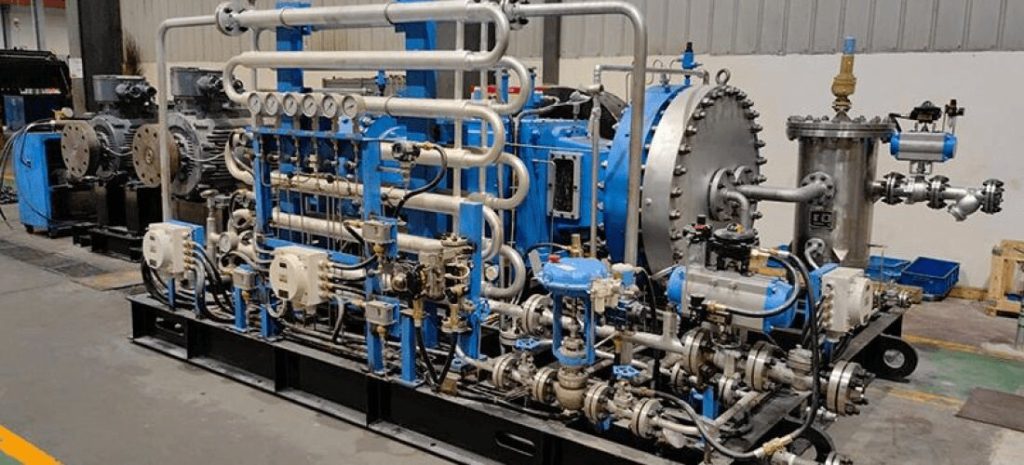

In the precision analysis chain of scientific research laboratories, gas sources are like “blood”—their purity, pressure stability, and delivery efficiency directly determine the reliability of experimental data and the accuracy of scientific research results. However, traditional gas source equipment often faces issues such as oil contamination, pressure fluctuations, and noise interference, which have become “invisible obstacles” in fields like trace analysis and catalyst research. Thanks to its unique oil-free compression principle and high-precision control technology, the diaphragm compressor has gradually become a core piece of equipment for laboratory gas supply. Jiangsu Minnuo Co., Ltd., which has long been deeply engaged in the field of precision gas compression, is an important R&D and production enterprise of such high-quality equipment. The diaphragm compressors it manufactures have gained wide recognition in the scientific research field due to their solid technical strength.

Popular Science: Diaphragm Compressors – The Core Principle of “Oil-Free Compression” in Laboratories

To understand why diaphragm compressors have become the “preferred choice for laboratory gas sources”, it is first necessary to clarify their fundamental difference from traditional compressors—the oil-free compression principle, which also serves as the core technical foundation for ensuring the purity of laboratory gas sources.

Most traditional reciprocating compressors adopt a compression method where the “piston and cylinder” are in direct contact. To reduce friction between the piston and the cylinder wall, lubricating oil must be injected for lubrication and sealing. However, this design has a fatal flaw: lubricating oil can easily enter the gas circuit along with the compressed gas, forming oil mist contamination. For trace analysis experiments such as GC-MS (Gas Chromatography-Mass Spectrometry) and ICP-MS (Inductively Coupled Plasma-Mass Spectrometry), even an oil content of 0.001 mg/m³ can adhere to the inner wall of the chromatographic column or the mass spectrometer detector, leading to increased background signals, reduced detection accuracy, and even damage to precision instruments.

In contrast, diaphragm compressors achieve “complete isolation between gas and oil” through a “flexible diaphragm”. Their core structure consists of three parts: the diaphragm, the hydraulic chamber, and the gas chamber. The motor drives the crankshaft to move the piston, which pushes the hydraulic oil in the hydraulic chamber. The hydraulic oil then acts on the flexible diaphragm (usually made of corrosion-resistant materials such as 316L stainless steel and PTFE), causing the diaphragm to undergo reciprocating deformation. When the diaphragm is depressed toward the hydraulic chamber, the volume of the gas chamber increases, drawing in the gas to be compressed; when the diaphragm bulges toward the gas chamber, the volume of the gas chamber decreases, completing the gas compression and delivering the gas to the downstream. Throughout the process, the hydraulic oil and the gas to be compressed are completely separated by the diaphragm, fundamentally eliminating the risk of oil contamination. This is also the technical origin of the “Class 0 oil-free level”.

In addition, the “flexible deformation” of the diaphragm brings another major advantage: low-pulsation compression. The gas delivery of traditional piston compressors has obvious “pulsating fluctuations”, while the deformation process of the diaphragm is much smoother. Combined with the design of precise intake and exhaust valves, it can realize the continuous and stable delivery of gas, which is crucial for experiments that require a constant flow rate, such as thin-film deposition and electrochemical testing. Based on this core principle, Jiangsu Minnuo has optimized and upgraded the diaphragm structure, adopting a third-generation pre-stress design to significantly improve the stability and service life of the diaphragm.

