- Home >

- Air Compressor >

- Oil-free Compressor>

- Oil Free Water Injected Rotary Screw Compresso

Oil Free Water Injected Rotary Screw Compressor

- Working Pressure:

- 2.4

- [bar]

- 35

- [psig]

- Free Air Delivery:

- 20~1607

- [cfm]

- 0.7~45

- [m³/min]

- Working Power:

- 5.5~250

- [kW]

- 7.5~335

- [hp]

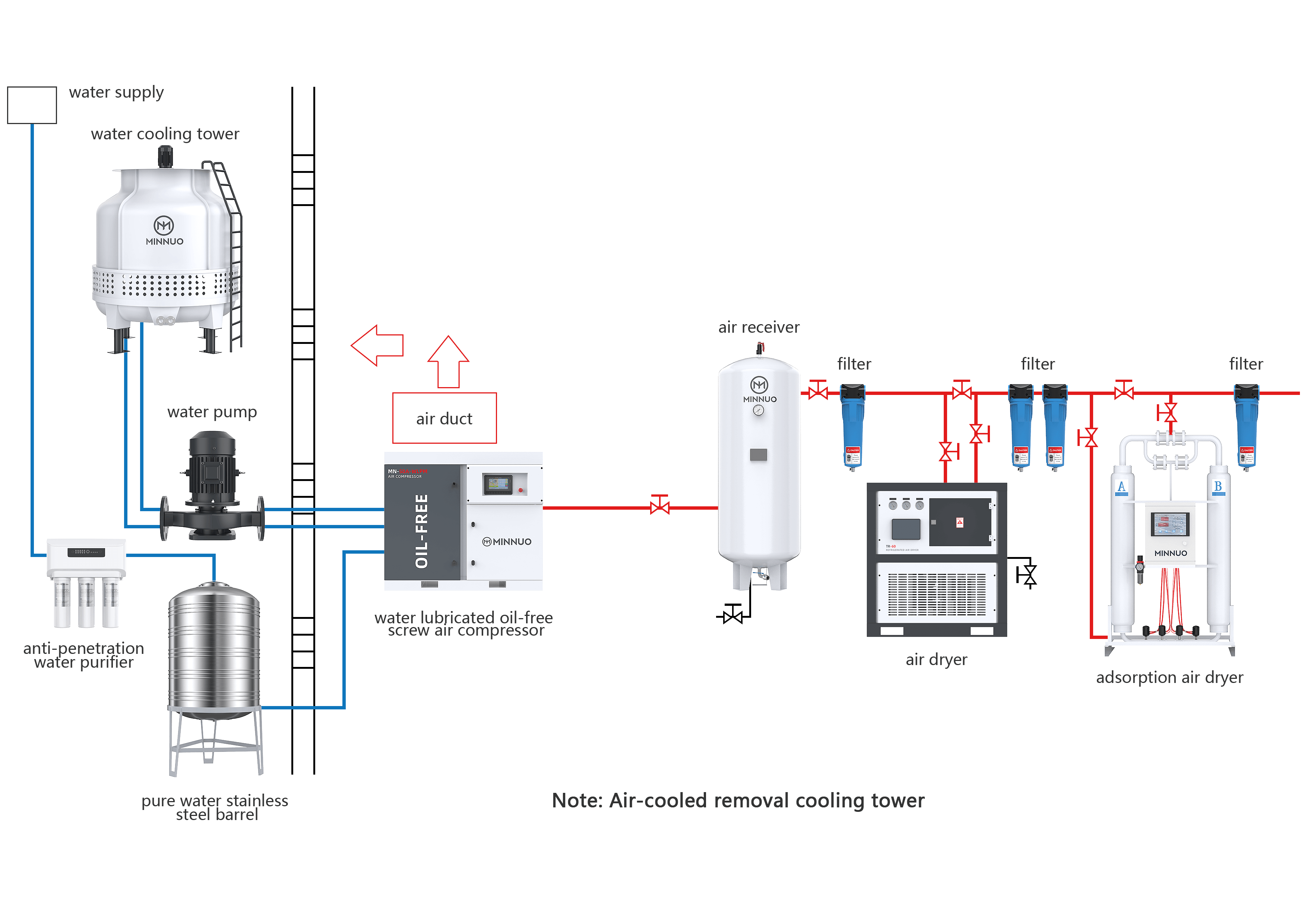

Working Principle

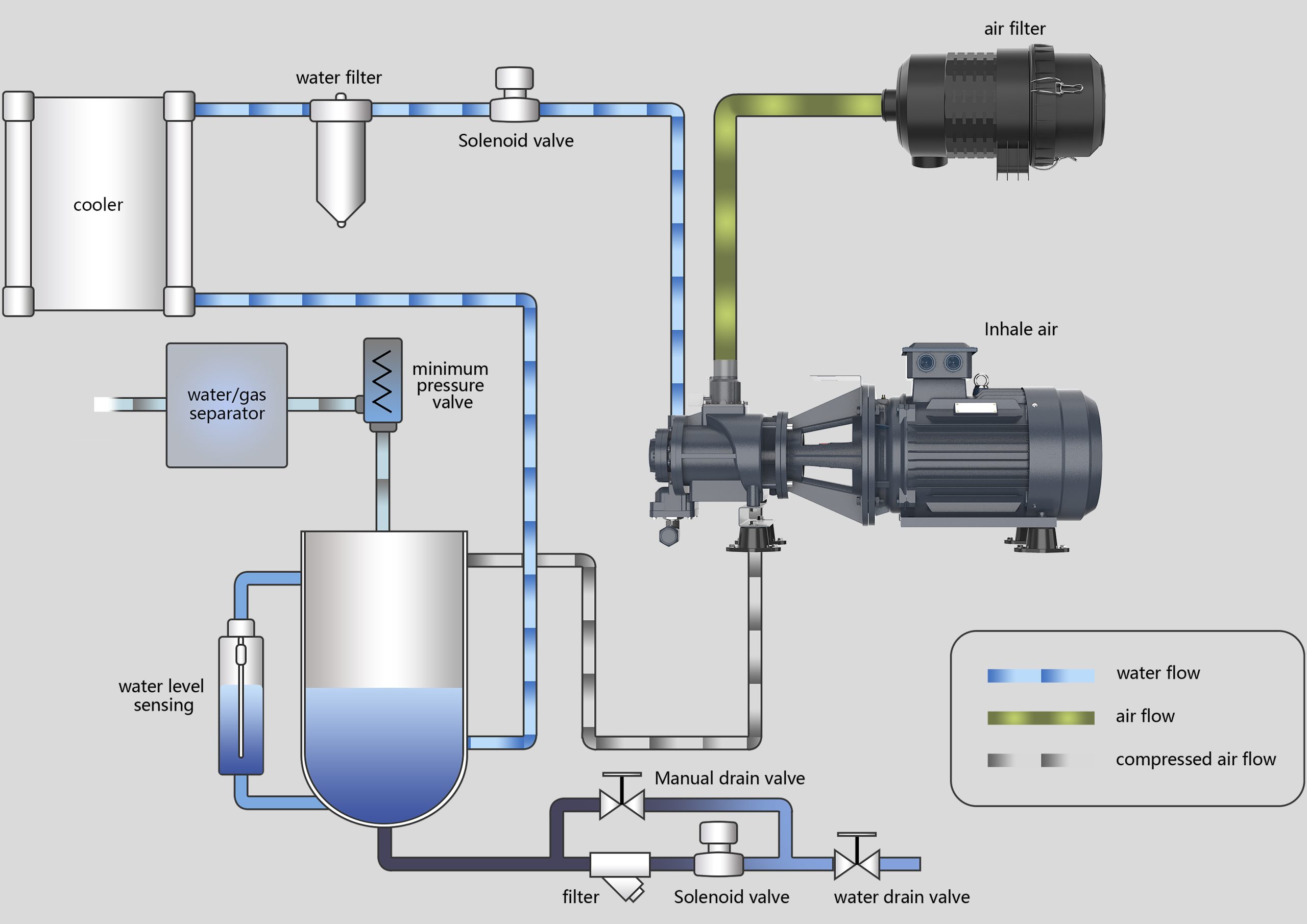

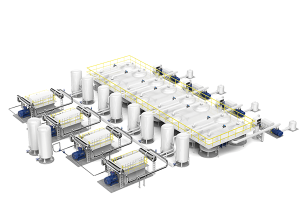

Oil-free water lubricated screw air compressor is mainly composed of compression element, water cooler, water separator, high efficiency filter element, control system and so on.

