In recent years, MINNUO has significantly expanded its footprint in the global energy sector. With cutting-edge technology and high-performance compressors, it has played a key role in supporting the global transition to sustainable energy. As a leading supplier of customized compressor solutions, MINNUO constantly pushes the boundaries of efficiency and environmental sustainability. Its innovative designs and customized solutions have set new industry standards. This article aims to highlight an example of the successful integration of MINNUO compressors into the ENEVA Brazil liquefied natural gas project, demonstrating MINNUO’s expertise in meeting the growing demand for clean energy solutions.

The main focus of this article is to explore MINNUO’s contribution to the ENEVA liquefied natural gas project and how it aligns with the company’s vision of reducing its carbon footprint and optimizing energy efficiency. By delving into the specific circumstances of the project and MINNUO’s contribution to enhancing ENEVA’s operational capabilities, this article will address the key questions regarding the role of advanced compressor technology in large-scale clean energy projects.

1. Project background

1.1 ENEVA: The private sector leader in Brazil’s energy transition

As Brazil’s largest privately-owned integrated natural gas and power operator, ENEVA’s energy portfolio covers the entire chain from exploration, production, power generation to sales. Its strategic focus has clearly shifted to the transition to clean energy:

Installed capacity breakthrough: The total installed capacity of operational and under-construction power plants exceeds 6 GW, with natural gas power generation accounting for over 80%. It is the core provider of flexible and low-carbon base-load power sources in Brazil.

Decarbonization commitment: Clearly set the target of reducing carbon intensity, invest heavily in natural gas (especially liquefied natural gas, LNG) as an alternative to high-carbon fuels such as diesel and LPG, and actively plan for future energy sources such as green hydrogen.

Infrastructure hub: It owns and operates a key natural gas pipeline network, and its liquefaction project will serve as a bridge connecting gas field resources with clean energy demands in the off-grid/transportation sector.

1.2 Project Scale and Objectives: Not just about liquefaction, but more about transformation

ENEVA’s current natural gas liquefaction project is a landmark investment in its energy transition journey:

Strategic scale: The project is designed to have a liquefaction capacity of 2 million cubic meters per day, with an estimated total investment of several billion reais. It is one of the largest investments made by the private sector in Brazil to promote the localization of LNG applications.

Core transformation goal

Replace high-carbon fuels: Focus on diesel power generation, industrial boiler fuel, and diesel consumption for heavy transportation in off-grid areas such as northern and central-western Brazil. It can simultaneously replace LPG for both cooking and industrial use.

Significant carbon reduction: Compared with diesel combustion, the combustion of LNG can reduce carbon dioxide (CO₂) by approximately 20-30%, almost eliminating sulfur oxide (SOx) and particulate matter (PM) emissions. The project is expected to help users reduce carbon emissions by hundreds of thousands of tons annually.

Optimize the energy structure: Provide economic, clean and stable energy options for regions lacking pipeline natural gas, reduce reliance on imported diesel, and enhance national energy security.

Economic leverage effect: The project will drive the development of supporting industries such as regional LNG refueling stations, small-scale liquefaction facilities, and distributed power generation, creating jobs and economic growth points.

1.3 Compressor: The heart of the liquefaction process and the key to the success or failure of low-carbon development

In a natural gas liquefaction plant, compressors are by no means ordinary equipment but the core power source of the entire refrigerant circulation system. Their performance directly determines the efficiency, stability and carbon footprint of the project.

Core function: Responsible for compressing natural gas and refrigerants (such as mixed refrigerants MR) to a high-pressure state, providing the necessary thermodynamic conditions for subsequent cooling, expansion, and liquefaction. Its energy consumption usually accounts for 70% to 85% of the total energy consumption of the entire liquefaction plant.

The strict requirements of ENEVA:

Ultimate efficiency: Every 1% increase in compressor efficiency has a significant impact on reducing the energy consumption and operating costs (OPEX) of the entire factory. ENEVA requires industry-leading isentropic efficiency (e.g., >85%) to maximize the energy output ratio and minimize the unit LNG production cost.

