This guide explains oxygen purity from basic definition to five main purity grades and how to choose the right one for your application.Oxygen, an indispensable substance for sustaining life on Earth, plays a pivotal role in numerous fields. From life-supporting medical equipment in hospitals to industrial processes driving production in factories, and even scientific research in laboratories, oxygen is ubiquitous. Understanding the purity levels of oxygen and their applications is crucial for the efficient operation and safety assurance of various industries.

Based on purity, oxygen can be classified into industrial grade (90%-95%), medical grade (≥99.5%), food grade (≥99%), high purity (99.9%-99.99%), and ultra-high purity (99.99%-99.999%). These grades are applied in fields such as metallurgy, chemical engineering, healthcare, semiconductor manufacturing, and aerospace.

1. What is Oxygen Purity?

Oxygen purity refers to the concentration ratio of oxygen (O₂) in a given sample, typically expressed as a percentage. The higher the percentage, the higher the oxygen purity. Generally, when oxygen purity reaches 99.5% or above, it is considered pure oxygen. Even in such seemingly pure oxygen, trace amounts of gases like nitrogen (N₂), argon (Ar), and carbon dioxide (CO₂) may still exist. These trace impurities should not be underestimated, as they can significantly impact the final outcome in applications requiring extremely high oxygen purity. For example, in semiconductor manufacturing, even minute impurities in oxygen can cause defects in chips, affecting their performance and quality.

2. Oxygen Purity Levels and Their Applications

The classification of oxygen purity levels is not arbitrary. It depends not only on the actual concentration of oxygen molecules (O₂) but also on the control of impurity components (such as nitrogen, argon, and carbon dioxide). These factors collectively determine the suitability of oxygen for different applications.

(1) Industrial Grade Oxygen (90%-95%)

Industrial grade oxygen is widely used in industrial production. In metallurgical combustion, for instance, oxygen blowing significantly increases furnace temperatures. In steelmaking, injecting oxygen into the furnace accelerates the decarbonization process of molten iron, greatly improving smelting efficiency and producing more stable steel quality. In chemical synthesis, many reactions require oxygen, and the appropriate purity of oxygen facilitates smooth reactions. In wastewater treatment, industrial grade oxygen is used in the activated sludge process to provide sufficient oxygen for microorganisms, accelerating the decomposition of organic matter and purifying water quality.

(2) Medical Grade Oxygen (≥99.5%)

Medical grade oxygen demands extremely high purity as it directly impacts patient health. In intensive care units, high-purity oxygen is critical for maintaining the vital signs of critically ill patients. During emergencies such as cardiac arrest, high-purity oxygen is essential for resuscitation, providing sufficient oxygen to the patient’s organs and buying time for rescue efforts. In neonatal care, especially for premature infants whose respiratory systems are not fully developed, oxygen with a purity of 99% or higher is necessary to support breathing and ensure normal growth and development.

(3) Food Grade Oxygen (≥99%)

Food grade oxygen is primarily used in food preservation and fermentation processes. In modified atmosphere packaging, precise adjustment of oxygen levels inhibits microbial growth, extending the shelf life of food. For example, fresh meat, fruits, and vegetables can maintain freshness and taste for extended periods when packaged with the appropriate ratio of food grade oxygen. In fermentation, oxygen provides a suitable growth environment for microorganisms, promoting smooth fermentation and producing high-quality fermented products.

(4) High Purity Oxygen (99.9%-99.99%)

High purity oxygen plays a key role in fields requiring extreme precision. In semiconductor manufacturing, wafer etching is a delicate process conducted in a plasma environment. High purity oxygen is crucial here, as any impurities can disrupt plasma stability, affecting etching precision and quality, and potentially leading to chip manufacturing failure. In precision welding, high purity oxygen ensures that metal surfaces are not oxidized during welding, improving weld strength and quality, and ensuring the reliability of welded joints.

(5) Ultra-High Purity Oxygen (99.99%-99.999%)

Ultra-high purity oxygen is mainly used in advanced fields such as aerospace propulsion systems and nuclear physics experiments. In aerospace, rocket fuels often use liquid oxygen (LOX), which requires extremely high purity to ensure combustion safety and stability. Any instability in fuel combustion during rocket launches can have catastrophic consequences. In nuclear physics experiments, ultra-high purity oxygen is used in special experimental environments to provide a pure gas atmosphere, preventing impurities from interfering with experimental results.