Its working principle can be simply described as follows: air enters the compression chamber through the air inlet, and under the rotation of the screw rotor, the air is gradually compressed and finally discharged through the exhaust port.

Advantage

Fifth-Generation Oil-Free Screw Compressor

- Constructed with stainless steel alloys, featuring direct-drive, noise reduction, and vibration resistance for extended service life.

- Large rotors and low speed (≤3000 rpm).

Energy-Efficient and High-Performance

- Isothermal compression for improved volumetric efficiency.

- Offers an average energy savings of over 15% compared to two-stage dry oil-free screw compressors.

- 10% higher airflow capacity than dry oil-free screw compressors, with an exhaust temperature below 50°C.

Outstanding Performance

- Absolute oil-free cleanliness, suitable for direct breathing applications.

- Lower dew point of saturated compressed air, with moisture content 25% lower than dry screw compressors.

- Pressure range from 2 bar to 40 bar, supporting customized auxiliary heating systems for cold and high-altitude environments.

Smart Control

- PLC-based intelligent control, with automatic fault detection, warning, maintenance alerts, and failure reminders.

- Supports 24-hour unmanned operation and remote control capabilities.

Easy Maintenance

- Minimal maintenance requirements and simple operation, usable by non-professionals.

- Automatic water replacement and cleaning systems to maintain internal cleanliness and reduce maintenance complexity.

Features

Fifth-Generation Oil-Free Screw Compressor

At MINNUO, we understand that your needs go beyond mere performance—you want a compressor that aligns seamlessly with your operational goals. Our water-lubricated compressors offer powerful discharge and high efficiency, aided by near-isothermal compression that enhances energy savings and extends the lifespan of your system.

Thanks to advanced Germany Schaeffler bearing/Swedish SKF bearing and stainless steel rotors, our compressors operate quietly and with minimal vibration, creating a calm and productive workspace. The oil-free design ensures clean air, free from contamination, giving you peace of mind.

Our intelligent monitoring system makes maintenance a breeze, with modular design simplifying every inspection. MINNUO water-lubricated compressors not only save energy and reduce costs, but they also minimize maintenance expenses and extend operational longevity.

Most importantly, we prioritize environmental responsibility. Clean, safe, and zero-emission operation makes MINNUO a truly sustainable choice. By choosing MINNUO, you’re opting for an environmentally-friendly, economical, and reliable compressed air solution.