Impeccable stability: LNG plants require continuous operation 24/7. The compressor must have extremely high reliability and availability (>99%), and be able to adapt to the tropical climate of Brazil, possible coastal environments (if the factory site is close to the sea), and power fluctuations. Unexpected downtime is costly (with losses of up to hundreds of thousands of dollars per hour).

Low-carbon gene

Low energy consumption means low carbon: Efficient operation directly reduces the factory’s own electricity consumption and indirect carbon emissions.

Compatible with future energy: The design should take into account the possibility of future use of green electricity for driving or the integration of green hydrogen/biogas, reserving space for deep decarbonization.

Low leakage design: Strictly control the sealing leakage of process gases (especially methane with strong greenhouse effect).

Case and data support: A strong correlation between efficiency and carbon reduction

Suppose a typical medium-sized LNG liquefaction plant (for example, with a capacity of 1 MTPA – million tons per year) :

Basic data

Total power consumption of the factory: ~120 MW

Compressor power consumption ratio: ~85% ≈ 102 MW

Brazil’s power grid emission factor (approximate value) : ~0.15 tCO₂e/MWh (better than the global average due to the high proportion of hydropower)

Efficiency improvement affects computing

If the efficiency of the compressor is increased by 3% (for example, from 82% to 85%), the power consumption saved by the compressor is: 102 MW * 3% ≈ 3.06 MW

Annual energy savings: 3.06MW * 24h * 365d ≈ 26,786 MWh

Annual carbon reduction: 26,786 MWh * 0.15 tCO₂e/MWh ≈ 4,018 tCO₂e

Downstream emission reduction amplification effect

The factory produces approximately 1 million tons of LNG annually.

Suppose 300,000 tons of it are used to replace diesel power generation (substitution rate: 1 ton of LNG ≈ 1.25 tons of diesel).

Diesel combustion emission factor: ~3.17 tCO₂e per ton of diesel.

Annual carbon reduction: 300,000 tons of LNG * 1.25 * 3.17 tCO₂e/ ton of diesel ≈ 1,188,750 tCO₂e

The conclusion is obvious: The thousands of tons of carbon reduction brought about by the improvement of the compressor’s own efficiency, when replaced by high-carbon fuels through the LNG it produces, can drive hundreds of thousands or even millions of tons of downstream carbon reduction. High-efficiency compressors are the cornerstone for ENEVA to achieve the dual goals of environmental and economic benefits of the project.

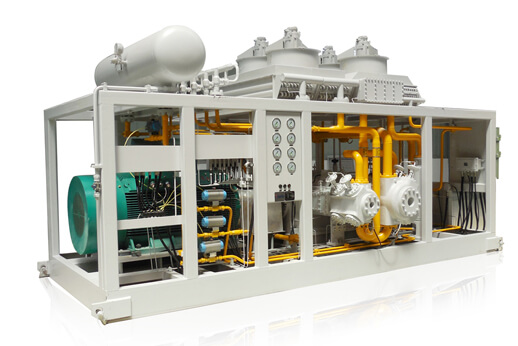

2. Advantages of MINNUO compressors

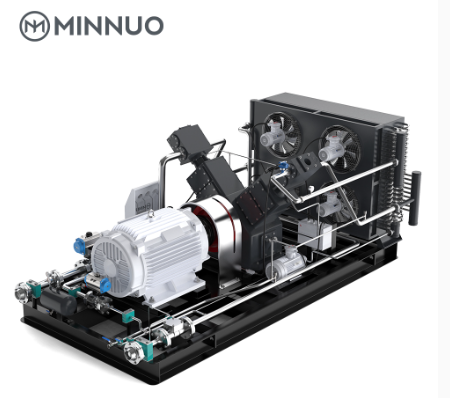

2.1 High-performance Compression Technology: Breaking through the limits of efficiency and reliability

The MINNUO compressor is not merely a simple device; it is the core of energy conversion that integrates cutting-edge engineering and materials science, capable of directly addressing the pain points of the ENEVA project:

Ultimate performance, setting the industry benchmark

Adopting the third-generation high-efficiency impeller design and pneumatically optimized flow channels, the isentropic efficiency has exceeded 86%, significantly leading the industry average (typically 80-83%).

