Within the industrial air compressor landscape, screw and piston machines dominate the mainstream view. However, a machine utilizing a unique technological path—the scroll air compressor—is demonstrating irreplaceable advantages in specific application scenarios with its exceptional quietness, stability, and energy efficiency, becoming the “Quiet Guardian” for users who demand high-quality air.

I. Core Technology Principle: The Elegant Scrolls

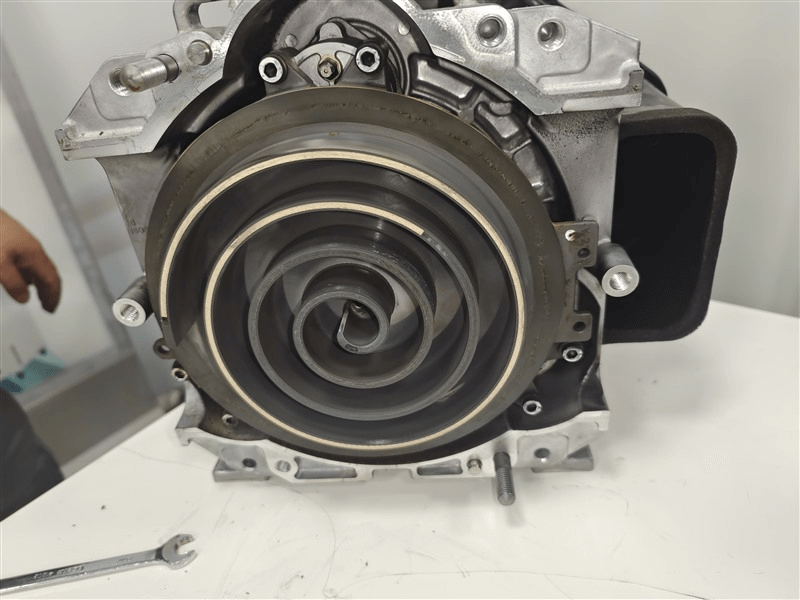

The heart of a scroll compressor lies in its unique compression method. It consists of a fixed scroll (orbiting scroll) and a moving scroll that orbits eccentrically without rotating. These two scrolls intermesh, forming a series of crescent-shaped compression pockets.

The operating process is a display of mechanical elegance:

Intake: Gas is drawn into the crescent-shaped pockets at the outer periphery of the scrolls.

Compression: As the orbiting scroll moves, these pockets continuously travel towards the center, their volume steadily and smoothly decreasing, thereby compressing the gas.

Discharge: The gas, compressed into the central smallest pocket, is continuously discharged through a central port.

This “gradual” compression shares similarities with screw compressor principles but features a simpler structure, enabling direct power transmission and efficient compression.

II. Prominent Performance Advantages: Excellence by Design

The core design of scroll compressors grants them several inherent advantages that are difficult for screw and piston compressors to match:

Exceptionally Low Noise and Vibration: With no reciprocating motion like piston compressors and no high-speed meshing noise like screw compressors, scroll compressors operate with remarkable smoothness and quietness. Noise levels can easily be kept below 60 dB(A), making them ideal for locations with strict environmental noise requirements.

Outstanding Energy Efficiency and Reliability: They possess far fewer moving parts than screw or piston compressors (the orbiting scroll is the primary moving part). Reduced mechanical friction points minimize energy loss, enhancing not only efficiency but also fundamentally lowering failure rates and extending service life.

Clean, Stable Air Delivery: The compression process is smooth and continuous, resulting in minimal discharge pressure fluctuation (can be controlled within ±0.2 bar). Furthermore, the compression chambers themselves offer good inherent sealing, effectively reducing oil carry-over. Especially in full oil-free designs, they can deliver very clean compressed air.

III. Typical Application Scenarios: Where Advantages Shine

Precisely because of these characteristics, scroll compressors have become the preferred choice in the following fields:

Healthcare and Laboratories: Hospitals (outpatient departments), dental clinics, and laboratories where quiet environments are essential and high air quality is required. Their low noise doesn’t disrupt patient communication, while stable, clean air ensures medical device safety.

Precision Instruments and High-End Manufacturing: Providing fluctuation-free, stable air for precision measuring instruments, optical components, semiconductor inspection equipment, etc., preventing pressure variations from interfering with delicate processes.

Office and Commercial Environments: Integrated into quiet workspaces for automated office equipment, food and beverage packaging, etc.

Small Workshops and New Energy Vehicles: Powering small-scale spray painting, pneumatic tools, and ideal for new energy vehicle maintenance (e.g., tire nitrogen inflation).

MINNUO Scroll Air Compressors: Precision-Engineered Reliability

With deep insight into market segment needs, MINNUO has introduced a high-performance scroll air compressor series that maximizes the advantages of this technology:

High-Efficiency Profile Design: Utilizes optimized scroll profiles for improved leakage control and high volumetric efficiency, achieving approximately 5%-10% better energy efficiency compared to standard models.

Advanced Quiet Operation Technology: Professional acoustic encapsulation and low-speed airend optimization ensure the equipment runs as quietly as a normal conversation, even at close range.

Integrated Intelligent Control: Features a smart controller for user interface, parameter setting, and fault self-diagnostics. Select models support IoT connectivity for remote intelligent management.

Conclusion

With its unique technological approach, the scroll air compressor sets the benchmark in its niche market for noise, efficiency, and reliability. It is not a replacement for all applications but offers a near-perfect solution within its domain of expertise. When your application demands stringent requirements for quietness, cleanliness, and stability, the MINNUO Scroll Air Compressor stands as a trustworthy and intelligent choice.

Email

Email sales:+86 15366749631

sales:+86 15366749631