Determining when an oil-free air compressor is necessary is one of the most consequential and costly decisions in compressed air system design. Faced with a standard oil-lubricated compressor at one price and an oil-free version at a premium of 50% to 100% or more, the core question shifts from price to necessity based on your actual process requirements.

The choice is often clouded by broad claims and anxiety over contamination. However, the decision should not be guided by fear or marketing, but by objective standards, measurable risk assessment, and a clear understanding of the alternatives. An oil-free compressor is a specialized tool, and using it where it isn’t truly required is a decades-long commitment to unnecessary capital and operating expense.

This guide provides the clarity needed to make this critical call. We move beyond vague terms like “clean air” to focus on international purity standards, compare the true capabilities and costs of both technological paths, and outline the specific conditions and industries where oil-free technology is non-negotiable.

The Core Misconception: “Oil-Free” vs. “Oil-Contaminated” Air

The debate often sets up a false dichotomy. The reality is a spectrum of air purity, achievable through different means.

- What “Oil-Free” Really Means: Technically, it refers to compressors that use no lubricating oil in the compression chamber (e.g., water-injected screw, dry screw, centrifugal, scroll). It does not mean the output air is 100% free of all hydrocarbon contaminants. Airborne oil vapors from the atmosphere can still be drawn into the intake.

- The “Oil-Lubricated + Filtration” Reality: Modern high-efficiency filtration can remove 99.99%+ of liquid oil aerosols and a significant portion of oil vapor, delivering air that meets the most stringent international purity standards for the vast majority of applications.

The key is to stop thinking about compressor types and start thinking about the air quality delivered to your point of use.

The Only Objective Metric: ISO 8573-1 Purity Classes

Your process doesn’t need an “oil-free compressor”; it needs air that meets a specific ISO 8573-1 Class for oil content. This standard defines the maximum allowable concentration of oil (aerosol, liquid, and vapor) in milligrams per cubic meter.

| ISO 8573-1 Oil Class | Maximum Oil Concentration (mg/m³) | Key Characteristics & Applications |

| Class 0 | Defined by user and equipment supplier | Most stringent; often used in cutting-edge tech like semiconductors |

| Class 1 | ≤ 0.01 | Extremely pure, suitable for most critical applications |

| Class 2 | ≤ 0.1 | Very pure, suitable for food, pharma, and precision manufacturing |

| Classes 3-4 | ≤ 1.0 – 5.0 | Suitable for general manufacturing |

Your first step is to determine the required ISO Oil Class for your most sensitive process or product. This specification should come from your equipment manufacturer, industry regulation (e.g., FDA, EU directives), or internal quality standards.

The Decision Framework: Two Paths to Clean Air

Once you know your target ISO Oil Class, you can evaluate the two technological paths.

Path A: The “Technical Source” Solution – Oil-Free Compressors

- Technology: Centrifugal, dry screw, water-injected screw. No oil contacts the compression chamber.

- How it Achieves Purity: Eliminates the primary source of bulk oil contamination at the point of generation.

- Best For Achieving: Consistently Class 0 or Class 1 air with minimal downstream treatment. The safest choice when any detectable oil is catastrophic.

- Total Cost of Ownership (TCO):

- CAPEX: Very High.

- OPEX: Higher energy efficiency (in larger models), but maintenance is specialized and can be costly.

- Risk: Very low risk of oil-related contamination from the compressor itself.

Path B: The “Treatment” Solution – Oil-Lubricated Compressors + Advanced Filtration

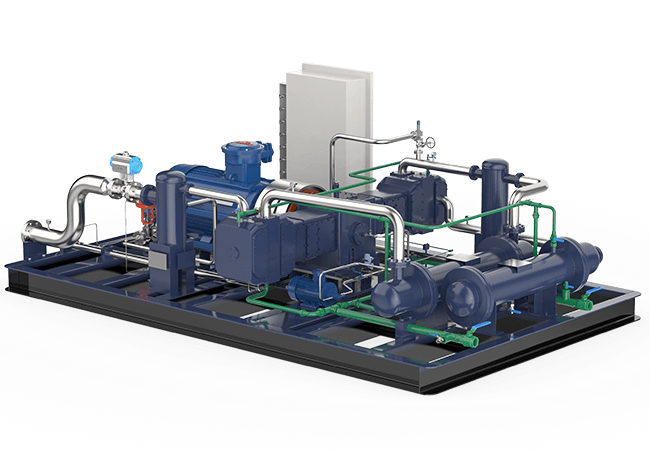

- Technology: Standard oil-flooded screw or piston compressor + a guaranteed purification chain.

- How it Achieves Purity: Removes oil through staged filtration: a coalescing filter (removes 99.99% of liquids/aerosols) followed by an activated carbon filter (adsorbs oil vapor).

