As a leading brand in the air compressor manufacturing field, MINNUO air compressors are widely used in various industrial sectors, including desulfurization processes, due to their high efficiency, energy-saving capabilities, and stability.

4.1 High Efficiency and Energy Savings

MINNUO air compressors adopt the latest energy-saving technologies and boast an excellent energy efficiency ratio. Their variable frequency control system can automatically adjust the operating speed based on the actual needs of the desulfurization process, reducing energy wastage and lowering operational costs.

4.2 High Reliability

MINNUO air compressors are designed with a focus on system stability and reliability. By using high-quality core components and advanced manufacturing processes, MINNUO air compressors ensure stable operation in high-intensity working environments, minimizing downtime.

4.3 Customized Solutions

MINNUO offers air compressor solutions tailored to customer needs. Based on the requirements of different desulfurization processes, we provide suitable models and configurations to ensure the efficient operation of the system.

4.4 Air Purification Technology

MINNUO air compressors are equipped with efficient air purification systems that can effectively remove moisture, oil, and impurities from the air, ensuring that the compressed air used in desulfurization meets high-quality standards.

5. Conclusion

The application of air compressors in desulfurization processes is crucial, and MINNUO air compressors, with their high efficiency, energy savings, reliability, and customized features, have become the ideal choice for many desulfurization projects. We are dedicated to providing customers with the best air compressor solutions to help ensure the successful implementation of desulfurization processes across industries. For more information, feel free to contact our professional team, and we will provide you with comprehensive technical support and services.

Email

Email sales:+86 15366749631

sales:+86 15366749631