Under the guidance of the global “dual carbon” goals, hydrogen energy, as a clean and efficient new energy source, is becoming a core energy carrier in fields such as fuel cell power generation and new energy vehicles. As a key piece of equipment in the hydrogen energy industry chain, hydrogen compressors are tasked with compressing low-pressure hydrogen to high pressure (1.3MPa–40MPa), ensuring gas source purity and stable delivery. They directly determine the operating efficiency, service life, and safety performance of fuel cells. Traditional hydrogen compression equipment often faces issues such as oil contamination, significant pressure fluctuations, and insufficient explosion-proof performance, which have restricted the large-scale development of the hydrogen energy industry. Jiangsu Minnuo Group (Minnuo) has been deeply engaged in compressor manufacturing for 37 years. Its independently developed high-pressure oil-free hydrogen diaphragm compressors, with core advantages including 100% oil-free compression, precise pressure control, and comprehensive explosion protection, have become the “reliable power leader” in the hydrogen fuel cell power generation industry. This article will elaborate on why hydrogen diaphragm compressors can serve as the “solid support” for the hydrogen energy industry from perspectives such as technical principles, core advantages, and application scenarios.

1. Technical Popularization: The Principle of “Oil-Free High-Pressure Compression” for Hydrogen Diaphragm Compressors

Hydrogen fuel cells have extremely high requirements for hydrogen purity (needing to reach 99.999% or higher). Any oil contamination or impurities may lead to poisoning of fuel cell catalysts and failure of membrane electrodes. Meanwhile, high-pressure delivery is crucial for improving the efficiency of hydrogen energy storage and transportation. The core competitiveness of hydrogen diaphragm compressors stems from their innovative technology of multi-stage diaphragm compression + complete gas-oil isolation, which is also the key to achieving the dual goals of “high pressure + cleanliness”.

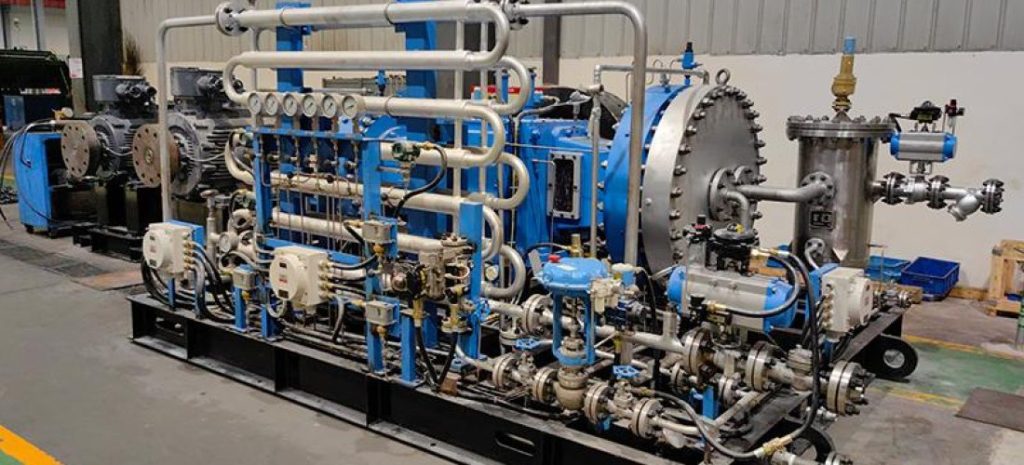

Traditional hydrogen compressors mostly adopt a piston-type compression design and rely on lubricating oil for sealing and lubrication. However, lubricating oil is prone to mixing into hydrogen, forming oil mist contamination. Even after complex filtration, it is still difficult to completely remove oil impurities, making them unable to meet the purity requirements of fuel cells. In contrast, hydrogen diaphragm compressors establish an absolute isolation between the gas chamber and the hydraulic chamber through a “flexible diaphragm”. The core structure consists of a multi-layer composite diaphragm, a hydraulic drive system, and a gas chamber. The motor drives the crankshaft to move the hydraulic piston, and the hydraulic oil pushes the diaphragm to undergo reciprocating deformation, thereby realizing the step-by-step compression of hydrogen. Throughout the process, hydrogen is always enclosed in the gas chamber by the diaphragm, completely isolated from the hydraulic oil. This fundamentally eliminates oil contamination, achieves 100% oil-free compression, and ensures that the hydrogen purity reaches 99.999%.

