In the current context of global energy transition and increasingly strict environmental protection requirements, CNG (Compressed Natural Gas) compressors, as key equipment in the clean energy industry chain, their performance and reliability directly affect the operational efficiency of gas filling stations, the stability of industrial production, and the safety of energy transportation.

This article will focus on the world’s top ten renowned CNG compressor manufacturers, delving into their core technologies, market advantages, and applicable scenarios. It aims to provide buyers from various industries with comprehensive references ranging from technology selection to cost control, helping them find the most suitable high-pressure gas compression solution in the complex market.

Next, we will take you into the technology laboratories and global service landscapes of these industry leaders to see how they use innovation to address the triple challenges of “energy conservation, stability, and low maintenance”, and why choosing the right manufacturer can ensure that your compressed natural gas system continues to lead industry standards for the next 5 to 10 years.

What is CNG?

CNG (Compressed Natural Gas), or compressed natural gas, is a high-density gaseous fuel formed by purifying natural gas with methane (CH₄) as its main component (usually accounting for more than 90%), and then increasing its pressure to 20-25 mpa through a compressor. Its production process mainly includes three major steps: natural gas pretreatment (purification steps such as desulfurization, dehydration, and decarbonization to remove impurities like hydrogen sulfide and moisture, and prevent equipment corrosion or ice blockage), compression and pressurization (the core link), and storage and transportation.

In the CNG industrial chain, the compressor is the core power equipment and can be called an “energy converter” – it compresses low-pressure natural gas (usually from pipeline gas or shale gas fields, with a pressure of about 0.1 to 1MPa) to a high-pressure state through mechanical work, reducing its volume by approximately 250 times, thereby achieving efficient storage and transportation. Without the pressurization process of the compressor, natural gas cannot meet the filling density requirements of vehicle fuel and is also difficult to be transported over long distances by tube bundle vehicles.

The application fields of CNG have expanded from the initial vehicle fuel to diverse scenarios: In the transportation sector, as an alternative fuel for taxis, buses, and heavy trucks, its carbon emissions are reduced by approximately 20% to 30% compared to gasoline vehicles, making it an important choice for the global promotion of the “dual carbon” goals. In the industrial field, it can be used as a fuel for kilns to replace coal, or as a chemical raw material for the synthesis of ammonia, methanol and other products. In the field of distributed energy, CNG storage tanks are used to provide power generation or heating energy for remote areas.

The future market space is showing a continuous expansion trend. According to industry reports, with the surging global demand for clean energy, the compound annual growth rate of the global CNG market size is expected to remain at 8% to 10% from 2025 to 2030. Especially in emerging economies (such as Southeast Asia, the Middle East, and Africa), the penetration rate of CNG for vehicles is rapidly increasing, and the construction of supporting gas filling stations is driving the demand for compressors. Meanwhile, the deepening of the “coal-to-gas” policy in the industrial sector will also drive the development of CNG compressors towards larger sizes and higher efficiency.

What kind of compressor is suitable for CNG?

Not all compressors can meet the special requirements of CNG. Compressors suitable for CNG need to meet three core standards:

High-pressure stability: It is necessary to be capable of stably outputting high-pressure gas at 20-25MPa for a long time, and the pressure fluctuation should be controlled within ±0.5MPa to ensure the safety of the gas filling process and the filling efficiency.

Gas cleanliness guarantee: During the compression process, it is necessary to avoid lubricating oil contamination (by using oil-free lubrication or efficient oil-gas separation technology), to prevent the decline of methane purity or impurities from clogging the engine nozzles. Especially for automotive CNG, gas cleanliness directly affects the engine’s lifespan.

Adapt to extreme working conditions: It must be able to withstand trace corrosive components in natural gas (such as residual hydrogen sulfide) and operate normally in an ambient temperature range of -30 ℃ to 50℃ – for instance, the high temperatures in the Middle East’s deserts, the severe cold in Northern Europe’s winters, or the high humidity in coastal areas.

In addition, there are detailed requirements for different application scenarios: The compressor of the vehicle gas filling station needs to have the ability of rapid filling (single-gun filling speed ≥20kg/min) and the adaptability to frequent start and stop. For large industrial compressors, emphasis should be placed on continuous operation reliability and low energy consumption characteristics. Mobile compressors (used for emergency gas supply) need to take into account both portability and anti-vibration performance.

