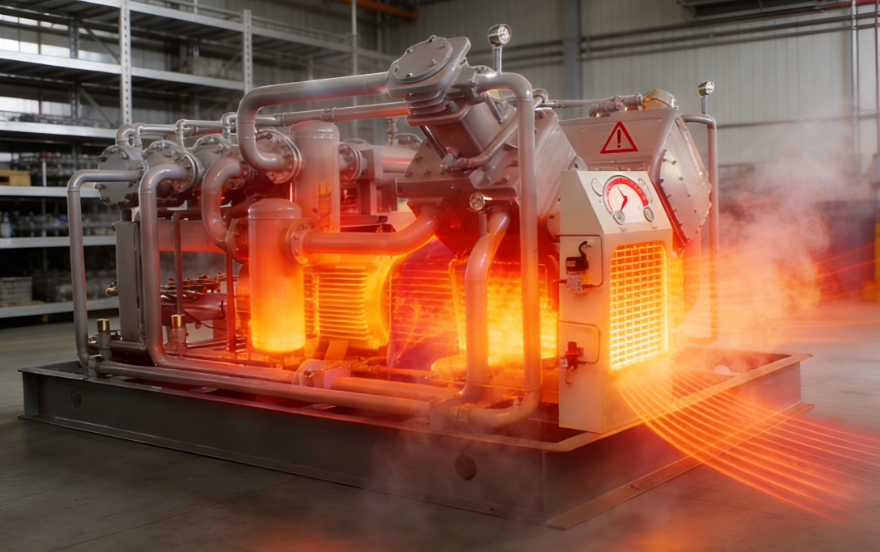

According to a report by the World Meteorological Organization (WMO), the global average surface temperature has risen by 1.45±0.12℃ compared to pre-industrial levels since 2023, reaching a historical peak. The continuous extreme weather is deeply impacting the manufacturing infrastructure. The Air compressor, the lifeblood of industrial power, are facing systemic risks such as an 18% decline in heat dissipation efficiency (data from the International Compressed Air Association), a 40% increase in failure rates, and a 3-5 year reduction in equipment lifespan in an environment above 35℃. In the face of more severe high-temperature warnings this summer, building a scientific defense system has become a strategic necessity to ensure the continuous production of enterprises.

This article will provide a complete set of solutions ranging from immediate maintenance to long-term guarantee for industrial enterprises facing high-temperature challenges By scientifically diagnosing the mechanism of high-temperature hazards, implementing refined maintenance operation norms, assessing the input-output ratio of extreme environment computer room construction, and integrating MINNUO’s intelligent monitoring and emergency service network, it helps enterprises reduce compressor failure rates by more than 41% and cut comprehensive operation and maintenance costs by ≥25% And demonstrate how MINNUO’s high-performance compressors revolutionize industrial operations, helping enterprises maximize energy efficiency, extend equipment lifespan and reduce operating costs.

When a certain auto parts factory suffered a heart-wrenching case where the main shaft seized due to the failure of the compressor’s heat dissipation, resulting in a 22-hour production line paralysis, a fine of $40,000 for delayed delivery, and equipment maintenance costs of $21,000, with a cumulative loss of over $70,000, it sounded the alarm MINNUO has laid out high-temperature defense systems for over 500 enterprises worldwide. Just like a certain Middle Eastern photovoltaic enterprise, in an extreme environment of 50℃, through MINNUO’s customized intelligent air guiding system and machine room spray cooling solution, the ambient temperature of the compressor was stably suppressed below 38℃, achieving a record of zero downtime for 15,000 consecutive hours during the high-temperature season. Save $50,000 in operation and maintenance costs annually. Whether you need to deal with sudden workshop shutdowns, optimize maintenance budgets, or plan high-temperature resilient infrastructure, you can get customized solutions from MINNUO.

1. Potential hazards of high temperature to compressors

1.1 Piston compressor: Mechanical wear and thermal stress

Collapse failure of the gas valve system: When the exhaust temperature exceeds the safety threshold of 140℃ (for R22 refrigerant) or 150℃ (for R717 ammonia refrigerant), the fatigue strength of the valve plate material drops by more than 50%. Continuous high temperatures cause the lubricating oil to carbonize and form hard carbon deposits, which scratch the sealing surface of the valve plate and reduce the elasticity of the spring. For the H-198/13.7 piston engine of a certain steel plant, at an exhaust temperature of 190℃, the cleaning cycle of the air valve was shortened to 500 hours, and the replacement frequency of the valve plate was increased by three times.