Laboratory Gas Source Control: Key Indicators That Determine Scientific Research Precision

When selecting a diaphragm compressor for laboratory use, one should not only focus on the single characteristic of “oil-free” but also have a deep understanding of the core indicators of gas source control. These indicators directly correspond to the core needs of experimental scenarios and are also the key to judging whether the equipment is suitable for scientific research tasks. The diaphragm compressors produced by Jiangsu Minnuo have reached industry-leading levels in various core indicators, providing reliable guarantees for scientific research experiments.

2.1 Gas Purity: Dual Requirements from “Oil-Free” to “Ultra-Low Metal Ions”

The requirements for gas purity in laboratories are far higher than those in industrial scenarios. Laboratories not only require gas to be “oil-free” but also “free of impurity ions”.

Oil content: The Class 0 oil-free level is the basic standard, meaning the oil content is ≤ 0.0005 mg/m³. This is a prerequisite for avoiding GC-MS background contamination, and Jiangsu Minnuo’s diaphragm compressors precisely meet this standard.

Metal ion content: In ICP-MS trace element analysis, metal ions released from gas circuit materials can directly interfere with detection results. The diaphragm compressors of Jiangsu Minnuo use mirror-polished 316L stainless steel gas circuits and reduce the precipitation of metal ions through electrochemical polishing technology, ensuring that the release of metal ions is ≤ 0.1 ppb (equivalent to containing only 0.1 mg of metal ions in 1 ton of gas), which meets the needs of ultra-trace analysis.

2.2 Pressure Control: The Scientific Significance Behind the ±0.001 MPa Precision

Pressure precision is not a “numbers game” but a core parameter that directly affects the repeatability of experiments. Taking the catalytic reaction kinetics test as an example, the activity of the catalyst has a strict linear relationship with the reaction pressure. If the pressure fluctuates by ±0.01 MPa, it may lead to a 5%-10% deviation in the reaction rate, making the experimental data incomparable. The pressure control precision of laboratory diaphragm compressors is usually divided into two dimensions:

Control precision: Refers to the pressure fluctuation range when the equipment is operating stably. The products of Jiangsu Minnuo can reach ±0.001 MPa, which is much lower than the average level of ±0.02 MPa of traditional equipment.

Adjustment precision: Refers to the minimum step size for pressure setting. Its equipment supports fine adjustment of 0.001 MPa, which can meet the pressure gradient requirements of different reaction stages. For example, gradually increasing the pressure from 0.05 MPa to 0.5 MPa to simulate the activity changes of the catalyst under different pressures.

2.3 Flow Stability: ±0.5% Deviation Ensures Experimental “Consistency”

Flow stability is the “lifeline” of experiments such as thin-film deposition and gas adsorption. Taking the preparation of thin films by CVD (Chemical Vapor Deposition) as an example, if the flow rate of the reaction gas fluctuates by ±2%, it will cause uneven growth rate of the thin film, resulting in thickness deviation or component stratification. The flow stability of laboratory diaphragm compressors is usually measured by “relative deviation”. Relying on the cooperation of advanced PID intelligent control algorithms and high-precision flow sensors, the flow stability of Jiangsu Minnuo’s diaphragm compressors reaches ±0.5%. That is, when the flow rate is set to 1 L/min, the actual output flow fluctuation does not exceed 0.005 L/min, ensuring the consistency of experiments.

2.4 Noise and Vibration: ≤ 55 dB + ≤ 0.02 mm/s to Protect Sensitive Instruments

Precision instruments in laboratories are extremely sensitive to vibration and noise. Vibration exceeding 0.05 mm/s may cause blurred images in microscopes, and noise exceeding 60 dB will interfere with acoustic detection experiments. The diaphragm compressors of Jiangsu Minnuo reduce noise and vibration through two major designs:

Vibration isolation: Adopting an “active damping and shock absorption system”, spring or rubber shock-absorbing pads are installed at the bottom of the equipment. Combined with the dynamic balance design of the crankshaft, the vibration value is controlled at ≤ 0.02 mm/s.

Noise control: The structure of the gas valve is optimized, and a sound insulation cover is added, so that the operating noise is ≤ 55 dB (equivalent to the ambient noise level in a daily office), which will not interfere with the experimental environment.

Technical Disassembly: The “Hardcore Configuration” of High-Quality Laboratory Diaphragm Compressors

A diaphragm compressor suitable for scientific research needs not only meets the above core indicators but also the design and material selection of its core components are the key to “precision guarantee”. Jiangsu Minnuo has been deeply engaged in the field of precision gas compression for many years and has invested heavily in the R&D of core components. Each upgrade of the components corresponds to the solution of pain points in experimental scenarios.