The working principle and core attributes of CNG compressors

The working principle of CNG compressors is based on “positive displacement compression” – achieving pressurization by reducing the gaps between gas molecules. The mainstream technical routes include reciprocating piston compressors and diaphragm compressors.

Reciprocating piston compressor: It drives the piston to reciprocate in the cylinder through the crankshaft. During the suction stage, the cylinder volume expands and low-pressure natural gas enters. During the compression stage, the volume of the cylinder decreases, the gas is compressed and pressurized, and is finally discharged through the exhaust valve. Its advantages are high compression ratio (single-stage compression can reach 1:10) and large flow rate, making it suitable for large gas filling stations or industrial centralized gas supply scenarios.

Diaphragm compressor: It uses an elastic diaphragm (usually made of metal or composite materials) to isolate the compression chamber from the driving mechanism, and achieves gas compression through the reciprocating deformation of the diaphragm. As the gas is completely isolated from the lubricating oil, it can ensure extremely high gas purity and is mostly used in scenarios with strict cleanliness requirements (such as the compression of high-end industrial gases or hydrogen energy mixed with CNG).

The core attributes of a compressor include:

Exhaust volume: The volume of high-pressure gas output per unit time (m³/h), which determines the service capacity of a gas filling station or the scale of industrial gas supply.

Energy efficiency ratio: The amount of compressed gas generated per unit power consumption (m³/kWh), which directly affects the operating cost. The requirements for energy efficiency grades stipulated in the new national standard GB 19153-2025 have become a key factor in selection.

The service life of the air valve: Under high-pressure conditions, the opening and closing times of the air valve can reach millions of times. Its wear resistance determines the maintenance cycle of the equipment.

The degree of intelligence: Whether it is equipped with pressure sensors, temperature monitoring, and remote diagnosis systems affects fault early warning and operation and maintenance efficiency.

These attributes jointly determine the adaptability of compressors in the CNG industrial chain and are also the key indicators that enterprises need to evaluate when making selections.

Why choose the world’s leading manufacturer of compressed natural gas compressors?

With proven expertise: Providing reliable and high-performance compressed natural gas solutions for decades.

Advanced Innovation: The most advanced technology to maximize efficiency and energy performance.

Tailor-made solutions: Systems custom-designed for your oil, gas and chemical applications.

Comprehensive support: Full life-cycle services to ensure continuous operation and long-term value.

Now is the ideal time to upgrade your energy operation. Explore our list of the top ten CNG compressor manufacturers in the world by 2025, learn about their outstanding quality, reliability and excellent service, and explore how to enhance your competitive position. Take action now, learn about their products, explore their customized solutions, and consult tailor-made plans to take your oil, gas and chemical projects to new heights.

Top ten famous CNG compressor manufacturers

Atlas Copco

Headquarters Location: Atlas Copco is headquartered in Sweden and its business covers the world.

The main technology: The company is renowned for its comprehensive solutions that combine magnetic levitation and variable frequency drive technologies. Their magnetic levitation compressors are highly efficient, and the variable-frequency models can provide excellent adaptability to the constantly changing gas demands.

Core advantage: Atlas Copco enjoys a high reputation for quality and innovation. The VSD + series technology is a prime example. It selects high-quality components and can operate stably in an ambient temperature as high as 46° C. Even in the electrical room of the frequency converter, it can withstand a temperature as high as 55°C. The transmission system is designed with an IP66 protection level, effectively preventing dust and contaminants. Moreover, it features a simple design without vulnerable parts such as gears, belts, and shaft seals, reducing the risk of wear and ensuring the stable operation of the compressor.

Applicable industries: Serving industries such as automotive, manufacturing, and energy, where reliable and efficient gas compression is of vital importance.

After-sales service evaluation: Atlas Copco has a wide global service network. Take the CU series heavy-duty gas compressors as an example. They adopt advanced maintenance concepts, and the cylindrical piston technology is mature and reliable, which extends the maintenance cycle and reduces downtime. The biennial interval for changing the compressor oil and the 2,000-hour maintenance interval for the engine belt significantly reduce the frequency of maintenance. Moreover, the company has on-site service engineers in 160 countries and regions around the world, providing professional maintenance services to ensure the long-term stable operation of the equipment.

