Purchasing an air compressor based solely on the equipment price tag is one of the costliest mistakes a plant manager can make. The true expense lies in the electricity it consumes over its 10+ year lifespan. You’re not just buying a machine; you’re locking in a long-term energy consumption profile.

The central dilemma emerges: the Variable Speed Drive (VSD) compressor promises significant energy savings but commands a higher upfront cost. The Fixed Speed (or “constant speed”) compressor is simpler and cheaper to buy but can be notoriously inefficient under real-world, fluctuating demand.

This guide moves beyond simple technical specs to provide a Total Cost of Ownership (TCO) framework. We’ll equip you with the insights to determine whether the VSD’s premium is a wise investment or an unnecessary expense for your specific operation.

The Core Difference: How They Match Supply to Demand

Understanding the fundamental control strategy is key to grasping their cost implications.

- Fixed Speed Compressor: The motor runs at a constant speed. To match variable air demand, it uses a load/unload or start/stop control. In load/unload mode, the compressor produces full pressure when loaded, then idles (unloaded) while still consuming significant power but producing no air. This cycling leads to wasted energy.

- VSD Compressor: An inverter drives the motor, allowing its speed to vary precisely. It adjusts the motor speed in real-time to deliver exactly the airflow needed. This eliminates the wasteful unloading cycle, dramatically improving efficiency at partial loads.

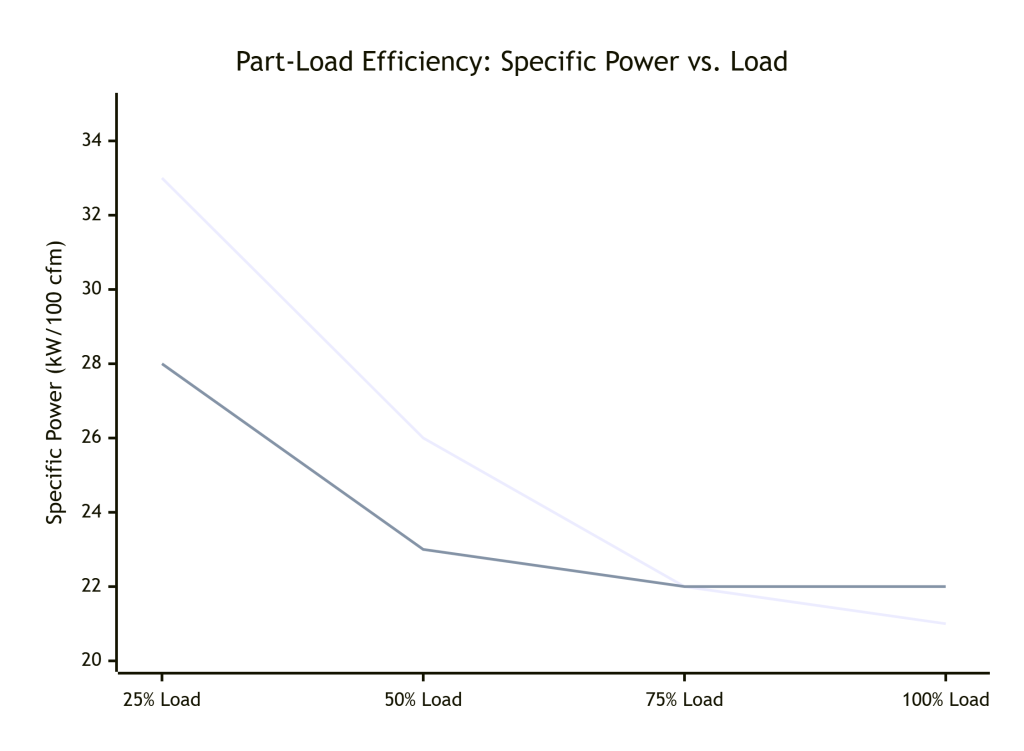

The following graph illustrates the critical impact of this difference on energy consumption across different load levels:

This model shows how a Fixed Speed compressor’s efficiency drops at lower loads due to unloading losses, while a VSD maintains high efficiency across a wide range.

The Total Cost of Ownership (TCO) Breakdown

To make an intelligent choice, you must look beyond the purchase order. Let’s dissect the TCO for each technology.

1. Capital Expenditure (CAPEX): The Initial Investment

| Factor | Fixed Speed Compressor | VSD Compressor | TCO Impact |

| Purchase Price | Lower | Higher (Typically 20-40% premium) | Direct impact on upfront capital. |

| Installation | Generally simpler | May require consideration for electrical harmonics | Moderate influence on project cost. |

Verdict: The fixed-speed unit wins on day-one cost. This is its primary advantage.

2. Operational Expenditure (OPEX): The Long-Term Battle

This is where the decision is truly won or lost. Energy costs typically constitute 60-80% of a compressor’s lifetime TCO.

- Energy Costs: As shown in the graph, the VSD’s superiority in partial-load conditions translates directly to lower energy consumption. Savings of 20-35% are common for applications with variable demand.

- Maintenance Costs: Fixed-speed compressors experience repeated thermal and pressure cycles, stressing components. VSDs run more smoothly, reducing mechanical wear but introducing power electronics that require specialized servicing. Long-term costs are often comparable but distributed differently.

- System Impact: The VSD’s soft-start reduces electrical stress on motors and the grid, which can improve overall system reliability and potentially avoid utility demand charges.

Verdict: The VSD aggressively attacks the largest chunk of TCO: energy. It transforms your cost structure from high operational expense to a higher initial investment with lower long-term operating costs.

