You’re diligent about oil changes and filter replacements. But there’s one critical component, buried in the heart of your air compressor, that’s likely being neglected: the air cooler.

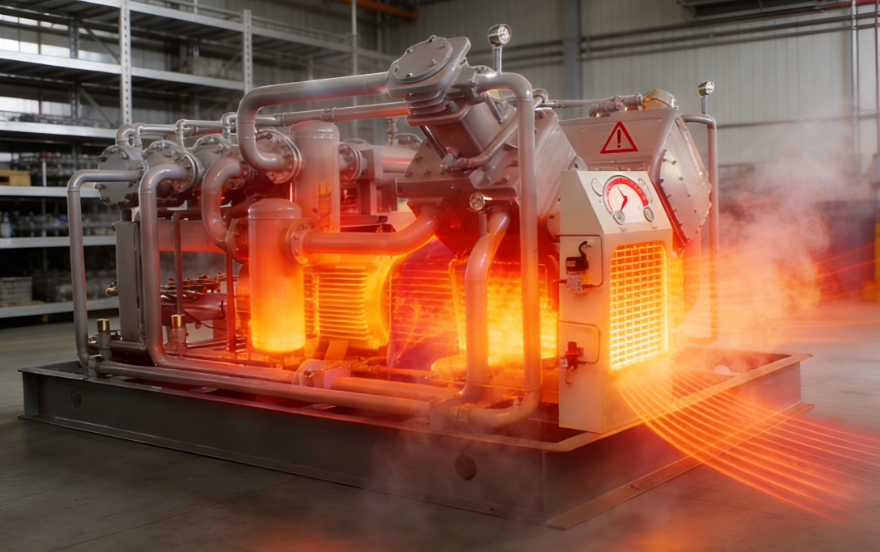

Out of sight, out of mind. As it sits there, day after day, it slowly gets choked with dust, pollen, oil mist, and factory debris. This isn’t just a cleanliness issue—it’s a silent, progressive chokehold on your compressor’s performance, efficiency, and lifespan. It’s the primary cause behind most cases of preventable compressor overheating, leading users to desperately search for overheating solutions.

Ignoring the cooler doesn’t just mean your compressor runs a little warmer. It triggers a catastrophic chain reaction that leads to thousands in wasted energy, premature parts failure, and ultimately, a devastating and costly shutdown. This guide reveals why cooler maintenance is non-negotiable and provides a clear plan to prevent the meltdown.

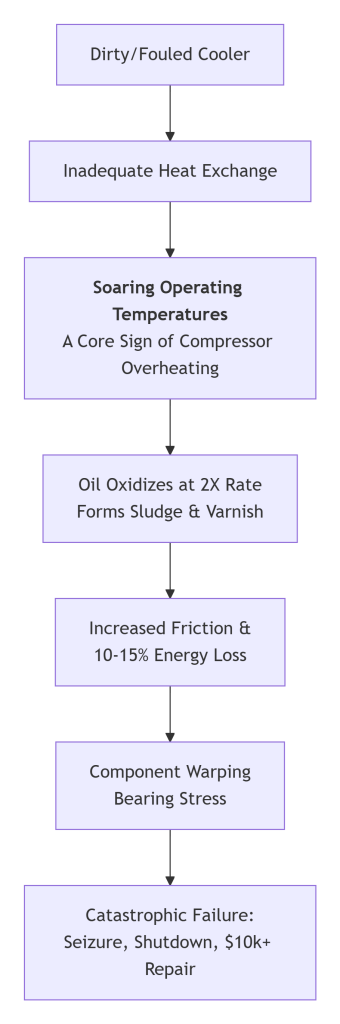

The Domino Effect of a Dirty Cooler: A Visual Guide to Failure

One problem doesn’t stay isolated. It starts a costly chain reaction, best understood visually:

From Symptom to Data: Your Diagnostic Toolkit

Before you open a cleaning kit, open the data log. Modern compressors provide the clues you need. Monitoring these key parameters can give you an early warning long before a shutdown occurs, turning reactive panic into proactive planning.

- Discharge Air Temperature: This is your primary indicator. Consistently running 10-15°C (18-27°F) above the manufacturer’s specified normal range is a clear red flag pointing directly to cooling inefficiency.

- Oil Temperature: Follows closely behind. High oil temperature is a direct result of poor cooling and a leading cause of oil degradation.

- Cooler Approach Temperature (For Air-Cooled Units): This is the temperature difference between the ambient air and the cooled air/oil leaving the cooler. A widening approach temperature (e.g., from a design spec of 10°C to 20°C) is a pure, quantitative measure of cooler fouling.

- Water Temperature Differential (For Water-Cooled Units): Monitor the difference between the cooling water inlet and outlet. A decreasing differential indicates that heat is not being transferred effectively due to internal scaling or blockage.

Pro Tip: Don’t just glance at gauges. Trend the data. A gradual creep in temperatures over weeks is the silent story of a slowly choking cooler.

