Two Stage Screw Compressor

Two-stage compressor with parallel two-stage compression; the whole machine adopts a box structure, highlighting the humanized design and reserving a spacious maintenance space, which is convenient for equipment maintenance,the use of high-efficiency NEMA motors and high-quality components, reliable and durable. Compared to single-stage compressors, the discharge capacity is 15% higher and the energy saving is 8% higher.

- Working Power: 5.5~250kw | 7.5~350hp

- Working Pressure: 7~13bar | 102~189 psig

- Treatment Capacity :29~1447cfm | 0.81~40.5m3/min

- Sound level: 62±2~84±2dB(A)

What is two-stage VSD Compresor?

Two-stage compressor, where the primary and secondary compression rotors are combined in a single housing and are each directly driven by helical gears the compression process consists of natural air passing through an air filter into the first stage of compression, where it is mixed with a small amount of lubricating oil in the compression chamber while the mixed gas is compressed to interstage pressure. The compressed gas enters a cooling channel, where it comes into contact with a large amount of oil mist, thus reducing the temperature considerably. The cooled compressed gas enters the second stage rotor for secondary compression and is compressed to the final discharge pressure. Finally the compressor is discharged through the discharge flange, completing the entire compression process.

Advantages of PM VSD Compressor

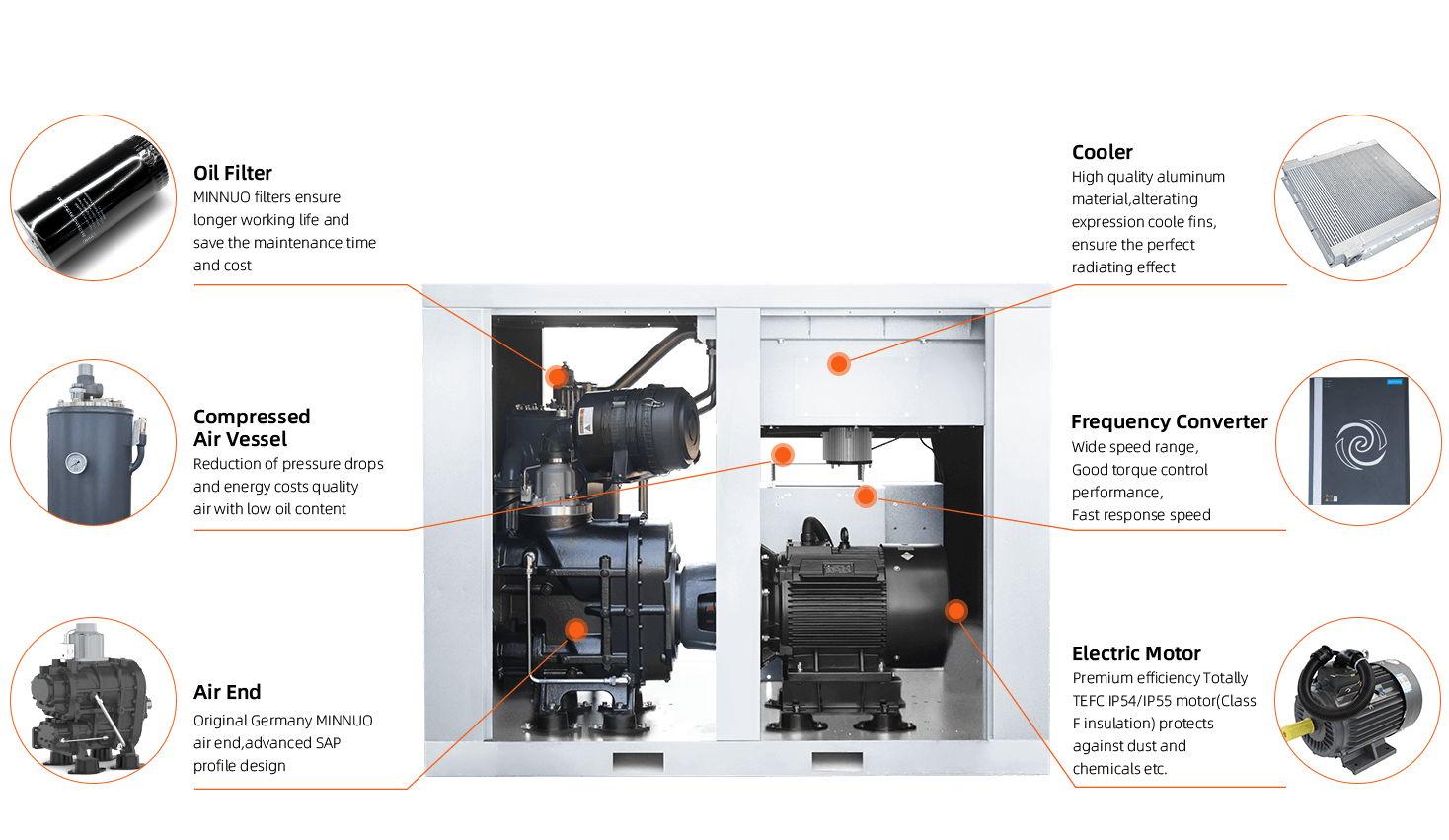

- energy-saving screw mainframe, low noise, low vibration, and high efficiency.

- High-efficiency oil and gas separator, with a service life of up to 6000 hours, more energy-saving than traditional filters, and large filtering area

- Adopt high efficiency fin type large heat exchange area cooler, 30% heat exchange surplus

- Professional new integrated air inlet valve, air inlet adjustment range 0-100%