| Model |

Maximum working pressure |

FAD | Motor power |

Noise | Cooling water outlet/inlet diameter |

Ouantity of cooling water inlet water 32℃ |

Quantity of lubricating water |

Dimension LxWxH |

Weight | Air outlet |

|---|---|---|---|---|---|---|---|---|---|---|

| Mpa | M³/min | KW/HP | DB | / | T/H | L | mm | KG | / | |

| MN-7.5A-WLPM | 0.8 | 0.3-0.78 | 5.5/7.5 | 57 | 3/4″ | 1.5 | 10 | 800×800×1200 | 320 | 3/4″ |

| 1 | 0.2-0.65 | |||||||||

| MN-10A-WLPM | 0.8 | 0.35-1.17 | 7.5/10 | 57 | 3/4″ | 2 | 10 | 800×800×1200 | 320 | 3/4″ |

| 1 | 0.3-1.05 | |||||||||

| MN-15A-WLPM | 0.8 | 0.54-1.72 | 11/15 | 60 | 1″ | 2.5 | 26 | 1200×755×1130 | 400 | 3/4″ |

| 1 | 0.45-1.42 | |||||||||

| MN-20A-WLPM | 0.8 | 0.75-2.43 | 15/20 | 60 | 1″ | 3.5 | 26 | 1200×755×1130 | 440 | 3/4″ |

| 1 | 0.65-2.17 | |||||||||

| MN-25A-WLPM | 0.8 | 0.9-3.13 | 18.5/25 | 63 | 1″ | 4 | 30 | 1400×900×1285 | 640 | 1″ |

| 1 | 0.9-2.82 | |||||||||

| MN-30A-WLPM | 0.8 | 1.1-3.7 | 22/30 | 63 | 1″ | 5 | 30 | 1400×900×1285 | 640 | 1″ |

| 1 | 0.97-3.21 | |||||||||

| MN-40A-WLPM | 0.8 | 1.55-5.2 | 30/40 | 66 | 1¹/4″ | 7 | 40 | 1400×950×1390 1500×1080×1300(W) |

760 | 1¹/4″ |

| 1 | 1.255-4.43 | |||||||||

| MN-50A-WLPM | 0.8 | 1.91-6.50 | 37/50 | 66 | 1¹/4″ | 9 | 40 | 1580×1000×1485 1500×1080×1300(W) |

880 | 1¹/4″ |

| 1 | 1.60-5.33 | |||||||||

| MN-60A-WLPM | 0.8 | 2.50-8.30 | 45/60 | 68 | 2″ | 10 | 90 | 1800×1300×1680 1800×1360×1670(W) |

1050 | 2″ |

| 1 | 1.91-6.30 | |||||||||

| MN-75A-WLPM | 0.8 | 3.0-10.3 | 55/75 | 69 | 2″ | 12 | 100 | 2050×1300×1690 1800×1360×1670(W) |

1100 | 2″ |