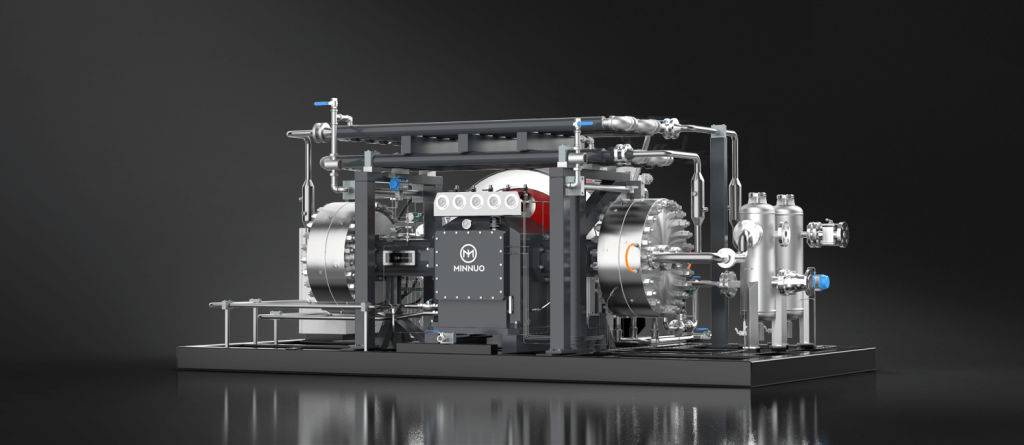

3. Technical Solutions: PSA Oxygen Generators and Oxygen Boosters

(1) PSA Oxygen Generators

PSA oxygen generators operate based on pressure swing adsorption technology. They selectively adsorb nitrogen using zeolite molecular sieves, separating high-purity oxygen.

In the medical field, they can provide oxygen with a purity of 93%-96%, meeting the basic needs of home oxygen therapy and emergency care. For patients requiring long-term oxygen therapy, using a PSA oxygen generator at home is both convenient and economical. In industrial applications, they support production in metallurgy, chemical engineering, and water treatment, with purities reaching 90%-95%. In special environments, such as high-altitude military stations, PSA oxygen generators provide stable oxygen supply to soldiers. In aquaculture, they are used to oxygenate water, ensuring the healthy growth of aquatic organisms.

PSA oxygen generators are compact, energy-efficient, and capable of 24-hour continuous operation, providing reliable oxygen sources across various fields.MINNUO PSA oxygen generators utilize pressure swing adsorption technology, leveraging zeolite molecular sieves to separate oxygen, with significant advantages:

- Intelligent Control: Self-developed algorithms adjust oxygen production based on real-time usage and precisely control molecular sieve cycles, extending their lifespan by 30% and reducing costs.

- Stable Purity: Multi-layer filtration controls impurities, with oxygen impurity levels 50% lower than industry averages in semiconductor manufacturing.

- Strong Adaptability: High-altitude adaptive pressure adjustment, with heat dissipation and moisture-proof designs for harsh environments, ensuring 20% higher operational stability than peers.

- Easy Maintenance: User-friendly interface and modular structure simplify maintenance and part replacement, reducing maintenance time by 40%.

(2) Oxygen Boosters

Oxygen boosters employ oil-free lubrication technology, avoiding oil contamination and ensuring oxygen purity. In medical cylinder filling, they can boost low-pressure oxygen from PSA generators to 150bar for respiratory cylinders, facilitating emergency use by medical staff. In industrial combustion, they provide high-pressure oxygen for cutting and combustion processes, improving efficiency and precision. Oxygen boosters also feature multi-stage compression and high-temperature/high-pressure protection systems, seamlessly integrating with VPSA/PSA oxygen generation systems to ensure safe and stable operation.

MINNUO oxygen boosters use oil-free lubrication technology, offering the following advantages:

- Precise Pressure Control: Pressure sensors and closed-loop systems maintain pressure fluctuations within ±0.5bar, ensuring safety in medical cylinder filling and improving industrial cutting precision by 30%.

- Safety and Reliability: In addition to standard protections, they include leak detection and automatic shut-off devices, with key components made of fireproof and explosion-proof materials.

- Wide Compatibility: Unique interfaces and algorithms enable seamless integration with most VPSA/PSA oxygen generation systems on the market.

- Comprehensive After-Sales Service: Provides inspections, maintenance guidance, 24/7 technical support, and a 5-year warranty, exceeding industry averages.

4. Oxygen Purity Testing and Certification

To ensure oxygen purity meets application standards, scientific testing methods and strict certification processes are required. Common testing techniques include gas chromatography and paramagnetic analysis. Gas chromatography precisely separates and detects impurities in oxygen, accurately calculating its purity. Paramagnetic analysis measures oxygen’s response in a magnetic field to determine its purity. For certification, medical grade oxygen must meet FDA (U.S. Food and Drug Administration) or EMA (European Medicines Agency) standards, ensuring patient safety. Industrial gases must comply with ISO 9001 quality management systems, ensuring stable and reliable oxygen quality for industrial processes.

5. Future Trends

As technology advances and industries evolve, the demand for oxygen purity continues to change. In the future, emerging fields such as semiconductors and nanotechnology will drive increased demand for 99.999% purity oxygen. These fields require extremely pure environments, and high-purity oxygen, as a critical process gas, will see growing demand. Additionally, intelligent control technologies will gradually be applied to oxygen production and testing. Digital technologies will enable real-time monitoring and precise control of oxygen production, improving efficiency and product quality. Moreover, with the growing emphasis on green production, PSA oxygen generators, due to their low energy consumption, will become a key choice for sustainable development and are expected to see broader applications.

6. Conclusion

Selecting the appropriate oxygen purity level requires comprehensive consideration of application needs, cost budgets, and safety standards. PSA oxygen generators and oxygen boosters, with their efficiency and flexibility, have become core equipment in healthcare, industry, and many other fields.

MINNUO has over 20 years of experience in gas technology, with a professional team and extensive industry expertise. If you have customized service needs, please feel free to contact us. We are committed to providing exceptional service!

Email

Email sales:+86 15366749631

sales:+86 15366749631