High efficiency sliding vane compressor, energy saving more durable!

Minnuo, 30 years + manufacturer of sliding vane compressors, our latest design and production of sliding vane compressors, can be adapted to a variety of complex working conditions.

- Host life 10W hours

- Max. temperature resistance 70℃

- Efficiency 20% higher than screw machine

- Support customization

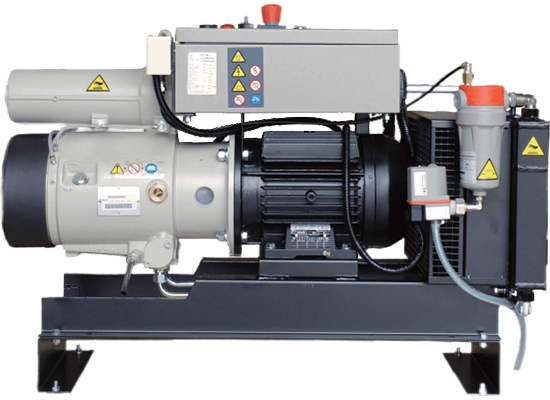

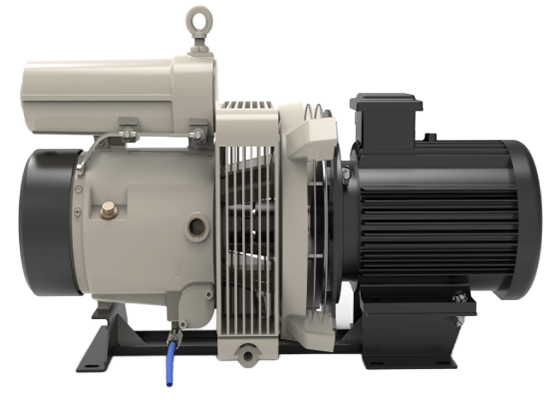

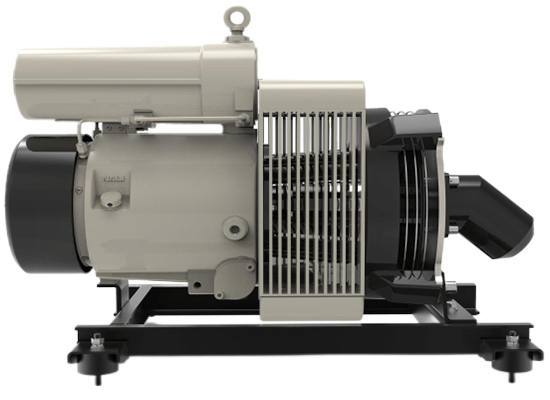

Hot Selling Sliding Vane Compressor

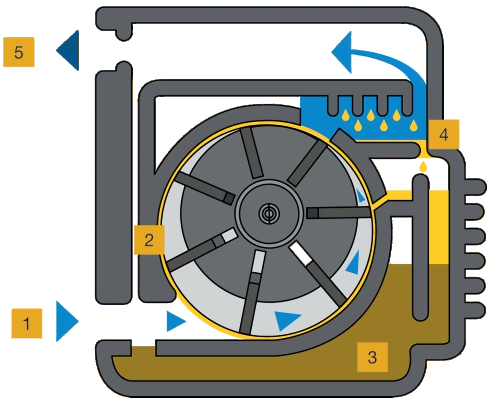

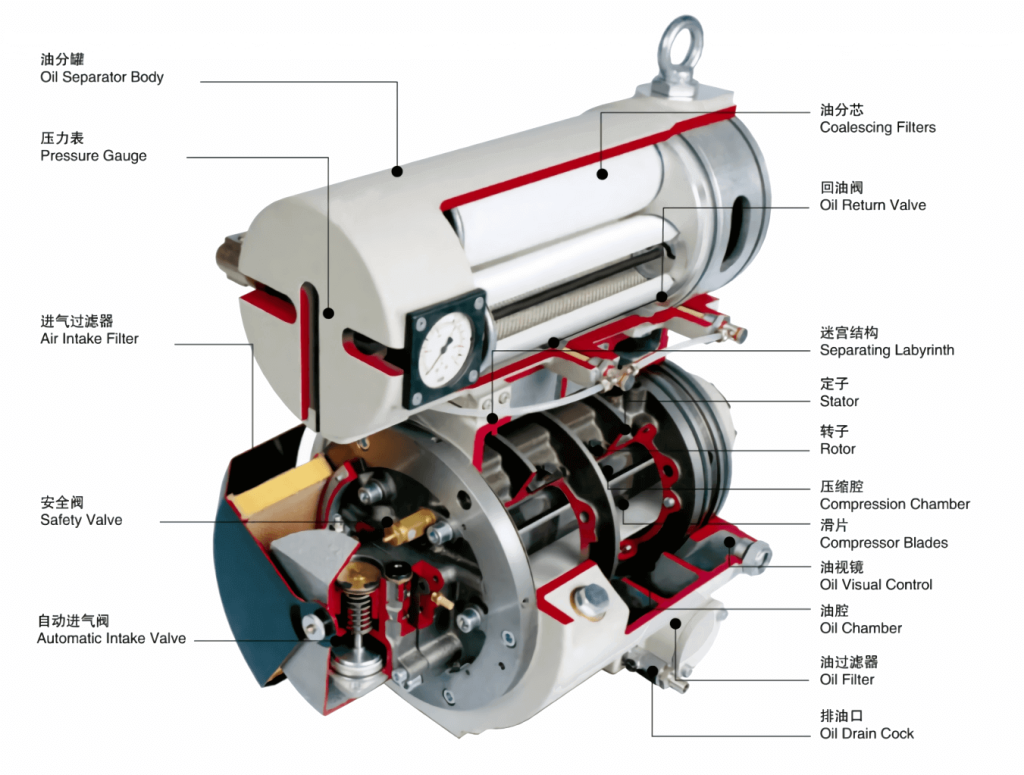

Sliding vane compressors are volumetric rotary compressors consisting of a stator cylinder and a rotor, which is centrifugally placed in the stator. The rotor has corresponding slots for the sliding blades to slide in, and the centrifugal force keeps them in contact with the sides of the stator as they rotate.

ERC sliding vane air compressor 200 series

ERC sliding vane compressors utilize an eccentric rotor and sliding vanes, which rotate to form a closed compression chamber, compressing the gas by reducing the volume of the chamber.

Model | Rated motor power (kw) | Air flow (m³/min) | Noise Levels | Sizes(mm)L*W*H | Weight(kg) | ||

L | H | HH | |||||

ERC2030 | 30 | 5.62 | 4.67 | 3.67 | 79 | 1915*805*1168 | 600 |

ERC2037 | 37 | 6.80 | 5.65 | 4.80 | 79 | 1915*805*1168 | 700 |

ERC2045 | 45 | 8.28 | 7.00 | 5.85 | 79 | 1935*805*1168 | 730 |

ERC2055 | 55 | 9.65 | 8.90 | 7.10 | 79 | 1950*805*1168 | 740 |

Power supply for the above model is 380v/50hz, L=8bar, H=10bar, HH=13bar

Specialized air compressor for construction machinery

It is an integrated air compressor with modulating mode intake regulator valve, complete oil cooler as well as motor, oil level mirror and temperature protection switch.

