Rotary Screw Air Compressor

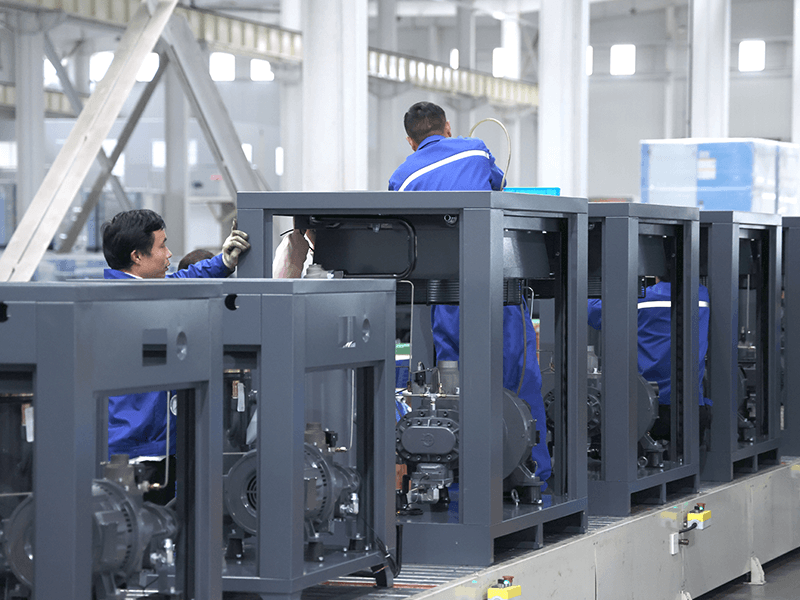

Minnuo, a 30-Year Rotary Screw Compressors Manufacturer and Supplier, Offers Professional Custom Solutions for Industrial Air Compressors.

- Low Energy Consumption, Over 35% Energy Savings

- Stable, Achieving 100% Duty Cycle

- Easy to Maintain, Low Maintenance Costs, 3-Year Warranty

Rotary Screw Air Compressors

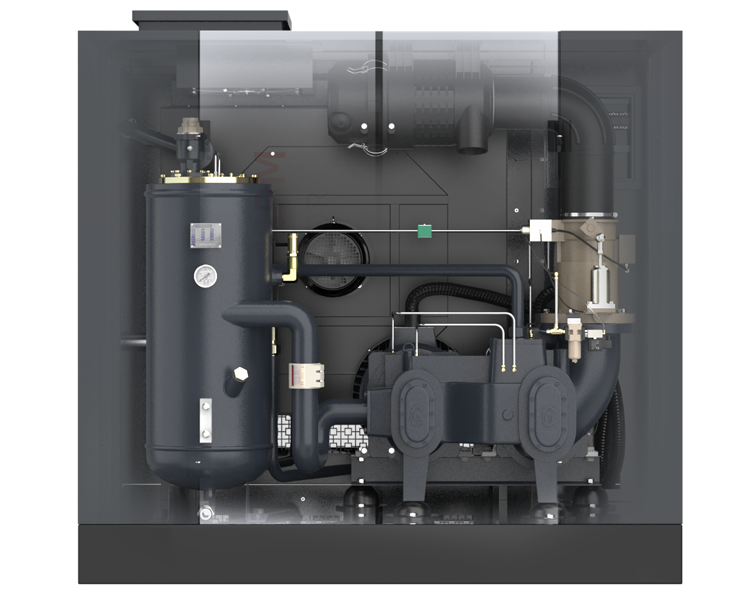

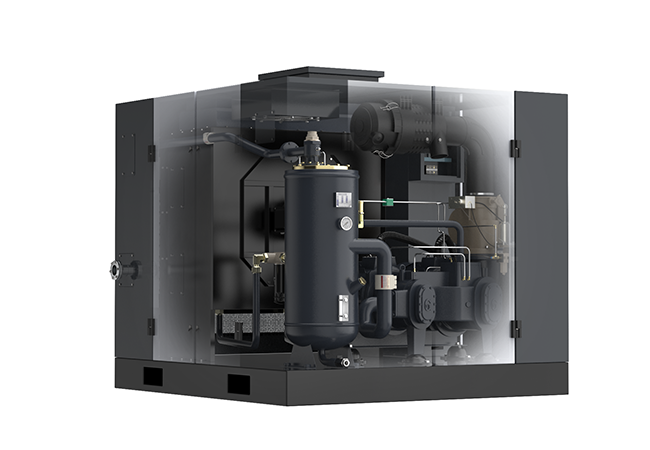

Rotary screw air compressors are available in single-screw and twin-screw varieties. Minnuo’s models are engineered for continuous, high-volume air delivery and can operate at a 100% duty cycle. They typically feature noise-reducing casings. Minnuo offers a complete line of industrial-grade rotary screw air compressors to suit various business requirements.

- Energy efficient and suitable for long time continuous operation.

- Low noise design, suitable for working environments with high noise requirements.

- Simple maintenance, reducing the need for maintenance and extending the service life of the equipment.

General Hot Selling Screw Air Compressor

Rotary screw air compressors are the preferred choice for many industries and a variety of compressor applications.