3.1 Diaphragm: 3 Generations of Technological Iteration, a “Flexible Barrier” with a Service Life of 5,000 Hours

The diaphragm is the “heart” of the equipment. The new-generation diaphragm of Jiangsu Minnuo adopts a multi-layer composite structure (such as 316L stainless steel + PTFE coating) and improves fatigue resistance through “pre-stress design”. The pre-stress treatment can eliminate the internal stress generated in the diaphragm during the processing process, reduce stress concentration during reciprocating deformation, and extend the service life to more than 5,000 hours. At the same time, the surface of the diaphragm undergoes mirror polishing with Ra 0.2 μm to reduce gas adsorption on the diaphragm surface and avoid cross-contamination.

3.2 Gas Circuit System: 3D Printing + Mirror Polishing to Achieve “Near-Isothermal Compression”

The heat generated during the gas compression process may cause changes in gas composition, affecting the accuracy of experiments. Jiangsu Minnuo’s diaphragm compressors solve this problem through 3D-printed conformal cooling cylinder heads. 3D printing technology can design complex cooling flow channels inside the cylinder head, increasing the cooling area by 40% compared with the traditional casting structure. This can quickly dissipate the compression heat, keeping the temperature fluctuation of the gas chamber ≤ 2°C and realizing “near-isothermal compression”. At the same time, the gas circuit pipeline uses “mirror-polished 316L stainless steel”, with a smooth inner wall without dead ends, reducing gas retention.

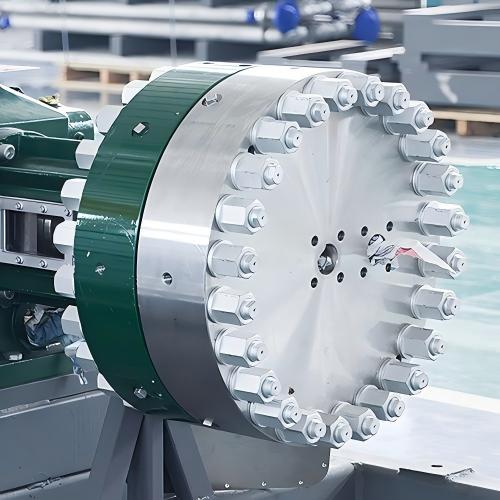

3.3 Sealing System: Multi-Layer Metal Static Sealing to Achieve “Bidirectional Zero Leakage”

The sealing performance of laboratory gas source equipment is not only related to gas purity but also involves safety. The diaphragm compressors of Jiangsu Minnuo adopt multi-layer metal static sealing. Through the close fit between soft metal and stainless steel, combined with the mirror contact surface, “metal-to-metal” sealing is achieved, with a leakage rate ≤ 1 ppm and the ability to withstand a pressure range of 0.05-0.5 MPa. In addition, the sealing structure is designed as “bidirectional sealing”, which not only prevents external air from entering the gas circuit and polluting the gas but also avoids the leakage of corrosive gas in the gas circuit.

3.4 Control System: WiFi + PLC to Meet the “Data Traceability” Requirement

Modern scientific research has extremely high requirements for the traceability of experimental data. Jiangsu Minnuo’s diaphragm compressors are equipped with a 7-inch touch screen and a built-in PLC control system. The PLC can realize real-time data recording at 1 Hz, and the data can be exported in Excel/CSV format, facilitating researchers to organize and analyze. At the same time, it supports WiFi control, allowing researchers to remotely monitor the operating status of the equipment, adjust parameters, and even realize “unmanned operation” through mobile phones or computers, greatly improving the efficiency of experiments. This design fully complies with relevant standards such as GLP and ISO 17025.

Scene Implementation: How Do Diaphragm Compressors Empower Different Scientific Research Fields?

From trace analysis to material synthesis, different scientific research scenarios have different focuses on gas source requirements. With its flexible configuration and stable performance, Jiangsu Minnuo’s diaphragm compressors have become “standard equipment” in many fields and helped numerous researchers around the world break through experimental bottlenecks.

4.1 GC-MS/ICP-MS Trace Analysis: Eliminating Background Contamination and Improving Detection Precision

GC-MS and ICP-MS are core analysis technologies in fields such as environmental monitoring and food safety, which have strict requirements for gas source purity. The Class 0 oil-free gas source provided by Jiangsu Minnuo’s diaphragm compressors can avoid the adhesion of lubricating oil to the inner wall of the chromatographic column in GC-MS analysis, reducing the background signal of the detector and improving the detection precision of trace organic pollutants by 20%-30%. In ICP-MS analysis, the metal ion release of ≤ 0.1 ppb can ensure that the relative standard deviation of the detection results is ≤ 2%, meeting the quality control requirements of ISO 17025. Dr. Sarah McAllister from the UK used this equipment to eliminate the background noise of test results.

