Air compressors are a core power source for industrial and daily applications, making the selection of the correct type crucial. Based on their operating principles and structure, air compressors are primarily categorized into four basic types: Reciprocating (Piston), Rotary Screw, Centrifugal, and Scroll. Each type has distinct characteristics regarding pressure range, flow output, energy efficiency, and maintenance requirements, making them suitable for different scenarios—from home workshops to large-scale industrial manufacturing. Understanding these core differences is the critical first step in ensuring a return on investment and operational efficiency.

Find Your Compressor Type Now

Whether you need to inflate car tires, power pneumatic tools in a woodworking shop, or supply continuous power for large manufacturing processes, selecting the right air compressor type is fundamental to success. The core conclusion is: air compressors are divided into four main categories: Reciprocating, Rotary Screw, Centrifugal, and Scroll.

- Reciprocating compressors are ideal for intermittent, high-pressure needs.

- Rotary Screw compressors provide a continuous, high-volume air supply.

- Centrifugal compressors are designed for ultra-large-scale, ultra-high-flow applications.

- Scroll compressors are known for being quiet and efficient, suitable for sensitive environments requiring high air quality.

This article will delve into the operating principles, pros, cons, and typical applications of these four types to help you make a precise decision based on your specific needs.

Reciprocating (Piston) Compressors: The Reliable and Versatile Workhorse

Reciprocating compressors, often called piston compressors, are the most common and easily recognizable type. Their operation is similar to an internal combustion engine: a motor drives a piston to move back and forth within a cylinder, drawing in air through an intake valve, compressing it, and then discharging it through an outlet valve into a storage tank.

Key Features & Pros/Cons

| Pros | Cons |

| * High-Pressure Capability: Can generate very high pressures (up to 200 psi or more), suitable for applications requiring high-pressure air. | * Pulsating Airflow and Noise: Operates with significant noise and the output airflow is pulsating. |

| * Low Initial Cost: Typically less expensive to purchase than other industrial-grade compressors. | * Higher Maintenance Needs: Has many moving parts, and wear parts (like piston rings, valves) require regular replacement. |

| * Mature Technology, Simple Maintenance: Straightforward structure, with easily obtainable repair parts. | * Relatively Lower Energy Efficiency: Especially in continuous running mode. |

Primary Applications

- Automotive repair shops (for tire inflation, impact wrenches).

- Small woodworking shops and DIY projects.

- Pneumatic painting requiring high-pressure gas.

- Industrial applications as a backup or for low usage frequency.

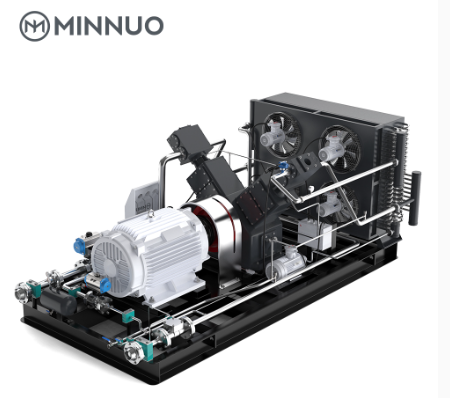

Rotary Screw Compressors: The Pillar of Continuous Industrial Operation

The rotary screw compressor is the most common continuous air supply solution in modern industrial facilities. It uses two intermeshing helical rotors (male and female) that rotate within a sealed chamber to compress the air.

Key Features & Pros/Cons

| Pros | Cons |

| * Continuous and Stable Air Supply: Delivers a smooth, non-pulsating flow of compressed air. | * Higher Initial Investment. |

| * High Energy Efficiency & Low Operating Costs: Designed for 24/7 operation, highly efficient at full load. | * Maintenance requires higher specialized expertise. |

| * Compact Structure, Low Vibration: Relatively small footprint, smooth and quiet operation. | * Compressed air in some models may contain oil (requires post-treatment equipment for oil-free air). |

| * Long Maintenance Intervals: Fewer moving parts; main maintenance involves changing lubricants, oil filters, and air filters. |

Primary Applications

- Large manufacturing plants and assembly lines.

- Food and beverage processing industries (requires oil-free models).

- Pharmaceutical and electronic manufacturing.

- Any industrial environment requiring a continuous and high volume of compressed air.

Centrifugal Compressors: The Power Giant for Ultra-High-Flow Applications

The centrifugal compressor is suitable for extremely large-scale applications with massive airflow requirements. It transfers kinetic energy to the air via a high-speed rotating impeller, which is then converted into pressure energy in a diffuser.

Key Features & Pros/Cons

| Pros | Cons |

| * Ultra-High Flow Output: Capable of delivering extreme flows of thousands of cubic feet per minute (CFM). | * Extremely Expensive Initial Cost and Installation Fees. |

| * Completely Oil-Free Air: Air does not contact the lubricant, providing the highest quality clean air. | * Efficiency can drop significantly when operating at partial load. |

| * High Reliability and Low Maintenance: Simple design with few moving parts, suitable for long, uninterrupted operation. | * Large physical size, unsuitable for small to medium-sized applications. |

Primary Applications

- Large-scale oil refineries and chemical plants.

- Steel manufacturing and metal smelting.

- Starting large marine engines.

- District air supply systems and ultra-large-scale air separation units.

Scroll Compressors: The Quiet, Efficient Professional Choice

The scroll compressor uses one fixed scroll and one orbiting moving scroll that intermesh, forming a series of continually decreasing air pockets to compress the air. It represents advanced technology for medium to low-flow applications.