| 1 | 2.60-8.55 | |||||||||

| MN-100A-WLPM | 0.8 | 3.95-13.00 | 75/100 | 72 | 2″ | 18 | 100 | 2180×1350×1705 1800×1360×1670(W) |

1230 | 2″ |

| 1 | 3.40-11.50 | |||||||||

| MN-120A-WLPM | 0.8 | 5.0-16.60 | 90/120 | 73 | 2″ | 20 | 120 | 2550×1500×1825 2200×1550×1800(W) |

2080 | 2¹/2″ |

| 1 | 4.30-14.66 | |||||||||

| MN-150A-WLPM | 0.8 | 6.0-20.2 | 110/150 | 75 | 2″ | 24 | 120 | 2550×1500×1825 2200×1550×1800(W) |

2230 | 2¹/2″ |

| 1 | 5.0-16.66 | |||||||||

| MN-180A-WLPM | 0.8 | 6.75-23.52 | 132/180 | 75 | 2″ | 30 | 120 | 2800×2128×1860 2200×1550×1800(W) |

2360 | 2¹/2″ |

| 1 | 6.0-19.97 | |||||||||

| MN-220A-WLPM | 0.8 | 8.5-28.11 | 160/220 | 77 | 2″ | 35 | 160 | 2700×1800×1970 | 3900 | DN80 |

| 1 | 7.6-25.45 | |||||||||

| MN-250A-WLPM | 0.8 | 10-31.32 | 185/250 | 77 | 2″ | 38 | 160 | 2700×1800×1970 | 4050 | DN80 |

| 1 | 8.72-29.00 | |||||||||

| MN-270A-WLPM | 0.8 | 11.2-36.75 | 200/270 | 78 | 2″ | 42 | 200 | 2700×1800×1970 | 4200 | DN100 |

| 1 | 9.68-31.8 | |||||||||

| MN-300A-WLPM | 0.8 | 12.2-39.6 | 220/300 | 79 | 2″ | 47 | 200 | 2700×1800×1970 | 4400 | DN100 |

| 1 | 11.2-35.7 | |||||||||

| MN-340A-WLPM | 0.8 | 13.5-45.0 | 250/340 | 79 | 2″ | 53 | 200 | 2700×1800×1970 | 4800 | DN100 |

| 1 | 12.3-40.0 |

Details of Our Products

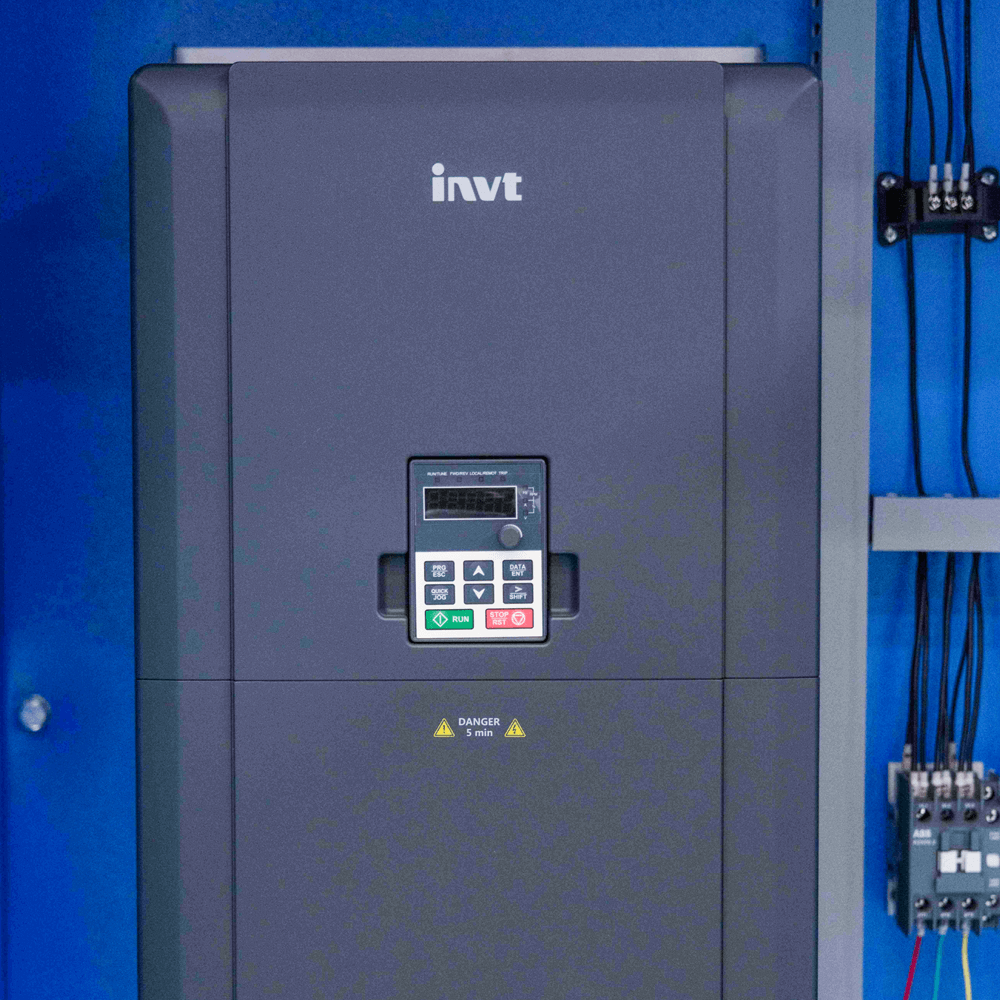

Built-in frequency conversion

① zone optimization control, more stable pressure, more energy saving, forced cooling system ensures long life of inverter electronics. ② Stable and smooth start, no mechanical shock; start current close to rated current, no electrical shock, energy saving up to 30-35%.