Ariel

Headquarters Location: Ariel is located in the United States and is a well-known brand in the North American market.

Main technology: Focusing on natural gas compressor technology, with an emphasis on reciprocating compressors. Their compressors are designed to handle high-pressure gas compression effectively.

Core advantage: Ariel compressors are renowned for their durability and high-performance gas compression. The company has an in-depth understanding of natural gas applications and can provide customized solutions for specific requirements.

Applicable industries: Mainly serving the oil and gas industry, including natural gas production, processing and transportation.

After-sales service evaluation: We have a reliable service network in North America. The customer appreciated their professional knowledge in handling issues related to natural gas compressors and the availability of original factory spare parts.

MINNUO

Headquarters Location: Jiangsu, China.

Main technologies: Provide full-chain closed-loop services and customized solutions. They have integrated advanced technologies such as intelligent Internet of Things monitoring into the compressor.

Core advantage: MINNUO stands out for its ability to provide tailor-made solutions for the diverse needs of different customers. With the CNG solution centered on the previous double-piston compressor, it not only retains the flexibility of customized design but also, with advantages such as high compression ratio, strong load capacity, and adaptability to multiple gas sources, has established an irreplaceable competitive edge in scenarios with strict requirements for compression efficiency and working condition compatibility, becoming the preferred partner of many industry customers.

Applicable industries: It serves a wide range of industries, including gas filling stations, industrial gas production and energy transportation.

After-sales service evaluation: MINNUO’s intelligent Internet of Things monitoring and predictive maintenance system. Through various sensors installed on the compressor, the operation data of the equipment such as temperature, pressure and vibration are collected in real time and transmitted to the cloud platform for analysis. The system can accurately identify potential fault hazards and issue early warnings to customers and service centers in advance, achieving “repair before failure”.

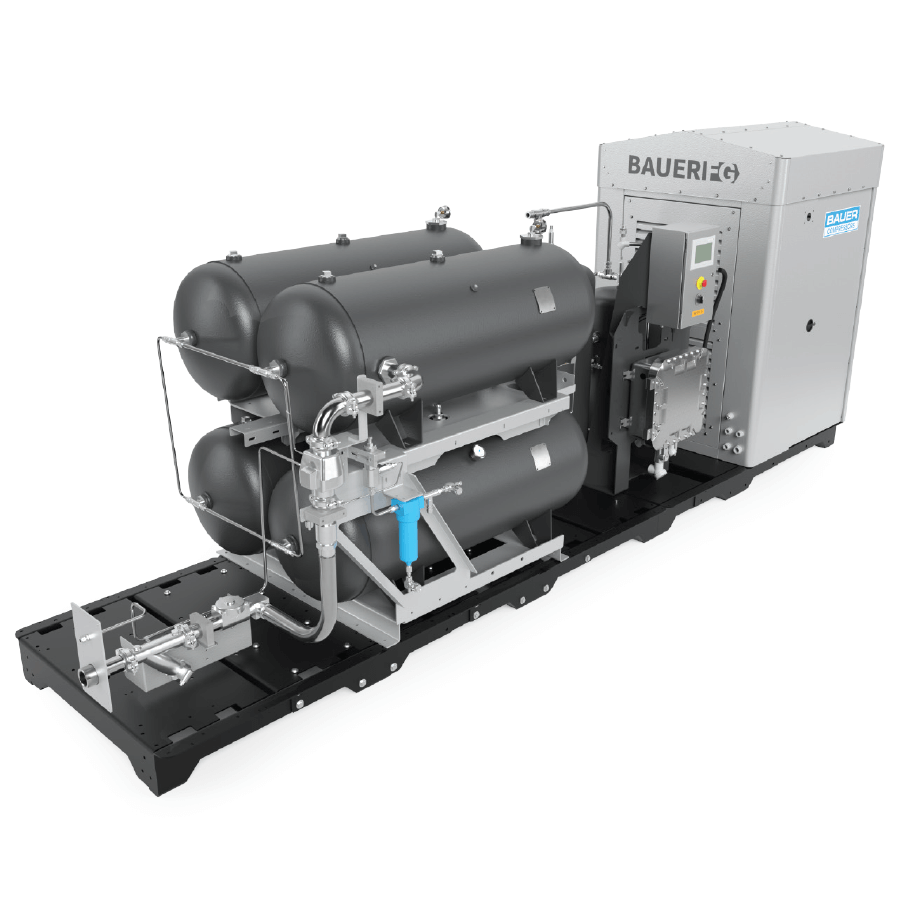

Bauer compressor

Headquarters Location: Bauer’s headquarters is located in Germany and it has a strong influence in the European market.