- Intelligent microcomputer control system with remote monitoring function

- The two-stage compressor in the same power as the single machine compression exhaust volume increased by 15%, can achieve more than 15% of the energy-saving space

- The main motor is an IP55-rated energy-efficient permanent magnet motor, which has an optimized coefficient of approximately 5-8% compared to other motors.

| MODEL &POWER | TREATMENT CAPACITY | PRESSURE(Mpa) | AIR-COOLED DIMENSION (L*W*H) | ROTATING SPEED | NOISE DB(A) | PROTECTIVE CLASS | OUTLET SIZE |

| MN-30A-TSPM 22KW | 4.1 | 0.8 | 1380*850*1180 | 1500 | 76±2 | IP54/F | G1″ |

| MN-40A-TSPM 30KW | 5.8 | 0.8 | 1700*1000*1340 | 1500 | 76±2 | IP54/F | G1 1/2″ |

| MN-50A-TSPM 37KW | 7 | 0.8 | 1700*1000*1340 | 1500 | 78±2 | IP54/F | G1 1/2″ |

| MN-60A-TSPM 45KW | 9.4 | 0.8 | 2150*1740*1550 | 1500 | 78±2 | IP54/F | DN65 |

| MN-75A-TSPM 55KW | 12 | 0.8 | 2150*1740*1550 | 1500 | 78±2 | IP54/F | DN65 |

| MN-100A-TSPM 75KW | 15.2 | 0.8 | 2150*1740*1550 | 1500 | 78±2 | IP54/F | DN65 |

| MN-120A-TSPM 90KW | 19.8 | 0.8 | 2530*1730*1930 | 1500 | 85±2 | IP54/F | DN80 |

| MN-150A-TSPM 110KW | 22.3 | 0.8 | 2530*1730*1950 | 1500 | 85±2 | IP54/F | DN80 |

| MN-175A-TSPM 132KW | 26.3 | 0.8 | 3330*1830*2160 | 1500 | 88±2 | IP54/F | DN80 |

| MN-200A-TSPM 160KW | 32.5 | 0.8 | 3330*1830*2160 | 1500 | 88±2 | IP54/F | DN125 |

| MN-250A-TSPM 185KW | 38.5 | 0.8 | 4100*2200*2450 | 1500 | 88±2 | IP54/F | DN125 |

| MN-270A-TSPM 200KW | 41 | 0.8 | 4100*2200*2450 | 1500 | 88±2 | IP54/F | DN125 |

| MN-300A-TSPM 220KW | 43.5 | 0.8 | 4100*2400*2600 | 1500 | 88±2 | IP54/F | DN125 |

| MN-340A-TSPM 250KW | 50 | 0.8 | 4100*2400*2450 | 1500 | 88±2 | IP54/F | DN160 |

| MN-380A-TSPM 280KW | 55.1 | 0.8 | 4100*2400*2600 | 1500 | 88±2 | IP54/F | DN160 |

01. PMII MOTOR

The motor frame and end caps are made of cast iron to provide uniform clearance between the rotor and the spindle.