Model | Rated motor power (kw) | Air flow (m³/min) | Noise Levels | Sizes(mm)L*W*H | Weight(kg) | ||

L | H | HH | |||||

ER504 | 4 | 0.7 | 0.53 | 0.49 | 65 | 842*380*500 | 110 |

ER505 | 5.5 | 0.89 | 0.76 | 0.57 | 65 | 934*400*503 | 112 |

ER507 | 7.5 | 1.38 | 1.15 | 0.96 | 69 | 1270*450*535 | 160 |

ER511 | 11 | 1.97 | 1.7 | 1.35 | 69 | 1270*450*535 | 170 |

Power supply for the above model is 380v/50hz, L=8bar, H=10bar, HH=13bar

ERY hydraulic ram air compressor

More perfect compressed air for industrial and mining machinery

Converts hydraulic power into compressed air with maximum efficiency, is compact and lightweight, and can replace old traction compressors.

Model | Head parameters | Hydraulic motor parameters | Cooling method | ||||||

Head model | Exhaust pressure | Max. exhaust volume | Rated RPM | Max. exhaust volume | Max. RPM | Motor capacity | Oil pressure | ||

ERY3H | M65 | 8 | 0.32 | 3000 | – | – | 8 | 210 | Integrated cooling |

ERY4L | M80D | 8 | 0.70 | 1480 | 1.12 | 2400 | 16 | 210 | |

ERY5L | M80F | 8 | 0.89 | 1480 | 1.42 | 2400 | 16 | 210 | |

ERY7L | M86D | 8 | 1.38 | 1480 | 2.52 | 2400 | 32 | 210 | |

ERY11L | M86J | 8 | 1.97 | 1480 | 3.15 | 2400 | 32 | 210 | |

ERY15L | M111D | 8 | 2.70 | 1480 | 4.32 | 2400 | 56 | 210 | Split cooling |

ERY18L | M111F | 8 | 3.28 | 1480 | 5.24 | 2400 | 56 | 210 | |

ERY22L | M111H | 8 | 3.75 | 1480 | 6 | 2400 | 56 | 210 | |

ERY135L | M135D | 8 | 5.6 | 1480 | 8.96 | 2400 | 56 | 210 | |

Compression process

- Inlet side

- Lubrication of main components mixed with air

- Three stage oil separation

- Outlet side

Product Features

Application Areas

WHY CHOOSE US ?

Partners You can Rely On

Why More Than 300+ Clients Trust Us?

- Source factory - 20,000 units per year, factory price, you will save time and money because of our air compressor energy saving 30-50% efficiency

- Quality assurance- fully automatic machining center production, from production to shipment after 5 quality inspection. 100% satisfaction feedback

- Strong technical team - We offer a wide range of cost-effective industrial solutions for every project. Cost savings for you.

- Huge stock quantity - spot supply, same day delivery at the earliest, 8-10 days for custom-made products. You will get the latest models faster than other dealers

Frequently Asked Questions

Sliding vane compressors are better suited than screw compressors for operation under low load conditions and are more energy efficient. They are generally quieter and less costly to maintain.

We will recommend the appropriate model based on the size of your plant, air demand and frequency of use. Through detailed evaluation and analysis, we can ensure that the most cost-effective solution is selected.

Sliding vane compressors typically have simple maintenance requirements, such as regular slide and cartridge changes. We offer detailed maintenance programs and services to ensure long term stability.

Installation is usually relatively simple, but depends on the specific application and equipment type. We provide professional installation services or guidance to ensure a smooth installation process.

Sliding vane compressors typically have low running costs due to their high efficiency and energy savings. We can calculate the specific energy consumption and running costs for you so that you can make an informed investment decision.

Sliding vane compressors are generally quieter than other types of compressors and are particularly suited to applications that require a low noise environment. We can provide specific noise figures and recommendations for control measures to meet your needs.

Selection of sliding vane compressors need to provide the parameters

- The exhaust volume of the sliding vane air compressor

- Exhaust pressure value of sliding vane air compressor

- The quality of compressed air of the sliding vane air compressor

- Air field environment

Send Your Inquiry Now!

Get Sliding Vane Compressor Solution

We will arrange for a professional engineer to design a solution to suit your needs.

Email

Email sales:+86 15366749631

sales:+86 15366749631