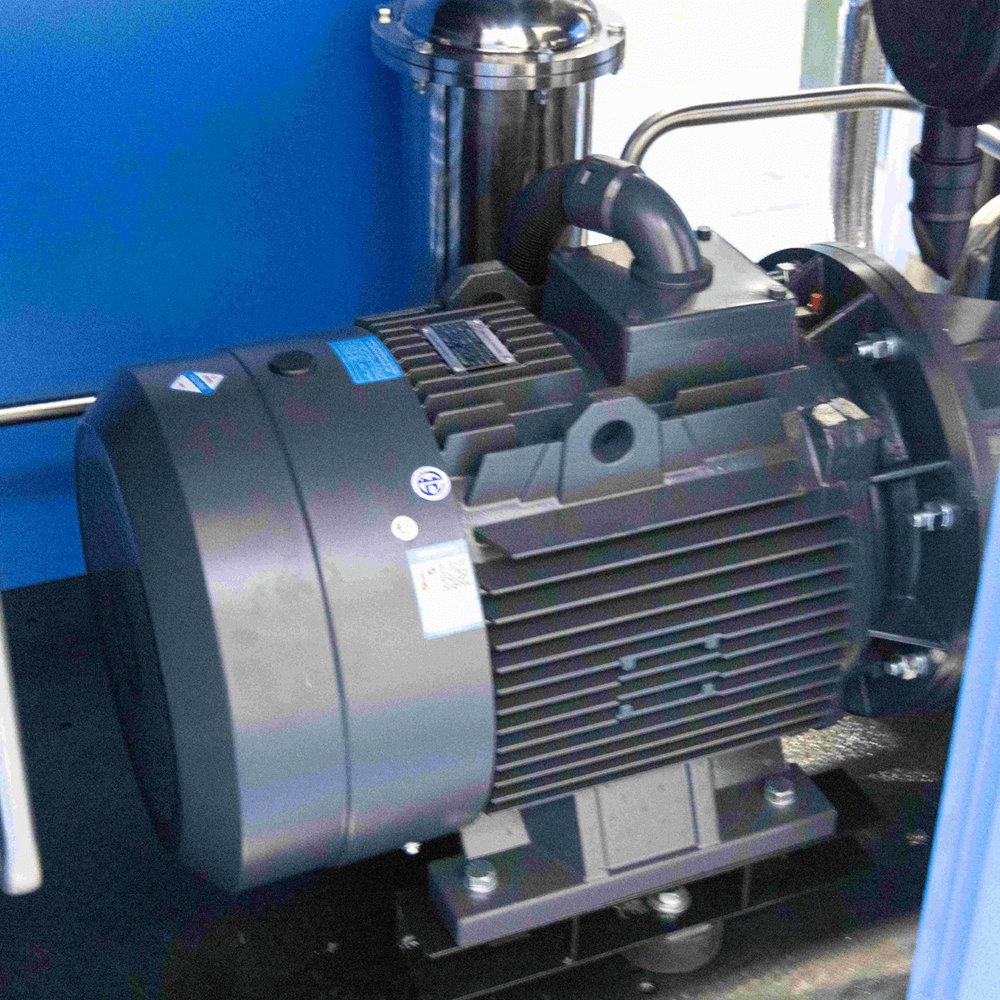

Motors and electrical components

① Siemens motor, IE3 high efficiency motor. ② Inverter motors (for inverter products) Main electrical components adopt Siemens, Siemens inverter.