Main technology: Renowned for its expertise in high-pressure and mobile compressor technology. Their compressors are compactly and powerfully designed, suitable for applications that require mobility and high-pressure gas transportation.

Core advantage: Ball compressors are renowned for their robust structure and are suitable for operation in harsh environments. The company also offers a high level of customization for its products.

Applicable industries: It serves industries such as diving, fire rescue, and mobile gas filling, which require high pressure and reliable gas compression.

After-sales service evaluation: Possessing a service network that caters to its specific customer base. Customers value the timely service they provide for the maintenance of mobile compressors and the availability of spare parts for their high-pressure models.

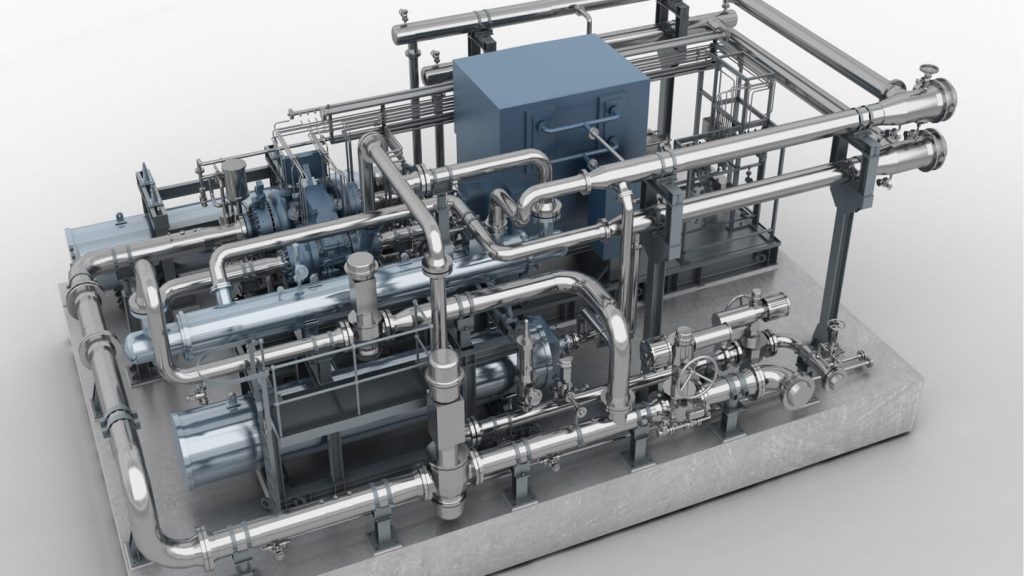

Siemens Energy

Headquarters location: Germany, with global influence in the energy sector.

Main technology: Combining high-end centrifugal and reciprocating compressor technologies. Their products adopt advanced digital control systems to achieve the best performance.

Core advantage: Siemens Energy has a strong R&D capability and is capable of developing highly efficient and reliable compressors. Their products are often used in large-scale energy projects.

Applicable industries: It serves the power generation, oil and gas, and petrochemical industries that require large-scale, high-performance gas compression.

After-sales service evaluation: Provide a comprehensive global service network. Customers benefit from their expertise in handling complex compressor systems and their ability to provide remote monitoring and diagnostic services.

Ingersoll Rand

Headquarters Location: The headquarters is located in Ireland and has a wide influence worldwide.

Main technology: Focusing on intelligent energy management of compressors. Their products usually feature variable frequency drives and intelligent control systems.

Core advantages: Ingersoll Rand compressors are renowned for their energy-saving capabilities and intelligent operation. The company provides integrated solutions for energy-saving gas compression.

Applicable industries: Serving industries such as manufacturing, food and beverage, and healthcare, which are crucial for energy efficiency and reliable gas supply.

