Introduction: The “Good” Compressor Conundrum

Every compressor salesperson will tell you their model is “good.” But when you’re faced with dozens of brands, hundreds of models, and a dizzying array of technical specifications, how do you make a choice you won’t regret in two years?

The truth is, a truly “good” industrial air compressor isn’t about having the highest horsepower or CFM on a spec sheet. It’s about one thing: whether it can run stably, efficiently, and cost-effectively in your specific application for the next 5 to 10 years.

This guide cuts through the marketing noise. We’re providing a practical, 5-point checklist used by industry professionals to define and select an air compressor that is genuinely “good” for your business and your bottom line.

Checkpoint 1: Unshakable Reliability – Will It Quit on You?

Reliability is the non-negotiable foundation of a “good” compressor. It’s not about a sales promise; it’s about engineering and proven performance. Evaluate it based on these concrete factors:

- Demand the Data on Mean Time Between Failures (MTBF). Ask any potential supplier for the MTBF rating of their compressor’s core component—the air-end. A robust, industrial-grade machine should have an MTBF of 50,000 hours or more. This single number tells you more about long-term reliability than any sales pitch.

- Examine the Air-End Design. The precision-machined rotors are the engine of your compressor. Look for asymmetric rotor profiles (designed to reduce internal leakage and boost air output efficiency). The quality of bearings and the integrity of the sealing system are what separate a decade-long workhorse from a frequent-flyer at the repair shop.

- Verify the True Duty Cycle. Many compressors are designed for intermittent operation. A “good” industrial air compressor is built for 24/7 continuous operation without performance degradation. Check the manufacturer’s specifications for the designated duty cycle—it should be explicitly stated.

🚩 Red Flag: Vague warranties, especially on the air-end, or a refusal to provide MTBF data.

Checkpoint 2: Honest Efficiency – Is It a Power Hog?

A “good” compressor saves you money every minute it runs. The initial price tag is a tiny part of the financial story; electricity is typically 70-80% of its total lifetime cost.

- Focus on the Key Metric: Specific Power. Forget horsepower. Specific power (kW/CFM) measures how much electrical energy is required to produce a unit of air. A lower number means a more efficient—and a truly “better”—compressor. Always compare models based on this spec.

- Understand the VSD vs. Fixed-Speed Decision. The choice between VSD and fixed-speed air compressor efficiency is critical.

- Choose VSD if: Your air demand fluctuates significantly (e.g., batch processes). A quality VSD can cut your energy bill by 20-40%.

- Consider Fixed-Speed if: Your air demand is incredibly constant and stable 24/7.

| Factor | VSD Compressor | Fixed-Speed Compressor |

| Best For | Fluctuating air demand (batch processes, shifts) | Constant 24/7 air demand |

| Energy Savings | 20-40% reduction | Minimal savings |

| Initial Cost | Higher | Lower |

| Ideal Application | Workshops with variable equipment usage | Plants with stable production lines |

- The Hidden Cost Calculator: A 10% improvement in efficiency might not sound like much. But for a 100 HP compressor running two shifts, that can translate to over $5,000 in annual savings at standard electricity rates.

Checkpoint 3: Total Cost of Ownership (TCO) – What’s the REAL Price?

The cheapest compressor off the truck is often the most expensive one to own. A “good” compressor is defined by its low Total Cost of Ownership.

| Cost Component | Percentage of Total TCO | Key Influence Factor |

| Energy Cost | 70-80% | Specific Power (kW/CFM), operation hours |

| Maintenance Cost | 10-15% | Air-end quality, parts availability |

| Initial Cost | 5-10% | Brand, model, installation |

| Downtime Cost | 5-10% | MTBF, local service support |

- The Smart Question: Is a compressor that costs $10,000 less upfront but consumes $15,000 more in electricity over five years actually “good”?

Checkpoint 4: Perfect Suitability – Is It Built for YOUR Job?