Key Features & Pros/Cons

| Pros | Cons |

| * Extremely Quiet and Smooth Operation. | * Higher manufacturing cost; price is often higher than comparable reciprocating models. |

| * High Energy Efficiency, especially suited for variable speed operation. | * Limited unit flow and pressure range (typically used for low to medium pressure, small to medium flow scenarios). |

| * Simple structure, high reliability, and extremely low maintenance needs. | * Once internal damage occurs, it often requires complete replacement, leading to high repair costs. |

| * Provides clean, oil-free air. |

Primary Applications

- Medical air systems in hospitals and dental clinics.

- HVAC systems (for driving refrigerants).

- Laboratories and precision instruments requiring clean, oil-free air.

- High-end car dealerships and work environments sensitive to noise.

How to Choose? Quick Comparison Guide

The table below summarizes the key differences between the four main compressor types to help you quickly filter your options:

| Feature | Reciprocating (Piston) | Rotary Screw | Centrifugal | Scroll |

| Operating Principle | Piston reciprocation | Dual screw rotation | High-speed impeller (centrifugal force) | Intermeshing scrolls form moving air pockets |

| Typical Pressure Range | Medium – Very High | Medium – High | Medium – High | Low – Medium |

| Typical Flow Range | Low – Medium | Medium – Very High | Extremely High | Low – Medium |

| Airflow Quality | Pulsating | Smooth, continuous | Smooth, continuous | Smooth, continuous |

| Energy Efficiency (Full Load) | Fair | Excellent | Excellent (at full load) | Excellent |

| Noise Level | High | Medium – Low | Medium – High | Very Low |

| Initial Cost | Low | Medium – High | Very High | Medium – High |

| Maintenance Needs | High | Medium | Low | Very Low |

| Best Application | Intermittent, High-Pressure Needs | Continuous Industrial Operation | Ultra-Large Process Industry | Quiet, Clean Air Requirements |

Frequently Asked Questions

Q: Which compressor should I choose for a small auto repair shop?

A: For a typical auto repair shop, a Reciprocating (Piston) compressor is usually the most cost-effective choice. It can provide sufficiently high-pressure air for tire inflation, impact wrenches, and paint guns. If the budget allows and there are higher requirements for noise reduction and continuous air supply, a small to medium-sized Variable Speed Drive (VSD) Rotary Screw compressor could also be considered, as it offers a more stable airflow and lower energy consumption.

Q: Is an “oil-free” compressor truly necessary? Which industries is it critical for?

A: “Oil-free” air is essential for industries with strict requirements for final product quality or process safety. For example, in food and beverage, pharmaceuticals, electronic chip manufacturing, and medical breathing air, lubrication oil contamination can lead to product spoilage, equipment failure, or even personal harm. In these applications, you should choose a model where the technology itself achieves oil-free compression, such as Centrifugal, Scroll, or Oil-Free Screw compressors, and not just rely on filters.

Q: Which is more durable: Rotary Screw or Reciprocating?

A: Durability depends on usage and maintenance. Based on the general practice experience of compressed air system experts, the Rotary Screw compressor, designed for continuous or heavy-duty operation, typically exhibits a longer service life and lower failure rate in industrial settings because its operation is smoother and wear is more uniform. Conversely, a Reciprocating compressor is more durable in intermittent duty cycles with frequent starts and stops, but in continuous heavy-duty use, its parts like piston rings and valves wear out faster.

Q: How do I determine the required flow (CFM)?

A: First, list the manufacturer’s rated CFM requirement for all pneumatic tools that will be used simultaneously (usually found on the tool’s nameplate or manual). Sum their CFM values and then multiply by a safety factor of 1.3–1.5 (to account for piping leaks and efficiency losses). The resulting total CFM is the minimum output flow your compressor unit needs to meet. Remember that pressure (PSI) and flow (CFM) are two separate and equally important parameters.

Q: What are the advantages of Variable Frequency Drive (VFD) compressors?

A: VFD compressors (commonly found in screw and scroll types) automatically adjust the motor speed according to the actual air demand. Their main advantages are: 1) Significant energy savings, avoiding energy waste during no-load or unloaded operation; 2) Maintaining stable system pressure, improving process quality; and 3) Reducing stress on the power grid and mechanical components, extending equipment life. If your air consumption fluctuates significantly, VFD is the ideal choice.

Conclusion and Next Steps

Choosing the right air compressor type is not an easy task, but by understanding the characteristics of the four core types—Reciprocating, Rotary Screw, Centrifugal, and Scroll—you’ve taken the critical first step. Remember, there is no “best” type, only the one “most suitable” for your specific needs. Your next actions should be:

- Quantify Your Needs: Accurately calculate the maximum working pressure (PSI) and total air consumption flow (CFM) you require.

- Analyze Operating Mode: Assess whether the usage is intermittent or continuous and the extent of the air consumption fluctuation.

- Evaluate Environment and Budget: Consider installation space limitations, noise requirements, air quality standards, and the total cost of ownership (including purchase, installation, energy consumption, and maintenance).

- Consult Experts: Contact renowned compressed air system suppliers or local authorized dealers like Minnuo Group. They can provide professional selection software, on-site evaluations, and energy efficiency analysis to ensure you acquire a reliable and economical solution.

Source Declaration

This article was written by a strategist with over ten years of experience in industrial equipment selection and energy management. The information is based on research reports on best practices for compressed air systems from the U.S. Department of Energy (DOE) Industrial Technologies Program, technical performance data sheets from the Compressed Air and Gas Institute (CAGI), and professional insights gained from conducting compressed air system audits and energy efficiency optimization projects for clients. The recommendations and comparisons are intended to provide objective educational information, and specific brand and model selection should be based on qualified engineering assessment.

Email

Email sales:+86 15366749631

sales:+86 15366749631