To meet the high-pressure requirements of 1.3MPa–40MPa, the equipment adopts a “multi-stage compression” design: the hydrogen compression process is divided into multiple stages. After each stage of compression, the temperature is reduced through a cooling system before entering the next stage of compression. This avoids excessive temperature rise caused by single-stage compression (hydrogen is prone to decomposition or explosion risks at high temperatures). At the same time, the gas chamber and diaphragm are made of nickel alloy and 316L stainless steel, which possess strong corrosion resistance and sealing performance. They can cope with the strong permeability and flammable and explosive characteristics of hydrogen, ensuring the safe and stable operation of the high-pressure compression process.

In addition, the equipment is equipped with a PLC + VFD intelligent control system, which can real-time monitor the pressure, flow rate, and temperature of hydrogen. Through frequency conversion technology, it automatically adjusts the diaphragm movement frequency, controlling the flow fluctuation within ±2%, thus providing a continuous and stable hydrogen supply for fuel cells.

2. Core Advantages: Meeting the Stringent Requirements of the Hydrogen Fuel Cell Industry

The requirements of hydrogen fuel cell power generation for compression equipment far exceed those of ordinary industrial scenarios. It not only needs to meet the core indicators of “ultra-high purity, high-pressure output, and stable flow rate” but also must possess characteristics such as explosion protection, corrosion resistance, and long service life. The hydrogen diaphragm compressors developed by Jiangsu Minnuo accurately match industry needs in various key indicators, demonstrating multiple solid advantages.

2.1 Ultimate Cleanliness: 100% Oil-Free Compression to Protect the Service Life of Fuel Cells

The membrane electrodes of fuel cells are extremely sensitive to oil impurities. Even trace oil contamination can lead to a decrease in catalyst activity, an increase in membrane resistance, and a significant reduction in the service life of fuel cells. The hydrogen diaphragm compressors of Jiangsu Minnuo adopt a multi-layer composite diaphragm design. The diaphragms undergo third-generation pre-stress treatment and Ra0.2μm mirror polishing, which not only improves fatigue resistance (with a service life of ≥8000 hours, 50% longer than traditional diaphragms) but also completely blocks the contact between hydraulic oil and hydrogen, achieving 100% oil-free compression. At the same time, the gas circuit of the equipment is made of nickel alloy and 316L stainless steel, and its surface is treated with a PVD coating to reduce hydrogen adsorption and impurity precipitation. This ensures that the hydrogen purity is stably maintained at 99.999%, fundamentally protecting the long-term and efficient operation of fuel cells.

2.2 High-Pressure Precision: Adjustable Pressure Range of 1.3MPa–40MPa with Stable Flow Rate and No Fluctuations

Hydrogen fuel cell power generation and hydrogen refueling station scenarios have extremely high requirements for the stability of hydrogen pressure and flow rate: insufficient pressure will lead to a decrease in the output power of fuel cells, while flow rate fluctuations will cause fluctuations in power generation efficiency. The rated pressure range of Jiangsu Minnuo’s hydrogen diaphragm compressors covers 1.3MPa–40MPa, which can be flexibly adjusted according to different scenarios – distributed power stations need to maintain a pressure range of 1.3–10MPa, while hydrogen refueling stations need to increase the pressure to 35–40MPa. In terms of pressure control, the equipment supports real-time PID adjustment, with a pressure accuracy of up to ±0.1MPa; the flow stability is ≤±2%. Combined with CFD-optimized nano-scale laminated valves (with a volumetric efficiency of 95%), it ensures the continuous and stable delivery of hydrogen, avoiding abnormal operation of fuel cells caused by pressure or flow rate fluctuations.

