In the food and beverage industry, every step of production has extremely high requirements for hygiene and quality. As consumers’ demand for health and quality increases, food and beverage companies face stricter quality control standards. This article will explore in depth the application scenarios and key roles of oil-free air compressors in the food and beverage industry to understand how it can help companies improve production efficiency and ensure product safety.

Oil-free air compressors can provide pure, pollution-free compressed air to ensure the cleanliness and safety of the production process in the food and beverage industry, fully complying with food-grade safety standards. With ISO 8573-1 Class 0 certified air quality, oil-free air compressors effectively avoid oil contamination and are widely used in food packaging, beverage filling, fermentation processes, powder food delivery and equipment cleaning. Oil-free air compressors not only improve production efficiency, but also reduce maintenance costs. They are an ideal choice for food and beverage companies to ensure product safety and quality.

Why does the food and beverage industry need oil-free air compressors?

In the production process of the food and beverage industry, any air contamination may affect the quality and safety of the product. Traditional air compressors rely on lubricating oil for compression, and this oil can easily penetrate into the air and form aerosol or oil mist pollution. The oil air compressor has a unique design that does not require lubricating oil, which ensures the thorough removal of air from the source and ensures the air quality of food and beverage production.

Pollution-free air output

Oil-free air compressors do not use lubricating oil, so the compressed air produced is clean of any oil or particle contaminants, which is an ideal choice for food-grade clean air.

Food safety standards

Oil-free air compressors are ISO 8573-1 Class 0 certified to ensure that the air is clear of oil or harmful particles and meet global food safety standards.

Environmentally friendly

Oil-free air compressors do not produce oil mist or waste oil, which reduces the impact of oil pollution on the environment and is more friendly to the food and beverage production environment.

These features make oil-free air compressors a key equipment in the food and beverage industry, protecting every link in food production from pollution.

Five application scenarios of oil-free air compressors in the food industry

Food packaging: clean packaging process

During the food packaging process, compressed air blowing is used to blow clean and hygienic inside the packaging bags and containers to ensure the clean and hygienic packaging of the products. The oil-free compression provided by the oil-free air compressor avoids oil residues in the packaging bags and containers, keeping the products clean in the packaging and meeting hygiene standards.

Beverage food: ensure that there is no drop of waste

The beverage process has extremely high requirements for air quality. The oil-free air compressor can provide clean and pollution-free compressed air to ensure that every bottle of beverage in the bottle process is not contaminated. The use of oil-free air effectively avoids the safety hazards caused by oil and ensures the quality and shelf life of the beverage.

Food fermentation: ensure the stability of the fermentation process

In the production of fermented foods such as soy sauce and vinegar, compressed air is used to provide oxygen to the fermentation tank to promote the activity of the strain. The fermentation process has extremely high requirements for air purification, and any oil stains will destroy the activity of the strain. The machine can provide oil-free air to ensure the smooth progress of the fermentation process and improve the quality and flavor of fermented foods.

Powder pipeline: keep powder food clean

During the production process of powdered foods such as milk powder and coffee powder, compressed air is used to pipe powder raw materials. Oil-free air compressors provide pollution-free compressed air in the powder pipeline process to ensure that powdered foods do not clump or deteriorate due to oil contamination, ensuring the quality of the product.

Equipment cleaning and drying: ensure the hygiene of the production line

Production equipment in the food and beverage industry needs to be cleaned and dried regularly to maintain hygiene standards. The oil-free compressed air provided by the oil-free air compressor can effectively remove pollutants and moisture, avoid oil pollution of equipment, help companies reduce maintenance costs, and extend the service life of equipment consumption.