Two Stage Screw Compressor

Two-stage compressor uses sectional compression to increase air volume, pressure, and efficiency through dual-stage cylinder compression.

- Working Power: 5.5~250kw | 7.5~350hp

- Working Pressure: 7~13bar | 102~189 psig

- Treatment Capacity :29~1447cfm | 0.81~40.5m3/min

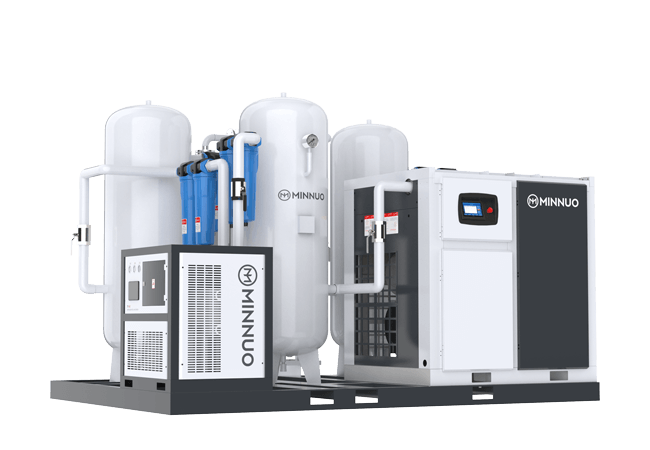

Type 5- in -1 Integrated Compressor

The 5-in-1 integrated screw air compressor combines VSD technology, air dryer, tank, filter, saving 50% energy with compact efficiency.

- Working Power: 4~22kw,5~30hp

- Working Pressure: 8~16bar,116~232psig

- Treatment Capacity :21~128cfm,0.6~3.6m3/min

Variable Speed Air Compressor

Variable frequency adjusts motor speed, reducing power consumption, starting current, losses, and extending equipment lifespan in compressors.

- Working Power: 5.5~250kw | 7.5~350hp

- Working Pressure: 7~13bar | 102~189 psig

- Treatment Capacity :29~1447cfm | 0.81~40.5m3/min

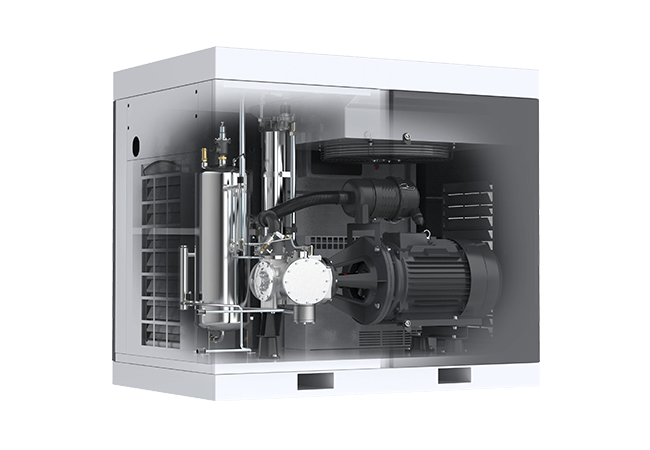

Oil Free Water Injected Rotary Screw Compressor

Oil-free water-lubricated screw air compressor uses water as lubricant, ensuring high air quality for demanding applications.

- Working Power: 5.5~250kW

- Working Pressure: 0.8~1.25MPa

- Treatment Capacity :0.3~39.30m³/min

Oil-free Dry Screw Air Compressor

Dry oil-free air compressors ensure pure output air, ideal for industries like medical, pharmaceutical, semiconductor, and precision electronics.

- Working Power: 45~400kW

- Working Pressure: 0.7~1.0MPa

- Treatment Capacity :3.78~67.36m³/min

Portable Diesel Engine Air Compressor

Suitable for applications with power shortages and harsh environments.

- Working Power:55KW-194KW | 75hp-260hp

- Working Pressure:8bar-16Bar | 116-232psig

- Discharge volume: 1.05-26.1m³/min

Our Air System Solutions Process

Advantages of our screw compressors

Minnuo’s rotary screw air compressor range utilizes high-end design, advanced features and technology to provide cost-effective, long-lasting, reliable and high-quality compressed air solutions for light to heavy-duty industrial applications.

- Our screw air compressor mainframe is German technology GU brand, power supply protection level/insulation level is IP54/F, IP55 and better, inverter is Danish brand Helip, electronic components are American Eaton brand.

- The oil is Shell, a joint venture between Holland and UK.

- The efficiency reaches national level energy efficiency.

- The noise level is much lower than the industry level.

- We have done OEM for Ingersoll Rand, the world’s No.1 brand.

Advantages of the machines used in conjunction

Freeze dryer:

- The refrigerants we use are environmentally friendly refrigerants R134A, R410A, R407C

- The compressor of the freeze dryer adopts the high-end brand of Panasonic from Japan, which ensures the good performance of the equipment.

- Equipped with intelligent controller, it can monitor the temperature and pressure, display the dew point temperature in real time, automatically record the accumulated running time, and has self-diagnostic function.