After-sales service evaluation: Possessing a complete service network. Customers appreciate their ability to provide energy efficiency audits and maintenance services to optimize the performance of compressors.

Kobelco compressor

Headquarters location: Japan, renowned for its precision engineering.

Main technology: Emphasize the production of compressors with high stability. Their products are designed with advanced Japanese engineering technology and operate reliably.

Core advantage: Kobelco compressors are highly regarded for their long-term stability and low maintenance requirements. The company uses high-quality materials in the manufacturing process.

Applicable industries: It serves industries such as electronics, pharmaceuticals, and automobiles, where stable gas compression is crucial for the production process.

After-sales service evaluation: We have a service network in regions such as Asia. The customer praised their attention to the details of maintenance services and the availability of spare parts for Japanese-made compressors.

Mann’s Energy Solutions

Headquarters location: Germany, enjoying a high reputation in the energy and industrial fields.

Main technology: Specializing in large-scale energy and industrial compressor technology. Their products typically employ advanced high-pressure and large-volume gas compression engineering.

Core advantage: MAN Energy Solutions has a long history of providing reliable and high-performance compressors for large-scale projects. They offer comprehensive engineering services and their products.

Applicable industries: It serves industries such as power generation, oil and gas refining and chemical processing, and large-scale industrial manufacturing that require large-capacity and efficient gas compression.

After-sales service evaluation: With a global service network, we have professional knowledge in handling large compressor systems. Customers value their ability to provide on-site maintenance and upgrade services for their complex compressor installations.

Sundyne (Honeywell)

Headquarters Location: Colorado, USA.

Main technologies: Focus on zero-leakage technology, especially in the compression of hydrogen and natural gas. Their compressor is designed with an advanced sealing mechanism.

Core advantage: Sundyne compressors are highly regarded for their safety features, especially their zero-leakage design. This makes them suitable for applications where gas leakage may pose significant risks.

Applicable industries: Serving industries such as hydrogen fuel production and gas storage, as well as applications subject to strict safety and environmental regulations.

After-sales service evaluation: Possessing a professional service network capable of handling zero-leakage compressors. The customer appreciated their expertise in ensuring the integrity of the compressor’s sealing system.

Jereh Group

Headquarters Location: China, a leading exporter of energy equipment.

Main technologies: We offer a range of compressor technologies, with a focus on meeting international standards. Their products integrate advanced digital control and energy-saving functions.

Core advantages: Jerry Group possesses strong manufacturing capabilities and a profound understanding of international market demands. They can offer cost-effective and high-quality compressor solutions.

Applicable industries: Serving the global oil and gas industry, including onshore and offshore natural gas production, transportation and refueling stations.

After-sales service evaluation: Possessing a continuously expanding global service network. Given the group’s position as a major exporter of energy equipment in China, customers in the international market appreciate their ability to provide timely service and support.

Comparison table: Specifications, energy efficiency and service

| Manufacturer | Technical parameters (e.g., maximum pressure, flow rate | Energy efficiency grade | After-sales response time | Global distribution |

| Atlas Copco | High-pressure range, variable flow rate, depending on the model | High efficiency, meeting the new efficiency standards for magnetic levitation and frequency converter models | It takes 2 to 4 hours, depending on the region | It is widely distributed in America, Europe, Asia and Africa |

| MINNUO | Customization – Design parameters based on customer requirements | The high efficiency of customized reciprocating piston compressors and Internet of Things models | Global 2-hour emergency response | With an ever-expanding global influence and 28 service centers |

| Ariel Company | Designed specifically for high-pressure natural gas applications, different models with specific flow rates | It meets the industry standard efficiency of reciprocating compressors | It takes 4 to 6 hours in North America, and longer in other regions | It performs strongly in North America and also has business in other regions rich in oil and gas resources |

| Bauer compressor | Compact design with high-voltage output, suitable for mobile applications | It has moderate efficiency and is optimized for high-voltage and mobile use | Europe: 3 to 5 hours, global differences | It has strong capabilities in Europe and operates in areas with diving and mobile refueling needs |

| Siemens Energy | High-capacity models with high pressure and high flow capabilities | The advanced digital control system achieves high efficiency | The main industrial area takes 2 to 3 hours | Globally, especially in the field of large-scale energy projects |