The Cold Hard Math: Quantifying the Cost of Neglect

Let’s move from symptoms to dollars. Ignoring the cooler isn’t just a technical fault; it’s a financial drain. Consider this analysis for a typical 75 kW (100 HP) lubricated screw compressor:

| Cost Factor | Normal Operation (Clean Cooler) | Neglected Operation (Dirty Cooler) | Annual Cost Impact |

| Energy Consumption | Baseline: ~Full-load efficiency | +8% to +15% due to increased friction & heat | +$4,800 to $9,000(at $0.12/kWh, 8,000 hrs/yr) |

| Synthetic Oil Life | 8,000-hour change interval | Oil degrades 2-3x faster: ~3,000-hour interval | +$1,200 to $1,800(2.7 extra changes x $450/change) |

| Filter Replacements | Standard interval | Accelerated contamination: Interval reduced by 30% | +$300 to $500 |

| Risk of Major Failure | Low probability | High probability of seized bearings, carbonized oil | +$15,000 to $30,000(Cost of air-end rebuild + downtime) |

| **Estimated Total Annual Impact | $6,300 to $11,300 + Catastrophic Risk |

The Conclusion is Inescapable: What seems like a minor maintenance oversight can silently bleed over $10,000 per year from your bottom line for a single compressor, not including the sword of Damocles that is a potential $20,000+ catastrophic failure. A $500 professional cleaning service offers one of the highest ROIs in your plant.

Step-by-Step: How to Inspect and Clean Your Compressor Cooler

Don’t wait for a failure. Integrate this into your preventive maintenance schedule.

Visual Inspection & Temperature Guide:

- What to Do: Monthly, with power OFF, shine a light through the cooler core.

- Clean: Light is visible through most fins.

- Needs Cleaning: Light is blocked; fins appear matted.

Cleaning Process: CRITICAL DOs and DON’Ts

| Step | For Air-Cooled Compressors | Key Warning |

| 1. Dry Clean | Use compressed air FROM THE INSIDE OUT (reverse of airflow). | Always wear safety glasses & a mask. |

| 2. Wet Clean | Use non-corrosive fin cleaner. Rinse with LOW-PRESSURE water. | DO NOT USE A PRESSURE WASHER. It bends fins permanently. |

| 3. Final Check | Ensure unit is COMPLETELY DRY before restarting. | Moisture can cause electrical damage. |

For Water-Cooled Systems: Monitor inlet/outlet water temperature differential. A shrinking gap indicates internal scaling, which requires professional chemical descaling.

Your Optimal Maintenance Schedule

Match the frequency to your operating environment for maximum protection:

| Operating Environment | Inspection Frequency | Recommended Cleaning Frequency |

| Light Duty(e.g., Clean, climate-controlled rooms) | Quarterly | Annually |

| Standard Industrial(e.g., General manufacturing) | Monthly | Every 6 Months |

| Harsh Duty(e.g., Woodworking, textiles, foundries) | Bi-Weekly | Quarterly |

Pro Tip: Install a differential pressure gauge across the cooler. A rising pressure drop is the most accurate, real-time indicator of fouling and the root cause of cooler performance issues.

Frequently Asked Questions

Q1: Can I use a pressure washer to clean my air cooler?

A1: Absolutely not. High pressure will bend the delicate cooling fins, permanently reducing airflow and making the problem worse. Always use low-pressure water or specialized cleaning tools.

Q2: Our compressor is in a dusty location. Is a filter on the cooler intake a good idea?

A2: Yes, but with caution. A coarse, low-restriction pre-filter can help. However, any filter adds some pressure drop and requires its own maintenance schedule. The best solution is to relocate the compressor’s air intake to a cleaner area if possible.

Q3: We cleaned the cooler, but temperatures are still high. What now?

A3: The issue may lie elsewhere: insufficient cooling airflow (blocked vents, faulty fan), low oil level, a failing thermostat, or an internal issue like a blocked oil passage. After verifying cooler cleanliness, it’s time for a professional system diagnosis.

Conclusion: The Highest ROI Maintenance Task

Cleaning your compressor’s cooler isn’t glamorous, but it is arguably the single most cost-effective maintenance task you can perform. It directly protects your most valuable assets: the compressor itself and your uninterrupted production.

By preventing the domino effect of heat, you safeguard efficiency, slash energy and oil costs, and eliminate the risk of a catastrophic failure. Turn this ignored task into a scheduled priority, and your compressor will repay you with years of reliable, efficient service.

Is Your Compressor Running Hot?

Don’t let a choked cooler throttle your productivity and profits. The team at MINNUO specializes in maximizing compressor reliability and efficiency through proactive care and precise diagnostics.

Contact our compressor experts today to discuss your cooling system performance and explore strategies for optimal maintenance.

Email

Email sales:+86 15366749631

sales:+86 15366749631