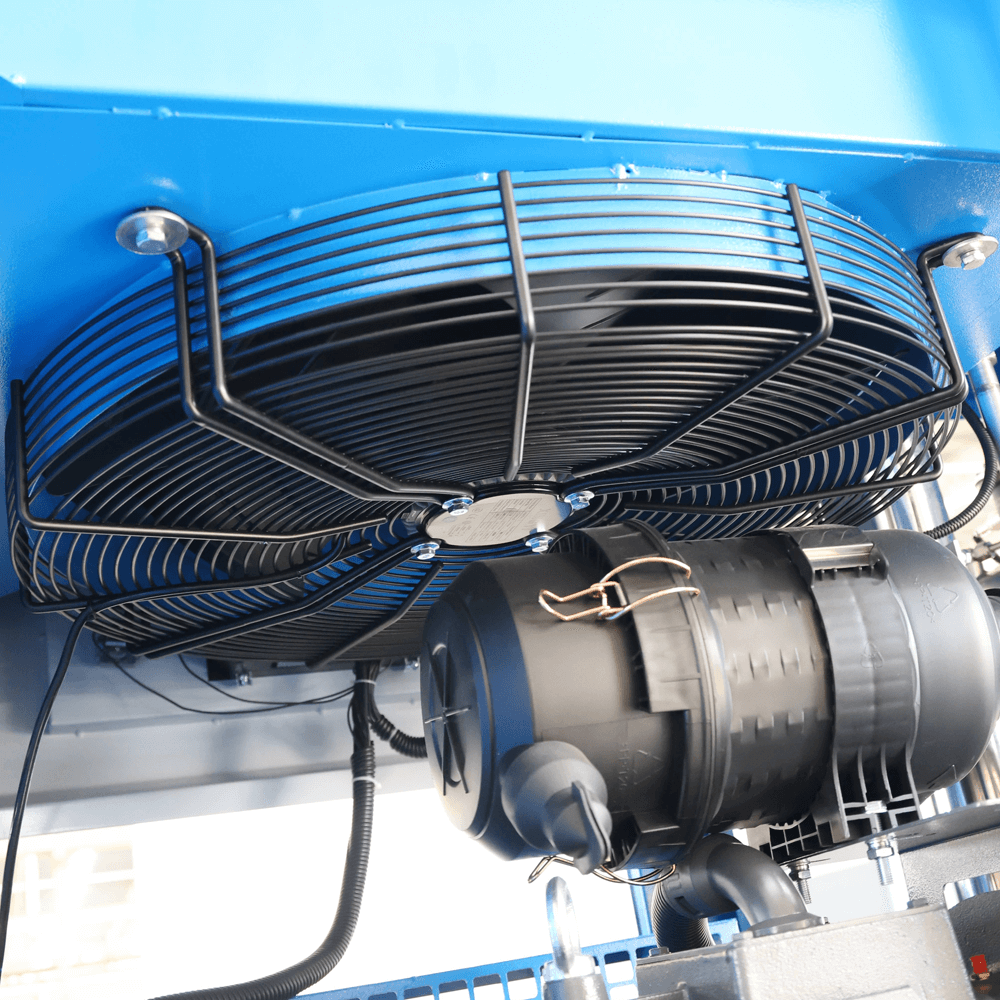

Fans & Cooling System

① Centrifugal fans are installed in soundproof enclosures for easy disassembly and installation, reinforced coolers to ensure cooling performance, and highly efficient cooling centrifugal fans to ensure excellent energy consumption. ② Noise isolation design allows installation in most workplaces without the need for a separate compressor room.