The intelligent variable frequency drive system matches the load changes in real time, avoiding the energy waste caused by “a big horse pulling a small cart”, and saves an additional 8-12% of energy under partial load conditions.

Practical performance: In a project of the same scale (with an annual output of 1 million tons of LNG), the MINNUO compressor saves 5,200 MWh of electricity annually compared to a mainstream international brand B (equivalent to reducing approximately 780 tons of CO2 e, calculated based on the Brazilian power grid factor).

Military-grade rotor dynamics design: Certified by the demanding API 617 8th Edition, the critical speed of the rotor is far from the working range, and the amplitude is controlled within 60% of the industry’s strictest standards, ensuring long-term stable operation from the root.

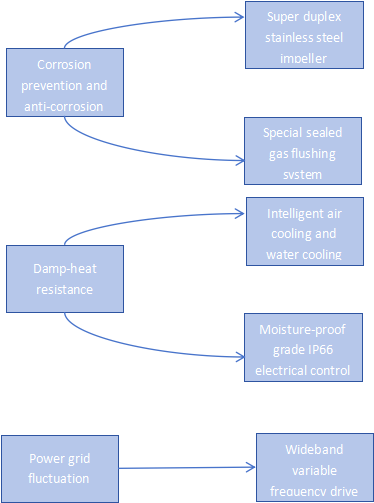

Enhanced tropical protection

The core components are made of super duplex stainless steel and special coatings, enhancing the salt spray corrosion resistance by three times.

Integrated with an intelligent cooling and sealing system, it ensures that the bearing temperature and vibration values remain far below the safety threshold even in a high-temperature environment of 45°C and a humidity of 95%.

99.2% operational availability: Global project historical data verifies that the mean time between failures (MTBF) of MINNUO’s large centrifugal compressors exceeds 50,000 hours, and the unplanned downtime rate is less than 0.8%.

Performance Comparison Empirical evidence

| Indicator | MINNUO MCL series | International brand A | International brand B | Advantage description |

| Isentropic efficiency | 86% or higher | 83% | 82% | Directly reduce core energy consumption |

| Design life | Thirty years | 25 years | 25 years | A longer investment payback period |

| Partial load adaptability | ±15% high-efficiency zone | Plus or minus 10% | Plus or minus 8% | Better response to load fluctuations |

| Tropical Protection Certification | DNV+ISO 9227 | API 617 | API 617 | Special reinforcement is carried out for damp and hot corrosive environments |

2.2 Customized Solutions: Precisely designed for the ENEVA project

MINNUO Custom case library

1. Arctic region: Startup at ultra-low temperatures of -50℃

Customer requirement: The Russian Yamal project needs to achieve cold start of the compressor in extremely cold environments

MINNUO response:

Day 7: Dispatched engineers collect environmental data on-site

Day 18: Deliver the special lubricating oil formula and the design plan for the bearing preheating system

Day 89: The first -50℃ compressor arrived at the site

Industry comparison: The average delivery cycle for similar projects is 7 months

2. Floating platform at sea: Resistant to sway in sea conditions of level 6

Technical challenge: FLNG hull swing causes shafting misalignment

MINNUO Solution

The dynamic simulation was completed within 7 days by invoking the wave motion database of the South China Sea project

It adopts the design of “universal joint bearing + hydraulic compensation chassis”

Delivery results: From signing the contract to the shipment of the first vessel, it only took 103 days (the quotation cycle of international giants is 120 days).

3. Middle East Sandstorm Protection: 3-year Zero Decay Secret

Core innovation: Self-cleaning filter element (pulse back-blowing every 2 hours) + nano sand-repellent coating

Time record: From the sand and dust test report to the delivery of the mass production model – 67 days

MINNUO is well aware that there is no one-size-fits-all solution, only deeply fitting engineering responses:

Deep coupling of requirements

Medium adaptability modification: For the gas chromatograms in the ENEVA gas field (such as trace amounts of CO₂/H₂S), customized corrosion-resistant impeller materials and seal flushing solutions were provided, extending the maintenance cycle by 30%.