| Ingersoll Rand | A variable flow model with intelligent energy management functions | High energy-saving potential is achieved through frequency converters and intelligent control | 2 to 4 hours, depending on the service level agreement | Global manufacturing and energy-conscious industries |

| Kobelco compressor | It performs stably under specific pressure and flow ratings | Medium to high efficiency, depending on the model | It takes 3 to 5 hours in Asia, and longer in other regions | Centered in Asia, it also has some business in other industrial zones |

| Mann’s Energy Solutions | Large models with high pressure and large capacity capabilities | High efficiency suitable for large-scale applications | 3 to 5 hours (main industrial areas) | Global large-scale energy and industrial projects |

| Sundyne (Honeywell | Zero leakage design, with specific pressure and flow ratings for hydrogen and natural gas | Medium to high efficiency, focusing on safety-related functions | 4 to 6 hours, depending on the complexity of the application | Globally, in regions with strict gas safety regulations |

| Jereh Group | The range of models with international standard parameters | Comply with international energy efficiency standards | 3-5 hours in Asia, global expansion | Globally, especially in regions that produce oil and gas |

How does MINNUO solve your problem

Service network

MINNUO’s 28 service centers are strategically distributed all over the world. This extensive network ensures that the team can respond within two hours in case of any emergency. Whether it’s gas filling stations in the Middle East or industrial gas plants in Southeast Asia, customers can rely on MINNUO’s prompt service. This significantly reduces downtime and minimizes the losses of enterprises.

Design of reciprocating piston compressor

MINNUO deeply integrates intelligent Internet of Things monitoring technology into the design of reciprocating piston compressors, forming a dual advantage of “hardware + digitalization”. Reciprocating piston compressors adopt a multi-stage differential compression structure. Through precisely matched piston rings and cylinder liners, they form a staged seal. Combined with a patented gas valve group design, the gas leakage rate is controlled below 0.05%, reducing the leakage by 80% compared to traditional single-stage piston models. In compression scenarios of flammable and explosive gases like CNG, It can effectively avoid potential safety hazards.

This structural feature enables it to perform outstandably in high-flow continuous compression scenarios. By optimizing the matching of piston stroke and rotational speed, a single unit can achieve a CNG processing capacity of over 500 cubic meters per hour. Moreover, the cylinder block is made of wear-resistant alloy materials and equipped with a forced lubrication system, which not only prevents impurities caused by mechanical wear from contaminating the gas It can also ensure that the dew point of the output CNG is stably below -40℃, meeting the strict requirements for gas cleanliness in fields such as gas filling stations and industrial gas supply.

Special protective design for extreme conditions

Understanding the challenges of operating under extreme conditions, MINNUO has developed a special protective design for its compressors. In the high-temperature Middle East region, its reciprocating piston compressor is equipped with ceramic-coated piston rings that can withstand temperatures up to 120℃ and a multi-channel forced air cooling system. Even in the scorching midday environment of the gas station, it can still maintain stable compression efficiency, with a high-temperature degradation rate reduced by 40% compared to ordinary models. In the humid Southeast Asian region, the key components of the machine body are made of duplex stainless steel, combined with a nano-level anti-corrosion coating, which can resist corrosion and microbial erosion in a 95% humidity environment, extending the service life of the equipment to 1.5 times that of traditional models. In addition, a full-chain quality control system runs through every link from design, production to installation, ensuring that each compressor has reliable performance. Its reinforced crankshaft and precisely balanced connecting rod mechanism can maintain stable gas output pressure and flow even during long-term and high-intensity operation, guaranteeing the continuity of customers’ production and operation.

Intelligent Internet of Things monitoring + predictive maintenance

MINNUO integrates intelligent Internet of Things monitoring into its CNG compressors, creating a comprehensive system that continuously collects and analyzes real-time operational data. This includes parameters such as temperature, pressure, vibration and energy consumption. By leveraging advanced algorithms, the system can accurately predict potential equipment failures before they occur. For instance, if the data indicates an abnormal increase in the vibration of a certain component, the system will send an alert to the customer and MINNUO’s service team. This allows for proactive maintenance, scheduling for repairs or part replacements during planned downtime, rather than dealing with unexpected failures. Once a problem occurs, technicians can quickly reach the scene and, in combination with the fault diagnosis information provided by the system, complete the repair rapidly, significantly reducing downtime.