Piston ring melting wear: High temperature causes the oil film on the cylinder wall to break, and the dry friction of the metal leads to melting wear between the piston ring and the cylinder liner. Actual measurements show that when the cylinder head temperature exceeds 120℃, the wear rate of the support ring filled with polytetrafluoroethylene material increases by 300%, and the seal failure causes the gas leakage to increase by 15%, forming a vicious cycle of “high temperature – leakage – even higher temperature”.

Crankcase lubricating oil coking: In a splash lubrication environment, when the crankcase oil temperature exceeds 70℃, it will trigger a doubling of the lubricating oil oxidation rate. Measured data from a certain agricultural machinery factory shows that when the oil temperature rises from 65℃ to 85℃, the acid value (AN) of the oil increases fourfold, and the generated sludge clogs the oil filter, causing the connecting rod bearing to be burned due to lack of oil.

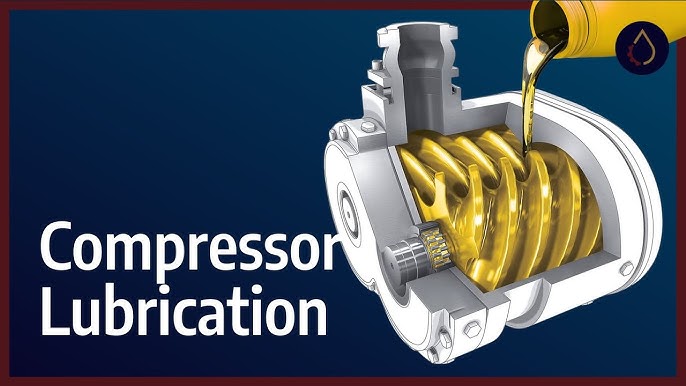

1.2 Screw Compressor: Oil Circuit deterioration and thermal deformation

Loss of rotor system accuracy: High temperature causes uneven thermal expansion between the male rotor and the star wheel plate, breaking the design critical value of the meshing clearance <0.05mm. A case of a certain fluorine chemical enterprise shows that for every 10℃ increase in the temperature of the main unit, the axial movement of the rotor increases by 0.02mm, causing metal shaves to be produced due to end face friction, and eventually leading to a seizing accident.

Lubricating oil cracking chain reaction: Screw compressors rely on lubricating oil for sealing and cooling, but continuous operation above 95℃ will cause the base oil to crack

The evaporation of the light components leads to a 30% increase in viscosity

The heavy components polymerize to form coking substances that clog the oil passage

The increase in acid value corrodes the raceway of the bearing

Experiments have proved that when the oil temperature is above 100℃, the service life of the oil is shortened to one quarter of the normal value.

Volumetric efficiency collapse: Traditional screw compressors face the “overcompression” predicament under high-temperature conditions – the fixed volume ratio of the national standard design cannot match the high-temperature condensing pressure. The measured data of a certain photovoltaic factory shows that when the cooling water temperature rises to 38℃, the external pressure ratio of the compressor reaches 4.8, while the internal volume ratio is only 3.2, resulting in an efficiency loss of 18% and a monthly electricity bill increase of $10,000.

2. Special Guide for High-temperature Maintenance of Piston Compressors

The high-temperature protection of piston compressors should focus on the lubrication guarantee and thermal stress control of mechanical moving pairs.

2.1 Valve System: The first line of defense against high-temperature failure

Enhanced valve plate cooling: Install heat dissipation fins (fin coefficient ≥3) on the air valve cover, or introduce forced air cooling (wind speed >6m/s). After the renovation of a certain compressor factory, the temperature of the valve plate was reduced by 28℃ and its service life was extended to 8,000 hours.

Preventive cleaning of carbon deposits

Disassemble and inspect the gas valve every 500 hours and soak it in a metal cleaner (pH 9-10) for 30 minutes

Microscopic carbon deposits are removed using an ultrasonic cleaner (40kHz, 60℃)

The sealing surface of the valve seat is subjected to diamond grinding (Ra≤0.8μm)

Upgrade high-temperature materials: Recommended to use:

PEEK reinforced valve plate (continuous operating temperature 250℃)

Chromium-molybdenum alloy gas valve spring (anti-relaxation temperature >300℃)

Metal-based solid lubricating coating (coefficient of friction <0.15)

2.2 Cylinder Block and Cooling System: Thermal Management Core

Water-cooled jacket optimization

Maintain water pressure ≥0.2MPa and flow rate >1.5m/s

Check the thickness of scale every month (chemical cleaning is required if it is greater than 0.5mm).

