For most plants, the air compressor is a necessary utility—a sizable line item on the energy bill. A common goal is to make it more efficient through better control, leak management, and sizing. But what if you could transform this cost center into a productive asset that directly offsets other energy expenses?

The reality is stark: Over 90% of the electrical energy fed to a typical air compressor is converted into heat. The compressed air itself carries away only a tiny fraction of this. The majority—often 50-70% of the input power—is rejected as waste heat through the aftercooler and lubricant cooling circuit. This isn’t just an efficiency loss; it’s a massive, continuous stream of untapped thermal energy leaving your building.

This guide moves beyond awareness to action. It provides a clear, step-by-step framework to evaluate the feasibility and calculate the Return on Investment (ROI) for a heat recovery project, turning a thermal liability into a process gain.

I. The Energy Map: Where Does the Heat Go?

To capture value, you must first understand the flow of energy. For a lubricated screw compressor (the most common industrial type), the energy distribution looks something like this:

- Useful Energy (10-15%): The energy contained in the compressed air at the desired pressure and flow.

- Radiation & Convection Losses (5-15%): Heat lost from the motor, casing, and piping to the surrounding air.

- Recoverable Heat (50-70%): This is the goldmine. It’s heat transferred to the compressor lubricant (oil) during compression and to the air in the aftercooler. This heat is high-grade (typically 70°C to 90°C / 158°F to 194°F) and is removed by cooling systems to protect the compressor.

The primary target for recovery is the lubricant cooling circuit, as it holds the largest, most consistent, and highest-temperature energy stream.

II. The Recovery Technology Matrix: Matching Heat to Need

The best application for your recovered heat depends on your plant’s needs. Here are the two most common and effective methods:

- Hot Water Production (The Most Versatile)

- How it Works: A liquid-to-liquid heat exchanger is installed in the compressor’s oil cooling loop. Plant water (or a glycol mix) is pumped through the exchanger, capturing up to 50-70% of the input power as hot water (typically heated to 50-70°C / 122-158°F).

- Best For: Pre-heating boiler feed water, providing process hot water for cleaning or reactions, or supplying domestic hot water for washrooms and kitchens.

- ROI Driver: Directly displaces the cost of gas, steam, or electricity that would have been used to heat that water.

- Space Heating (The Lowest-Cost Option)

- How it Works: The hot air discharged from the compressor’s integrated fan cooler (or the hot oil cooler exhaust) is ducted directly to adjacent spaces like workshops, warehouses, or loading bays.

- Best For: Facilities in colder climates with seasonal heating needs and the compressor room located near areas requiring heat.

- ROI Driver: Displaces the cost of running primary space heaters (gas, electric, oil).

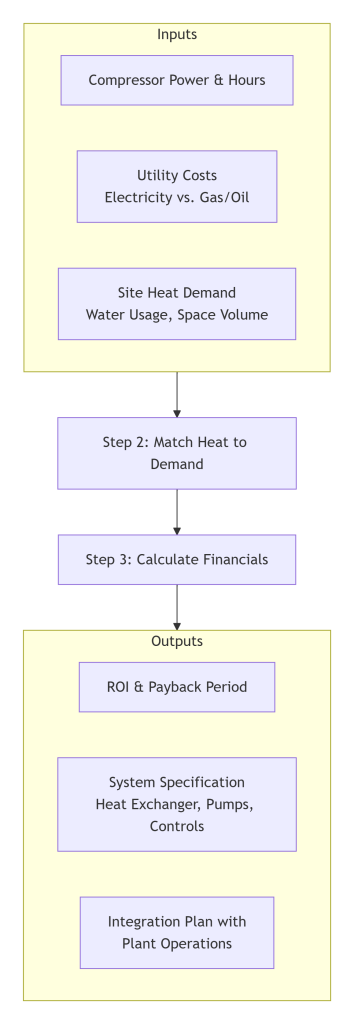

III. The 4-Step Feasibility & ROI Assessment Framework

Follow this structured approach to evaluate your opportunity.

Step 1: Gather Your Data

- Compressor Data: Nameplate power (kW), annual operating hours, type (fixed-speed, VSD).

- Utility Costs: Your current costs for electricity ($/kWh) and the fuel you’d displace ($/therm for gas, $/liter for oil).

- Heat Demand Profile: Do you have a year-round need for hot water? What is the daily/weekly volume (liters/gallons)? Do you have spaces that require winter heating?

Step 2: Match Heat Availability to Demand

- Calculate Available Heat: Available Heat (kWh/year) = Compressor Power (kW) x Annual Hours x Recovery Factor (use 0.5 for a conservative estimate).

