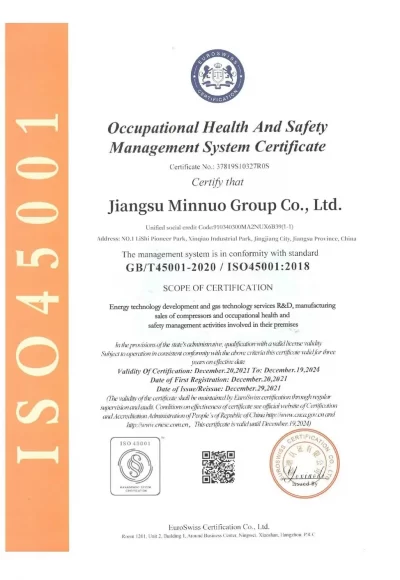

Quality Control

Strict compliance with QHSE laws and regulations, ISO standard production

Since 1987 we have been leading the production and testing of air compressors and compressors in accordance with ISO UNI EN 9001 standards.

- ISO CE SGS Certificate

- High quality raw materials, raw material composition analysis and non-destructive testing.

- Branded machining centres with increased accuracy to U class

- Self-inspection of each process and provision of third party inspection reports

- Test run of the equipment before leaving the factory to check the overall performance

Our Producting & Testing Process

Japanese, Korean and Italian brand top-class machining centres

German kappa, Italian SU machining center. Improved rotor accuracy to u class

As a precision component, the air compressor is in continuous operation at high speeds for long periods of time. So a sufficiently high degree of machining precision. In order to increase the precision of every part produced, we use world-renowned machining equipment for production and inspection.

Fully automated production lines

Accuracy is improved to optimise and increase productivity, and any deviations are automatically corrected before the cycle is completed.

German hexagon coordinate measuring machines

Improving the accuracy of air compressor testing. Control the accuracy range to 0.1u

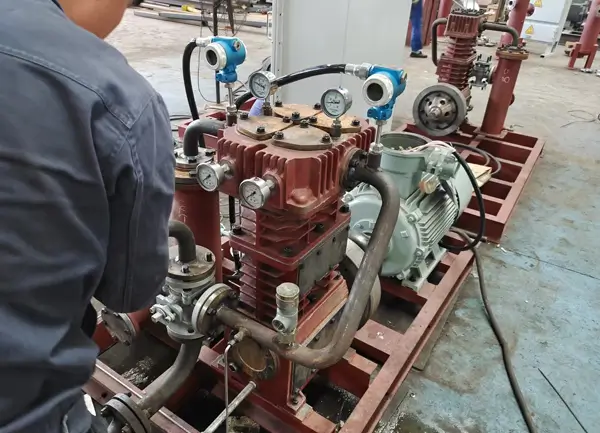

Mechanical running tests

Before leaving the factory, the compressor should be subjected to a no-load mechanical test at operating speed for 4 hours of continuous operation. A video of the test is sent to the customer prior to shipment. Provision of test reports

Compressor water pressure test

The test pressure of the cylinder block, cylinder head, piston and other pressurised parts in the air chamber is at least 1.5 times the maximum allowable working pressure and lasts for more than 30 minutes. The test pressure of the water chamber of the above components is at least 1.5 times the maximum allowable working pressure of the water chamber and not less than 0.6 MPa.

Certificates

Are you insterst?

WANT TO DISSCUSS WITH US Compressor Solution

We put the customer's needs first and offer a full guarantee from design, manufacture, compliance, and training through to maintenance. 6 years warranty

Email

Email sales:+86 15366749631

sales:+86 15366749631