Add corrosion and scale inhibitor (with a concentration maintained at 200ppm)

Precise control of piston ring clearance

Under high-temperature working conditions, the reserved thermal expansion gap is: 0.0012D when the cylinder diameter is less than 500mm, and 0.001D when it is greater than 500mm (D is the cylinder diameter).

The wedge-shaped ring design is adopted to compensate for thermal deformation

Fill polytetrafluoroethylene rings and add molybdenum disulfide to enhance self-lubrication

Innovative application of balance chamber: The new generation of balance chamber is arranged on the side of the cylinder head and reduces the intake air temperature through a series flow. The actual measurement shows:

The intake air temperature is reduced by 12℃

The temperature of the stuffing box dropped by 18℃

The service life of the piston rings has been increased by 30%

2.3 Lubrication System: An important project for resisting high temperatures

Oil product upgrade strategy

Switch to SAE50 high-viscosity mineral oil (VI>120)

Add high-temperature antioxidants (such as dialkyl diphenylamine)

Keep the oil level above two-thirds of the window

Key control points of the oil circuit:

Oil injector flow calibration: ≥3 drops per minute at each point (at 80℃)

The circulating oil pressure is maintained at 0.15-0.25MPa

Replace the oil filter immediately if the pressure difference is greater than 0.15MPa

Table: List of Key Parameters for High-temperature Maintenance of Piston Compressors

| System | System | Standard value | Over-standard measures |

| Air valve system | Air valve system | R22≤145℃, R717≤150℃ | Shut down for cleaning |

| Cooling system | Cooling system | ≤15℃ (Inlet and outlet) | Acid washing for scale removal |

| Lubrication system | Lubrication system | 40 ~ 65 ℃ | Check the cooler |

| Transmission system | Transmission system | 70 ℃ or less | Shutdown inspection |

3. Special Guide for High-temperature Curing of Screw Compressors

The core of high-temperature protection for screw compressors lies in the coordinated control of the stability of the oil circuit system and the thermal deformation of the rotor.

3.1 Oil Circuit System: Root Cause Control of High-temperature Faults

Full life cycle management of oil products

Switch to polyalphaolefin (PAO) fully synthetic oil (VI≥140, pour point <-25℃)

Oil spectrum analysis every 2000 hours: When Fe>15ppm or Cu>10ppm, it warns of bearing wear

The oil change cycle during the high-temperature season is shortened by 30%

Deep cleaning technology for oil circuits

Online cleaning: Add hydrocarbon cleaning agent (8% addition ratio) before oil change, and circulate at 80℃ for 1 hour

Offline soaking: When coking is severe, use an alkaline water-based cleaning agent (pH 11-12) and soak at 60℃ for 48 hours

Ultrasonic cleaning: The oil separator tank is cleaned using 40kHz ultrasonic waves combined with solvent emulsification

Precise regulation of the temperature control valve

Regularly test the opening temperature (71±2℃)

When the valve core is stuck, grind the valve stem with 800-mesh sandpaper

Upgrade the electronic proportional control valve (control accuracy ±1℃)

3.2 Rotor System: Active compensation for thermal deformation

Gap dynamic compensation technology

Alloy with matching coefficient of thermal expansion (male rotor: aluminum bronze CT≈18×10⁻⁶/℃; Star wheel plate: Engineering plastic CT≈45×10⁻⁶/℃

A thermal expansion gap of 0.08-0.12mm is reserved for high-temperature working conditions

The shape and position tolerances of the rotor are inspected by laser every quarter

Innovative design of exhaust structure

The radial exhaust port Angle has been optimized to 90-115° (the traditional design is 70-90°).