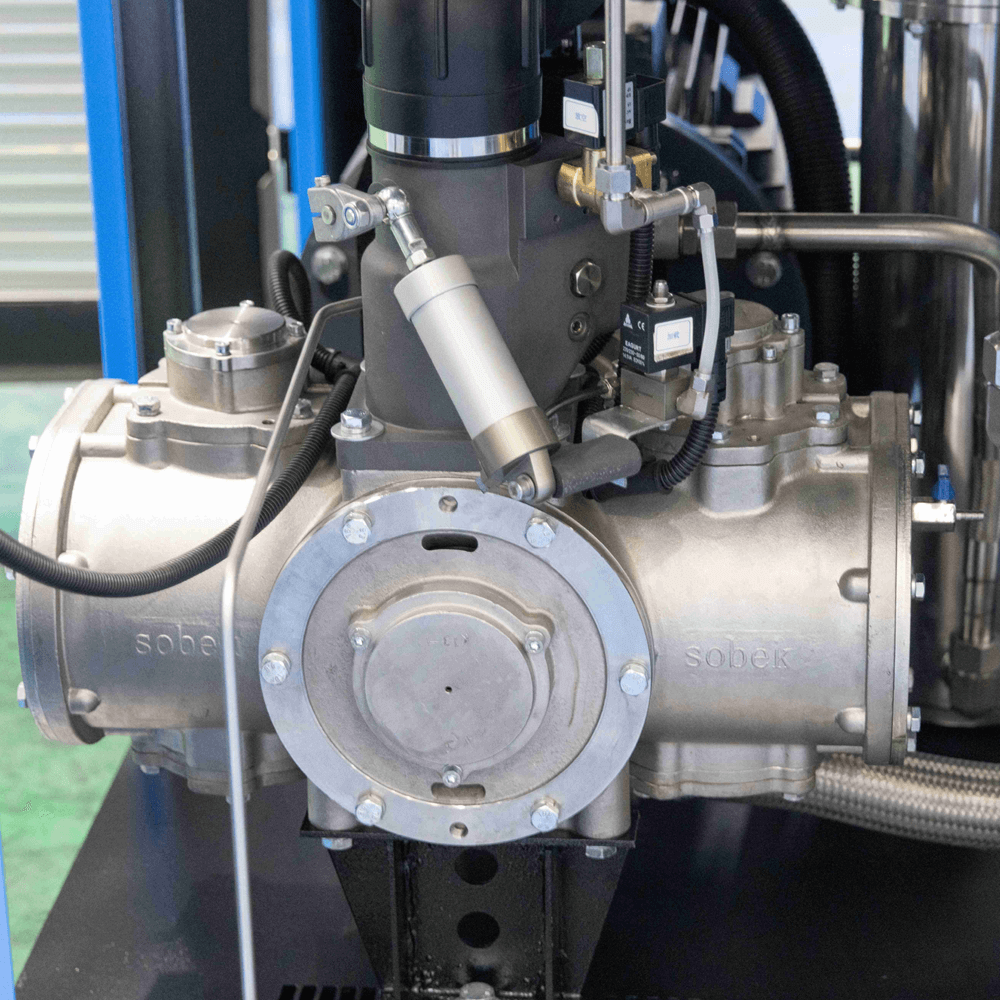

Self-developed water jet lubrication ceramic host

① 100% oil-free guarantee in the compression chamber of the host, high-quality aluminum and copper shell No risk of corrosion of the host, ceramic twin-screw host with high performance and good stability, no risk of corrosion. ② Hydraulic suspension bearings, rotating on the water film, no mechanical wear and tear, stainless steel shaft no risk of corrosion.

Frequent Asked Question

An oil-free water-lubricated screw air compressor is a type of screw compressor that uses water as a lubrication and cooling medium. Unlike traditional oil-lubricated screw compressors, it replaces lubricating oil with water, avoiding oil contamination and ensuring that the output air is completely oil-free. This design is ideal for industries that require high air purity, such as pharmaceuticals, food processing, and electronics manufacturing.

The oil-free water-lubricated system is more energy-efficient than traditional dry oil-free screw compressors. The isothermal compression technology provides higher volumetric efficiency. Compared to dry oil-free screw compressors, the energy savings in two-stage compression can reach up to 15%, and in one-stage compression, it can exceed 25%, significantly reducing operational costs.

Maintenance of an oil-free water-lubricated screw compressor is relatively simple. Due to its integrated design and fewer failure points, daily maintenance can be performed without the need for specialized personnel. The main maintenance tasks involve replacing the air and water filter cartridges, which are easy to do and require fewer consumables, reducing long-term maintenance costs.

No, it does not. Our compressor systems are made from stainless steel alloys that effectively prevent corrosion while ensuring the durability of the system and the purity of the compressed air, guaranteeing no risk of oil contamination.

Choosing the right air compressor should be based on the following factors:

- Working pressure and flow rate requirements (MPa or bar, m³/min or cfm)

- Temperature and humidity conditions of the working environment (°C, %RH)

- Frequency of compressor use and load conditions (e.g., continuous operation, intermittent operation, load fluctuations, etc.)

We have a professional technical team that will provide the best recommendations and selection services based on your specific needs.

We offer comprehensive after-sales support to ensure stable operation and high performance of the equipment. Our service includes:

- Regular Maintenance: We provide scheduled inspections and maintenance to ensure long-term efficient operation.

- Remote Monitoring: Real-time monitoring of equipment status to detect potential issues early and offer remote diagnostics.

- Emergency Repairs: 24/7 emergency repair services to ensure quick response and problem resolution.

- Technical Support: We provide operation training and technical consultation to optimize equipment use.

Our global service network ensures timely responses and continuous technical support for your peace of mind.

Email

Email sales:+86 15366749631

sales:+86 15366749631