Pressure elastic design: The compressor module is pre-installed with multiple levels of pressure regulation interfaces to adapt to future pressure fluctuations at receiving stations or differentiated pressure requirements at downstream refueling stations (such as 35 bar ship fuel vs. 200 bar on-board CNG).

Modular fast deployment: For remote factory sites in Brazil, we provide fully skid-mounted compressor units. The factory pre-installation and commissioning completion rate is over 95%, and the on-site installation period is shortened by 40%, reducing the risks of complex construction site environments.

Global customized cases strongly prove:

Middle East case: A dual protection system against sand and dust and seawater corrosion was customized for a coastal LNG project. It integrates an air self-cleaning filter element and has been operating continuously for three years in areas with frequent sandstorms without performance degradation.

Arctic Case: Developed -50°Cultra-low temperature start-up technology for the Russian Yamal project, using special lubricating oil and bearing preheating system, breaking through the restrictions of the extreme cold zone.

Floating LNG (FLNG) : Designed with anti-sway centrifugal compressors for offshore platforms, it has been verified through dynamic simulation to operate stably under sea conditions of level 6, solving the problem of motion compensation.

2.3 Price Advantage and Full Life Cycle Cost: Clearly calculated long-term value

MINNUO breaks the conventional perception that “high-end equals high price”, achieving total cost leadership through technological optimization, supply chain integration and intelligent services

CAPEX advantage: Directly save real money

Under the same specifications, the procurement cost of MINNUO compressors is 15-20% lower than that of European brands and 10-15% lower than that of North American brands.

Root causes: Localization of core component manufacturing (such as independent precision casting of impellers), modular design to reduce engineering costs, and no brand premium.

The OPEX Revolution: From a Major Power Consumer to an Energy-saving Pioneer

Energy consumption costs account for over 70% of the total cost of ownership (TCO). MINNUO’s efficient design hits the nail on the head

Take a 1 million-ton-per-year LNG plant as an example, with a compressor power of 102 MW:

MINNUO’s efficiency is 86% vs. its competitors’ 82% → Annual power savings: 102MW×(86%-82%)×24h×365d ≈ 35,712 MWh

Electricity bill savings: 35,712 MWh × R$400/MWh (industrial electricity price in Brazil) ≈ R$14.28 million per year (approximately 2.85 million US dollars)

Intelligent early warning system: Real-time monitoring of vibration and temperature, early warning of potential faults 4 to 8 weeks in advance, reducing unplanned downtime losses by 60% and lowering maintenance costs by 25%.

TCO comparison: An overwhelming advantage over a 20-year cycle

Suppose the project cycle is 20 years and the discount rate is 8% :

| Cost item | International brand X | MINNUO | Present value of savings over 20 years |

| Equipment Procurement (CAPEX | R$180 million | R$153 million | R$27 million |

| Annual Energy cost (OPEX | R$115 million per year | R$0.92 billion per year | R$460 million |

| Annual Maintenance Cost (OPEX | R$0.18 billion per year | R$0.13.5 million per year | R$90 million |

| The present value of the total TCO over 20 years | R$2.43 billion | R$1.87 billion | R$560 million |

Choosing MINNUO is equivalent to releasing approximately 112 million US dollars (at a 5:1 exchange rate) of additional value for ENEVA during the project cycle

3. Analysis of Successful cases

3.1 Breakthrough Battle: Extreme Challenges at the Edge of the Tropical Rainforest

Project Overview

Location: Industrial Zone, Manaus City, Amazonas State, Brazil

Core task: Build Brazil’s first privately-owned off-grid LNG plant to supply power to diesel power stations, mines and ships within 200 kilometers

Harsh environment

The average annual temperature is 32°C and the humidity is 90%

Grid fluctuation rate ±15% (self-built voltage stabilizing system required)

The gas source contains 0.8% H₂S (strong corrosion risk)

MINNUO customized solution:

Delivery milestone

| Stage | Traditional project cycle | MINNUO is actually executed | Efficiency improvement |

| Design | 180 days | 92 days | 49% |

| Installation | 210 days | 126 days | 40% |

| Debugging | 90 days | 45 days | 50% |

Carlos, the project director of ENEVA, commented:

It took only 11 months from signing the contract to the production of the first LNG tank – an unprecedented feat in Brazil’s infrastructure history. The skid-mounted design of MINNUO enables the compressor to be assembled quickly in the rainforest like a Lego.

