Air compressors are indispensable tools in numerous industries, from manufacturing and automotive to construction and home workshops. They convert power into compressed air, which is then used to perform work or power various tools and equipment.

There are several types of air compressors including reciprocating, rotary screw, centrifugal, scroll, diaphragm, and dynamic compressors. Each type of compressor serves distinct functions and suits different applications. Reciprocating compressors work best for small-scale operations, while rotary screw compressors excel in continuous industrial use. Centrifugal and axial compressors manage high flow rates and handle large-scale processes. Understanding these types helps you choose the best compressor for your specific needs. This guide explores the main types of air compressors, their unique characteristics, advantages, and applications.

How Air Compressors Work

To fully grasp the diverse types of air compressors and their applications, it is essential to first understand how they operate. Air compressors function by converting mechanical energy into compressed air. The core components include a motor, pump, tank, regulator, and control systems. The basic principle involves drawing air into a chamber, compressing it, and then storing it in a tank. This compressed air can then be used to power tools, equipment, or processes.

With this foundational understanding, we can now delve into the different types of air compressors and explore how each type works to meet various needs.

Types of Air Compressors

Air compressors come in several types, each suited to different applications and operational requirements. Below, we will explore these types in detail, starting with the most common and widely used types and moving towards those designed for specific, high-demand applications.

Reciprocating Compressors

Reciprocating compressors are the most common type of air compressors. They use a piston to compress air, operating on a back-and-forth motion. These compressors are known for their reliability and simplicity.

- Single-Stage Compressors: Compress air in one stroke of the piston, making them suitable for lower pressure requirements.

- Two-Stage Compressors: Compress air in two strokes, making them ideal for higher pressure needs.

Advantages: These compressors are cost-effective and efficient for intermittent use. They are also relatively easy to maintain.

Disadvantages: They can be noisy and require regular maintenance to ensure optimal performance.

Applications: Commonly used in home workshops, small manufacturing settings, and automotive repair, reciprocating compressors are versatile and affordable solutions for various needs.

Rotary Screw Compressors

Description: Rotary screw compressors utilize two interlocking helical screws to compress air. They are designed for continuous operation and are known for their efficiency and reliability.

- Oil-Flooded: Uses oil to lubricate and cool the screws, providing a cost-effective solution for many applications.

- Oil-Free: Employs alternative methods to avoid oil contamination, making them suitable for applications requiring clean air.

Advantages: These compressors are ideal for continuous operation and offer lower noise levels compared to reciprocating compressors.

Disadvantages: They come with a higher initial cost and require more complex maintenance.

Applications: Commonly found in industrial settings, large-scale operations, and continuous processes where high efficiency and reliability are crucial.

Centrifugal Compressors

Centrifugal compressors use a rotating impeller to increase the velocity of the air, which is then converted into pressure. This design is suited for applications requiring high flow rates and continuous operation.

- Single-Stage: Utilizes one set of impellers for moderate pressure increases.

- Multi-Stage: Employs multiple sets of impellers to achieve higher pressures.

Advantages: They offer high efficiency and capacity, making them ideal for large industrial processes.

Disadvantages: Centrifugal compressors are expensive and require high-speed operation, which can lead to higher maintenance costs.

Applications: Used in large industrial processes, HVAC systems, and power generation, these compressors are essential for applications demanding high flow rates and continuous operation.

Scroll Compressors

Scroll compressors use two interlocking spiral-shaped scrolls to compress air. They are appreciated for their compact size and quiet operation.

- Fixed Displacement: Provides a constant output of compressed air.

- Variable Displacement: Adjusts the output based on demand, offering greater flexibility.

Advantages: Scroll compressors are known for their quiet operation and compact design, making them ideal for applications where space and noise are factors.

Disadvantages: They come with a higher cost and are generally limited in capacity compared to other types.

Applications: Commonly used in air conditioning systems, refrigeration, and small to medium industrial applications where space and noise are considerations.

Diaphragm Compressors

Diaphragm compressors utilize a diaphragm to compress air. This design is favored for its ability to deliver clean, oil-free air.

Advantages: Ideal for applications where the purity of compressed air is critical, such as medical and laboratory environments.

Disadvantages: They have a lower capacity compared to other types and may require more maintenance.

Applications: Common in medical, laboratory, and food processing industries where contamination must be avoided.

Selecting the Right Air Compressor

With a comprehensive understanding of air compressor types, selecting the right one requires balancing performance, cost, and application needs. Below are key factors supported by actionable data to guide your decision.

Key Selection Factors

- Required Pressure & Flow Rate: Home use: 75-100 PSI, 1-5 CFM (e.g., nail guns, inflators)

- Automotive repair: 100-150 PSI, 5-15 CFM (e.g., impact wrenches)

- Industrial manufacturing: 100-200 PSI, 50-500 CFM (e.g., assembly lines)

- Environment & Space: Noise-sensitive areas (clinics, offices): Choose scroll models (≤65 dB) over reciprocating (≥75 dB)

- Small workshops: Vertical reciprocating models (footprint ≤2 sq. ft.) save space

- Outdoor use: Weatherproof rotary screw models with IP54 rating

- Budget & Operational Costs: Short-term use (≤2 years): Reciprocating (total cost of ownership ~$1,200)

- Long-term industrial use (≥5 years): Rotary screw (lower energy costs offset higher initial price by 30% in 3 years)

Application-to-Compressor Match Guide

| Application | Recommended Type | Key Specs |

|---|---|---|

| Home Workshop | Reciprocating (Single-Stage) | 90 PSI, 3 CFM |

| Auto Repair Shop | Reciprocating (Two-Stage) | 150 PSI, 12 CFM |

| Food Processing | Diaphragm | 120 PSI, 8 CFM, Class 0 Air |

| Large Manufacturing | Rotary Screw (Oil-Flooded) | 125 PSI, 100 CFM |

Maintenance and Troubleshooting

Proper maintenance is crucial for the longevity and efficiency of your air compressor. Each type of compressor has specific maintenance needs and common issues that may arise.