This proactive maintenance mode not only reduces the probability of sudden failures but also cuts down on unnecessary routine maintenance frequency and costs, making it more worry-free and effortless for customers. This proactive maintenance approach is a key component of MINNUO’s customized CNG compressor solution, which can enhance the overall reliability of the equipment.

Final purchase prompt

How to screen the models suitable for your industry among global manufacturers

Different industries have unique requirements for CNG compressors. For gas filling stations, factors such as fast refueling speed, large flow rate, and compatibility with various vehicle types are of vital importance. Industrial gas applications may require precise pressure control and the ability to handle specific gas components. In the field of energy transportation, compressors need to be durable enough to withstand long-distance transportation vibrations and various environmental conditions.

First, clearly define the specific needs of your industry. List the required pressure range, flow rate, gas type and operating environment (temperature, humidity, etc.) and other parameters. Then, study the product specifications of different manufacturers around the world and look for those that have a good track record in serving your industry. For example, if you are engaged in the oil and gas industry, then manufacturers like Ariel Corporation and MINNUO, which have rich experience in this field, might be more suitable. Check the customer reviews and case studies of enterprises in your industry to learn about the performance of compressors from specific manufacturers. This is an important part of the CNG compressor purchasing guide, which can ensure that you choose the right gas compressor for your industry.

How to calculate the return on investment (ROI)

Calculating the return on investment of CNG compressors requires taking into account both the initial investment and long-term savings and benefits. The initial investment includes the purchase price, installation cost and any necessary training for the operators. The long-term factors to be considered include energy conservation (due to the high-efficiency model), reducing maintenance costs and minimizing downtime losses.

The formula for the return on investment is: [(Total revenue – total cost)/total cost] x 100%

The overall advantages include the value of saving energy costs, reducing maintenance expenses and avoiding production losses caused by downtime throughout the entire life cycle of the compressor. The total cost consists of the initial purchase price, installation fee, training fee and ongoing maintenance cost. By accurately calculating these figures, you can determine how long it will take for the compressor to recover its cost and make a wise investment decision.

The importance of establishing long-term technical and service cooperation with manufacturers

Establishing a long-term cooperative relationship with CNG compressor manufacturers can bring many benefits. A manufacturer familiar with your operations can provide continuous technical support based on your specific needs. They can offer advice on optimizing compressor performance, upgrading equipment as business grows, and ensuring compliance with evolving industry standards and regulations.

In terms of service, long-term partnerships often lead to more sensitive and personalized services. Manufacturers are more likely to prioritize your maintenance and repair needs, ensuring that any issues are resolved promptly. They may also offer preferential prices for spare parts and service contracts to long-term customers. In addition, long-term cooperation enables manufacturers to gain a deeper understanding of the performance history of your equipment, thereby providing more accurate predictive maintenance and technical solutions. This helps to maximize the service life of the compressor, reduce operating costs, and ensure the continuous reliability of the gas compression system.

Conclusion

The future trend of CNG compressor selection is clearly moving towards intelligence, energy efficiency and customization. Intelligence driven by the Internet of Things and advanced monitoring systems can achieve better control, predictive maintenance and optimized performance. Driven by new regulations and the need to reduce operating costs, energy efficiency is driving manufacturers to develop more efficient technologies, such as magnetic levitation and variable frequency drives. As different industries have unique requirements, customization is becoming increasingly important. Manufacturers are responding by providing tailor-made solutions to meet specific operational needs.

In the competitive landscape, international giants and Chinese manufacturers each have their own strengths. International manufacturers often have a long history of technological innovation, extensive global service networks and strong brand recognition. They perform outstandingly in high-end technologies and large-scale industrial applications. On the other hand, Chinese manufacturers are catching up rapidly in terms of technology while offering more cost-effective solutions. Companies such as Jereh Group and MINNUO are emerging through competitive prices, improved quality and expanded global service networks. They are particularly strong in providing customized solutions that meet the specific needs of emerging markets.

Email

Email sales:+86 15366749631

sales:+86 15366749631