- Best For Achieving: Reliably Class 1 or Class 2 air. The most cost-effective choice for the majority of industrial applications.

- Total Cost of Ownership (TCO):

- CAPEX: Lower.

- OPEX: Energy efficiency is excellent. Adds cost for filter element and carbon bed replacement. Requires disciplined maintenance.

- Risk: Risk is managed through rigorous maintenance and monitoring of the purification chain.

The Decision Rule:

- If your requirement is ISO Class 0 or a strictly enforced Class 1, and your risk tolerance is very low, an Oil-Free compressor is necessary.

- If your requirement is ISO Class 1 or 2, and you can commit to proper system design and maintenance, the Oil-Lubricated + Filtration path offers superior lifetime economics and is typically sufficient.

Industry Application Guide: When is it Necessary?

- Semiconductor & Electronics Manufacturing (ISO Class 0 or 1): Necessary. Trace hydrocarbons can ruin microchips. Oil-free is the industry standard.

- Breathing Air Systems (ISO Class 0/1): Necessary. Directly impacts human safety. Often mandated by regulations.

- Pharmaceuticals (Sterile Processes, API production): Often necessary. Regulatory oversight (FDA, EMA) and extreme risk aversion typically mandate oil-free or its equivalent for the highest purity air.

- Food & Beverage (Direct Contact, e.g., mixing, fermentation, packaging): Context-dependent. For high-risk, ready-to-eat products, oil-free is common. For many applications, Class 2 air achieved via certified filtration systems (using H1 lubricants) is sufficient and standard.

- Automotive Painting, Precision Pneumatics (Class 2): Usually NOT necessary. Well-maintained, high-quality filtration systems are the standard and are highly effective.

- General Manufacturing, Workshops (Class 3 or 4): Not necessary. Oil-lubricated compressors with basic filtration are perfectly adequate and most economical.

FAQ: Your Top Questions Answered

Q1: If my ISO standard requires Class 1 oil purity, can I use an oil-lubricated compressor?

A1: Yes, absolutely. A properly designed purification system—consisting of a high-efficiency coalescing filter followed by a properly sized activated carbon filter—is certified to deliver Class 1 air (≤0.01 mg/m³). The system must be meticulously maintained, and performance should be validated with oil test kits.

Q2: Don’t activated carbon filters remove all oil? Why isn’t that enough?

A2: Activated carbon filters are only effective against oil vapor. They are easily and instantly destroyed by liquid oil or aerosols. They must be installed after a high-quality coalescing filter that removes all liquids. They are also a consumable item with a finite adsorption capacity and must be replaced regularly.

Q3: Aren’t oil-free compressors more energy-efficient?

A3: This is a common myth. While oil-free centrifugal compressors are highly efficient at very large scales (200+ HP), oil-injected screw compressors are generally more efficient in the mid-range (20-200 HP). Always compare specific power (kW/CFM) figures for the exact models and operating conditions you are considering.

Q4: How can I monitor my air quality to ensure my filtration system is working?

A4: Implement proactive monitoring.

- Use differential pressure gauges on filters to signal element changes.

- Install an inline oil aerosol monitor for continuous, real-time verification of Class 1 or Class 2 compliance.

- Use periodic laboratory analysis or colorimetric test kits for audit-grade verification.

Q5: Our customer demands “oil-free air” for our food packaging. What should we specify?

A5: Move the conversation from vague terms to precise specifications. Ask your customer or their standard to define the required ISO 8573-1 Oil Class. If they cannot, propose a specific class (e.g., Class 2) based on industry best practice. Then, you can engineer and validate a system—whether oil-free or oil-lubricated with filtration—to meet that objective, demonstrable standard.

Conclusion: Necessity is Defined by Risk and Specification

The necessity of an oil-free compressor is not a matter of opinion but of quantifiable risk and defined specification. It is necessary when the consequence of even trace oil contamination is catastrophic (safety, massive product loss) and when the target air purity is at the absolute pinnacle of what is measurable (ISO Class 0 or enforced Class 1).

For the broad spectrum of industrial applications, advanced filtration technology provides an exceptionally reliable and economically superior path to achieving the required air purity. The investment in a robust filtration system and a disciplined maintenance regimen often yields a better return than the premium for oil-free technology.

Begin your decision with the definitive step: establish your required ISO 8573-1 Oil Class. With that in hand, the choice between technological paths becomes a clear exercise in risk management and cost analysis.

To define your requirement and model the total cost of both solutions, start with a Compressed Air Purity Needs Analysis. At MINNUO, we help clients translate process needs into specific ISO classes, assess contamination risks, and provide detailed TCO comparisons between oil-free and advanced filtration systems, ensuring your capital investment is both necessary and optimal.

Email

Email sales:+86 15366749631

sales:+86 15366749631