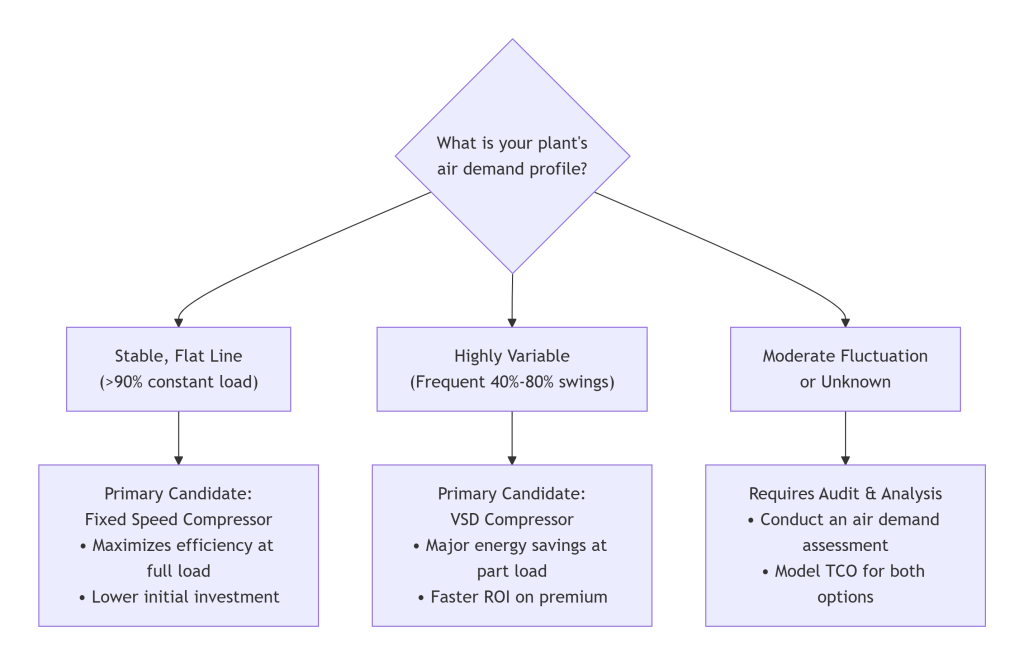

The Decision Guide: Which Technology Fits Your Profile?

The optimal choice is dictated by one factor above all: Your Air Demand Profile. Use the guide below to identify the most promising path.

Scenario Analysis

Choose a Fixed Speed Compressor if:

- Your air demand is extremely stable and consistently high (e.g., a base-load compressor in a large system).

- Your budget is severely constrained, and you cannot justify any capital premium.

- Your annual operating hours are very low.

Choose a VSD Compressor if:

- Your air demand fluctuates significantly with production cycles (e.g., automotive plants, workshops, packaging).

- Your facility has high electricity costs.

- You need very stable system pressure for sensitive equipment.

From Concept to Calculation: Estimating Your ROI

The decision must become financial. Here is a simplified framework to estimate the payback on a VSD premium.

1. Gather Your Data:

- Compressor Size: _____ HP / _____ kW

- Annual Operating Hours: _____ hours

- Local Electricity Cost: _____ $/kWh

- Estimated Average Load: _____%

- Price Premium for VSD: _____ $

2. Simplified Savings Estimation (Conceptual Formula):

Annual Energy Savings = (Compressor kW) × (Operating Hours) × (Electricity Cost) × (Estimated Efficiency Gain %)

*Example: A 100hp (75kW) compressor running 8,000 hours/year at $0.10/kWh with a 25% estimated VSD savings yields:*

*75kW × 8,000 hrs × $0.10 × 0.25 = $15,000 annual savings.*

3. Calculate Simple Payback:

Payback Period (Years) = (VSD Price Premium) / (Annual Energy Savings)

*Example: With a $30,000 premium: $30,000 / $15,000 = 2-year payback.*

This exercise highlights a powerful truth: In the right application, the VSD premium can pay for itself in a short time, after which the savings flow directly to your bottom line.

FAQ: Navigating Common Questions

Q1: Aren’t VSD compressors less reliable due to the complex inverter?

A1: Modern VSD components are highly reliable. While the inverter adds complexity, it also eliminates the harsh mechanical and electrical cycling of a fixed-speed machine, reducing wear on key components. Overall system reliability is often comparable or improved.

Q2: How can I accurately know my air demand profile?

A2: You must measure it. A Data Logging Air Audit involves installing flow and pressure sensors on your main air header for a period of time. This reveals your exact consumption pattern, providing the essential data for a confident investment decision.

Q3: We have multiple compressors. Should they all be VSD?

A3: Not necessarily. The most efficient system is often a combination. A common strategy is to use a fixed-speed compressor as the base load unit and a VSD compressor as the trim unit handling fluctuations. This optimizes both capital and operational costs.

Conclusion: It’s a Financial Decision

The choice between VSD and fixed speed is not about which technology is superior. It is a capital allocation decision with a clear financial metric: Return on Investment (ROI).

A fixed-speed compressor is a lower-risk option for predictable, high-load scenarios. A VSD compressor is a capital investment in energy efficiency, with the payoff being reduced operating costs for years to come.

The critical step is moving from guesswork to data. A professional compressed air system audit provides the definitive business case, translating your operational patterns into a projected TCO and ROI for each option.

At MINNUO, our engineering process begins with this analysis. We provide clients with a data-driven comparison that clarifies not just the potential savings, but the precise financial pathway to achieving them.

Email

Email sales:+86 15366749631

sales:+86 15366749631