Designed speed, torque, and operating parameters to meet the load requirements of the compressor.

SKF heavy-duty bearings are used, which greatly increase the stability and life of the motor.

High-efficiency motor with class F insulation and class B temperature rise, longer service life, and better adapted to harsh environments.

Motors with IP55 protection class, effectively preventing dust and water from entering the motor.

03.Electrical control systems

- The main control components are of EATON brand, with high working reliability and long trouble-free running time

- The use of PLC with integrated intelligence and higher intelligence that can be programmed to control the operation of the whole unit in an economical and efficient way.

05.Air Systerm

- Inlet filter adopts original imported filter material, with a 99.9% dust removal effect, ensuring the compressor host is effectively dustproof.

- Inlet valve assembly by specially designed servo cylinder, with check function, no need to install oil check valve and oil cut-off valve.

- Unique external air pre-filter to keep the machine clean inside, extend the maintenance cycle, and can be easily disassembled and cleaned.

02.Mainframe

Low noise: unique rotor profile, low speed and low vibration operation of the main engine with graded compression, effectively reducing the vibration of the pipeline air flow and reducing noise

High reliability: superior pressure ratio distribution, reducing the bearing load, making the bearing life up to 150,000 hours, the rotor is highly meshed, long service life graded compression, effectively reducing the leakage of lubricating oil, to facilitate the formation of oil film to protect the rotor

Super energy saving: superior pressure ratio distribution, greatly improving compression efficiency, using inter-stage cooling, close to isothermal compression

04. Cooling System

- Large, high-quality oil cooler and rear cooler.

- Prolongs the life of lubricants, filters, and seals.

- Use the unique low-temperature difference design, with high temperature and high humidity environment as the design premise, suitable for any regional environment.

06.oil pipe

The high pressure oil hose is made of Italian Manuli, which has 5 times longer life than ordinary oil hose, and adopts the unique inverted lock technology of Ziqi, which does not leak oil

Frequent Asked Question

The two-stage compressor screw mainframe uses two stages of sectional compression, with the compressed air compressed by the first stage cylinder and discharged again into the second stage cylinder, where the gas density is greatly altered by the two stages of compression, allowing the air volume and pressure to be increased and improving compression efficiency

15% more efficient than single stage compression. two compression when the first stage is compressed to 3 bar enters the two stage , generating more compressed air by reducing the compression ratio, reducing the loss and consumption of energy in the cooling system and lower operating costs, meaning more productivity is created during normal operating hours.

Theoretically, two compressor increases the exhaust volume by 8-15% compared to single-stage compression, resulting in corresponding energy savings of 8-15% and cooler operation. The ratio of efficiency to cost is excellent when running continuously at full load for long periods.

Two-stage compressors because they are more precise, have a lower compression ratio, are cooler, produce more air with fewer revolutions and produce less noise, 76±2 to 88±2 dB(A)

Air compressor one-stage and two-stage mainly from the structure of the host to distinguish. one stage screw air compressor consisting of a pair of rotors,compressed one time; two stage screw air compressor is composed of two pairs of rotors, gas compression twice

two stage compression ratio is high and power is low. The compression process is divided into two, using equal pressure ratio to set the inter-stage pressure, so each stage compression ratio is much lower than the single-stage compression ratio, the return leakage between the rotors is greatly reduced, while the volumetric efficiency and adiabatic efficiency has been greatly improved, correspondingly improving the final gas production

After a rigorous production and testing process. We can deliver in 15-20 days

Send Your Inquiry Now!

No spam, notifications only about new products, updates. new instant price.

Email

Email sales:+86 15366749631

sales:+86 15366749631