- Assess Temporal Match: Does your compressor run when you need the heat? (e.g., For space heating, do your winter operating hours align?).

Step 3: Perform the Financial Calculation

- Annual Energy Savings: Savings = Available Heat (kWh) x Displaced Fuel Unit Cost ($/kWh equivalent).

- *Example: 100 kW compressor, 6,000 hours, 50% recovery = 300,000 kWh of heat. If displacing natural gas at $0.03/kWh equivalent, savings = $9,000/year.*

- Estimate Project Cost: A standard hot water recovery system for a mid-sized compressor can range from $8,000 to $20,000, depending on complexity.

- Calculate Simple Payback: Payback (Years) = Project Cost / Annual Savings. A payback of less than 2-3 years is typically considered excellent.

Step 4: Plan for Implementation

- Key Questions: Is there physical space for a heat exchanger and pumps? Can hot water piping be routed to the point of use? Who will operate and maintain it?

- Next Steps: Engage a qualified supplier (like MINNUO) to review your assessment, provide a detailed quote, and design a system that integrates seamlessly with your compressor and plant operations.

IV. Application Spotlight: Heat Recovery in Action

Heat recovery isn’t theoretical—it’s delivering value across industries. Here are two common scenarios:

- Scenario 1: Food & Beverage Plant – Process Water Pre-heating

- The Need: A dairy requires large volumes of 60°C hot water daily for cleaning (CIP) and pasteurization.

- The Solution: The compressed air heat recovery system captures waste heat from the main air compressors to pre-heat incoming cold water from 10°C to 50°C before it enters the gas-fired boiler.

- The Gain: The boiler’s energy consumption is slashed by 40%, paying back the heat recovery investment in under 18 months. This is a classic food factory compressed air heat recovery application.

- Scenario 2: Automotive Manufacturing Plant – Workshop Space Heating

- The Need: A large assembly bay requires substantial heating during winter months, traditionally provided by expensive gas-fired unit heaters.

- The Solution: Ductwork is installed to redirect the hot exhaust air from multiple compressor oil coolers directly into the workshop ceiling space.

- The Gain: For the 6-month heating season, the gas heaters rarely activate. This space heating via compressor waste heat provides free, sustainable comfort and cuts the plant’s seasonal gas bill by thousands.

Frequently Asked Questions

Q: How do I accurately calculate the potential savings from a compressed air heat recovery system?

A: Follow the formula in Step 3 of our framework: Savings = Compressor Power x Operating Hours x Recovery Factor x Cost of Displaced Energy. The key is using your actual energy rates and a conservative recovery factor (0.5-0.6). For a precise compressed air heat recovery savings calculation, a site audit by a specialist is recommended.

Q: Is heat recovery suitable for Variable Speed Drive (VSD) compressors?

A: Absolutely, and it can be highly efficient. While the total available heat varies with speed, a well-designed system with appropriate controls can effectively capture heat across the operating range. The ROI for VSD compressor heat recovery remains strong, as it displaces energy 24/7.

Q: What’s the typical payback period for such a project?

A: Payback depends heavily on your compressor size, runtime, and local energy costs. For a standard system with consistent heat demand, simple payback periods of 1.5 to 3 years are common. Systems displacing expensive fuels (like oil or electric resistance heating) see the fastest returns.

Q: Can we recover heat from an old compressor?

A: Yes, in most cases. Retrofitting a heat recovery unit to an existing compressor is a common and cost-effective practice. The main considerations are physical space for the heat exchanger and integration with your plant’s hot water or air distribution system.

Q: Does heat recovery affect my compressor’s warranty or reliability?

A: A properly engineered system will not compromise your compressor. In fact, by providing a more stable and controlled cooling outlet, it can help maintain optimal oil temperature, potentially extending compressor component life. Always ensure the design is approved by your compressor supplier or a qualified integrator.

VI. Conclusion: From Overlooked Waste to Strategic Asset

Implementing a heat recovery system is more than an energy-saving project; it’s an upgrade to your plant’s metabolic efficiency. It closes an energy loop, reduces your carbon footprint, and provides a measurable return that improves with rising energy costs.

The process begins with a shift in perspective: seeing the air compressor not just as an air source, but as a significant, reliable heat source. By applying the straightforward assessment framework above, you can move from concept to a compelling business case with clear financial metrics.

At MINNUO, we view efficiency holistically. While we optimize your compressed air generation, we also identify opportunities like heat recovery to maximize the total value of your system investment. Our expertise ensures that the captured energy is delivered reliably to your process, turning a line item of waste into a stream of savings. Let’s calculate your potential gain.

Email

Email sales:+86 15366749631

sales:+86 15366749631