The axial exhaust port adopts a butterfly-shaped diffusion structure

Reduce over-compression loss by 7%

Intelligent preloading system for bearings

Install disc spring groups to compensate for thermal displacement

Ceramic rolling element bearings (temperature resistance >250℃) are adopted

The preload force is automatically adjusted with temperature (20-80N/℃)

3.3 Cooling System: Practical Solutions for Efficiency Enhancement

Air-cooling system enhancement

Fin cleaning standard: Dust accumulation thickness ≤0.3mm

Install a wind deflector (increase wind speed by 40%)

Cooling fan with variable inclination Angle blades (air volume increased by 25%

Water cooling system upgrade

Plate heat exchanger flow channel optimization: Flow rate ≥1.2m/s

Gradient nano-coating is adopted for scale prevention

Start online backwashing when the temperature difference is greater than 10℃

Active cooling in the computer room

Install an evaporative cooling system (wet bulb efficiency >90%)

The exhaust air volume is designed at 0.35m³/min/kW

Ensure that the temperature in the computer room is ≤38℃

Table: Key Parameters Table for High-temperature Maintenance of Screw Compressors

| System | Monitoring point | Warning value | Action measures |

| Oil circuit system | Oil filter pressure difference | > 0.15 MPa | Replace immediately |

| Cooling system | Temperature difference of the oil cooler | The < 8 ℃ | Chemical cleaning |

| Rotor system | Bearing vibration | > 2.8 mm/s | Shutdown inspection |

| Control system | Exhaust temperature | > 95 ℃ | Activate the cooling protocol |

4. The ultimate solution for special high-temperature/severe cold regions: Construction of compressor rooms

In regions with continuous high temperatures (such as over 40℃ in summer) or severe cold (below -10℃ in winter), it is difficult to ensure the long-term reliable operation of compressors solely through regular maintenance. Investing in the construction of professional compressor rooms is a strategic infrastructure that ensures the efficient, stable and economic operation of equipment. Its core values and design key points are as follows:

4.1 The Necessity of Building a professional compressor room

Precise temperature control, resisting extreme weather

The computer room creates a controllable micro-environment for the compressor, effectively isolating the external extreme heat (in summer) and severe cold (in winter). In summer, the operating environment temperature of the equipment can be stably controlled below the 40℃ allowed by the compressor (usually recommended to be ≤35℃), to avoid heat dissipation failure, deterioration of lubricating oil (the oxidation rate can double at high temperatures) and frequent shutdowns caused by high temperatures. In winter, the temperature in the machine room is maintained above 5℃ through insulation and auxiliary heating to prevent the lubricating oil from solidifying (the pour point is usually between -10℃ and -20℃), the pipelines from freezing and cracking, and the difficulty in cold starting, significantly reducing the operational risks.

Efficient noise reduction, enhancing environmental compliance

Professional sound insulation design (wall/ceiling sound-absorbing materials + intake and exhaust mufflers) can reduce the operating noise of the compressor by 15-25 decibels (A), ensuring that the noise at the factory boundary meets the environmental protection standard of less than 65 dB(A), improving the working environment and avoiding complaints and penalties.

All-round protection, reducing maintenance costs

The confined space effectively blocks the intrusion of dust (especially particles larger than PM10), rain, sand and foreign objects, protecting the core components of the equipment (such as precision rotors and motor windings). Actual measurements show that a well-protected machine room can extend the lifespan of key filter elements (air filters, oil filters) by 20-30% and significantly reduce the frequency of external cleaning of equipment.

Centralized management, optimizing operational efficiency

It is convenient for the parallel layout of multiple compressors, unified pipeline connection (to reduce pressure loss) and centralized monitoring (energy consumption and status). Supports the integration of waste heat recovery systems (with a recovery efficiency of up to 60-70%), which can be used for winter heating or process hot water, significantly improving energy utilization efficiency.

4.2 Key Elements of Compressor Room Design (MINNUO Professional Advice)

Scientific site selection and reasonable spatial planning

Give priority to choosing a location with good ventilation and far from heat sources such as boilers and kilns. Ensure that the equipment spacing is no less than 1.2 meters (maintenance access no less than 0.8 meters), and the ground load-bearing capacity is no less than 5000 kg/m² (specifically refer to equipment weight + dynamic load).

MINNUO Tips: We offer a free on-site inspection service. Based on your equipment model, quantity and future expansion plans, we accurately calculate the required area and load-bearing requirements.

Intelligent ventilation and active temperature control system

Forced ventilation: Calculate the required air volume based on the heat dissipation of the compressor (usually accounting for more than 90% of the input power) (for example, a 100kW unit approximately requires an exhaust air volume of ≥ 3000m ³/h). Install temperature-controlled variable-frequency intake/exhaust fans. Place the intake port (with insect-proof net) at the lower part of the machine room and the exhaust port at the upper part. Utilize the principle of natural ascent of hot air to enhance efficiency.