A race car is a “good” vehicle, but not for hauling lumber. A “good” compressor is one perfectly matched to your needs.

- Right-Size Your Air Supply Using Our Guide. Follow this air compressor sizing guide for your workshop or plant.

- Pressure (PSI/Bar): Know your highest required tool/process pressure and add a 10-15% safety margin.

- Flow (CFM/Nm³/min): Calculate the total airflow of all tools running simultaneously. An undersized compressor will kill productivity; an oversized one will waste energy and money.

- Ensure Air Quality. Clean, dry air protects your equipment and product. A “good” compressor system includes the correct dryer and filtration, meeting the required ISO 8573-1 air purity class for your application.

- Consider the Environmental Fit. Factors like noise levels (dB), physical footprint, and ventilation requirements are also part of what makes a compressor “good” for your specific space.

Checkpoint 5: Ironclad Support – Who Has Your Back When Things Get Tough?

Even the best-engineered compressor may eventually need service. The supplier’s support system is part of the product you’re buying.

- Verify the Local Service Network. How quickly can a certified technician be on-site? Delays cost you money.

- Assess Their Technical Expertise. Can their support team provide remote diagnostics and expert troubleshooting over the phone?

- Check Parts Availability. Are common wear-and-tear parts and filters kept in local stock, or do they require a long wait for international shipping?

Conclusion: Your Blueprint for a Smart Investment

Forget the vague notion of a “good” air compressor. A smart investment is defined by Reliability, Efficiency, Low TCO, Perfect Suitability, and Ironclad Support.

Use this 5-point checklist as your guide. Walk into any negotiation armed with these questions. The answers will clearly separate the market’s true workhorses from the overpriced pretenders.

Ready to Find a Compressor That’s “Good” for Your Bottom Line?

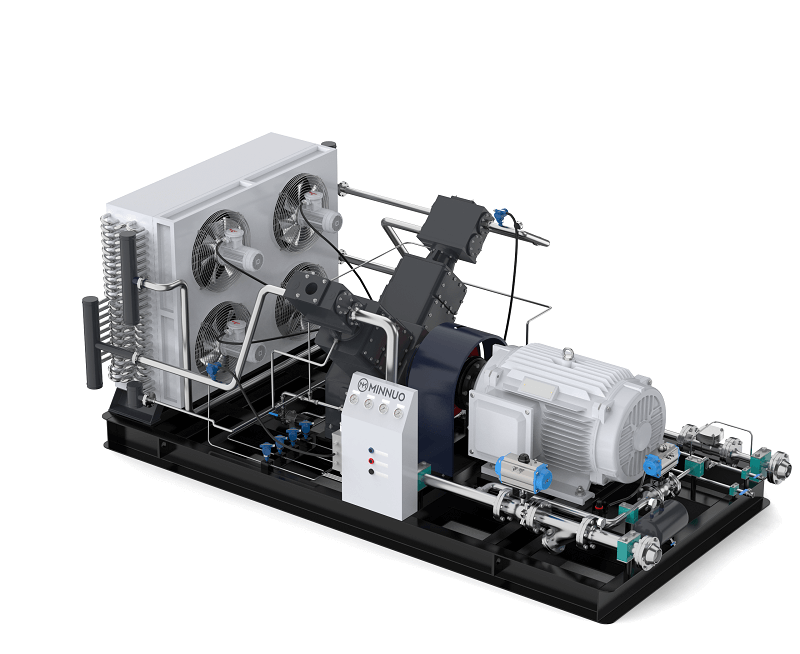

At MINNUO, we believe a true partner doesn’t just sell you a machine; they provide a cost-effective solution. Our experts are ready to walk you through this 5-point checklist specific to your operation.

Contact us today for a free, no-obligation Compressor Needs Assessment and TCO Analysis. We’ll help you cut through the specs and identify the compressor that delivers real value for years to come.

Email

Email sales:+86 15366749631

sales:+86 15366749631