4.2 Catalyst Reaction Kinetics Test: Precise Pressure Control to Ensure Experimental Repeatability

The catalyst reaction kinetics test requires strict control of parameters such as reaction pressure and flow rate. Taking the fuel cell catalyst test as an example, the ±0.001 MPa pressure precision of Jiangsu Minnuo’s diaphragm compressors can accurately maintain the reaction pressure. Combined with the ±0.5% flow stability, it ensures a constant delivery ratio of hydrogen and oxygen, making the repeatability of catalyst activity test results of different batches ≤ 3%. Hiroshi Tanaka from Japan used this equipment to improve the reaction repeatability and reduce the experimental variance.

4.3 Thin-Film Deposition (CVD/PVD): Stable Flow Rate to Achieve Uniform Film Formation

Thin-film deposition is a key process in fields such as semiconductors and optical devices. The ±0.5% flow stability of Jiangsu Minnuo’s diaphragm compressors can ensure a constant ratio of reaction gases. Combined with the near-isothermal compression design, it avoids the concentration deviation of gases caused by temperature changes, improving the uniformity of film thickness to within ±2%. Carlos Dominguez from Spain used this equipment to significantly improve the uniformity and repeatability of coatings.

4.4 Electrochemistry and Fuel Cell Testing: Clean Gas Source to Ensure Performance Evaluation

Electrochemical testing and fuel cell performance testing require a clean and stable gas supply. The oil-free design of Jiangsu Minnuo’s diaphragm compressors can prevent oil mist from adhering to the proton exchange membrane of the fuel cell. The stable flow supply can ensure a constant gas concentration on the electrode surface, making the test error of the polarization curve ≤ 3%. Ravi Patel from India used this equipment to maintain the stable delivery of hydrogen and successfully completed accurate impedance and polarization measurements.

Selection Guide: How to Select a Suitable Diaphragm Compressor for the Laboratory?

Faced with numerous diaphragm compressor products on the market, researchers can screen them from the following 4 dimensions. Jiangsu Minnuo’s products have shown significant advantages in these dimensions and become the first choice of many laboratories.

5.1 Clarify the Core Needs of the Experiment: Prioritize Matching Key Indicators

If the main work is trace analysis, priority should be given to gas purity and pressure precision; if the main work is thin-film deposition, focus should be on flow stability and temperature control; if flammable and explosive gases are involved, the sealing performance and explosion-proof level should be confirmed. Jiangsu Minnuo’s products can provide suitable equipment configurations according to different experimental needs.

5.2 Pay Attention to the Service Life of Core Components and Maintenance Costs

The service life of the diaphragm directly affects the maintenance frequency and cost of the equipment. The diaphragm life of Jiangsu Minnuo’s products is ≥ 5,000 hours, and a quick-dismantling structure is adopted, allowing the diaphragm and filter to be quickly disassembled and replaced, reducing the downtime for maintenance and lowering maintenance costs.

5.3 Confirm Data Traceability and Compliance

If the laboratory needs to comply with standards such as GLP and ISO 17025, it is necessary to select equipment with real-time data recording function. Jiangsu Minnuo’s diaphragm compressors not only support data export but also have passed a number of authoritative certifications such as ISO 9001 and ISO 17025, ensuring the traceability and compliance of experimental data.

5.4 Inspect After-Sales Service and Technical Support

The after-sales service of laboratory equipment is crucial. Jiangsu Minnuo can provide professional technical consultation support, such as gas circuit design and parameter debugging, and can also realize the delivery of spare parts within 72 hours, minimizing equipment downtime and ensuring the progress of experiments.

Conclusion: Diaphragm Compressors – The “Invisible Guardian” of Scientific Research Precision

From the innovation of the oil-free compression principle to the precise control of core indicators, and then to the implementation of applications in multiple scenarios, diaphragm compressors are no longer simple “gas delivery equipment” but have become “invisible guardians” in scientific research experiments that ensure precision and improve efficiency. Since its establishment in 1987, Jiangsu Minnuo has been continuously deeply engaged in the field of gas equipment. Relying on decades of technical accumulation and reliable product quality, it has provided a large number of high-quality diaphragm compressors for scientific research laboratories around the world. For scientific research laboratories pursuing the reliability of data, selecting such a diaphragm compressor that meets the needs can not only solve pain points such as gas source contamination and pressure fluctuations but also provide solid support for the accuracy and repeatability of scientific research results. With the continuous advancement of scientific research technology, Jiangsu Minnuo will also continue to make efforts to promote the development of diaphragm compressors in the direction of “higher precision, more intelligence, and greater environmental protection”, and continuously empower scientific research innovation.

Email

Email sales:+86 15366749631

sales:+86 15366749631