Active cooling/heating

Extreme high-temperature zone: When ventilation cannot maintain a temperature of ≤40℃, industrial air conditioners (with precise temperature control of ±1℃) or evaporative coolers (suitable for dry areas) need to be added. Objective: To maintain the temperature in the computer room within the optimal range of 28-35℃ allowed by the equipment.

In extremely cold regions: The walls are insulated with a thickness of ≥50mm (K value ≤ 0.4W /m²K), and are equipped with electric auxiliary heating/gas hot air curtains to ensure that the winter temperature is ≥5℃. MINNUO can design waste heat recovery solutions to convert the waste heat from compressors into heating sources, achieving an energy-saving rate as high as 30%.

Noise reduction and safety assurance

The interior walls and ceilings are covered with sound-absorbing cotton and perforated aluminum plates (NRC≥0.8), and the air ducts are equipped with impedance composite mufflers (insertion loss ≥25dB).

Strictly follow fire protection regulations: Use A-level fireproof materials, be equipped with CO₂ or dry powder fire extinguishers (at least one for every 50 square meters), install temperature and smoke detectors, and set up emergency exits with A width of ≥0.9m and explosion-proof lighting.

4.3 MINNUO provides you with professional support

In the face of extreme climate challenges, MINNUO compressors offer a full-chain solution from planning to implementation

✅ Free computer room design consultation: Based on local meteorological data, equipment parameters and budget, we provide customized layout and temperature control solutions.

✅ turnkey project service: Jointly certified contractor, complete the integrated construction of civil engineering, ventilation, electrical and noise reduction systems.

✅ Energy efficiency optimization solution: Integrate energy-saving technologies such as waste heat recovery and frequency conversion control to reduce the total life cycle cost.

✅ Remote monitoring access: Optional MINNUO SmartEye® system is available for real-time monitoring of temperature and humidity in the computer room, equipment status, and early warning of potential risks.

Case reference

Background: A certain petrochemical giant in the United Arab Emirates (a Fortune 500 company) has its factory located in the heart of the ABU Dhabi desert. The average daily temperature in summer is over 50℃. The original 6 250kW screw compressors have been shut down due to faults for 623 hours a year, resulting in direct losses of over $520,000.

Later, the insulated and heat-insulating machine room designed by MINNUO and the evaporative cooling system were adopted. The temperature in the machine room remained stable at ≤38℃ in summer, the failure rate of the compressor decreased by 40%, and the annual maintenance cost was saved by nearly $286,000.

Safety regulations: Comply with fire protection requirements (fireproof materials, fire extinguishers, and possibly temperature and smoke detectors), good lighting, emergency exits.

5. Maintenance cycle and MINNUO exclusive customized plan

5.1 The maintenance cycle is scientifically set

Table: Comparison of High-temperature Seasonal Maintenance Parameters for Piston and Screw Compressors

| Maintenance and repair project | Piston type | Screw type | Difference mechanism |

| Air filter cleaning | Daily (Dusty area | Every week | Piston machines have large intake pulsations and are prone to dust accumulation |

| Oil product replacement | 1,500 hours | 4,000 hours | The screw oil circuit operates in a closed loop, resulting in slow deterioration |

| Air valve/rotor inspection | Every month | Every quarter | The mechanical shock of the piston machine is large |

| The drive belt is taut | Weekly inspection | No need (direct drive) | Structural differences |

| Oil filter replacement | 500 hours | 2,000 hours | There are many metal abrasive particles in the piston machine |

5.2 MINNUO Differentiated Technical Services

Exclusive solution for piston machines

Infrared thermal imaging inspection: Scan the temperature field of the cylinder to locate local hotspots (accuracy ±2℃)

Crankcase air-cooling modification: Installation of axial flow forced cooler (lowering oil temperature by 8-12℃)

Valve life extension set: Nano-coated valve plate + spring preload force optimization

Exclusive solution for screw machines

Rotor clearance laser calibration: 0.01mm grade precision adjustment

Intelligent oil circuit monitoring system: Real-time monitoring of oil viscosity, moisture content and acid value

Variable frequency energy-saving transformation: Permanent magnet motor + dynamic adjustment of internal volume ratio

Practical case: Six screw compressors in a certain chemical plant adopted MINNUO intelligent oil circuit monitoring. During the high-temperature season of 2023, 17 unplanned shutdowns were avoided, saving maintenance costs of $52,900. The temperature of the cylinder head of the piston unit in a certain textile factory was reduced from 182℃ to 135℃ through the upgrade of the air valve, and the maintenance interval was extended from 3 months to 14 months.