2.3 Safety and Explosion Protection: Comprehensive Protection to Adapt to the High-Risk Characteristics of Hydrogen

Hydrogen is a flammable and explosive gas (with an explosion limit of 4%–75%) and has strong permeability, placing extremely high demands on the safety performance of compression equipment. Jiangsu Minnuo’s hydrogen diaphragm compressors have passed both ATEX and IECEx explosion-proof certifications. The entire machine adopts an explosion-proof motor and a sealed structure to eliminate electric sparks generated during operation. At the same time, the equipment is equipped with an intelligent leak detection system, which real-time monitors the airtightness of the gas circuit through high-precision hydrogen sensors. Once a leak is detected (leakage amount ≥1ppm), it immediately automatically cuts off the gas source and triggers an alarm. Combined with a multi-layer metal static sealing structure with bidirectional zero leakage, potential safety hazards are fundamentally eliminated. In addition, the crankcase and crankshaft of the equipment are made of integral cast iron and undergo ion nitriding treatment, reducing the vibration value by 20% compared with the national standard. This reduces the risk of seal failure caused by vibration and ensures absolute safety during high-pressure operation.

2.4 High Efficiency and Energy Conservation: IE5 Motor + VFD Frequency Conversion, Reducing Energy Consumption by 25%

The large-scale development of the hydrogen energy industry is inseparable from energy conservation and consumption reduction. Jiangsu Minnuo’s hydrogen diaphragm compressors are equipped with IE5 permanent magnet synchronous motors, combined with VFD frequency conversion control technology, which can automatically adjust the operating power according to the real-time hydrogen demand of fuel cells. In low-load scenarios (such as the nighttime off-peak power consumption period of distributed power stations), the motor speed is automatically reduced to reduce ineffective energy consumption; in high-load scenarios (such as peak hours of hydrogen refueling stations), the speed is increased to meet the demand for large flow rates. Compared with traditional fixed-speed compressors, energy consumption is reduced by more than 25%. At the same time, the equipment adopts a 3D-printed conformal cooling cylinder head, which increases the cooling surface area by 40%, realizes near-isothermal compression, further reduces energy loss during the compression process, and improves overall operating efficiency.

2.5 Long-Term Durability: Corrosion-Resistant Design + Modular Maintenance to Reduce Usage Costs

The strong permeability and corrosiveness of hydrogen can easily accelerate the aging of equipment components, thus compromising the service life. All core components of Jiangsu MINNUO hydrogen diaphragm compressors are crafted from corrosion-resistant materials: the diaphragm features a multi-layer composite structure, offering excellent resistance to hydrogen embrittlement and fatigue; the gas chamber and valves are manufactured from nickel alloy combined with 316L stainless steel, capable of withstanding long-term hydrogen erosion; the hydraulic piston is subjected to mirror grinding and DLC coating treatment, achieving a hardness of HV2000 and enabling oil-free, low-wear operation.

The equipment boasts an extended maintenance cycle of up to 8000 hours and adopts a modular design. Wearable parts including diaphragms and filters can be replaced quickly without the need for professional tools. Coupled with the global after-sales service that guarantees a 48-hour response time and spare parts delivery within 7 days, the downtime and maintenance costs are substantially reduced.

3. Scene Implementation: Covering the Entire Industry Chain of Hydrogen Fuel Cell Power Generation

With their core advantages of high pressure, cleanliness, and safety, hydrogen diaphragm compressors have been widely used in multiple key scenarios of hydrogen fuel cell power generation, providing reliable support for the large-scale development of the industry.

3.1 Industrial Park Hydrogen Refueling Stations: High-Pressure and Stable Gas Supply for Hydrogen Refueling of Fuel Cell Vehicles

Hydrogen refueling stations are core infrastructure in the hydrogen energy industry. They need to compress low-pressure hydrogen to 35–40MPa for rapid hydrogen refueling of fuel cell vehicles. Jiangsu Minnuo’s hydrogen diaphragm compressors can stably output high-pressure hydrogen of 40MPa, with a flow fluctuation of ≤±2%, ensuring that the hydrogen refueling process is fast and uniform, and avoiding prolonged refueling time caused by insufficient pressure. Their 100% oil-free compression feature ensures that the hydrogen purity reaches 99.999%, preventing catalyst poisoning of fuel cell vehicles; the ATEX/IECEx explosion-proof design and leak detection system are adapted to the high-risk environment of hydrogen refueling stations, ensuring the safe and reliable operation of the hydrogen refueling process. After a hydrogen refueling station in an industrial park in Japan adopted this equipment, the refueling time per vehicle was shortened from 15 minutes to 8 minutes, increasing the refueling efficiency by 47%, with no safety accidents occurring.