- There is also a constant pressure automatic expansion valve, balanced adjustment of refrigerant pressure, which can play the role of anti-freezing protection.

- The heat exchanger material is aluminum alloy, and add insulation layer to avoid cold loss.

Gas storage tanks:

- Each gas storage tank has ultrasonic and X-ray inspection of welds. The material used for the gas storage tanks is Q345R.

- Q345R is a low alloy steel and container steel plate. Its strength and toughness are better than Q235B, and its service life is 10 years.

- In addition, it is equipped with zero-loss automatic drainer and high-end CJ series filter. All spare parts are of high quality.

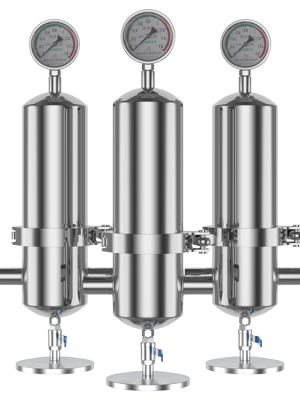

Air Filter:

- Compressed air oil removal filter, can reduce the oil content of compressed air to 0.003mg/m³, filter 0.01 micron particles, 99.999% filtration efficiency

Obtain more integrated solutions.

Screw Air Compressor Features

Rotary screw air compressors are the preferred choice for many industries and a variety of compressor applications.

Variable Speed Drive Technology

Adopts advanced VSD technology to adjust motor speed based on air demand, reducing wear, saving over 20% energy, and cutting frequent start/stop cycles.

Low Maintenance Cost

Uses durable materials like tungsten carbide and stainless steel alloys, with a modular design for easier maintenance, less downtime, and lower costs.

Horizontal Two-Stage Compression

Integrated coaxial design with 100% efficiency, staged compression for reduced leakage, and isothermal compression saving 15% energy. Horizontal layout ensures stability and less vibration.

Grade 1 Energy Efficiency

Exceeds top efficiency standards, saving over 30% energy compared to conventional compressors, ideal for carbon reduction goals.

Intelligent PLC Control

Smart PLC system with automatic adjustments, fault detection, alerts, and IoT-enabled remote monitoring for better efficiency and management.

Low Noise Design

Low-speed fan and sound-absorbing materials keep noise under 60 decibels, with a soundproof cover for quieter and more comfortable workplaces.

Energy-saving and emission reduction compressor to reduce operating costs!

How Screw Air Compressors Work ?

Rotary screw air compressor is an efficient and reliable compression equipment widely used in industrial air supply. Its core working principle is based on two intermeshing screw rotors (often called rotors), which rotate to realize air compression. The specific working process is as follows:

Air intake

When the screw rotors start to rotate, outside air is drawn in through the air inlet. The air inlet is usually equipped with a filter to ensure that the incoming air is clean, thus protecting the inside of the unit.

Compression process

Rotor: The screw rotor is the core component of the compressor and consists of two screws that engage with each other. As the rotor rotates, air is gradually compressed in the spiral groove of the rotor.

Oil seals: During the compression process, oil seals act as a seal to prevent air leakage and maintain internal pressure. They ensure effective separation of oil and air, optimizing compression efficiency.

Bearings: The rotation of the screw rotor depends on high-quality bearings that support the rotation of the rotor and reduce friction, thus increasing efficiency and equipment life.

Cooling and exhaust

The heat generated during compression causes the air temperature to rise, so screw compressors are usually equipped with a cooling system (e.g. water cooling or air cooling) to keep the equipment within the optimal temperature range. The compressed, high pressure air is discharged through an exhaust port for use by the user.

Control system

Modern screw air compressors are equipped with an intelligent control system, which can monitor the operation status in real time and automatically adjust the working parameters to improve energy efficiency and prolong the equipment life.

Screw air compressors have become the first choice for industrial air supply due to their high efficiency, low noise and stability. Through optimized design and advanced control technology, Minnuo’s screw compressors can meet the needs of various industrial applications and ensure efficient and reliable air supply.

WHY CHOOSE US ?

Partners You can Rely On

Why More Than 300+ Clients Trust Us?

- Source factory - 20,000 units per year, factory price, you will save time and money because of our air compressor energy saving 30-50% efficiency

- Quality assurance- fully automatic machining center production, from production to shipment after 5 quality inspection. 100% satisfaction feedback

- Strong technical team - We offer a wide range of cost-effective industrial solutions for every project. Cost savings for you.

- Huge stock quantity - spot supply, same day delivery at the earliest, 8-10 days for custom-made products. You will get the latest models faster than other dealers

Real Feedback From Our Customers

Frequently Asked Questions

Estimated Cost

The cost of a screw air compressor will depend on several factors, such as the size of the compressor, the brand of accessories and features.

On average, a 37kw screw air compressor price from $1,500 to $5000. Installation and maintenance costs should also be considered. Contact us and we’ll arrange for a professional engineer to estimate the cost of your project at a competitive price!

Fill Form Get Our Compelete price list

Your email address will not be published. Required fields are marked *

Email

Email sales:+86 15366749631

sales:+86 15366749631