5.3 How does MINNUO help customers cope with high-temperature challenges?

Facing the severe test of the stability and lifespan of compressors caused by continuous high temperatures, MINNUO, based on 20 years of industry experience, provides customers with full-cycle services from risk assessment to long-term guarantee, significantly reducing the risk of unplanned downtime caused by high temperatures (industry statistics account for more than 35%)

5.3.1 Professional Diagnosis and customized solutions

Free on-site environmental assessment

The MINNUO engineering team offers zero-cost on-site investigation services, accurately analyzing the geographical and climatic conditions of the customer’s location (such as the average number of high-temperature days per year), factory layout (ventilation conditions/heat source distribution), fluctuations in gas consumption load, and the status of existing equipment. Quantify the heat dissipation bottlenecks through tools such as thermal imaging detection, and identify high-risk points such as “intake air temperature exceeding 45℃” and “equipment spacing less than 0.8 meters”.

Customized response strategies

Based on the assessment data, provide a two-choice or combined solution:

High-temperature special maintenance plan: including cleaning standards, oil replacement cycles, inspection lists, etc., to match the customer’s operation and maintenance capabilities.

Feasibility Report on Compressor Room Construction: Including cost-benefit analysis (investment recovery usually takes 3-5 years), layout design and temperature control selection suggestions.

5.3.2 High-quality consumables ensure core performance

High-temperature special synthetic lubricating oil

Supply MINNUO HT series fully synthetic oil, with a high viscosity index of VI>140 and a 50% improvement in oxidation resistance (ASTM D943 test), ensuring continuous protection of rotors and bearings at 45 ° C oil temperature, and extending the oil change cycle by 30% compared to ordinary oil.

Original factory three-filter system

The air filter (dust holding capacity ≥500g/m²), oil filter (β value ≥200), and oil separator core (residual oil content ≤3ppm) have all passed the ISO 8573-1 certification, ensuring the cleanliness of the intake air and the smoothness of the oil passage from the source, and avoiding the accelerated wear caused by filter failure at high temperatures.

5.3.3 Professional service network ensures worry-free operation

Seasonal Preventive Maintenance (PM) Package

Special maintenance services are launched for the hot season from May to September, focusing on:

Deep cleaning of the radiator (restoring over 90% heat exchange efficiency)

Lubrication system inspection (oil quality testing + oil circuit sealing performance check)

Electrical safety calibration (temperature control sensor error ≤±2℃)

Turnkey project of compressor room

In collaboration with A first-class qualification partner in mechanical and electrical installation, we provide full-process services from design, construction to acceptance, ensuring temperature control (≤38℃ in summer), noise reduction (≤65 dB(A)), and fire compliance (GB50016 standard).

2/4/8-hour emergency response

With over 50 service outlets across the country, we promise to arrive within 4 hours in core areas. Our spare parts warehouse is always stocked with high-temperature and high-loss parts (such as motor windings and sealing kits) to reduce production downtime losses (average repair time MTTR≤6 hours).

5.3.4 Intelligent monitoring enables predictive protection

MINNUO SmartEye® Internet of Things System

Optional installation on existing equipment for real-time monitoring:

Key parameters: Exhaust temperature (warning threshold 100℃), oil temperature, ambient temperature and humidity

Operating status: Load rate, energy consumption curve, filter element pressure difference

By using AI algorithms to identify abnormal trends (such as a weekly decline in heat dissipation efficiency >10%), maintenance reminders are pushed 7 days in advance, reducing sudden failures by 60%.

Conclusion

High-temperature conditions continuously challenge industrial operations, especially for compressors. Maintaining optimal performance is crucial for long-term efficiency and cost-effectiveness. MINNUO’s expertise in providing high-quality and energy-efficient compressors is the key to ensuring reliable operation in harsh environments. MINNUO always prioritizes performance and environmental responsibility, providing customers with advanced solutions aimed at reducing operating costs and extending the service life of equipment.

With MINNUO’s professional guidance and customized maintenance strategies, enterprises can protect their systems from the destructive effects of extreme high temperatures. Even under the most demanding conditions, our solutions can ensure continuous reliable operation and higher energy efficiency. As all industries are confronted with increasing energy demands and environmental pressures, MINNUO is always committed to providing sustainable high-performance compressor systems and after-sales support to ensure smooth operation regardless of temperature.

Email

Email sales:+86 15366749631

sales:+86 15366749631