3.2 Distributed Hydrogen Energy Power Stations: Continuous and Stable Hydrogen Supply to Optimize Power Generation Efficiency

Distributed hydrogen energy power stations convert hydrogen energy into electrical energy through fuel cells to provide clean electricity for industrial plants and commercial buildings. They require equipment to continuously output stable hydrogen for 24 hours. Jiangsu Minnuo’s hydrogen diaphragm compressors support pressure adjustment in the range of 1.3–10MPa, which can flexibly match the flow demand according to the installed capacity of the power station; their long-term pressure maintenance design and flow stability of ±2% ensure that the output power of fuel cells is constant, and the power generation efficiency is maintained above 45% (the industry average is 38%). The operating noise of the equipment is ≤70dB, allowing it to be directly deployed indoors in the power station; the IE5 motor + VFD frequency conversion technology reduces the overall energy consumption of the power station by 20%, significantly improving economic benefits. After a distributed hydrogen energy power station in Germany adopted this equipment, its annual power generation increased by 12%, and electricity costs decreased by 25%.

3.3 Backup Power Sources for Factories and Data Centers: Safe and Uninterrupted Operation to Ensure Emergency Power Supply

Factories and data centers have extremely high requirements for the reliability of backup power sources. Hydrogen fuel cell backup power sources need to start quickly when the power grid is interrupted and continuously output electricity. Jiangsu Minnuo’s hydrogen diaphragm compressors have a quick-start function (start-up time ≤3 minutes), which can immediately provide stable hydrogen for fuel cells in emergency scenarios; their 8000-hour long-life diaphragms and low failure rate design ensure that the equipment can still operate reliably after long-term standby. The explosion-proof design and leak detection system of the equipment are adapted to the safety environment requirements of data centers and factories, avoiding safety risks caused by hydrogen leakage. After a data center in Canada adopted this equipment as a core component of its backup power source, it successfully responded to 3 power grid interruptions, achieving seamless switching each time and ensuring zero downtime for the data center.

3.4 Containerized Hydrogen Energy Storage Units: Flexible Adaptation to Facilitate Peak Shaving and Valley Filling of the Power Grid

Containerized hydrogen energy storage units can convert renewable energy such as wind power and photovoltaic power into hydrogen energy for storage, and generate electricity and connect to the power grid through fuel cells during peak periods of the power grid to achieve peak shaving and valley filling. Jiangsu Minnuo’s hydrogen diaphragm compressors adopt a modular design, which can be integrated into containers to adapt to mobile energy storage scenarios; their wide pressure range of 1.3–40MPa can meet different pressure requirements for hydrogen energy storage and power generation – during the energy storage stage, low-pressure hydrogen of 1.3MPa generated by electrolysis is compressed to 35MPa for storage, and during the power generation stage, high-pressure hydrogen is decompressed to 1.3MPa for use in fuel cells. The near-isothermal compression technology and efficient cooling system of the equipment avoid energy loss caused by excessive temperature rise during the hydrogen compression process, improving the energy storage – power generation cycle efficiency. After a containerized hydrogen energy storage project in Brazil adopted this equipment, the cycle efficiency increased to 68%, 15% higher than that of traditional compression equipment.

3.5 Hydrogen Energy Testing and Evaluation Laboratories: Precise Pressure Control to Support Scientific Research Verification

Hydrogen energy testing laboratories need to simulate the performance of fuel cells under different pressure and flow conditions, which places extremely high requirements on the accuracy and flexibility of compression equipment. Jiangsu Minnuo’s hydrogen diaphragm compressors support fine pressure adjustment of ±0.1MPa and can realize multi-stage programmable pressure increase (such as gradually increasing from 1.3MPa to 40MPa and staying for a specified time at each stage), accurately simulating the actual operating conditions of fuel cells. Their hydrogen purity of 99.999% and flow stability of ≤±2% ensure the accuracy and repeatability of test data; the equipment supports ISO17268 and SAEJ2601 protocols and can seamlessly connect with the laboratory’s SCADA system to realize real-time data collection and analysis. After a hydrogen energy testing laboratory in the UK adopted this equipment, the data repeatability of fuel cell performance tests increased to 98%, providing reliable support for scientific research verification.