Regular Maintenance:

- Reciprocating Compressors: Regularly check oil levels, replace filters, and inspect components.

- Rotary Screw Compressors: Monitor oil quality, perform routine inspections, and address any issues promptly.

- Centrifugal Compressors: Maintain impellers, ensure proper cooling, and check for system leaks.

- Scroll Compressors: Inspect for wear and tear, and perform regular cleaning.

- Diaphragm Compressors: Replace diaphragms as needed and check seals for integrity.

Common Issues and Solutions:

- Leaking Air: Identify and seal leaks to maintain efficiency.

- Excessive Noise: Investigate for worn components or loose parts and address them accordingly.

- Reduced Performance: Ensure proper maintenance, check for blockages, and make necessary adjustments.

Maintenance and Troubleshooting

Proper maintenance extends compressor life by 50% and reduces repair costs by 40%. Below are type-specific maintenance schedules:

- Reciprocating: Oil change (every 500 hours), filter replacement (every 3 months)

- Rotary Screw: Oil analysis (every 1,000 hours), airend inspection (every 10,000 hours)

- Scroll: Dryer filter replacement (every 6 months), coil cleaning (every 12 months)

Common issues and quick fixes: Air leaks: Use soapy water to detect leaks; replace O-rings for 90% of casesReduced pressure: Clean intake filters (solves 75% of low-pressure issues)Excessive noise: Tighten loose mounting bolts or replace worn bearings

FAQs

Q1: How do I calculate the right CFM for my air tools?

A1: Multiply the CFM requirement of each tool by the number of tools used simultaneously, then add a 20% buffer. For example, 2 impact wrenches (5 CFM each) need 12 CFM total (5×2×1.2). Use our interactive tool for precise calculations.

Q2: What’s the difference between oil-free and oil-flooded compressors?

A2: Oil-flooded models use oil for lubrication (lower cost, 10-15% higher efficiency) but risk minor oil carryover. Oil-free models (ISO Class 0) use dry lubrication, critical for food, medical, or electronics industries. The extra cost (30-50% higher) is justified for contamination-sensitive applications.

Q3: How long should an industrial air compressor last?

A3: With proper maintenance, reciprocating compressors last 5-10 years, rotary screw models 10-15 years, and centrifugal compressors 15-20 years. Our Minnuo compressors come with a 5-year warranty on airends for rotary screw models, doubling the industry average.

Q4: Can I use a home compressor for industrial tasks?

A4: No—home compressors (≤5 CFM) lack the airflow for continuous industrial use, leading to overheating and premature failure. Industrial applications require compressors with 50+ CFM and duty cycles ≥75% (vs. 25-50% for home models).

Q5: What energy-saving features should I look for?

A5: Variable speed drives (VSD) reduce energy use by 30-50% vs. fixed-speed models, while heat recovery systems can reuse 80% of wasted heat for space heating or water heating. All Minnuo rotary screw compressors include VSD as standard.

Conclusion

Understanding the various types of air compressors and their applications helps in selecting the right one for your specific needs. Whether for a small workshop or a large industrial process, choosing the appropriate compressor ensures efficiency, reliability, and cost-effectiveness. By considering the factors outlined and following proper maintenance practices, you can maximize the performance and lifespan of your air compressor.

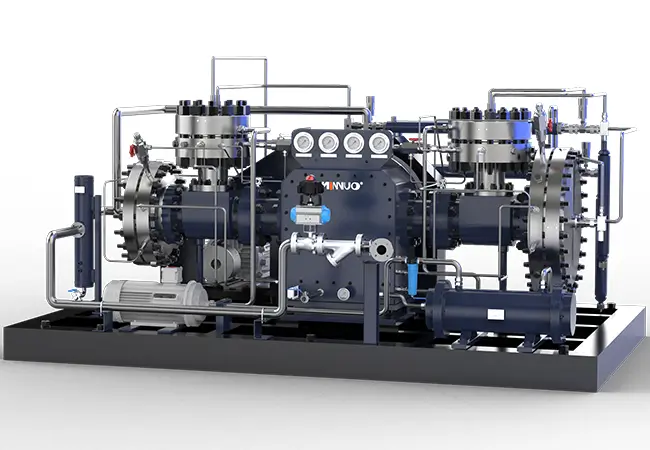

At Minnuo, we specialize in manufacturing a wide range of air compressors designed to deliver superior performance, reliability, and efficiency. Our products cater to various applications, from home workshops to industrial processes. Whether you require a robust rotary screw compressor for continuous operation or a versatile reciprocating compressor for home use, Minnuo has the right product for you.

Experience the difference with Minnuo’s state-of-the-art technology and dedicated customer support. Contact us today to learn more about our products and how they can enhance your operations.

Email

Email sales:+86 15366749631

sales:+86 15366749631