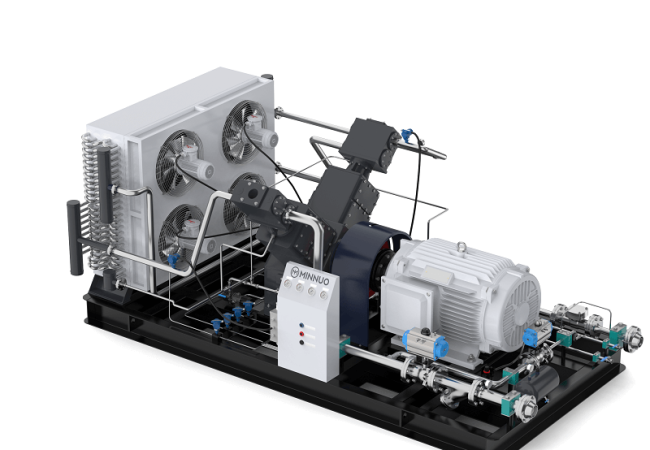

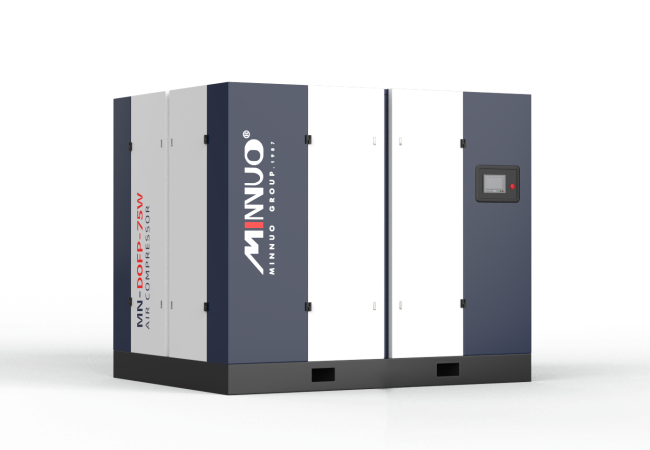

The core advantages of MINNUO oil-free air compressor

Comply with food-grade air standards

MINNUO oil-free air compressors are ISO 8573-1 Class 0 certified to ensure air purification and pollution-free. Our oil-free air compressors also comply with international food safety standards such as ISO 22000 and HACCP, and are an important choice for the food and beverage industry.

Reduce maintenance costs

Oil-free air compressors eliminate the need for lubricating oil, significantly reducing demand, lowering the frequency of oil filter and lubricating oil replacements, and cutting down operating costs for the enterprise.

Improve production efficiency

The stability and high cleanliness of oil-free air compressors reduce the need for continuous cleaning, maintain the continuity of production, and effectively improve production efficiency.

Environmental protection and pollution-free

MINNUO oil-free air compressors meet modern environmental protection requirements, do not produce oil mist and waste oil, improve the air quality of the production environment, and establish an environmentally friendly image for the company.

Frequently Asked Questions (FAQ)

Why do the food and beverage industry need oil-free air compressors?

The food and beverage industry needs oil-free air compressors to provide pollution-free compressed air, ensure clear oil pollution in the air, and ensure the cleanliness and safety of the product.

What are the advantages of oil-free air compressors in food production?

Oil-free air compressors provide clean compressed air, clear oil and air, meet food-grade safety standards, and reduce the risk of pollution.

What is the difference between oil-free air compressors and traditional air compressors?

Oil-free air compressors do not use lubricating oil and will not produce oil pollution, while traditional air compressors use lubricating oil, which may bring air pollution risks.

What are the applications of oil-free air compressors in powder food production?

Oil-free air compressors deliver oil-free compressed air in the production of powdered foods like milk and coffee powder, preventing contamination during transportation and ensuring product safety.

What is the role of oil-free air compressors in beverage filling?

Oil-free air compressors provide oil-free air to avoid oil pollution, ensure the cleanliness of beverages during the filling process, and extend the shelf life of products.

Prospects of oil-free air compressors in the food industry

As the food and beverage industry continues to increase its requirements for air quality, the market demand for oil-free air compressors will continue to grow in the future. The widespread application of oil-free air compressors in the food and beverage industry provides companies with clean, pollution-free compressed air, and promotes companies to improve product safety and production efficiency. In the future, with the continuous development of technology, the application scenarios of oil-free air compressors will be more extensive, especially in terms of environmental protection and energy saving, which will bring more possibilities for clean production to the food and beverage industry.

Conclusion

MINNUO oil-free air compressors not only meet the company’s strict requirements for air quality, but also significantly improve production efficiency and reduce pollution and maintenance costs. For food and beverage companies that want to gain a competitive advantage in the market, oil-free air compressors are an ideal choice to ensure product safety. As the market continues to develop, oil-free air compressors will continue to play a key role in the food and beverage industry, providing companies with a safe and reliable supply of clean air.