4. Selection Guide: How Can Hydrogen Energy Enterprises Select Suitable Hydrogen Diaphragm Compressors?

The performance of hydrogen diaphragm compressors directly determines the safety, efficiency, and service life of hydrogen energy systems. When selecting models, enterprises should start from their core needs and focus on the following four key dimensions:

4.1 Prioritize Verification of Purity and Pressure Parameters

Hydrogen energy application scenarios have extremely strict requirements for purity and pressure: fuel cell power generation requires ensuring that the hydrogen purity is ≥99.999% and the pressure fluctuation is ≤±2%; hydrogen refueling stations require equipment to support high-pressure output of 35–40MPa. When selecting models, it is necessary to confirm whether the equipment has 100% oil-free compression technology and whether the core materials are nickel alloy + 316L stainless steel, to avoid fuel cell damage caused by substandard purity.

4.2 Attach Importance to Safety and Compliance Certifications

The flammable and explosive characteristics of hydrogen require the equipment to have comprehensive safety protection: products that have passed ATEX/IECEx explosion-proof certifications and ISO17268 standard certifications should be selected; it is necessary to confirm whether the equipment is equipped with safety designs such as real-time leak detection, automatic shutdown, and multiple seals to ensure reliable operation in high-pressure and high-risk environments.

4.3 Focus on Energy Efficiency and Maintenance Costs

The energy efficiency and maintenance costs of the equipment directly affect long-term operational benefits: priority should be given to equipment equipped with IE5 motors + VFD frequency conversion technology to reduce energy consumption; attention should be paid to the diaphragm service life (it is recommended to be ≥8000 hours) and modular maintenance design to reduce downtime maintenance time and labor costs. At the same time, the after-sales service capabilities of the brand should be evaluated to ensure global 48-hour response and spare parts delivery within 7 days, avoiding the shutdown of the hydrogen energy system due to equipment failure.

4.4 Match the Flexibility of Scenario Requirements

Different scenarios have significant differences in equipment requirements: hydrogen refueling stations require high pressure and large flow rates; distributed power stations require continuous operation and low noise; laboratories require fine pressure control and data integration. When selecting models, it is necessary to confirm the pressure adjustment range and flow adaptation capacity of the equipment, as well as whether it supports functions such as SCADA system connection and multi-stage programmable control, to ensure that the equipment accurately matches the application scenario.

5. Conclusion: Hydrogen Diaphragm Compressors – The “Core Engine” for the Large-Scale Development of the Hydrogen Energy Industry

As an important part of the future energy system, the large-scale development of the hydrogen energy industry is inseparable from technological breakthroughs in key equipment. As a core equipment in the hydrogen energy storage, transportation, and power generation links, hydrogen diaphragm compressors directly determine the purity, safety, and utilization efficiency of hydrogen energy. With 37 years of experience in compressor manufacturing, Jiangsu Minnuo Group has deeply met the stringent requirements of the hydrogen energy industry. The hydrogen diaphragm compressors it has developed have reached the industry-leading level in core indicators such as purity, pressure, safety, and energy efficiency, and have passed multiple international certifications including CE, ATEX, and ISO17268, becoming a trusted choice for many global hydrogen energy enterprises.

In the future, with the rapid development of the hydrogen energy industry, the requirements for hydrogen compressors will be further enhanced – higher pressure, higher energy efficiency, and more intelligent control will become the development direction. Jiangsu Minnuo will continue to focus on technological innovation, promote the upgrading of hydrogen diaphragm compressors towards “ultra-high pressure, low energy consumption, and intelligence”, provide more reliable solutions for scenarios such as hydrogen fuel cell power generation, hydrogen refueling stations, and energy storage, and contribute strong impetus to the large-scale development of the global hydrogen energy industry and the achievement of the “dual carbon” goals.

Email

Email sales:+86 15366749631

sales:+86 15366749631