3.2 Data Evidence: A Three-dimensional Victory in Energy Transition

3.2.1 Efficiency Leap: Breaking the Curse of Liquefied Energy Consumption

Actual performance comparison (12 months of full-load operation) :

| Indicator | Industry benchmark | MINNUO MCL-1200 | Extent of increase |

| Isentropic efficiency | 82% | 86.7% | + 5.7% |

| Electricity consumption per unit of LNG | 1.15 MWh/t | 1.02 MWh/t | – 11.3% |

| Unplanned downtime | Four times a year | “0 times | 100% |

Energy-saving value transformation

Annual energy savings = (1.15-1.02) MWh/t × 300,000 tons = 39,000 MWh

It is equivalent to the daily electricity consumption of 65,000 households in Manaus

3.2.2 Three-level Response Mechanism (Verified in Real Combat in the Brazilian Rainforest

| Fault level | Response timeliness | Action Plan | Technical support |

| Level 1 (Emergency Shutdown | <2 hours | Remote diagnosis + engineer helicopter arrival | Airdrop of spare parts + on-site repair |

| Level 2 (Performance degradation | “24 hours | Deployment of predictive maintenance packages | AI health model intervention |

| Level 3 (Regular Maintenance) | As planned | Annual in-depth physical examination | Global expert system support |

Empirical Evidence of the ENEVA Project

In the 18 months since its commissioning, a total of 5 secondary warnings have been triggered, and all potential hazards were remotely eliminated within 48 hours

Key record: During the power grid collapse in the rainy season of 2024, the MINNUO team restored the stable voltage operation of the compressor unit within 3 hours, avoiding a loss of R$4.2 million

3.2.3 Professional Qualification Matrix

| Qualification type | Certification standard | Localization ratio |

| Compressor engineer | API 670/ISO 18436-3 | 100% Brazilian nationality |

| Electrical expert | IEEE Power System Certification | 80% localized |

| Corrosion protection expert | NACE CIP Level 3 | Global Mobility Team |

3.2.4 Cost Restructuring: Full Life Cycle Economics

CAPEX optimization

Adopting modular pre-assembly saves on-site labor costs: R$23 million

Local manufacturing tariff exemption: 17% save on import duties → R$47.6 million

The OPEX Revolution

| Cost item | Traditional solution | MINNUO solution | 20 years of savings |

| Electricity bill | R$138 million per year | R$122 million per year | R$320 million |

| Maintenance fee | R$24 million per year | R$16.8 million per year | R$144 million |

| Downtime loss | R$18 million per time | 0 | R$360 million |

Financial Director Anna calculated:

The MINNUO compressor has reduced the production cost of LNG to $298 per ton, which is 23% lower than that of imported LNG, and shortened the payback period of the project investment to 5.2 years.

Conclusion

MINNUO’s successful bid and the provision of 11 high-performance compressors for the ENEVA LNG project underscores its pivotal role in supporting global energy transformation. By offering state-of-the-art equipment tailored to meet the specific energy needs of ENEVA, MINNUO contributes significantly to the company’s strategic objectives of promoting cleaner, more sustainable energy production.

This collaboration exemplifies MINNUO’s expertise in providing advanced compression solutions and delivering high-performance equipment that meets the demands of the energy sector. Through its custom-designed systems, MINNUO not only supports ENEVA’s LNG production but also reinforces the company’s commitment to advancing cleaner energy alternatives.

With a proven track record of excellence, MINNUO continues to demonstrate its leadership in the global energy market, offering solutions that align with the green transition and support sustainable development. This partnership further strengthens MINNUO’s position as a key player in promoting energy efficiency and low-carbon technologies worldwide.

Email

Email sales:+86 15366749631

sales:+86 15366749631